-

- PCB TYPE

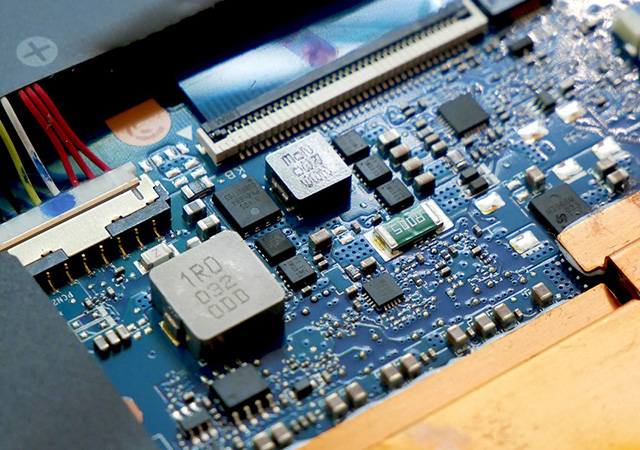

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

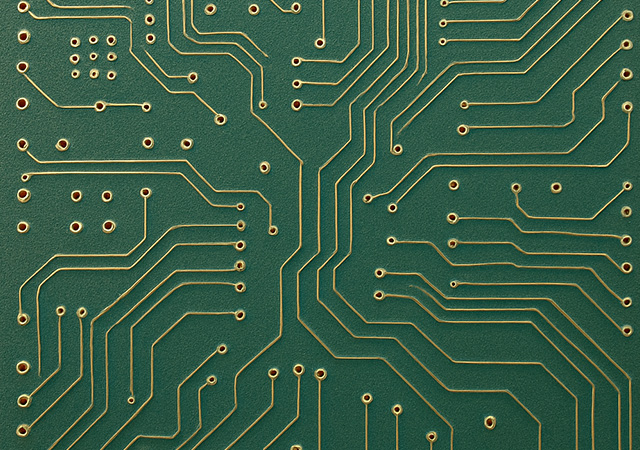

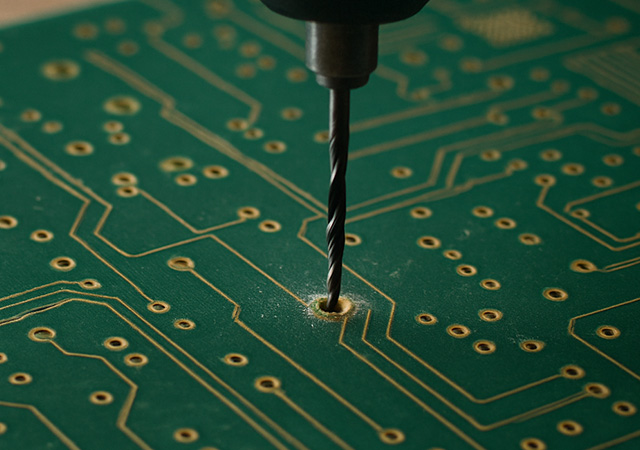

Discover how back drilling in PCB design enhances signal integrity and performance for high-speed applications, a vital aspect of the pcb manufacturing process.

Optimize your electronics with controlled depth backdrilled PCBs, enhancing signal integrity and reducing EMI in high-speed applications. Discover the benefits today!

Enhance high-speed PCB performance with backdrilling. Discover how this key manufacturing technique improves signal integrity and reduces EMI.

Discover how to select the best PCB manufacturer for your project needs. Learn essential tips on custom PCBs, assembly, quality, and cost considerations.

Explore the significance of blind buried via PCBs in modern electronics. Learn how they optimize space, improve signal integrity, and reduce layers in compact designs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB