-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 18. 2025, 09:10:08

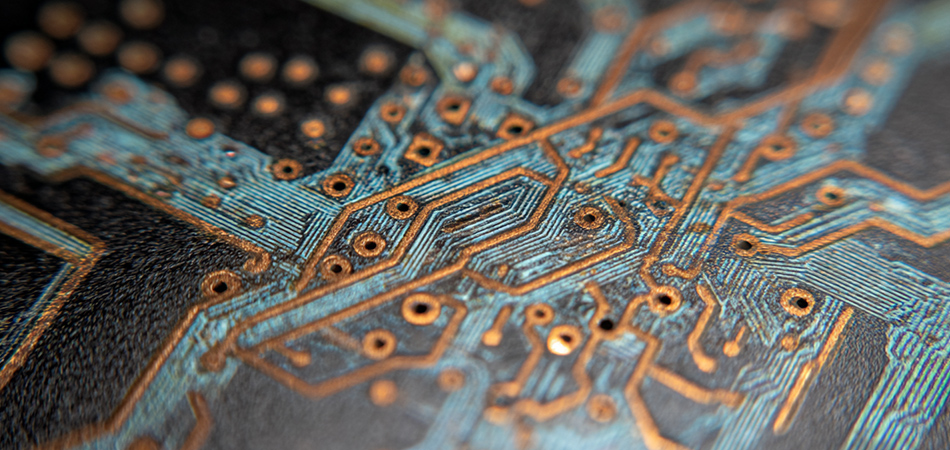

In the realm of aluminum printed circuit boards (PCBs), the integration of high-reflectivity soldermask has emerged as a game-changing innovation for optical applications. 95% reflectivity soldermask aluminum PCBs combine the thermal management strengths of aluminum substrates with specialized coatings that maximize light reflection, addressing critical efficiency challenges in LED lighting, display technologies, and optical sensors. This article explores the material science, design principles, applications, and manufacturing advancements behind these specialized PCBs, highlighting their role in driving performance gains in light-dependent electronic systems.

The Role of Soldermask in Aluminum PCBs

Beyond Traditional Protection

While standard soldermasks primarily protect PCB copper traces from corrosion, solder bridging, and environmental damage, high-reflectivity variants serve a dual purpose:

Optical Enhancement: Reflecting unused or scattered light back into the system (e.g., LED modules) rather than absorbing it, which would convert light to waste heat.

Thermal Compatibility: Maintaining stability under the thermal loads typical of high-power optical components, such as LED chips operating at elevated temperatures.

In aluminum PCBs, the soldermask interacts uniquely with the metal substrate—its adhesion to aluminum, resistance to thermal cycling, and optical properties directly impact both performance and longevity.

Why 95% Reflectivity Matters

Light absorption in conventional soldermasks (often dark-colored or low-reflectivity materials) can reduce system efficiency by up to 30% in optical applications. A 95% reflectivity soldermask minimizes this loss by:

Redirecting stray photons back into the light path, increasing usable output without requiring higher-power components.

Reducing heat generation from absorbed light, which complements the aluminum substrate’s thermal dissipation capabilities.

Ensuring consistent light distribution across large-area PCBs (e.g., LED panels), preventing hotspots or dim zones.

This efficiency gain is particularly critical in energy-sensitive applications, where reducing power consumption while maintaining brightness is a priority.

Material Innovations in High-Reflectivity Soldermasks

Advanced Polymer Formulations

Achieving 95% reflectivity requires specialized material science:

Ceramic-Filled Polymers: Titanium dioxide (TiO₂) or zinc oxide (ZnO) nanoparticles are dispersed in epoxy or acrylic resins to create a highly reflective matrix. These ceramics scatter and reflect light across visible wavelengths (400–700 nm), while the polymer base ensures flexibility and adhesion to aluminum.

UV-Stable Additives: Hindered amine light stabilizers (HALS) and benzophenone derivatives prevent yellowing from prolonged UV exposure—a common issue in outdoor LED applications that would degrade reflectivity over time.

Low-Absorption Binders: Clear, high-purity polymers (e.g., cycloaliphatic epoxies) minimize intrinsic light absorption, ensuring the soldermask itself does not act as a light sink.

These formulations balance optical performance with mechanical resilience, enduring thermal cycling, humidity, and chemical exposure.

Interface Engineering with Aluminum Substrates

The bond between soldermask and aluminum substrate is critical for performance:

Surface Activation: Plasma etching or anodization creates a micro-rough surface on the aluminum, enhancing mechanical interlock with the soldermask. This prevents delamination, which would expose dark aluminum and reduce overall reflectivity.

Adhesion Promoters: Silane coupling agents form chemical bonds between the soldermask’s polymer matrix and the aluminum oxide layer, ensuring long-term stability even under thermal stress.

Thermal Expansion Matching: Formulations with a coefficient of thermal expansion (CTE) close to aluminum (≈23 ppm/°C) minimize stress during temperature fluctuations, a key consideration in high-power LED PCBs.

Design Considerations for Maximum Reflectivity

Surface Uniformity and Smoothness

Even minor imperfections can reduce reflectivity:

Micro-Texture Control: Soldermask application processes (e.g., curtain coating, spray coating) are optimized to achieve a smooth, defect-free surface. Roughness above 0.5 μm can scatter light in unwanted directions, lowering effective reflectivity.

Edge Coverage: Precision masking ensures soldermask covers all exposed aluminum areas between copper traces, eliminating uncoated “bleed” zones that would absorb light. Special attention is paid to via pads and component footprints, where soldermask must conform to tight geometries.

Thickness Optimization

Soldermask thickness directly impacts performance:

Uniform Thickness: Variations in thickness (±5%) can cause uneven light reflection. Advanced coating techniques (e.g., electroplating for select formulations) ensure consistent coverage across the PCB.

Balancing Protection and Reflectivity: A thickness sweet spot (typically 20–30 μm) provides adequate protection against solder bridging and corrosion without introducing excessive light absorption. Thicker layers may incorporate air pockets or impurities that reduce reflectivity.

Compatibility with Optical Components

Designs must integrate seamlessly with light-emitting or light-sensing elements:

Component Placement: Soldermask is precision-registered around LED dies or photodiodes to avoid blocking light emission or detection, while covering adjacent areas to reflect stray light back into the optical path.

Thermal Vias and Heat Sinks: Strategic placement of thermal vias (covered with soldermask) ensures heat from LEDs is dissipated through the aluminum substrate without compromising reflectivity in critical light paths.

Manufacturing Processes for Consistent Performance

Precision Coating Techniques

Achieving 95% reflectivity at scale requires advanced manufacturing:

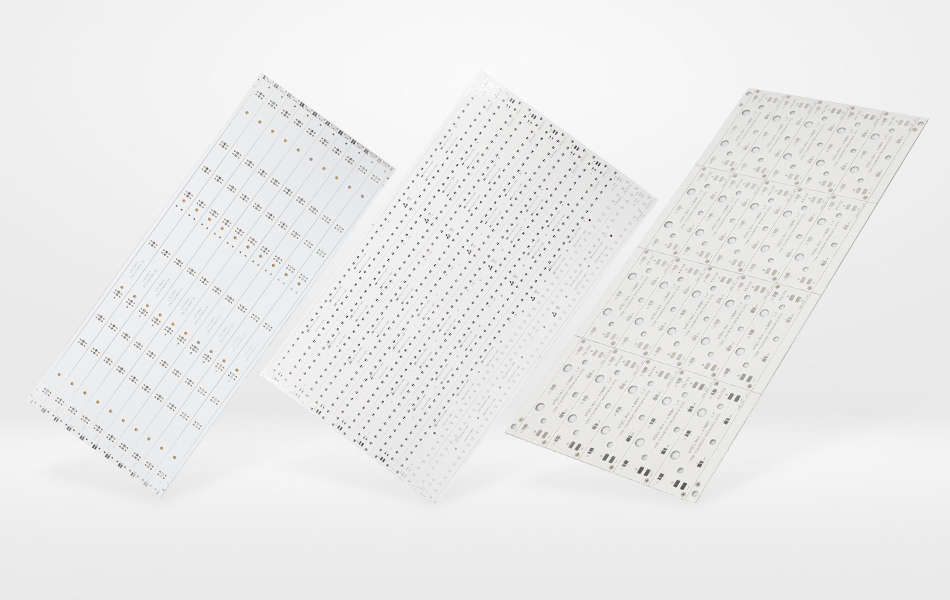

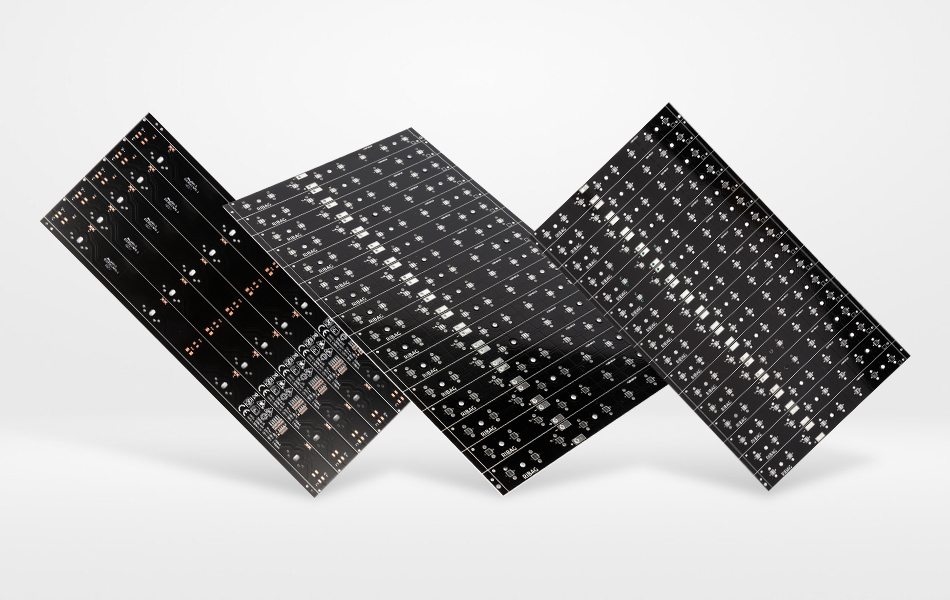

Roll-to-Roll Coating: For high-volume production (e.g., LED strip PCBs), automated roll coaters apply soldermask in a continuous process, ensuring uniform thickness and minimizing waste.

Selective Deposition: Inkjet printing technology deposits soldermask only where needed, reducing material usage and enabling intricate patterns on complex PCBs (e.g., automotive headlight PCBs with curved geometries).

UV Curing Optimization: Controlled UV exposure ensures complete polymerization of the soldermask, maximizing hardness and chemical resistance while preserving reflectivity—over-curing can cause yellowing, while under-curing leads to poor adhesion.

Quality Control and Testing

Rigorous testing ensures reflectivity specifications are met:

Spectrophotometric Analysis: Instruments measure reflectivity across the visible spectrum, verifying 95% performance at key wavelengths (e.g., 550 nm for white LEDs).

Thermal Cycling Tests: PCBs undergo repeated temperature cycles (-40°C to +125°C) to assess reflectivity retention, ensuring no degradation from soldermask delamination or yellowing.

Abrasion Resistance: Taber abrasion tests validate that reflectivity remains stable after mechanical wear, critical for PCBs in contact with other components during assembly.

Applications of 95% Reflectivity Soldermask Aluminum PCBs

LED Lighting Systems

High-reflectivity soldermask aluminum PCBs are transformative in lighting:

General Illumination: LED panels for offices, warehouses, and outdoor spaces use these PCBs to maximize lumen output per watt, reducing energy consumption.

Automotive Lighting: Headlights, taillights, and interior lighting benefit from uniform light distribution, with the aluminum substrate managing heat from high-power LEDs and the soldermask ensuring efficient light utilization.

Horticultural Lighting: Reflective soldermasks enhance the efficiency of grow lights, directing more photosynthetically active radiation (PAR) to plants without increasing power input.

Display and Signage Technologies

Backlit Displays: LCD and OLED backlights use these PCBs to distribute light evenly across screens, reducing the number of LEDs needed and lowering power requirements.

Digital Signage: Large-format LED billboards leverage high reflectivity to maintain brightness even in ambient light, ensuring visibility during both day and night.

Optical Sensing and Imaging

Sensor Arrays: Reflective soldermasks improve signal-to-noise ratios in optical sensors by reducing stray light absorption, enhancing accuracy in applications like machine vision and environmental monitoring.

Medical Lighting: Surgical lights and diagnostic equipment rely on consistent, high-brightness illumination, where soldermask reflectivity ensures reliable performance in critical healthcare settings.

Sustainability and Long-Term Performance

Energy Efficiency Benefits

By maximizing light output from existing LEDs, these PCBs reduce the need for higher-power components, lowering overall energy consumption. In commercial lighting systems, this can translate to significant carbon footprint reductions over the product lifecycle.

Durability and Longevity

UV stability and resistance to thermal degradation extend PCB lifespan, reducing replacement frequency and e-waste. The aluminum substrate’s recyclability further enhances sustainability, as end-of-life PCBs can be processed to recover aluminum and other materials.

Material Efficiency

High-reflectivity formulations often use fewer raw materials than multi-layer optical systems (e.g., separate reflectors or diffusers), simplifying PCB design and reducing manufacturing waste.

Future Trends and Innovations

Broad-Spectrum Reflectivity

Research is focusing on extending reflectivity beyond visible wavelengths, targeting near-IR (700–1100 nm) for applications like IR sensors and thermal imaging, where efficient light management is equally critical.

Smart Reflective Coatings

Integrating responsive materials that adjust reflectivity based on temperature or light intensity could enable dynamic optimization, further improving efficiency in variable environments (e.g., outdoor lighting that adapts to sunlight).

Integration with Advanced Substrates

Combining high-reflectivity soldermasks with next-gen aluminum composites (e.g., aluminum-graphene substrates) could enhance both thermal and optical performance, opening new possibilities in high-power, high-brightness applications.

Conclusion

95% reflectivity soldermask aluminum PCBs represent a convergence of optical engineering and PCB technology, addressing the critical need for efficient light management in modern electronics. By combining high-reflectivity materials with aluminum’s thermal capabilities, these PCBs enable brighter, more energy-efficient systems across lighting, displays, and sensing applications. As material science advances and manufacturing processes improve, their role in sustainable, high-performance electronics will only grow—proving that even subtle innovations in soldermask design can deliver significant gains in functionality and efficiency.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB