-

- PCB TYPE

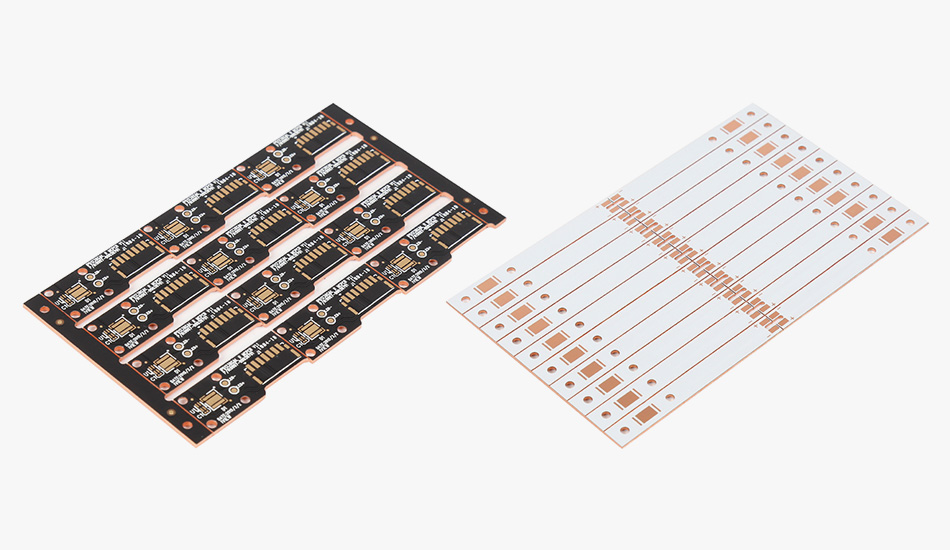

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 11. 2025, 15:07:38

In the competitive electronics industry, the demand for efficient, reliable, and compact printed circuit boards (PCBs) is soaring. Aluminum - based PCBs, prized for their thermal management and mechanical stability, have become a favored option. Among their manufacturing features, precision countersink holes are key to optimizing PCB performance. This article explores the design, manufacturing, quality control, applications, and future trends of precision countersink holes in aluminum PCBs, offering insights for informed decision - making in electronics design.

Understanding Aluminum PCBs

Structure and Composition

Aluminum PCBs, a type of metal - core PCB, are designed for high - power applications. They consist of three layers:

Aluminum Core: Serves as a heat sink, leveraging aluminum’s excellent thermal conductivity, affordability, and mechanical strength. It efficiently dissipates heat from high - power components, maintaining their optimal operating temperature and extending lifespan.

Insulating Dielectric Layer: Made of thermally conductive yet electrically insulating materials like specialized epoxy resin. It isolates the aluminum core from the copper layer while facilitating heat transfer. The layer’s thickness and material are carefully selected to balance electrical insulation and thermal performance.

Copper Circuitry Layer: Where electrical traces are etched to connect components. The copper layer’s thickness varies based on current - carrying requirements, with thicker layers handling higher currents.

Advantages of Aluminum PCBs

Superior Thermal Performance: Outperforms traditional FR - 4 PCBs in heat dissipation, making them ideal for high - power applications like LED lighting, power electronics, and automotive electronics.

Enhanced Mechanical Strength: The aluminum core provides rigidity, enabling the PCB to withstand mechanical stress and vibration, suitable for harsh environments.

Good Electrical Performance: The insulating layer ensures electrical isolation, preventing short - circuits. The aluminum core can also act as a ground plane, improving overall electrical performance.

The Role of Precision Countersink Holes in Aluminum PCBs

Mechanical Fixation

Precision countersink holes are crucial for mechanical fixation. When flat - head screws are inserted, they sit flush with the PCB surface, distributing clamping force evenly. This reduces stress concentrations, preventing PCB damage and component failure. In vibration - prone applications, such as automotive and industrial electronics, countersink - mounted fasteners maintain a secure connection, ensuring the PCB stays in place and electronic devices function properly.

Aesthetic and Space - Saving Considerations

Aesthetically, flush - mounted fasteners give PCBs a clean, professional look, enhancing the appearance of visible applications like consumer electronics and decorative lighting. Practically, countersink holes save space by eliminating the need for extra room for protruding fastener heads. This is vital in miniaturized electronics, enabling more compact PCB designs for wearable devices and small - form - factor products.

Electrical and Thermal Implications

Electrically, when the aluminum core acts as a ground plane, countersink - mounted fasteners can establish a reliable electrical connection to grounded components, reducing electromagnetic interference (EMI) and improving grounding. Thermally, they enhance heat transfer by creating a tight bond between the PCB and heat - dissipating structures, crucial for maintaining component performance in high - power applications.

Design Considerations for Precision Countersink Holes in Aluminum PCBs

Hole Dimensions

Diameter: The countersink hole diameter must precisely match the fastener. The conical section should be slightly larger than the fastener head to ensure a snug fit with a small clearance, while the straight part diameter should be marginally wider than the fastener shank for easy insertion.

Depth: The depth of the countersink is critical for a flush - mounted fastener. It must be sufficient to fully recess the fastener head without compromising the PCB’s structural integrity or interfering with internal layers.

Taper Angle: Common taper angles are 82° or 90°, depending on the fastener type. Maintaining the correct angle during manufacturing is essential for a secure fastener fit.

Location on the PCB

Hole placement should avoid electrical traces and components to prevent damage during installation. They must also align with mounting points on enclosures or other structures and be accessible for assembly. Even distribution across the PCB ensures balanced mechanical support and prevents warping under clamping force.

Interaction with PCB Layers

Insulating Layer: Designing the countersink hole to avoid penetrating the insulating layer is essential to prevent electrical short - circuits. Precise coordination between hole depth and layer thickness, along with optional non - conductive coatings, ensures electrical isolation.

Copper Layer: Depending on the application, the copper layer around the hole may need modification. For grounding, it can be widened or connected to a larger ground plane; for non - electrical use, it may be etched away to prevent accidental contact with fasteners.

Manufacturing Processes for Precision Countersink Holes

Drilling and Countersinking

High - precision CNC drilling machines create the straight part of the hole, with parameters like speed, feed rate, and coolant carefully controlled. Specialized countersink drill bits, milling cutters, or lasers then form the conical section, each method offering different precision and efficiency levels suitable for various production volumes.

Surface Treatment and Finishing

If the hole is for electrical connection, plating with copper, nickel, or gold can enhance conductivity. Deburring removes burrs and rough edges, followed by thorough cleaning to remove debris, plating residues, and chemicals, ensuring a clean surface for fastener installation.

Quality Control and Inspection

Dimension Inspection

Tools like calipers, micrometers, optical comparators, and 3D CMMs measure hole diameter, depth, and taper angle, ensuring they meet strict tolerance limits for proper fastener fit.

Surface Quality Inspection

Visual inspection under magnification, surface roughness testing, and non - destructive methods check for burrs and surface irregularities. For plated holes, cross - section analysis and XRF assess plating quality, including thickness, defects, and adhesion.

Electrical and Mechanical Testing

Electrical continuity and impedance tests ensure proper conductivity for electrical connections. Mechanical tests like torque and pull - out testing evaluate the strength of the fastener connection, ensuring the PCB can withstand normal operating forces.

Applications of Aluminum PCBs with Precision Countersink Holes

LED Lighting

In high - power LED modules, precision countersink holes secure the PCB to heat - sinks, enabling efficient heat transfer and withstanding environmental stress. In decorative lighting, they provide an aesthetically pleasing and space - saving design.

Automotive Electronics

Used in headlight, taillight assemblies, and ECUs, these holes ensure the PCB remains stable in the harsh automotive environment, withstanding vibrations, shocks, and temperature variations.

Industrial Electronics

In power electronics modules and industrial control panels, precision countersink holes offer reliable mechanical and electrical connections, ensuring the PCBs function properly in industrial settings.

Challenges and Future Trends

Current Challenges

Miniaturization demands higher precision in creating countersink holes in smaller PCBs. Balancing manufacturing quality with cost - effectiveness is also a challenge, as is ensuring material compatibility during processes like plating.

Future Trends

Advanced manufacturing technologies such as laser - based machining and additive manufacturing will improve precision and efficiency. Integration with smart manufacturing systems using IoT and AI will optimize the manufacturing process, while sustainable practices will gain importance in PCB production.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB