-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 21. 2026, 11:13:24

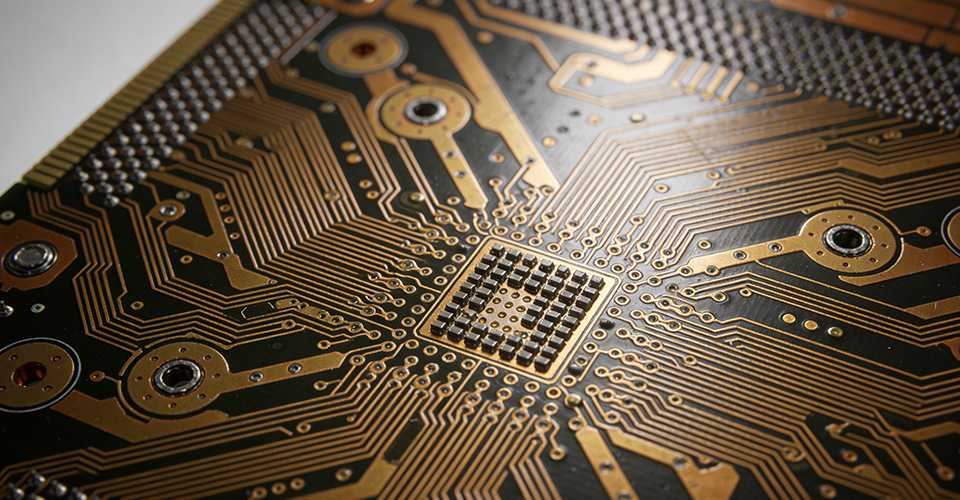

In the rapidly evolving world of high-power electronics, managing heat is the difference between a product’s success and its catastrophic failure. As a leading metal core pcb manufacturer, we have seen the industry shift from traditional substrates to high-performance metal core pcb (mcpcb) solutions.

Whether you are designing LED lighting, automotive power modules, or industrial converters, understanding the intricacies of metal core pcb is essential for ensuring product longevity and reliability.

Choosing the right metal core pcb manufacturer is not just about price; it is about engineering synergy. A professional manufacturer doesn't just print circuits; they optimize your metal core pcb stackup to balance cost and thermal performance.

For factory-scale buyers, the priority is consistency. When you source aluminium core pcb or metal clad pcb, you are looking for a partner who understands IPC Class 2 and Class 3 standards, ensuring that every batch survives the harsh thermal cycling of industrial applications.

While the term metal core pcb is a broad category, the most common variant is the aluminium core pcb. Often referred to as metal clad pcb, these boards use a base metal to spread heat away from critical components.

Aluminium metal core pcb is the industry standard because it offers the best balance of thermal conductivity, mechanical strength, and cost-effectiveness.

Thermal Conductivity: Typically ranges from 1.0 W/mK to 9.0 W/mK.

Mechanical Stability: Unlike fragile ceramics, aluminum offers superior durability for automotive and aerospace environments.

The debate of metal core pcb vs fr4 is the most common question we receive from hardware engineers. The answer lies in your power density.

| Feature | Standard FR4 PCB | Metal Core PCB (MCPCB) |

| Thermal Conductivity | 0.2 – 0.5 W/mK | 1.0 – 9.0 W/mK |

| Heat Dissipation | Poor (Requires Heat Sinks) | Excellent (Self-Cooling) |

| Mechanical Strength | Moderate | High |

| Cost | Low | Moderate to High |

| Weight | Light | Heavy |

The Verdict: If your components are generating more than 2W of heat per square inch, the metal core pcb board is no longer an option—it’s a necessity. Traditional FR4 acts as an insulator, trapping heat and shortening the lifespan of LEDs and power MOSFETs.

To avoid manufacturing delays, adhering to specific metal core pcb design guidelines is critical. Designing a metal core pcb board requires a different mindset than standard FR4.

Focus your high-heat components at the center of the board or distribute them evenly to avoid "hot spots." In a multilayer metal core pcb, vertical thermal vias are less common because the base metal itself handles the lateral heat spread.

Because the core is conductive metal, you must maintain larger clearances between the circuit traces and the board edge to prevent short-circuiting to the base.

For best metal core pcb manufacturers, we recommend ENIG (Electroless Nickel Immersion Gold) or OSP for better solderability and thermal contact.

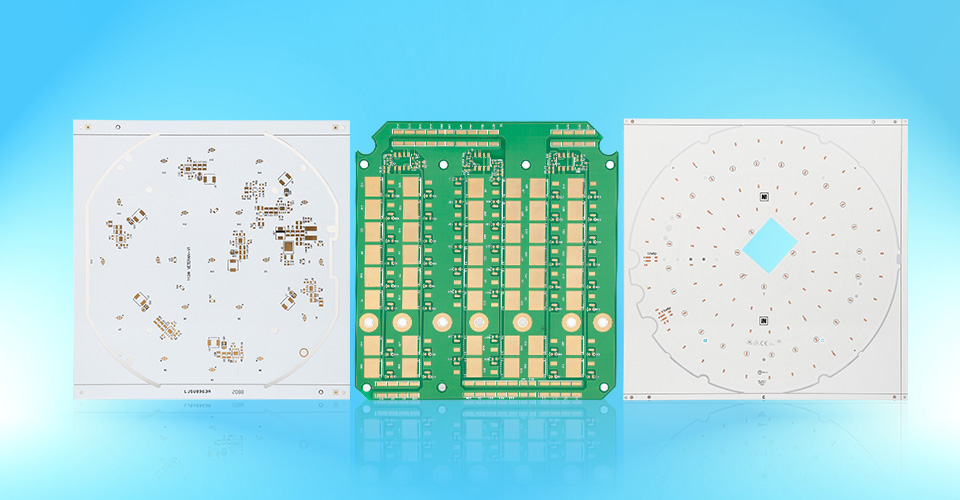

The metal core pcb stackup is the "DNA" of your thermal management strategy. A typical stackup consists of:

Circuit Layer: Copper foil (1oz to 6oz).

Dielectric Layer: The most critical part. This is a thermally conductive but electrically insulating layer.

Metal Base: Usually aluminum 5052 or 6061.

While aluminum is king, some high-end applications require Copper Core PCBs.

Aluminium: Best for LEDs and general power supplies.

Copper: Best for extremely high-current applications due to better conductivity (380+ W/mK), though it is significantly heavier and more expensive.

Understanding the metal core pcb manufacturing process helps buyers identify where quality can be compromised.

Lamination: Bonding the copper and dielectric to the metal base under high pressure.

Drilling: Unlike FR4, metal drilling requires specialized diamond-coated bits and slower feed rates.

Etching: Chemical removal of unwanted copper to form the circuit.

Profiling: Routing the metal edges requires CNC precision to avoid burrs that could cause electrical shorts.

Metal core pcb are used in industries where thermal runaway is a risk:

LED Lighting: Street lights, architectural lighting, and backlight units.

Automotive: Power steering, headlights, and EV battery management systems.

Power Conversion: DC-DC converters, inverters, and regulators.

Industrial Controls: Motor drives and high-current relays.

When sourcing from China, the best metal core pcb manufacturers are those who own their lamination equipment. Many "trading" factories outsource the metal bonding process, leading to delamination issues under high heat.

Checklist for Sourcing:

Do they offer multilayer metal core pcb capabilities?

Can they provide a metal core pcb thermal conductivity test report?

What is their minimum trace/space capability on heavy copper?

A metal core pcb (mcpcb) is a type of printed circuit board that incorporates a base metal (usually aluminum or copper) as a heat spreader to dissipate heat generated by electronic components.

A standard PCB typically uses a fiberglass substrate (FR4) which is an insulator. An MCPCB uses a metal plate as the core, providing much higher thermal conductivity.

The primary difference is heat management. FR4 has a thermal conductivity of ~0.25 W/mK, while an MCPCB can reach 1.0 to 9.0 W/mK. FR4 is lighter and cheaper, but MCPCB is essential for high-power applications.

The standard thickness of a metal core pcb board is 1.6mm, but it can range from 0.5mm to 3.2mm depending on the mechanical and thermal requirements of the application. The aluminum base typically accounts for 1.0mm to 1.5mm of that total.

Thermal management is the heartbeat of modern electronics. As an experienced metal core pcb manufacturer, ApolloPCB specializes in providing high-reliability aluminium core pcb and metal clad pcb for global clients. By following strict metal core pcb design guidelines and using premium metal core pcb material, we ensure your products stay cool under pressure.

[Get a Free Quote & Thermal Analysis for Your Aluminum PCB Project Today]

Related Articles:

Metal Core PCBs Electrical Excellence in Electronics

Metal Core PCB: Revolutionizing Thermal Management and Performance in Electronics

Metal Core PCB: Transforming Thermal and Electrical Performance in Modern Electronics

Metal Core PCB Pioneering Thermal and Electrical Excellence in Electronics

Metal Core PCB: Benefits, Applications, and Why It's the Best Choice for Your Electronics

Understanding Metal Core PCB: Key Advantages and Applications in Electronics Manufacturing

Metal Core PCB: Benefits, Applications, and Key Considerations

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB