-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 07. 2026, 19:07:27

In the rapidly evolving world of electronics, efficient thermal management is crucial for ensuring the longevity and reliability of devices. Traditional PCBs, such as those made from FR-4, often struggle with heat dissipation in high-power applications. This is where metal core PCBs (MCPCBs) come into play, offering superior heat dissipation, mechanical strength, and durability. This article explores the key benefits, applications, and considerations associated with metal core PCB technology, including its use in industries like automotive electronics and high-power systems.

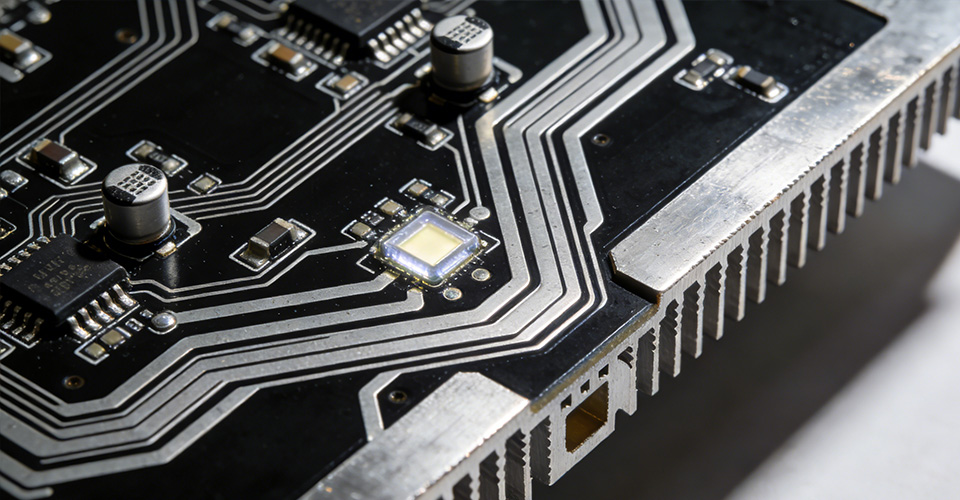

A metal core PCB is a type of printed circuit board that incorporates a metal base—typically aluminum or copper—underneath the PCB's conductive layers. The metal core serves as an efficient heat sink, drawing heat away from sensitive components and ensuring the PCB operates at optimal temperatures. Unlike traditional PCBs made from fiberglass or resin, metal core PCBs are designed for high-performance applications where thermal management is crucial.

The typical structure of a metal core PCB includes three main layers:

Copper Circuit Layer: This layer contains the electrical traces and components.

Dielectric Layer: A thermally conductive insulating layer that prevents electrical short circuits while allowing heat to pass through.

Metal Core: Commonly aluminum core PCB or copper core PCB, which provides thermal dissipation and mechanical support.

This unique design ensures efficient heat management and enhanced durability, making metal core PCBs ideal for high-power applications in various industries.

The most significant advantage of metal core PCB is its ability to efficiently dissipate heat. In high-power systems, heat buildup can severely impact performance and cause damage to sensitive components. By using a copper-clad laminate or copper-based PCB, the metal base layer rapidly conducts heat away from the components, maintaining stable operational temperatures. This makes metal core PCBs essential in applications like automotive PCBs, LED lighting, and power electronics, where managing heat is a top priority.

The metal core in the PCB provides additional mechanical support, making the board more robust and resistant to physical stress. Copper core PCBs or aluminum core PCBs are particularly effective in environments where vibration, shock, or temperature fluctuations are common, such as in automotive electronics or industrial control systems.

Due to their superior thermal management and mechanical strength, metal core PCBs have increased reliability and a longer operational lifespan compared to traditional FR-4 boards. This reduces the likelihood of failure caused by overheating or mechanical stress, ensuring that the devices remain functional for longer periods without the need for frequent maintenance or replacement.

In the automotive industry, automotive PCBs must be able to withstand harsh environments, including high temperatures, vibration, and shock. Metal core PCBs are commonly used in automotive electronics for applications such as power control units, lighting systems, and sensor modules. The copper core PCB ensures that these devices can handle high thermal loads and operate reliably under demanding conditions.

Additionally, metal core PCBs are increasingly used in electric vehicles (EVs) for efficient power conversion and energy storage systems. These PCBs help optimize the performance of power inverters and battery management systems, which are essential components of EVs.

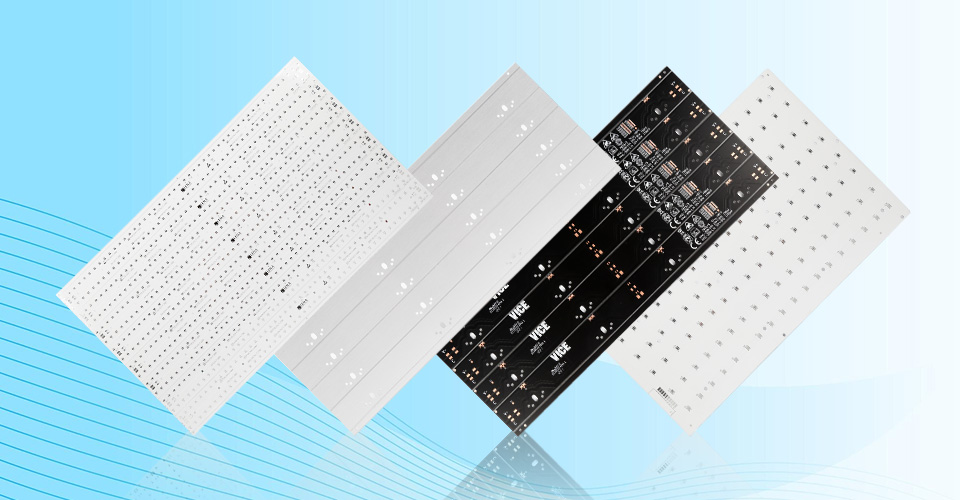

LED lighting is another major application where metal core PCBs shine. LEDs generate a considerable amount of heat, which, if not managed correctly, can lead to poor performance and reduced lifespan. LED lighting metal core PCBs use the metal core’s heat-dissipating properties to ensure that LEDs remain cool and operate at optimal temperatures. Copper-clad laminate or copper-based PCBs are commonly used for high-power LED systems, such as street lights, industrial lighting, and automotive headlights.

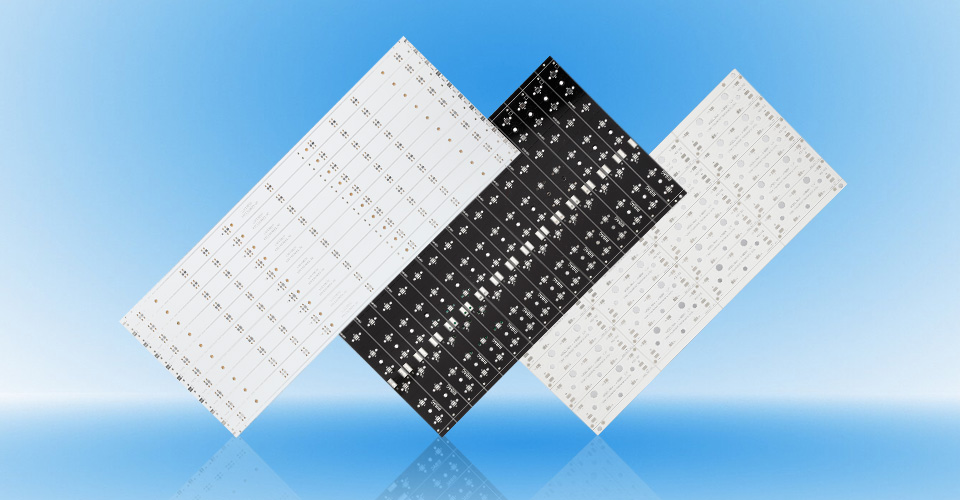

In high-power applications, such as power supplies, motor drives, and energy conversion systems, managing heat is crucial to maintaining performance and preventing damage to components. Metal core PCBs provide a solution by efficiently transferring heat away from power devices, ensuring stable operation. The copper core PCB design, in particular, is well-suited for these applications due to copper's excellent thermal conductivity.

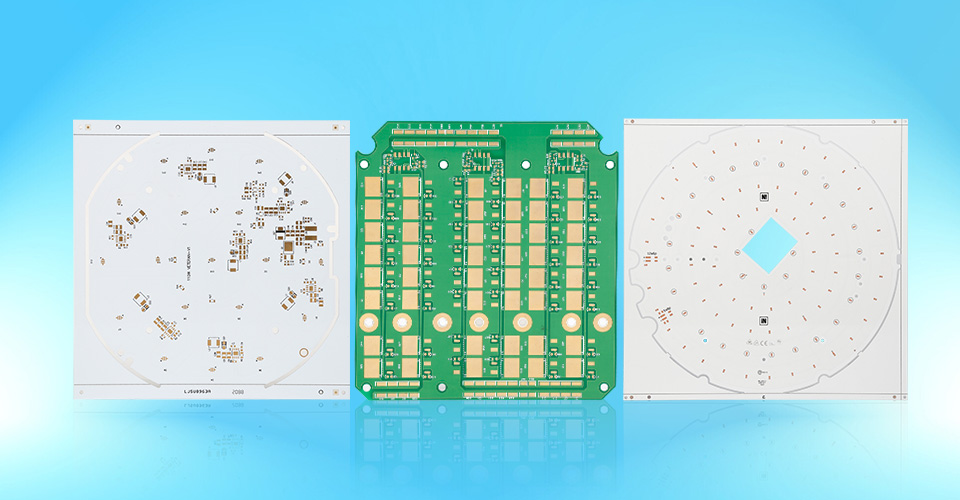

When designing a metal core PCB, choosing the right metal core material is critical for ensuring optimal performance. Aluminum core PCBs are typically used for general applications due to their cost-effectiveness and good thermal conductivity. However, copper core PCBs are often selected for more demanding applications, as copper has superior thermal and electrical conductivity compared to aluminum. The choice between copper-clad laminate and other materials should depend on the specific thermal and electrical requirements of the project.

Thermal conductivity is a key factor when selecting a metal core PCB. A copper-based PCB generally provides better heat dissipation than aluminum-based PCBs, but it also tends to be more expensive. It is essential to consider the thermal load of the application and the expected operating environment to determine which material is best suited for your needs.

The design of a metal core PCB can be more complex compared to traditional PCBs, especially when it involves blind and buried vias or intricate routing. It is important to work with a PCB manufacturer experienced in producing metal core PCBs to ensure the design meets both functional and thermal performance requirements.

Metal core PCBs are an essential technology for applications requiring efficient heat dissipation, mechanical durability, and reliable performance. From automotive electronics to LED lighting and power electronics, metal core PCBs are increasingly used in industries where thermal management is critical. With benefits such as enhanced thermal performance, mechanical strength, and increased reliability, metal core PCBs are the optimal choice for high-power applications.

When selecting metal core PCBs for your next project, consider factors such as material selection, thermal conductivity, and design complexity. By choosing the right copper core PCB or copper-clad laminate and collaborating with experienced PCB manufacturers, you can ensure the success of your electronic systems.

Answer:

Copper core PCBs are ideal for high-power applications because copper has superior thermal and electrical conductivity. This allows for efficient heat dissipation and stable performance, even under high thermal loads. Copper core PCBs are commonly used in power supplies, motor drives, and energy conversion systems.

Answer:

Copper-clad laminate is a key material used in metal core PCBs. It provides the conductive layer for the PCB and is bonded to the metal base layer (e.g., copper or aluminum). The copper-clad laminate helps in efficient signal transmission and contributes to the thermal management capabilities of the board.

Answer:

Automotive PCBs must operate in extreme conditions, including high temperatures, vibrations, and physical shocks. Metal core PCBs offer superior heat dissipation and mechanical strength, making them ideal for automotive applications such as power control units, lighting systems, and sensors, ensuring they perform reliably under demanding conditions.

Answer:

Yes, metal core PCBs are widely used in LED lighting systems to manage the heat generated by the LEDs. The metal core, typically made of aluminum or copper, helps dissipate heat efficiently, extending the lifespan and improving the performance of the LEDs in applications such as street lighting, automotive headlights, and industrial lighting.

Answer:

Copper core PCBs provide better thermal and electrical conductivity than aluminum core PCBs, making them ideal for high-performance applications requiring superior heat dissipation. However, aluminum core PCBs are more cost-effective and are commonly used in less demanding applications where heat dissipation is important but not as critical.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related Articles:

Metal Core PCB for High Thermal Management Applications | Apollo PCB

Metal Core PCB Manufacturer for High-Power LED Applications | Apollo PCB

Metal Core PCB Manufacturer | High Thermal Management Solutions

The Ultimate Guide to Metal Core PCB: Boosting Thermal Efficiency in High-Power Electronics

Metal Core PCB: Revolutionizing Thermal Management and Performance in Electronics

Metal Core PCB: Transforming Thermal and Electrical Performance in Modern Electronics

Metal Core PCB Pioneering Thermal and Electrical Excellence in Electronics

Metal Core PCB: Benefits, Applications, and Why It's the Best Choice for Your Electronics

Understanding Metal Core PCB: Key Advantages and Applications in Electronics Manufacturing

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB