-

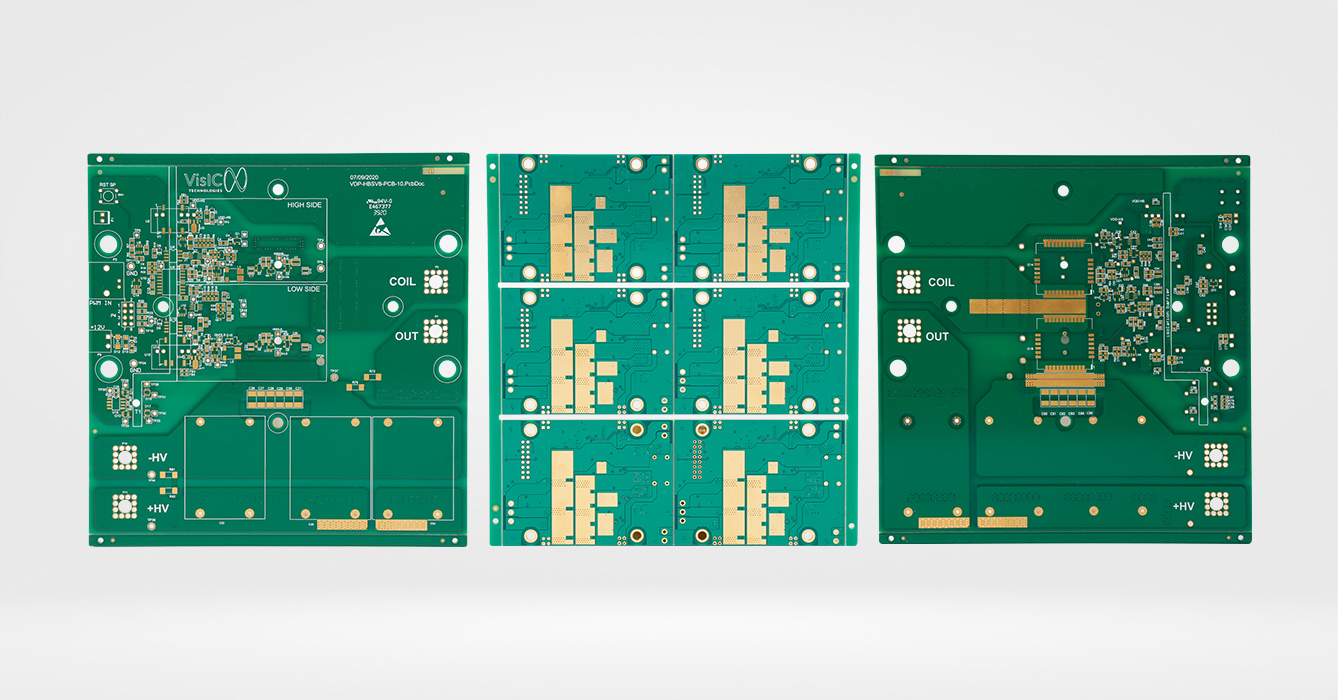

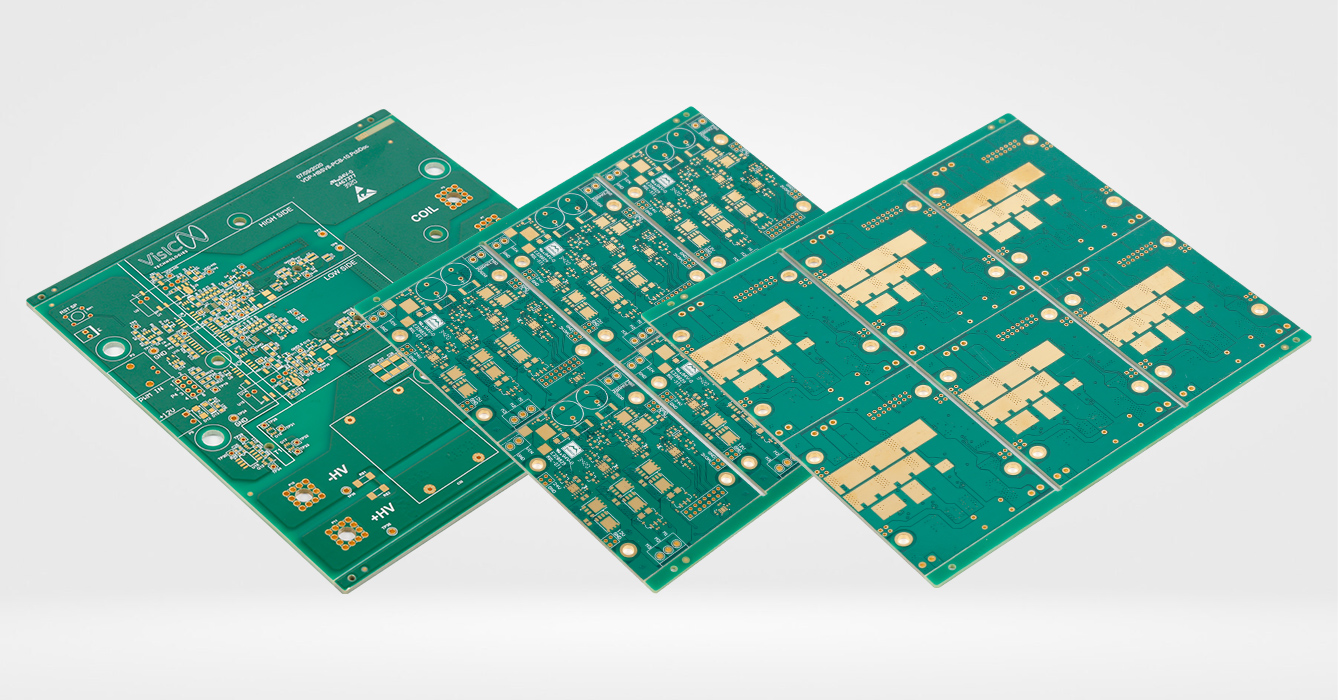

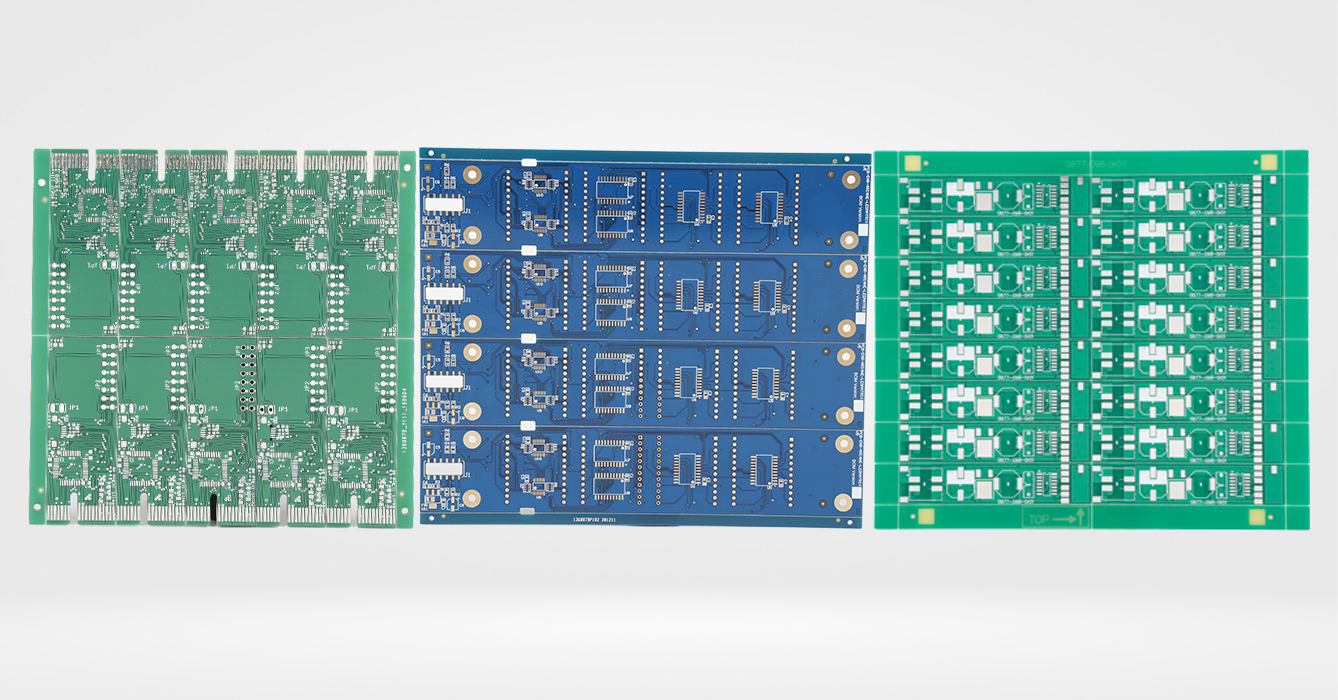

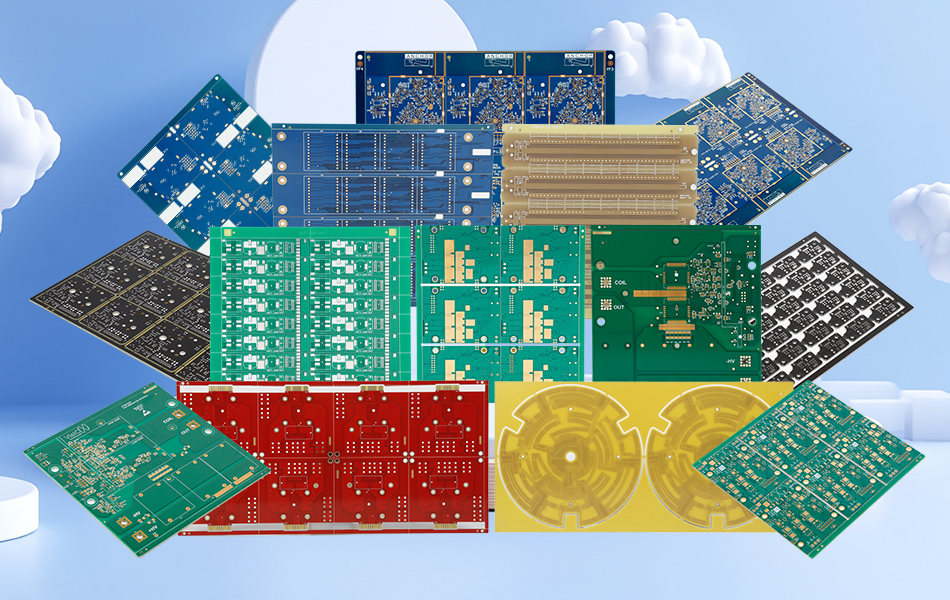

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 02. 2025, 13:25:18

In the landscape of printed circuit board (PCB) design, 3mm diameter counterbore FR4 PCB components stand as a vital bridge between mechanical stability and functional efficiency, offering a specialized solution for mounting hardware in mid-sized electronic assemblies. These cylindrical recesses, characterized by their precise 3mm diameter and flat-bottomed profile, enable the secure placement of fasteners, spacers, or component housings while maintaining the integrity of the FR4 substrate. This article explores the design principles, manufacturing techniques, application scenarios, quality standards, and innovative advancements of 3mm diameter counterbores in FR4 PCBs, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while keeping content distinct from prior discussions.

Counterbores differ from countersinks in their profile—featuring a straight-walled, flat-bottomed recess that accommodates the head of a fastener or the base of a component, rather than a tapered shape. For 3mm diameters, this design serves specific functional needs in FR4 PCBs:

Component Compatibility: 3mm counterbores are ideally sized to house standard small fasteners (e.g., M2 or M2.5 screws) and low-profile connectors, ensuring their heads sit flush with or below the PCB surface to avoid interference with enclosures or adjacent parts.

Load Distribution: The flat bottom of the counterbore spreads the force from tightened fasteners across a larger area of the FR4 substrate, reducing the risk of localized stress that could lead to cracking—particularly important in PCBs used in industrial machinery or automotive applications where vibration is common.

Assembly Flexibility: These recesses allow for adjustable mounting, enabling fine-tuning of component positions during assembly without compromising the PCB’s structural integrity, a key advantage in prototyping or custom electronics.

FR4’s composition—glass fiber reinforcement embedded in epoxy resin—interacts uniquely with 3mm counterbores:

Structural Support: The glass fiber matrix provides the rigidity needed to withstand the pressure of fastener installation in 3mm recesses, while the epoxy resin ensures a smooth, consistent surface finish that facilitates proper seating of components.

Machinability Considerations: The balance between the resin’s toughness and the fibers’ hardness requires precise tooling to achieve clean, burr-free counterbores, avoiding damage that could affect electrical insulation or mechanical performance.

Producing high-quality 3mm counterbores in FR4 demands specialized processes that balance precision, efficiency, and material preservation:

Specialized Drills and End Mills: Carbide-tipped tools with sharp cutting edges are used to create the 3mm diameter recesses, with designs optimized to minimize heat buildup—critical for preventing resin degradation in the FR4 substrate.

CNC Machining Centers: Computer-controlled systems with high positional accuracy (±0.02mm) ensure consistent placement of counterbores relative to component pads and conductive traces, avoiding short circuits or misalignment.

Depth Control Mechanisms: Z-axis precision tools maintain uniform counterbore depth (typically 0.5–1.5mm, depending on PCB thickness), ensuring compatibility with fastener lengths and preventing penetration through the substrate.

Pre-Machining Preparation: PCBs are securely clamped to prevent movement during machining, with alignment marks (visible via optical sensors) guiding the CNC system to target positions.

Stepwise Machining: Counterbores are often created in two stages: first, a pilot hole (smaller than 3mm) is drilled to guide the tool, followed by the full 3mm diameter cut to achieve the recess. This reduces tool deflection and ensures dimensional accuracy.

Deburring and Cleaning: Post-machining, abrasive brushes or ultrasonic cleaning remove residual glass fibers or resin particles from the counterbore edges, preventing electrical interference and ensuring proper fastener fit.

Maintaining consistency and reliability in 3mm counterbores requires rigorous testing and inspection protocols:

Optical Gauging: High-resolution cameras and laser scanners measure counterbore diameter, depth, and positional accuracy, ensuring compliance with design specifications. Deviations are flagged for rework or rejection to prevent assembly issues.

Cross-Sectional Analysis: Microscopic examination of sample PCBs checks for subsurface damage (e.g., delamination between FR4 layers) caused by excessive machining force, which could compromise structural integrity.

Fastener Retention Tests: Torque testing evaluates the ability of counterbores to secure fasteners under repeated tightening and loosening, simulating maintenance cycles in industrial applications.

Vibration and Shock Testing: PCBs with 3mm counterbores are subjected to accelerated life tests (e.g., sinusoidal vibration or drop testing) to verify that fasteners remain seated and the substrate resists cracking.

IPC Specifications: Manufacturing adheres to IPC-2221 (Generic Standard on Printed Board Design) and IPC-A-600 (Acceptability of Printed Boards), which outline requirements for hole quality, including edge smoothness and freedom from conductive contaminants.

Material Safety: For applications in aerospace or medical devices, counterbores are processed using non-toxic coolants and cleaning agents to meet regulatory standards for biocompatibility and environmental safety.

The versatility of 3mm counterbores makes them indispensable across diverse industries, where mid-sized mounting solutions are required:

Control Panels: Factory automation systems use 3mm counterbores to mount PCBs in control enclosures, securing boards against mechanical stress from motors and machinery while allowing easy access for maintenance.

Sensor Modules: Industrial sensors (e.g., for temperature, pressure, or motion detection) rely on these counterbores to attach to mounting brackets, ensuring stable positioning for accurate readings in harsh environments.

Appliance Control Boards: Washing machines, refrigerators, and HVAC systems use 3mm counterbores to mount PCBs, balancing secure fastening with the need for compact design in appliance interiors.

Audio Equipment: Amplifiers, mixers, and speakers employ these recesses to secure circuit boards, preventing vibration-induced noise and ensuring consistent performance.

Vehicle Dashboards: Infotainment systems and instrument clusters use 3mm counterbores to mount PCBs, withstanding temperature fluctuations and vibration from engine operation.

Marine Electronics: Navigation devices and communication systems rely on these counterbores for corrosion-resistant mounting, ensuring reliability in saltwater environments.

Advancements in manufacturing and design are enhancing the performance and versatility of 3mm counterbores in FR4 PCBs:

Coated Tools: Diamond-like carbon (DLC) coatings on cutting tools reduce friction and wear, extending tool life and maintaining precision in high-volume production runs of 3mm counterbores.

Adaptive Machining: AI-driven CNC systems adjust cutting parameters in real time based on material feedback (e.g., fiber density in FR4), optimizing tool paths to minimize defects.

3D Modeling and Simulation: CAD software now includes modules that simulate the stress distribution around 3mm counterbores during assembly, enabling engineers to optimize placement and depth before production, reducing prototyping costs.

Hybrid Mounting Solutions: Combining 3mm counterbores with adhesive bonding creates redundant fastening systems, enhancing reliability in critical applications like aerospace electronics.

Eco-Friendly Machining: Water-based coolants and recyclable tooling materials reduce the environmental impact of counterbore production, aligning with global sustainability goals in electronics manufacturing.

3mm diameter counterbore FR4 PCBs represent a critical innovation in balancing mechanical security and design flexibility in mid-sized electronic assemblies. Their ability to accommodate standard fasteners while preserving PCB integrity makes them a staple in industries ranging from industrial automation to consumer appliances. By leveraging advanced manufacturing techniques, strict quality control, and ongoing technological advancements, these counterbores continue to meet the evolving demands of compact, reliable electronics. As devices grow more complex and space-constrained, the role of 3mm counterbores in FR4 PCBs will remain essential, bridging the gap between functional design and practical assembly.

Keywords: 3mm Diameter Counterbore FR4 PCB, FR4 machining, PCB mounting solutions, industrial electronics assembly, counterbore quality standards, CNC drilling for PCBs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB