-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Explore the fundamentals of RF circuits, essential for wireless communication. Learn about active RF circuits, design considerations, and real-world applications.

Discover top 5G RF circuit board manufacturers enabling faster, reliable wireless communication. Choose expertise for superior performance and custom solutions.

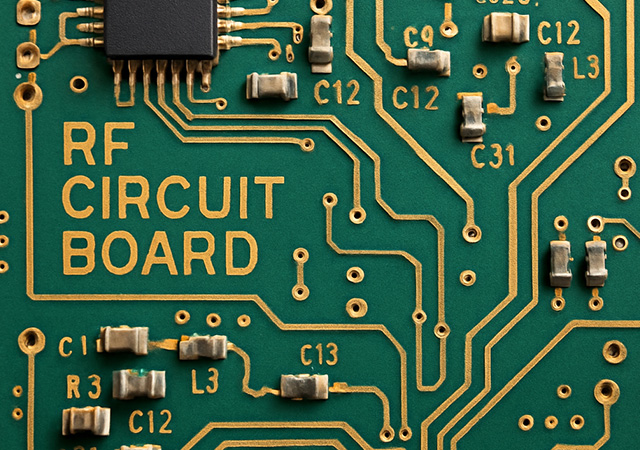

Streamline RF circuits PCB design with expert services. Enhance wireless communication devices efficiently with professional design solutions.

Find the ideal PCB manufacturer for your needs. Learn about key factors like design, assembly, quality standards, and cost to ensure project success.

Find the ideal high frequency PCB manufacturer to ensure top-tier design services and custom fabrication. Make informed choices for your next project.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB