-

- PCB TYPE

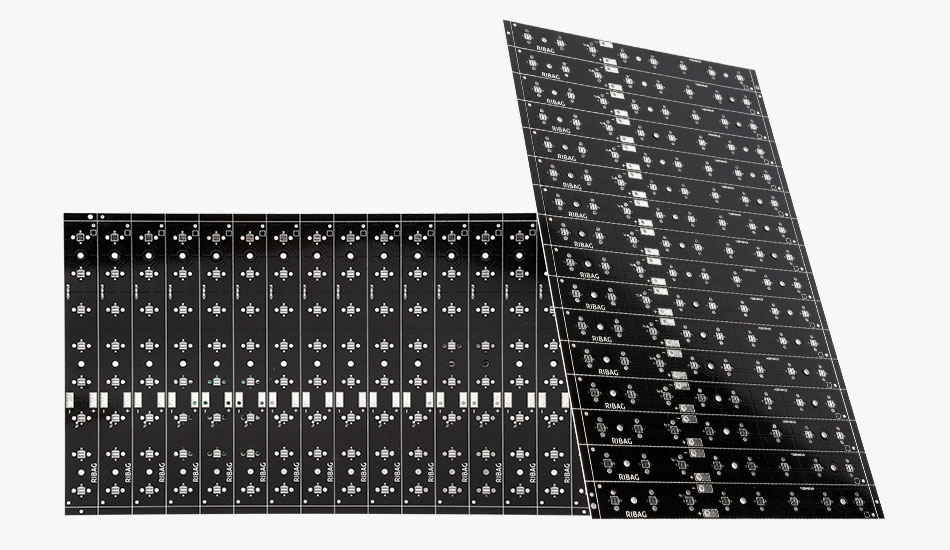

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 09. 2025, 11:30:58

In the dynamic landscape of printed circuit board (PCB) technology, 2 Layer Metal Core PCBs have emerged as a game - changing solution for a wide array of applications. These specialized PCBs combine the advantages of a two - layer circuit layout with the unique properties of a metal core, offering enhanced thermal management, mechanical strength, and electrical performance. This comprehensive article will explore every aspect of 2 Layer Metal Core PCBs, from their fundamental structure and benefits to their applications, design considerations, manufacturing processes, and the challenges they face.

What is a 2 Layer Metal Core PCB?

A 2 Layer Metal Core PCB is a type of printed circuit board that consists of two conductive copper layers separated by an insulating layer, all resting on a metal core. The two - layer design enables a more intricate circuit layout compared to single - layer PCBs, allowing for the connection of multiple components and the routing of electrical signals in two dimensions. The metal core, typically made of aluminum or copper, serves as both a mechanical support and a heat dissipation medium, setting it apart from traditional organic - based PCBs.

Structure of 2 Layer Metal Core PCBs

Top Copper Layer: This is the upper - most conductive layer where the majority of electronic components are mounted. The copper traces on this layer are precisely etched to form the electrical pathways that connect components. These traces are designed to ensure proper signal integrity and current - carrying capacity, depending on the requirements of the circuit. For example, in a high - speed data - transmission circuit, the trace width and spacing need to be carefully optimized to minimize signal attenuation.

Insulating Layer: Positioned between the top and bottom copper layers, as well as between the copper layers and the metal core, the insulating layer is a critical component. It is usually made of a thermally conductive dielectric material. Its primary function is to provide electrical isolation between the conductive layers, preventing short circuits. Simultaneously, it plays a crucial role in facilitating heat transfer from the components on the copper layers to the metal core. Different insulating materials have varying thermal conductivity and electrical properties, and the choice of material depends on the specific application requirements.

Metal Core: The metal core is the defining characteristic of this type of PCB. Aluminum is a commonly used material for the metal core due to its favorable combination of properties. It is lightweight, cost - effective, and has good thermal conductivity, making it an efficient heat sink. Copper, on the other hand, offers even higher thermal conductivity but is more expensive. The metal core not only helps in dissipating heat generated by components but also provides mechanical strength to the PCB, enabling it to withstand physical stress, vibrations, and shocks.

Bottom Copper Layer: The bottom copper layer can be used for additional electrical connections, ground planes, or power distribution. It provides an extra layer of flexibility in circuit design, allowing for more complex routing and the implementation of features such as shielding to reduce electromagnetic interference. In some applications, the bottom copper layer may be used to create a continuous ground plane, which helps in improving signal integrity and reducing noise.

Advantages of 2 Layer Metal Core PCBs

Efficient Thermal Management: One of the most significant advantages of 2 Layer Metal Core PCBs is their superior thermal management capabilities. In traditional two - layer PCBs with organic substrates, heat dissipation can be a major challenge, especially when dealing with power - hungry components. The metal core in these PCBs provides an efficient pathway for heat to be transferred away from the components. This rapid heat transfer helps to maintain lower operating temperatures, preventing thermal stress on components and reducing the risk of premature failure. As a result, the overall reliability and lifespan of the electronic device are enhanced. For instance, in high - power LED lighting applications, the ability to manage heat effectively is crucial for ensuring long - term performance.

Mechanical Robustness: The metal core imparts excellent mechanical strength to the PCB. It makes the board more durable and better able to withstand the rigors of handling, assembly, and operation in various environments. 2 Layer Metal Core PCBs are less likely to bend, crack, or break compared to traditional PCBs, which is particularly important in applications where the PCB may be subject to vibrations, shocks, or physical impacts, such as in automotive or industrial settings. The mechanical strength of the metal core also allows for the mounting of heavier components without the need for additional mechanical support structures in many cases.

Design Flexibility: Despite their specialized structure, 2 Layer Metal Core PCBs offer a high degree of design flexibility. The two - layer layout allows for more intricate circuit designs, including the routing of multiple signals, power distribution, and the integration of different types of components. Designers can take advantage of the metal core to optimize heat dissipation by strategically placing components and designing heat - dissipation paths. For example, heat - generating components can be placed directly over the metal core, and thermal vias can be used to enhance heat transfer between the copper layers and the metal core.

High Current Handling Capacity: The metal core provides a solid foundation for the copper traces, enabling better power distribution and reduced voltage drop. This makes 2 Layer Metal Core PCBs well - suited for high - power applications that require efficient power delivery. The improved thermal conductivity of the metal core also helps to reduce the risk of overheating when handling high current loads, ensuring the reliable operation of the PCB. In power electronics applications, such as inverters and power supplies, the ability to handle high currents is essential.

Applications of 2 Layer Metal Core PCBs

LED Lighting: In the LED lighting industry, 2 Layer Metal Core PCBs are widely used. LEDs generate heat during operation, and efficient thermal management is crucial for their performance and lifespan. The metal core in these PCBs helps to dissipate heat quickly, ensuring that the LEDs operate at optimal temperatures. Whether it's for general lighting, automotive lighting, or industrial lighting, 2 Layer Metal Core PCBs play a vital role in ensuring consistent light output and long - term reliability. For example, in streetlights, where high - power LEDs are used, the ability to manage heat effectively is essential to prevent premature failure and maintain illumination levels.

Automotive Electronics: The automotive industry is a major consumer of 2 Layer Metal Core PCBs. The harsh automotive environment, with its high temperatures, vibrations, and electrical interference, demands a PCB with excellent thermal and mechanical properties. These PCBs are used in various automotive applications, such as engine control units (ECUs), advanced driver - assistance systems (ADAS), and in - car infotainment systems. Their ability to withstand the rigors of the automotive environment while providing reliable electrical performance makes them an ideal choice. For instance, in an ECU, which controls various engine functions, the PCB needs to be highly reliable and able to handle the heat generated by the components.

Consumer Electronics: In the consumer electronics market, where products are becoming smaller, more powerful, and more energy - efficient, 2 Layer Metal Core PCBs are finding increasing applications. Smartphones, tablets, laptops, and other portable devices often require PCBs that can manage heat effectively and support high - density component integration. The design flexibility of 2 Layer Metal Core PCBs allows for the creation of compact and efficient circuit designs. For example, in a smartphone, the PCB needs to accommodate a large number of components, including a powerful processor, while also dissipating the heat generated by these components to ensure stable operation.

Industrial Electronics: Industrial applications, such as control systems, motor drives, and power supplies, often involve high - power components that generate a significant amount of heat. 2 Layer Metal Core PCBs are well - suited for these applications as they can handle the heat and provide the necessary mechanical strength to withstand the harsh industrial environment. In a motor drive, for example, the PCB needs to be able to handle high currents and dissipate the heat generated by the power transistors to ensure reliable operation.

Power Electronics: In power electronics applications, such as inverters, converters, and chargers, 2 Layer Metal Core PCBs are used to handle high - power levels and manage heat. The high current handling capacity and efficient thermal management of these PCBs make them essential for ensuring the reliable operation of power - electronic devices. For example, in an inverter that converts DC power to AC power, the PCB needs to be able to handle the high currents and voltages involved while dissipating the heat generated by the power - semiconductor devices.

Design Considerations for 2 Layer Metal Core PCBs

Thermal Design:

Component Placement: When designing a 2 Layer Metal Core PCB, the placement of heat - generating components is of utmost importance. Components should be strategically placed over the metal core to ensure efficient heat transfer. Thermal vias, which are small holes filled with a conductive material, can be used to connect the top copper layer to the metal core, further enhancing heat dissipation. The layout of components should also consider the airflow within the device, as natural or forced convection can also play a role in heat removal.

Insulating Layer Thickness and Conductivity: The thickness and thermal conductivity of the insulating layer have a direct impact on the thermal performance of the PCB. A thinner insulating layer can facilitate better heat transfer but may compromise electrical isolation. Designers need to carefully select an insulating material with the right balance of thermal conductivity and electrical insulation properties to meet the requirements of the circuit. Additionally, the choice of insulating material can also affect the overall cost and manufacturability of the PCB.

Mechanical Design:

Component Mounting: Heavier components on the PCB need to be mounted securely to prevent damage to the board during handling and operation. The mechanical strength of the metal core can support the weight of components, but appropriate mounting techniques, such as using brackets or adhesive bonding, may still be required. The design should also consider the stress distribution on the PCB when components are mounted, to avoid any potential warping or cracking of the board.

Board Shape and Edge Treatment: The shape of the 2 Layer Metal Core PCB can affect its mechanical strength. Unusual or complex board shapes may require additional considerations to ensure that the PCB can withstand mechanical stress without deforming. Rounding the edges or applying chamfers can reduce stress concentrations and prevent damage during handling and assembly. The thickness of the PCB also plays a role in its mechanical strength, and designers need to choose an appropriate thickness based on the application requirements.

Electrical Design:

Trace Width and Spacing: Determining the appropriate trace width and spacing is crucial for ensuring the electrical performance of the PCB. Wider traces are required for higher - current applications to minimize resistance and prevent excessive heat generation due to electrical losses. Adequate spacing between traces is necessary to prevent electrical short circuits, especially in high - voltage applications. The design should also consider the impedance requirements of the circuit, as proper impedance matching is essential for signal integrity.

Ground Plane Design: A well - designed ground plane on the 2 Layer Metal Core PCB can improve signal integrity, reduce electromagnetic interference (EMI), and provide a low - impedance path for electrical current. The ground plane should be continuous and have a sufficient area to effectively shield the signals on the PCB. In some cases, multiple ground planes may be used to further enhance the performance of the circuit.

Manufacturing Processes of 2 Layer Metal Core PCBs

Layer Preparation: The manufacturing process begins with the preparation of the individual layers. The metal core is thoroughly cleaned to remove any contaminants, such as oils, dirt, or oxides, which could affect the adhesion of the insulating layer. The copper foils for the top and bottom layers are also prepared by cleaning and roughening their surfaces to enhance bonding with the insulating layer. The insulating layer material, which is typically in the form of a film or a liquid resin, is formulated with thermally conductive fillers to improve heat transfer.

Lamination: The prepared layers are then laminated together. The insulating layer is placed between the metal core and the copper foils. The assembly is subjected to heat and pressure in a laminator or press. The heat softens the insulating material, allowing it to flow and bond the layers together, while the pressure ensures good adhesion and a uniform laminate structure. The lamination process parameters, such as temperature, pressure, and time, need to be carefully controlled to ensure the quality of the laminate.

Circuit Imaging and Etching: After lamination, the next step is to create the electrical circuit on the copper layers. Photolithography is commonly used for circuit imaging. A photosensitive resist is applied to the surface of the copper foils, and a mask with the desired circuit pattern is used to expose the resist to light. The exposed areas of the resist are then developed, leaving the copper traces underneath protected by the unexposed resist. The unprotected copper is then etched away using a chemical solution, leaving the conductive traces and pads that form the electrical circuit of the PCB.

Drilling and Plating: Holes are drilled through the layers of the PCB for various purposes, such as for component leads, vias, and mounting holes. Specialized drilling equipment is used to ensure accurate hole placement and smooth hole edges. After drilling, the holes are plated with a conductive material, usually copper, to create electrical connections between the different layers of the PCB. The plating process also helps to improve the mechanical strength of the holes.

Surface Finishing: The final step in the manufacturing process is surface finishing. The surface finish serves to protect the copper traces from oxidation and corrosion, as well as to provide a suitable surface for soldering components onto the PCB. Common surface finishes for 2 Layer Metal Core PCBs include hot - air solder leveling (HASL), electroless nickel immersion gold (ENIG), and organic solderability preservative (OSP). The choice of surface finish depends on factors such as the application requirements, cost, and environmental considerations.

Challenges and Solutions in 2 Layer Metal Core PCB Manufacturing

Cost: Although 2 Layer Metal Core PCBs offer long - term cost savings in terms of improved performance and reliability, the initial cost can be a concern for some projects. The cost of the metal core material, especially if using copper, and the more complex manufacturing processes can contribute to a higher price tag. To address this, manufacturers can explore options such as optimizing the design to reduce the amount of metal used, or by leveraging economies of scale through larger production runs. Additionally, the use of alternative materials or manufacturing techniques may also help to reduce costs without sacrificing performance.

Manufacturing Complexity: The manufacturing process for 2 Layer Metal Core PCBs is more complex compared to traditional two - layer PCBs. The need to laminate the metal core, ensure proper adhesion of the insulating layer, and control the thermal and electrical properties of the board requires advanced manufacturing equipment and skilled personnel. This complexity can lead to longer production times and potential quality control issues. To overcome this, manufacturers invest in state - of - the - art equipment and provide extensive training to their employees. They also implement strict quality control measures at each stage of the manufacturing process to ensure the reliability of the PCBs.

Compatibility with Components: Ensuring compatibility between the 2 Layer Metal Core PCB and the electronic components is crucial. Some components may be sensitive to the thermal and mechanical properties of the PCB. Designers need to carefully select components and perform thorough testing to ensure that they work well with the PCB. Additionally, the soldering process may need to be optimized to ensure proper connection between the components and the PCB, especially when using surface - mount components.

Future Trends in 2 Layer Metal Core PCB Technology

Miniaturization: As the demand for smaller and more powerful electronic devices continues to grow, there will be a trend towards miniaturizing 2 Layer Metal Core PCBs. This will involve developing thinner layers, smaller vias, and more precise component placement to fit more functionality into a smaller space. The manufacturing processes will need to be refined to achieve these miniaturization goals, while still maintaining the thermal and mechanical performance of the PCBs.

Integration with Advanced Technologies: There will be an increasing integration of 2 Layer Metal Core PCBs with emerging technologies such as 5G, the Internet of Things (IoT), and artificial intelligence. These technologies require PCBs that can support high - speed data transfer, low - power consumption, and efficient heat management. 2 Layer Metal Core PCBs will need to be designed to meet these specific requirements, for example, by improving their signal integrity and thermal performance at high frequencies.

Sustainable Manufacturing: With the growing focus on sustainability, there will be a push towards more environmentally friendly manufacturing processes for 2 Layer Metal Core PCBs. This may include the use of recycled materials, reducing waste during production, and implementing more energy - efficient manufacturing techniques. Manufacturers will also need to comply with increasingly strict environmental regulations, which will drive the development of more sustainable PCB manufacturing methods.

Conclusion

2 Layer Metal Core PCBs have revolutionized the world of printed circuit boards by offering a unique combination of thermal management, mechanical strength, and design flexibility. Their applications span across a wide range of industries, from LED lighting and automotive electronics to consumer and industrial electronics. By understanding their structure, advantages, design considerations, and manufacturing processes, designers and engineers can make the most of these PCBs to create innovative and reliable electronic devices. As technology continues to evolve, 2 Layer Metal Core PCBs will undoubtedly play an even more significant role in the future of electronics, adapting to meet the changing demands of modern applications.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB