-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

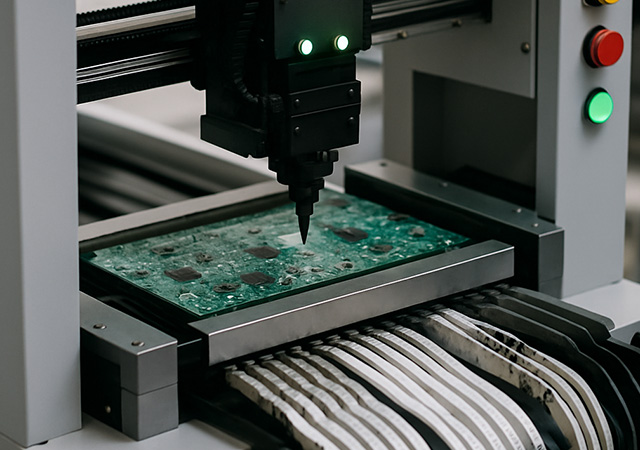

Explore the essential PCB assembly process, from solder paste application to final testing, ensuring efficient and reliable electronic devices.

Explore the advantages of rigid flex PCB assembly, a game-changing technology offering enhanced design flexibility, improved reliability, and reduced space and weight in electronics.

Explore the 5-layer rigid flex PCB assembly process, its benefits, and applications for electronics design. Discover why it's a leading choice in modern technology.

Discover the transformative impact of medical rigid flex PCB assembly on device innovation. Learn about its process, benefits, and PCB assembly services.

Discover the intricate PCB assembly process, from design to manufacturing, and learn how to create reliable electronic devices. Perfect for your next tech project!

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB