-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 08. 2026, 20:02:04

In the world of electronics, aluminum PCBs (Printed Circuit Boards) are becoming an essential solution for many high-performance applications. Known for their excellent thermal conductivity and mechanical strength, aluminum PCBs are particularly effective in environments where heat dissipation is crucial. This article explores the advantages of aluminum PCBs, their key applications, and important considerations when selecting the right aluminum PCB for your electronic products.

An aluminum PCB is a type of metal core PCB that utilizes aluminum as the base material. This metal core allows for excellent heat management, making aluminum PCBs highly effective in applications where overheating is a concern. The structure of an aluminum PCB typically consists of three layers:

Copper Layer: This is the conductive layer where the circuit is etched.

Dielectric Layer: An insulating layer that is thermally conductive, allowing heat to pass through while electrically isolating the copper from the aluminum.

Aluminum Base Layer: This layer provides mechanical strength and excellent thermal conductivity, making it ideal for dissipating heat from components like LEDs, power devices, and other heat-sensitive electronics.

The ability of aluminum PCBs to efficiently conduct heat makes them an ideal choice for modern electronics.

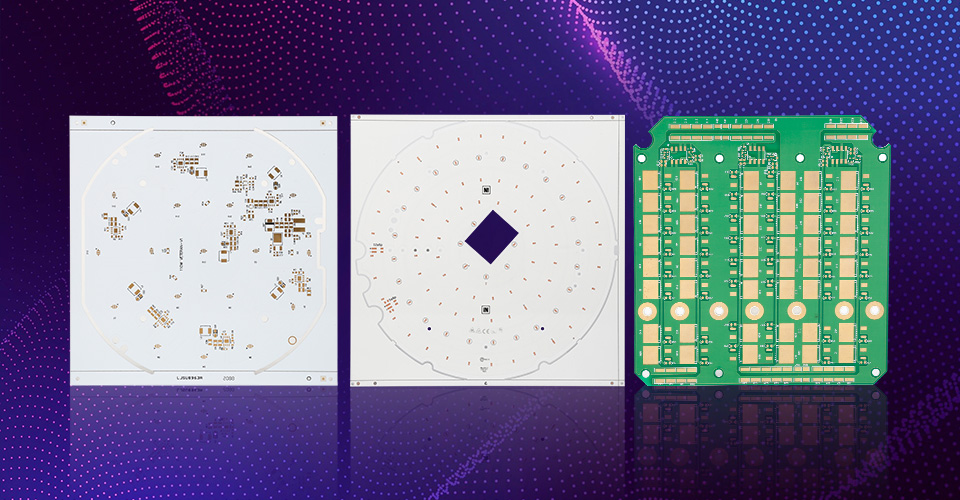

One of the most significant benefits of aluminum PCBs is their thermal conductivity. Aluminum’s natural ability to transfer heat helps keep components cool, ensuring that devices operate efficiently and last longer. In high-power applications, such as LED lighting and power electronics, managing heat is critical for preventing thermal damage and ensuring reliability.

The aluminum base provides mechanical strength to aluminum PCBs, making them more durable and capable of withstanding physical stresses. This is particularly useful in applications where the PCB may be subjected to vibration, impact, or other harsh conditions. Additionally, bendable aluminum PCBs offer flexibility, allowing them to be shaped and fitted into compact or irregular spaces without compromising their structural integrity.

Aluminum PCBs are often more cost-effective compared to copper-based PCBs, particularly when considering their thermal conductivity and mechanical properties. The relatively lower cost of aluminum makes it an attractive option for manufacturers looking to balance performance with cost.

With aluminum PCB’s efficient thermal conductivity, devices stay cooler and operate more reliably, which improves overall performance. This makes aluminum PCBs an ideal choice for industries such as automotive, telecommunications, and renewable energy, where device reliability and performance are paramount.

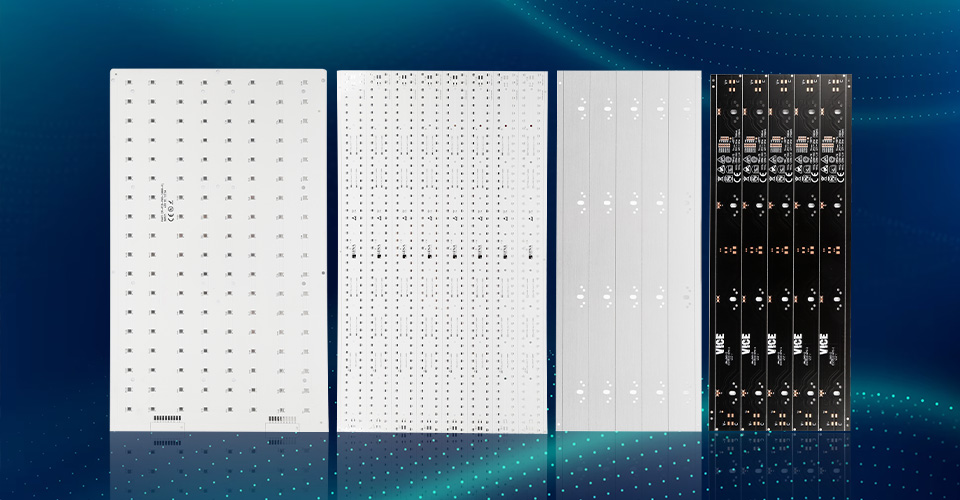

A Single Layer aluminum PCB consists of a single copper layer and is typically used in less complex applications. Single Layer aluminum PCBs are ideal for simpler designs, such as LED lighting modules, power supplies, and consumer electronics, where thermal management is needed but the design complexity is relatively low.

For more complex circuits requiring higher density, Multi-Layer aluminum PCBs are a better choice. These PCBs include multiple copper layers, which allow for more intricate circuit designs while still benefiting from the thermal conductivity of the aluminum base. Multi-Layer aluminum PCBs are commonly used in automotive control systems, high-performance power electronics, and advanced LED applications.

One of the most widespread applications of aluminum PCBs is in LED lighting. LEDs generate significant heat, and without proper heat management, their lifespan and performance can be compromised. Aluminum PCBs help dissipate the heat generated by LEDs, ensuring that they operate at optimal temperatures. Single Layer aluminum PCBs are typically used in smaller LED lighting applications, while Multi-Layer aluminum PCBs are used for more complex, high-power LED systems, such as those used in streetlights and automotive headlights.

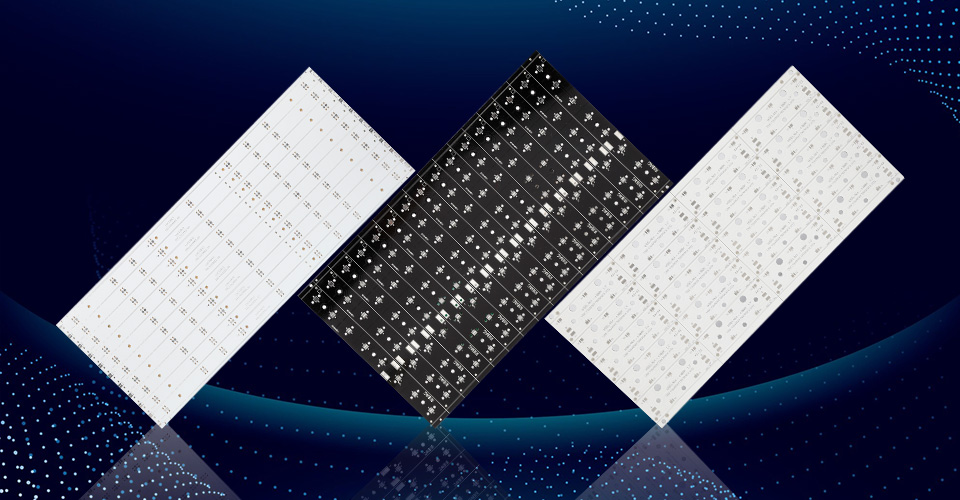

In the automotive industry, aluminum PCBs are used for power control units, automotive lighting, sensors, and other critical electronics. Aluminum PCBs help ensure that automotive systems can operate reliably under the extreme conditions of temperature and vibration encountered in vehicles. The bendable aluminum PCB is particularly useful for automotive applications that require flexibility in design.

Aluminum PCBs are also used extensively in power electronics, where efficient heat dissipation is essential. These include power supplies, power converters, motor drives, and energy systems. By using aluminum PCBs, these high-power devices can operate more efficiently and with improved thermal stability, reducing the risk of component failure due to overheating.

In renewable energy systems, such as solar inverters and wind turbine controllers, aluminum PCBs are used to ensure that these high-power systems remain cool and operate optimally. The thermal conductivity of aluminum PCBs plays a critical role in maintaining the efficiency and reliability of renewable energy systems.

The thermal conductivity of aluminum PCBs is one of the key factors to consider when selecting the right PCB for your project. If the application involves high-power components that generate significant heat, opting for aluminum PCBs with a higher thermal conductivity is crucial for effective heat management.

If your design requires flexibility, bendable aluminum PCBs are an excellent option. These flexible boards allow for easy integration into compact or irregular spaces, making them ideal for applications such as wearable electronics and compact automotive components.

For less complex designs, a Single Layer aluminum PCB may be sufficient. However, if your circuit requires more layers and intricate routing, a Multi-Layer aluminum PCB will provide the necessary complexity and flexibility for high-density designs.

While aluminum PCBs are generally more affordable than copper-based PCBs, it is important to consider the specific thermal and mechanical needs of your application. The cost of Multi-Layer aluminum PCBs can be higher due to the increased complexity, so balancing performance requirements with budget constraints is essential.

Aluminum PCBs are a powerful solution for applications requiring effective thermal conductivity, durability, and reliability. From LED lighting to automotive electronics and power electronics, the advantages of aluminum PCBs are clear. Whether you need a Single Layer aluminum PCB for a basic design or a Multi-Layer aluminum PCB for a more complex system, aluminum-based PCBs offer exceptional performance and cost efficiency.

By understanding the key benefits, applications, and considerations of aluminum PCBs, you can make informed decisions to optimize your designs and improve the overall performance of your electronic devices.

Answer:

Single Layer aluminum PCBs are ideal for simple designs, offering excellent thermal conductivity and durability at a lower cost. They are commonly used in LED lighting and low-power electronics where basic heat management is needed.

Answer:

Multi-Layer aluminum PCBs incorporate multiple layers of copper for more complex circuits and higher density. They are used in advanced applications that require more intricate designs, such as automotive electronics and power supplies.

Answer:

Thermal conductivity in aluminum PCBs ensures that heat generated by components is effectively dissipated, preventing overheating and improving the longevity and reliability of the device. This is especially critical in high-power applications like power electronics and LED lighting.

Answer:

Bendable aluminum PCBs are flexible boards that allow for customization in design, making them ideal for applications with space constraints or unique form factors, such as wearable electronics and automotive systems.

Answer:

Aluminum-based PCBs are generally more affordable than copper-based PCBs and offer excellent thermal conductivity for heat-sensitive applications. Copper-based PCBs are preferred for applications requiring superior thermal and electrical performance, but aluminum PCBs provide a more cost-effective solution for many designs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB