-

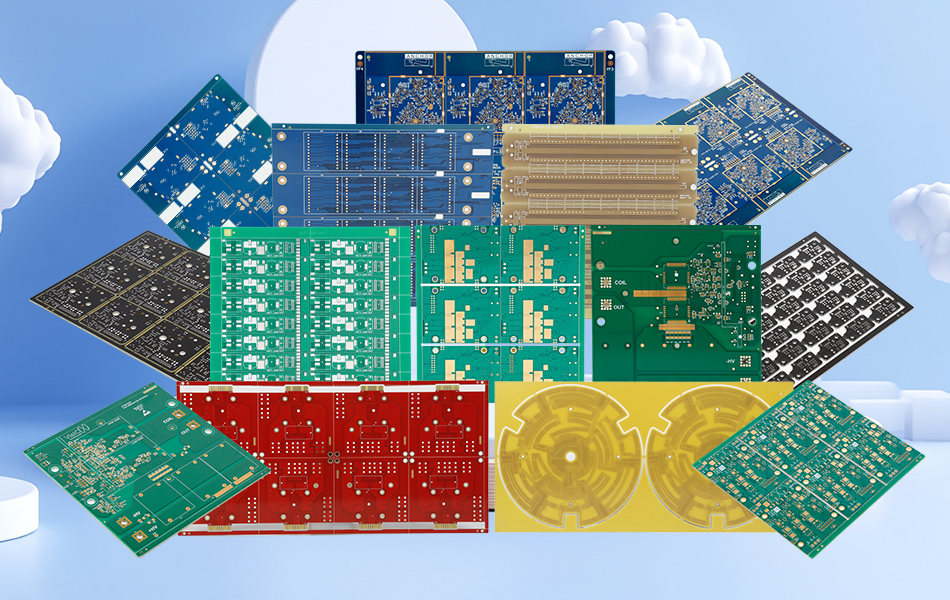

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 02. 2025, 13:33:32

In the realm of electronic manufacturing, Tapped Counterbore FR4 Circuit Board components represent a sophisticated integration of mechanical engineering and PCB design, offering a robust solution for secure, permanent fastening in complex assemblies. These specialized features combine a counterbore’s recessed profile with internal threading, enabling direct screw attachment without the need for additional hardware like nuts or standoffs. This article explores the design nuances, manufacturing processes, application scenarios, quality benchmarks, and innovative trends of tapped counterbores in FR4 circuit boards, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior discussions.

Tapped counterbores in FR4 circuit boards merge two critical functions: creating a recess to house screw heads and incorporating threads to engage fasteners directly, eliminating the need for secondary hardware. This design offers distinct advantages in precision-driven applications:

Integrated Fastening: The internal threads (typically metric or unified standards) allow screws to bite directly into the FR4 substrate, creating a secure, vibration-resistant connection ideal for devices subject to movement, such as robotics or automotive electronics.

Space Efficiency: By combining the counterbore recess and threading in a single feature, these designs reduce the need for extra components (e.g., nuts or washers), saving space in compact assemblies like medical devices or IoT sensors.

Assembly Speed: Direct threading streamlines production workflows, as screws can be fastened without aligning additional hardware, reducing labor time and minimizing assembly errors.

FR4’s glass fiber-epoxy composite presents unique challenges for tapping, as the material’s anisotropic nature (varying properties across directions) affects thread integrity:

Thread Strength: The glass fiber reinforcement enhances the shear strength of tapped threads, preventing stripping under torque, while the epoxy resin ensures consistent thread formation during tapping.

Machinability: The balance between the resin’s ductility and the fibers’ rigidity requires precise tooling to avoid thread distortion or fiber pull-out, which could compromise fastener grip.

Producing high-quality tapped counterbores in FR4 demands a sequence of precision machining steps, each tailored to preserve material integrity and thread accuracy:

Counterbore Drills: Carbide or high-speed steel drills with sharp cutting edges create the initial recess, ensuring a flat bottom and straight walls to support uniform thread formation.

Taps and Threading Tools: Specialized taps (spiral-flute or straight-flute designs) are used to cut threads into the counterbore walls. These tools are coated with titanium nitride (TiN) or diamond-like carbon (DLC) to reduce friction and extend lifespan.

CNC Machining Centers: Computer-controlled systems with multi-axis capabilities ensure precise alignment between the counterbore and threading operations, maintaining positional accuracy relative to circuit traces and component pads.

Counterbore Creation: The recess is first drilled to the required diameter and depth, with coolant applied to prevent heat-induced resin degradation and to flush away glass fiber debris.

Thread Tapping: After counterbore formation, taps are guided into the recess to cut threads, with controlled rotational speed and feed rate to avoid overheating or thread galling (material transfer between the tap and FR4).

Deburring and Inspection: Post-machining, brushes or air jets remove burrs from thread crests, ensuring smooth screw insertion. Optical inspection verifies thread pitch, depth, and uniformity.

Ensuring the reliability of tapped counterbores in FR4 circuit boards requires rigorous testing to validate thread integrity, mechanical strength, and compatibility with fasteners:

Thread Gauging: Go/no-go gauges check thread pitch and diameter, ensuring compatibility with standard fasteners. Optical profilometry assesses thread form accuracy, identifying defects like incomplete threads or irregular crests.

Cross-Sectional Analysis: Microscopic examination of sample boards evaluates thread depth and penetration into the FR4 substrate, confirming that threads engage sufficient glass fiber reinforcement for strength.

Torque-to-Failure Tests: Fasteners are tightened until thread stripping occurs, with results compared to design specifications to ensure adequate strength for application requirements (e.g., industrial vs. consumer use).

Cyclic Loading Tests: Repeated tightening and loosening simulate long-term use, evaluating thread durability and resistance to wear in applications requiring maintenance access.

Temperature Cycling: Boards with tapped counterbores undergo thermal cycling (-40°C to 85°C) to assess thread stability under expansion and contraction, preventing loosening in extreme environments.

Moisture Exposure: Humidity testing (85% RH at 85°C) checks for resin degradation or fiber corrosion, ensuring threads retain strength in high-moisture applications like marine electronics.

Tapped counterbores excel in industries where secure, space-efficient fastening is critical, spanning diverse sectors:

Robotic Control Systems: Tapped counterbores secure PCBs in robotic arms, withstanding vibration and repeated movement while enabling quick maintenance access to internal components.

Factory Control Panels: These features mount circuit boards in enclosures, ensuring stability in dusty or high-moisture factory environments without relying on external hardware.

Portable Diagnostic Equipment: Tapped counterbores provide lightweight, secure fastening in handheld devices (e.g., blood analyzers), where space and weight constraints demand minimal hardware.

Imaging Systems: In MRI or X-ray machines, these features mount PCBs in vibration-sensitive enclosures, ensuring precise alignment of electronic components critical for image quality.

Avionics Systems: Tapped counterbores secure circuit boards in aircraft instrument panels, withstanding altitude-induced temperature and pressure changes while meeting strict weight requirements.

Defense Electronics: In ruggedized devices (e.g., communication radios), these features ensure reliable fastening in harsh environments, from desert heat to arctic cold.

Advancements in materials and manufacturing are enhancing the performance and versatility of tapped counterbores in FR4 circuit boards:

Nanostructured Coatings: Taps with zirconium nitride (ZrN) coatings reduce friction during threading, extending tool life and improving thread surface finish in high-volume production.

Laser-Assisted Tapping: Laser pre-heating of FR4 localized to the counterbore area softens the epoxy resin slightly, reducing tap wear and improving thread uniformity in thick substrates.

Finite Element Analysis (FEA): Simulation software predicts stress distribution in tapped counterbores during fastening, enabling engineers to optimize thread depth and counterbore diameter for specific load requirements.

Hybrid Fastening: Combining tapped counterbores with adhesive bonding creates redundant connections, enhancing reliability in safety-critical applications like aerospace.

Eco-Friendly Coolants: Bio-based lubricants during tapping reduce environmental impact, aligning with green manufacturing initiatives in electronics production.

Recyclable Tooling: Taps and drills made from recycled carbide reduce waste, supporting circular economy practices in PCB manufacturing.

Tapped Counterbore FR4 Circuit Boards represent a fusion of mechanical precision and material science, offering a streamlined fastening solution for modern electronics. By integrating counterbore recesses with internal threading, these features eliminate the need for extra hardware, saving space and simplifying assembly in applications ranging from industrial robots to medical devices. Through advanced manufacturing techniques, rigorous quality control, and ongoing innovations in tooling and design, tapped counterbores continue to meet the demands of increasingly compact and reliable electronic systems. As technology advances, their role in enabling secure, efficient assemblies will only grow, solidifying their position as a critical component in the future of PCB design.

Keywords: Tapped Counterbore FR4 Circuit Board, FR4 threading, PCB fastening solutions, precision machining for PCBs, industrial electronics assembly, aerospace PCB design.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB