-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 25. 2025, 10:48:36

In the rapidly evolving landscape of high-power electronics, thermal management and current handling capability stand as make-or-break factors for device reliability and performance. The 2oz Copper Double Sided Sinkpad has emerged as a critical solution, addressing the dual challenges of efficient heat dissipation and stable high-current operation in compact electronic designs. Unlike conventional PCBs that often require external heat sinks or conductive enhancements, this specialized PCB integrates core functionalities into a single, streamlined structure—making it indispensable for industries pushing the boundaries of power density.

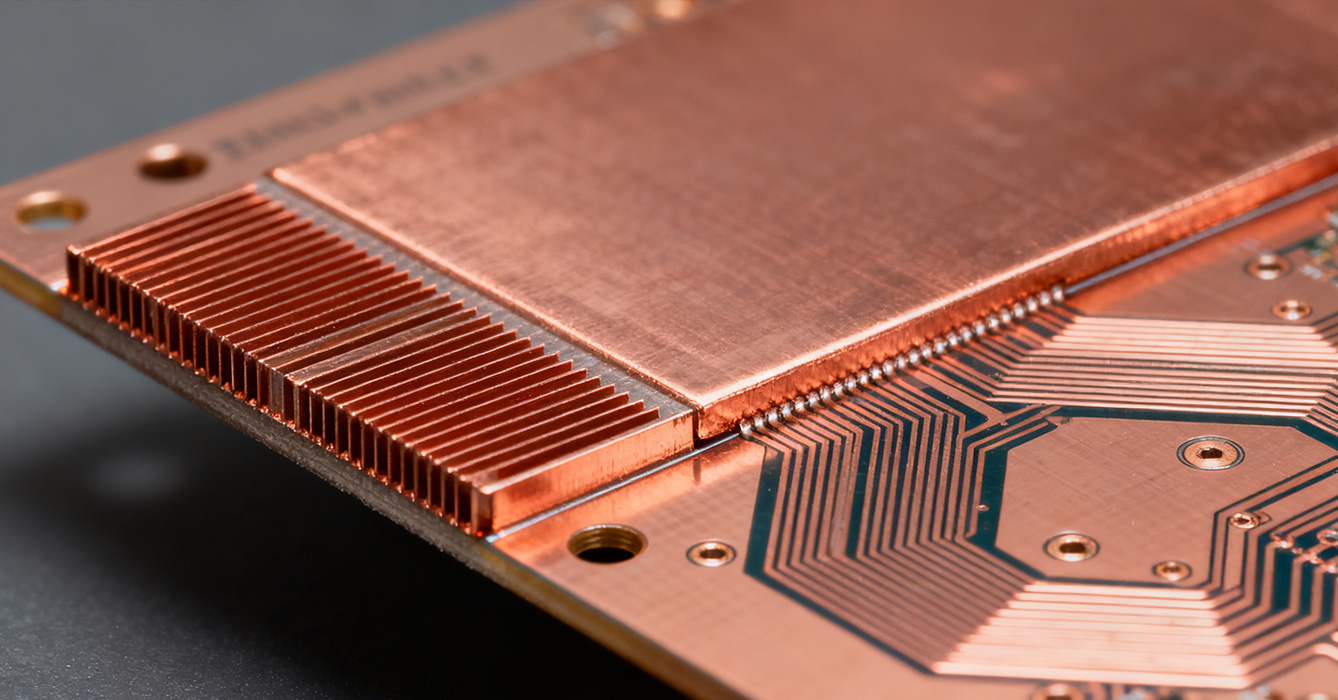

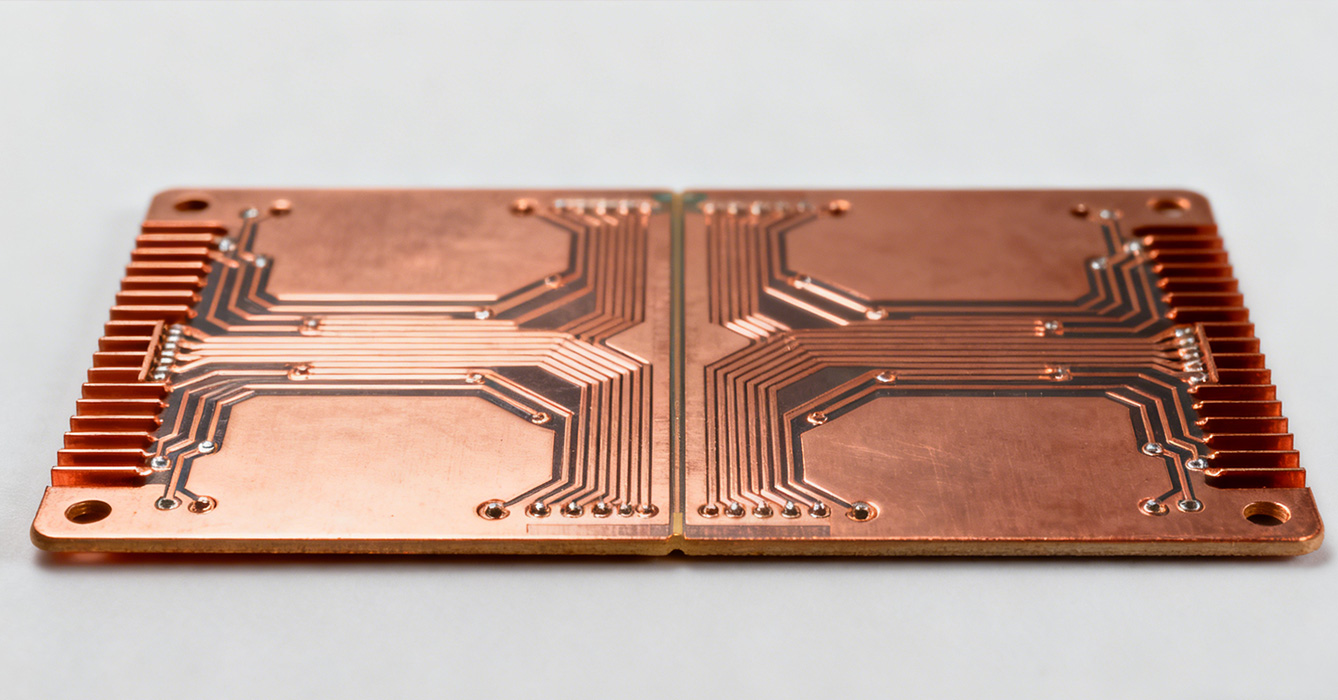

The technical prowess of the 2oz Copper Double Sided Sinkpad stems from the synergistic design of its key components. The 2oz copper layer, thicker than standard alternatives, serves as both a high-performance conductor and a thermal pathway. Its enhanced cross-sectional area minimizes electrical resistance, ensuring that even in high-current scenarios, energy loss through heat generation is kept to a minimum. This is particularly vital for applications where sustained operation at elevated power levels is non-negotiable, as excessive heat can degrade components, shorten lifespans, and compromise overall system efficiency.

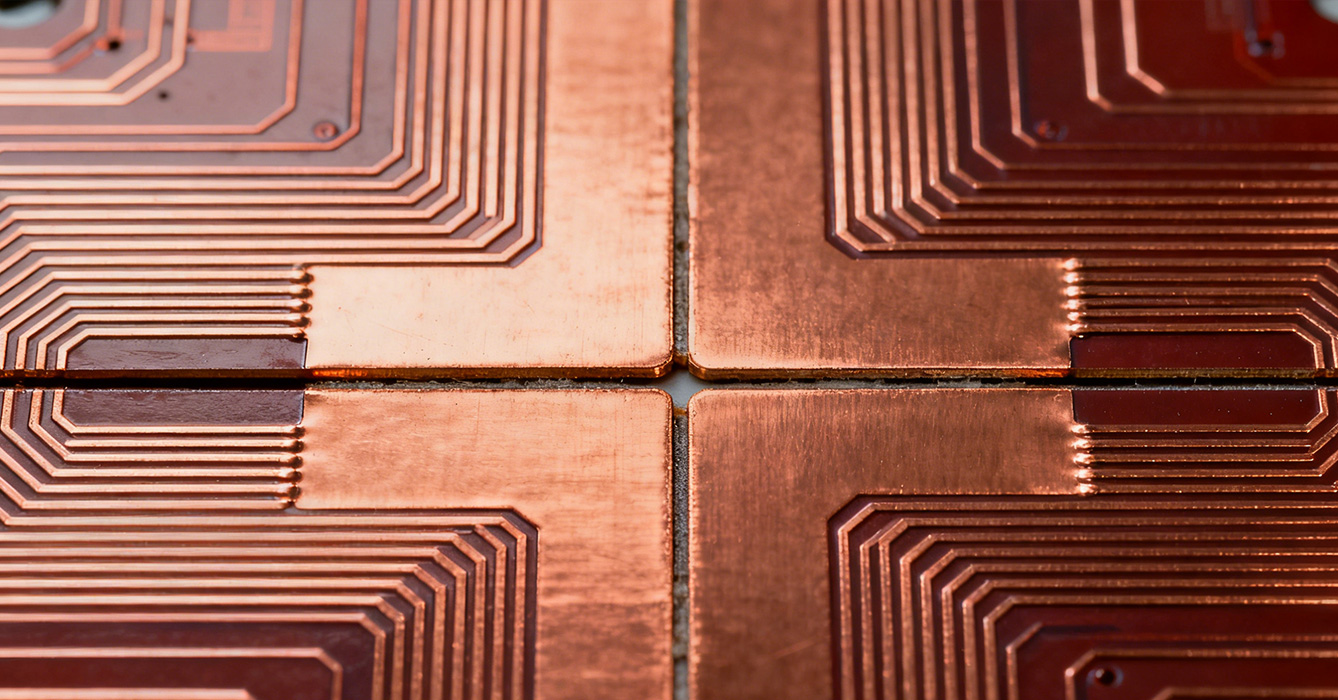

Complementing the thick copper layer is the double-sided sinkpad structure, which redefines integrated thermal management. By incorporating dedicated thermal sink regions on both sides of the PCB, heat generated by high-power components—such as LEDs, semiconductors, and power modules—is rapidly drawn away from critical junctions. This dual-sided design eliminates the limitations of single-sided thermal solutions, allowing for more flexible component placement and ensuring uniform heat distribution across the entire board. The sinkpad’s integration into the PCB substrate also eliminates the need for bulky external cooling systems, enabling sleeker, more compact device designs that align with modern consumer and industrial preferences.

One of the most compelling advantages of the 2oz Copper Double Sided Sinkpad is its versatility across industries. In high-power LED lighting, it enables the development of brighter, more energy-efficient fixtures by managing the intense heat produced by LED arrays. For automotive electronics, it supports the demanding requirements of electric vehicle powertrains, battery management systems, and on-board chargers—withstanding extreme temperature fluctuations and high current loads. Industrial automation benefits from its robust performance in motor drives and power inverters, where reliability in harsh operating environments is paramount. Even in precision applications like medical devices and aerospace electronics, the PCB’s stable thermal and electrical performance ensures consistent operation of critical systems.

Beyond its functional benefits, the 2oz Copper Double Sided Sinkpad aligns with the industry’s growing focus on sustainability and cost-effectiveness. By integrating thermal and conductive functionalities, it reduces the number of components required in a system, lowering material costs and simplifying assembly processes. Its durable construction also extends the lifespan of end products, reducing electronic waste and the need for frequent replacements. Additionally, the compatibility with lead-free surface finishes and environmentally friendly manufacturing processes makes it compliant with global sustainability standards, enhancing market accessibility for manufacturers.

As electronic devices continue to evolve toward higher power densities and smaller form factors, the demand for advanced thermal management solutions will only intensify. The 2oz Copper Double Sided Sinkpad stands at the forefront of this evolution, offering a balance of performance, flexibility, and reliability that conventional PCBs cannot match. Its ability to address the core challenges of high-power electronics—without compromising on design flexibility or cost—makes it a cornerstone technology for industries driving innovation in energy, transportation, manufacturing, and beyond. For engineers and manufacturers seeking to unlock the full potential of high-power devices, this specialized PCB is more than a component; it’s a strategic enabler of next-generation electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB