-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

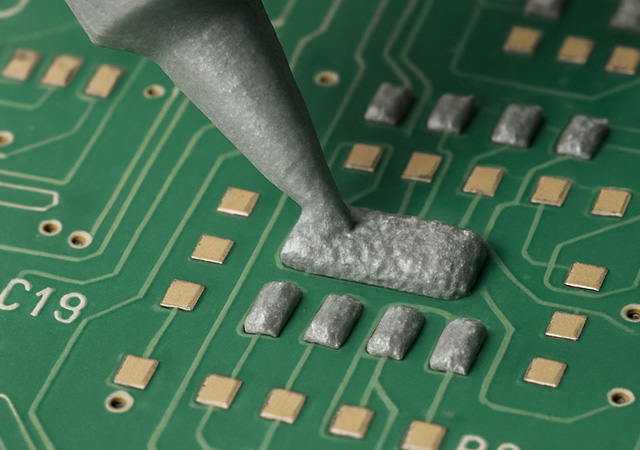

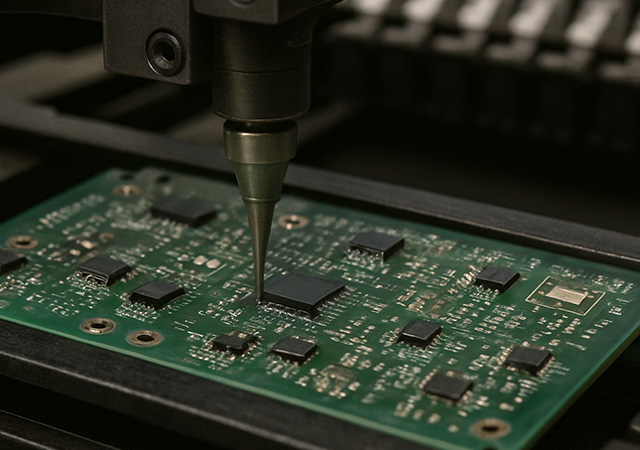

Explore the essentials of rigid PCB assembly, from fabrication to professional assembly services, ensuring durability and performance in electronic devices.

Explore the automotive PCB assembly process, crucial for modern vehicles' performance and safety, highlighting circuit board production steps and innovations.

Experience fast, efficient, and cost-effective quick PCB assembly services to speed up your production timeline and gain a competitive edge.

Discover the intricacies of PCB assembly, a vital process in electronics manufacturing, and learn the benefits of professional PCB assembly services for enhanced quality and efficiency.

Find the perfect PCB assembly manufacturer for your needs. Learn key factors like expertise, quality, and cost in our guide to circuit board assembly services.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB