-

- PCB TYPE

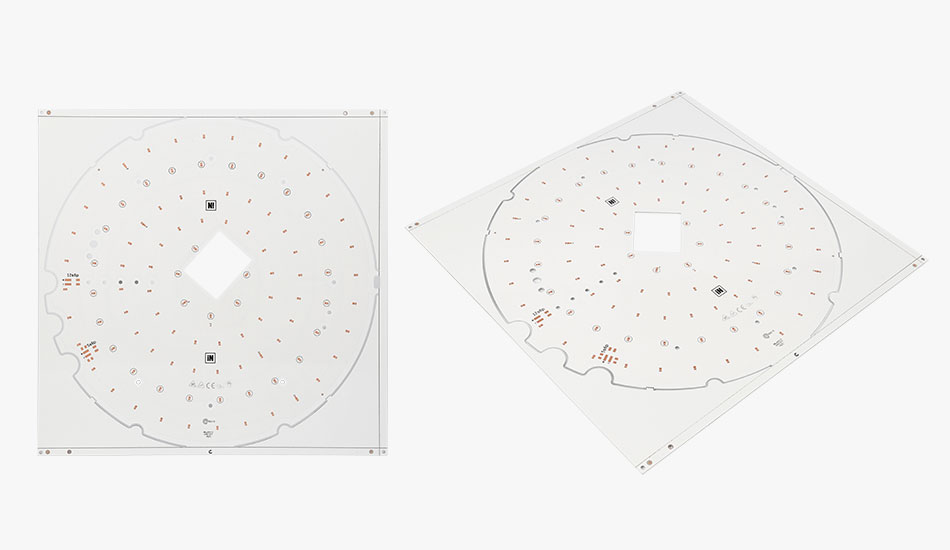

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 09. 2025, 11:20:24

In the intricate world of printed circuit board (PCB) technology, the 2 Layer Metal Core PCB with Hot - Air Solder Leveling (HASL) finish represents a specialized and widely - utilized solution. Combining the robust thermal and mechanical properties of a two - layer metal core PCB with the solderability advantages of the HASL finish, this type of PCB caters to a diverse range of applications. This article will provide an in - depth exploration of 2 Layer Metal Core PCBs with HASL finish, covering their structure, benefits, applications, design considerations, manufacturing processes, and future trends.

What is a 2 Layer Metal Core PCB with HASL Finish?

A 2 Layer Metal Core PCB consists of two conductive copper layers separated by an insulating layer, with a metal core, typically aluminum or copper, serving as the base. The two - layer design offers a more complex circuit layout compared to single - layer PCBs, enabling greater flexibility in component connection and signal routing. The HASL finish, applied to the surface of the copper layers, involves coating the exposed copper with a layer of solder using hot air to level the surface. This finish enhances the solderability of the PCB, ensuring reliable soldering of components during assembly.

Structure of 2 Layer Metal Core PCBs with HASL Finish

Top Copper Layer: This is the uppermost conductive layer where the majority of electronic components are mounted. The copper traces on this layer are carefully etched to form the electrical pathways that connect components, ensuring proper signal transmission and power distribution. The design of the traces must account for factors such as current - carrying capacity and signal integrity.

Insulating Layer: Positioned between the top and bottom copper layers, as well as between the copper layers and the metal core, the insulating layer is crucial. It is made of a thermally conductive dielectric material that provides electrical isolation, preventing short circuits. Simultaneously, it facilitates heat transfer from the components on the copper layers to the metal core, contributing to effective thermal management.

Metal Core: The metal core, usually aluminum or copper, is the defining feature of this PCB type. Aluminum is commonly chosen for its cost - effectiveness, lightweight nature, and adequate thermal conductivity, while copper offers superior thermal performance at a higher cost. The metal core provides mechanical strength to the PCB, enabling it to withstand physical stress, vibrations, and shocks, and also acts as an efficient heat sink.

Bottom Copper Layer: Similar to the top layer, the bottom copper layer can be used for additional electrical connections, ground planes, or power distribution. It provides an extra layer of flexibility in circuit design, allowing for more complex routing and the implementation of shielding to reduce electromagnetic interference.

HASL Finish: Applied to the surface of both the top and bottom copper layers, the HASL finish creates a smooth, solder - coated surface. This finish protects the copper from oxidation and corrosion, and its even surface ensures consistent solder wetting during the soldering process, enhancing the reliability of component connections.

Advantages of 2 Layer Metal Core PCBs with HASL Finish

Enhanced Solderability: The primary advantage of the HASL finish is its ability to improve the solderability of the PCB. The solder coating on the copper surface allows for easy and reliable soldering of components, reducing the risk of soldering defects such as cold joints or bridges. This is particularly important in high - volume manufacturing, where consistent soldering quality is crucial for production efficiency and product reliability.

Effective Thermal Management: The two - layer metal core structure provides excellent thermal management capabilities. Heat generated by components on the copper layers is efficiently transferred to the metal core, which can then dissipate the heat into the surrounding environment. This helps to maintain lower operating temperatures, preventing thermal stress on components and extending their lifespan. In applications where heat dissipation is critical, such as in power electronics or LED lighting, this thermal performance is essential.

Mechanical Robustness: The metal core imparts significant mechanical strength to the PCB. It makes the board more resistant to bending, cracking, and physical damage during handling, assembly, and operation. This mechanical durability is especially beneficial in harsh environments, such as automotive, aerospace, and industrial settings, where the PCB may be exposed to vibrations, shocks, and extreme temperatures.

Cost - Effective Solution: Compared to some other high - performance PCB surface finishes, HASL is relatively cost - effective. This, combined with the cost - efficient nature of two - layer metal core PCBs, makes 2 Layer Metal Core PCBs with HASL finish an attractive option for applications where performance and cost need to be balanced. They offer a good return on investment, especially in mass - produced products.

Compatibility with Assembly Processes: The HASL finish is highly compatible with standard PCB assembly processes, including wave soldering and reflow soldering. This compatibility simplifies the manufacturing process, as it allows for the use of existing assembly equipment and techniques without the need for significant modifications or additional investment.

Applications of 2 Layer Metal Core PCBs with HASL Finish

LED Lighting: In the LED lighting industry, 2 Layer Metal Core PCBs with HASL finish are widely used. LEDs generate heat during operation, and efficient thermal management is essential for their performance and lifespan. The metal core helps to dissipate heat, while the HASL finish ensures reliable soldering of the LEDs and other components, making these PCBs ideal for LED bulbs, streetlights, and high - bay lighting fixtures.

Automotive Electronics: The automotive environment is demanding, with high temperatures, vibrations, and electrical interference. 2 Layer Metal Core PCBs with HASL finish are employed in various automotive applications, such as engine control units (ECUs), advanced driver assistance systems (ADAS), and automotive lighting. Their mechanical strength, thermal management capabilities, and solderability make them well - suited for ensuring the reliable operation of electronic components in vehicles.

Consumer Electronics: For consumer electronics products like smartphones, tablets, and laptops, where cost - effectiveness and performance are key, 2 Layer Metal Core PCBs with HASL finish are often used. They can handle the heat generated by powerful processors and other components, while the HASL finish ensures reliable soldering during assembly, contributing to the overall quality and reliability of the devices.

Industrial Electronics: In industrial settings, power electronics components such as inverters, motor drives, and power supplies generate a significant amount of heat. 2 Layer Metal Core PCBs with HASL finish are used to dissipate this heat effectively and provide a robust platform for component mounting. Their mechanical durability allows them to withstand the harsh conditions of industrial environments, including dust, moisture, and mechanical stress.

Power Supplies: Power supply units require PCBs that can handle high currents and manage heat efficiently. 2 Layer Metal Core PCBs with HASL finish meet these requirements, providing a reliable electrical connection with their solderable surface and effective heat dissipation through the metal core.

Design Considerations for 2 Layer Metal Core PCBs with HASL Finish

Thermal Design:

Component Placement: Strategically placing heat - generating components over the metal core is crucial for effective thermal management. Thermal vias can be used to connect the copper layers to the metal core, enhancing heat transfer. Designers should also consider the thermal conductivity of the insulating layer and ensure that it is optimized for the specific application.

Metal Core Selection: The choice between aluminum and copper for the metal core depends on factors such as cost, thermal requirements, and weight constraints. Aluminum is a popular choice for general - purpose applications, while copper is preferred for high - power applications where superior thermal conductivity is needed.

Mechanical Design:

Component Mounting: Heavier components need to be mounted securely to the PCB to prevent damage during handling and operation. The mechanical strength of the metal core can support the weight of components, but appropriate mounting techniques, such as using brackets or adhesive bonding, may still be required.

Board Shape and Edge Treatment: The shape of the PCB and the treatment of its edges can affect its mechanical strength. Unusual or complex board shapes may require additional considerations to ensure that the PCB can withstand mechanical stress without deforming. Rounding the edges or applying chamfers can reduce stress concentrations and prevent damage.

Electrical Design:

Trace Width and Spacing: Determining the appropriate trace width and spacing is essential for ensuring the electrical performance of the PCB. Wider traces are needed for higher - current applications to minimize resistance and prevent excessive heat generation. Adequate spacing between traces is necessary to prevent electrical short circuits, especially in high - voltage applications.

Ground Plane Design: A well - designed ground plane can improve signal integrity, reduce electromagnetic interference (EMI), and provide a low - impedance path for electrical current. The ground plane should be continuous and have a sufficient area to effectively shield the signals on the PCB.

HASL - Specific Considerations:

Solder Coating Thickness: The thickness of the solder coating in the HASL finish can affect solderability and component clearance. Designers need to ensure that the coating thickness is within the recommended range to avoid issues such as excessive solder bridging or insufficient solder coverage.

Surface Flatness: The leveling process in HASL can affect the surface flatness of the PCB. This may impact the placement of components, especially those with fine - pitch leads. Designers should consider the surface flatness requirements of the components being used and ensure that the HASL process meets these requirements.

Manufacturing Processes of 2 Layer Metal Core PCBs with HASL Finish

Layer Preparation: The manufacturing process starts with the preparation of the individual layers. The metal core is cleaned to remove contaminants, and the copper foils for the top and bottom layers are processed to enhance adhesion. The insulating layer material, usually a thermally conductive dielectric, is prepared and applied to separate the copper layers from the metal core.

Lamination: The prepared layers are then laminated together under heat and pressure. This process bonds the layers firmly, creating a stable and cohesive PCB structure. The lamination parameters, such as temperature, pressure, and time, are carefully controlled to ensure proper adhesion and layer alignment.

Circuit Imaging and Etching: Photolithography is used to transfer the circuit design onto the copper layers. A photosensitive resist is applied, exposed to light through a mask with the circuit pattern, and then developed. The unprotected copper is etched away, leaving the desired conductive traces and pads.

Drilling and Plating: Holes are drilled through the PCB layers for component leads, vias, and mounting. After drilling, the holes are plated with copper to create electrical connections between the layers. The plating process ensures good electrical conductivity and mechanical strength of the holes.

HASL Finish Application: The HASL process involves immersing the PCB in a molten solder bath, followed by the application of hot air to level the solder coating. The PCB is first pre - treated to remove oxides and ensure good solder wetting. The molten solder adheres to the copper surface, and the hot air blows off excess solder, creating a smooth and even solder coating.

Quality Control: Throughout the manufacturing process, strict quality control measures are implemented. This includes inspecting the PCB for electrical continuity, checking the integrity of the layers, and verifying the quality of the HASL finish. Defective PCBs are identified and either reworked or discarded to ensure that only high - quality products are produced.

Challenges and Solutions in 2 Layer Metal Core PCB with HASL Finish

Solder Joint Reliability: Despite its advantages, the HASL finish can sometimes lead to solder joint reliability issues, such as voids or inconsistent solder thickness. To address this, manufacturers can optimize the HASL process parameters, use high - quality solder alloys, and implement advanced inspection techniques, such as X - ray inspection, to detect and correct potential problems.

Thermal Expansion Mismatch: Different materials in the PCB, including the metal core, insulating layer, and copper layers, have different coefficients of thermal expansion. This can lead to thermal stress and potential delamination or cracking of the PCB during temperature changes. Designers can mitigate this by carefully selecting materials with compatible thermal expansion coefficients and by using proper thermal management techniques.

Environmental Concerns: Traditional HASL processes may use lead - based solder, which raises environmental concerns due to the toxicity of lead. To comply with environmental regulations, manufacturers are increasingly adopting lead - free HASL processes, using alternative solder alloys such as tin - silver - copper (SAC) alloys. This requires adjustments in the manufacturing process and quality control to ensure consistent performance.

Future Trends

Advanced HASL Processes: Research is ongoing to develop more advanced HASL processes that can improve the quality and consistency of the solder finish. This includes the use of new solder alloys, improved flux formulations, and more precise control of the hot - air leveling process to achieve better surface flatness and solder joint reliability.

Integration with Miniaturization: As electronics continue to miniaturize, 2 Layer Metal Core PCBs with HASL finish will need to adapt. This may involve developing thinner layers, smaller vias, and more precise component placement. The HASL process will also need to be optimized to ensure reliable soldering of miniature components.

Sustainability Initiatives: There is a growing focus on sustainability in the PCB industry. Future 2 Layer Metal Core PCBs with HASL finish are likely to incorporate more environmentally friendly materials and manufacturing processes. This includes the use of recycled metals, bio - based insulating materials, and lead - free solder alloys, as well as reducing waste and energy consumption during production.

Conclusion

2 Layer Metal Core PCBs with HASL finish offer a unique combination of enhanced solderability, effective thermal management, mechanical robustness, and cost - effectiveness. Their wide range of applications across various industries, from LED lighting and automotive electronics to consumer and industrial electronics, showcases their versatility and importance. While there are challenges associated with their use, ongoing research and development efforts are addressing these issues. As technology continues to evolve, 2 Layer Metal Core PCBs with HASL finish will continue to play a significant role in the electronics industry, adapting to meet the changing demands of modern electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB