-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 25. 2025, 10:50:02

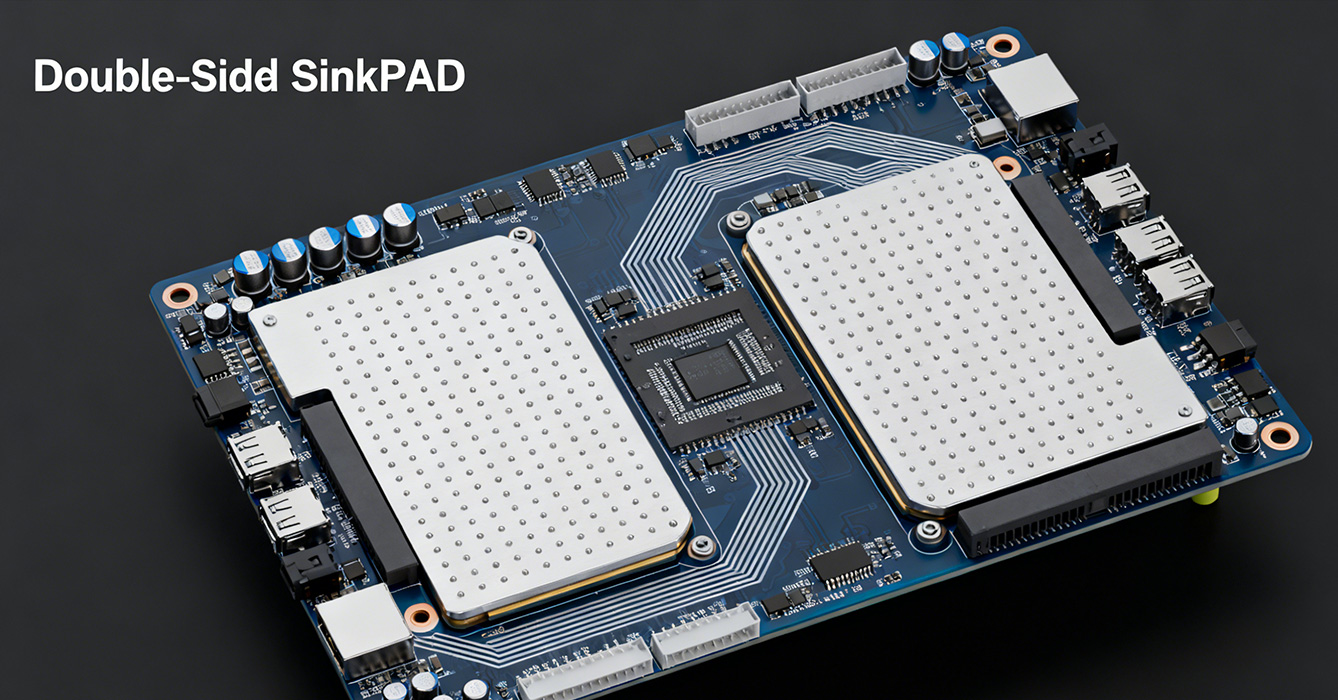

In the era of miniaturized, power-dense electronics, the ability to manage heat while optimizing circuit layout has become a defining challenge for engineers. The Double Sided SinkPAD Board emerges as a transformative solution, reimagining PCB design by integrating dedicated thermal management structures directly onto both sides of the board. Unlike traditional PCBs that treat heat dissipation as an afterthought, this specialized board unifies thermal performance, layout flexibility, and structural integrity—catering to the evolving needs of industries where space constraints and reliability are non-negotiable.

The core innovation of the Double Sided SinkPAD Board lies in its integrated thermal design. By incorporating sinkpad structures on both the top and bottom layers, the board eliminates the need for external heat sinks or adhesive thermal interfaces that add bulk and complexity. These sinkpad regions act as targeted heat collectors, drawing thermal energy directly from high-power components and distributing it across the board’s substrate. This approach not only shortens heat transfer paths but also ensures uniform temperature distribution, preventing hotspots that can degrade component performance and shorten operational lifespans. For systems operating at sustained high power levels, this integrated thermal management translates to enhanced stability and consistent performance.

One of the most significant advantages of the Double Sided SinkPAD Board is its ability to support dual-sided component placement without compromising thermal performance. Engineers can mount power-hungry devices—such as semiconductors, LED modules, and driver circuits—on both sides of the board, effectively doubling the available real estate for high-power components. This flexibility is a game-changer for compact electronic designs, allowing for more streamlined system architectures that reduce overall device size. Additionally, the separation of signal traces and thermal sink regions (a key feature of sinkpad technology) ensures electrical insulation while preserving thermal conductivity, eliminating trade-offs between circuit functionality and heat management.

Beyond thermal and layout benefits, the Double Sided SinkPAD Board delivers exceptional mechanical stability. The integration of sinkpad structures reinforces the board’s rigidity, reducing warpage caused by thermal cycling—a common issue in high-power electronics that can lead to solder joint failure or component misalignment. This robustness makes the board ideal for harsh operating environments, from industrial machinery subjected to vibration to automotive electronics exposed to extreme temperature fluctuations. By balancing thermal efficiency with mechanical durability, the Double Sided SinkPAD Board reduces maintenance requirements and extends the service life of end products, delivering long-term value for manufacturers and users alike.

The versatility of the Double Sided SinkPAD Board positions it as a key enabler for emerging technologies across industries. In smart lighting, it supports the development of high-brightness, compact fixtures by managing the heat of dense LED arrays. In electric mobility, it plays a critical role in battery management systems and on-board chargers, where space efficiency and thermal stability are paramount. Industrial automation benefits from its ability to cool motor drives and power inverters in tight equipment enclosures, while consumer electronics leverages its compact design for high-performance chargers and portable power devices. Even in precision sectors like medical technology, the board’s stable thermal performance ensures the reliability of critical diagnostic and therapeutic equipment.

The Double Sided SinkPAD Board aligns with two key industry trends: energy efficiency and sustainability. By optimizing thermal management, it reduces energy waste associated with overheating components, contributing to more efficient electronic systems. Its integrated design also minimizes the number of parts required in device assembly, lowering material consumption and simplifying manufacturing processes. Furthermore, the board’s compatibility with lead-free manufacturing and environmentally friendly surface finishes ensures compliance with global sustainability standards, making it a responsible choice for manufacturers aiming to reduce their environmental footprint.

As electronic systems continue to push the limits of power density and miniaturization, the Double Sided SinkPAD Board stands out as a forward-thinking solution that addresses core industry challenges. Its ability to integrate thermal management, layout flexibility, and mechanical durability into a single board design makes it an indispensable component for engineers seeking to innovate in high-power electronics. From consumer devices to industrial systems, this specialized PCB is powering the next generation of efficient, reliable, and compact electronic products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB