-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 18. 2025, 09:15:52

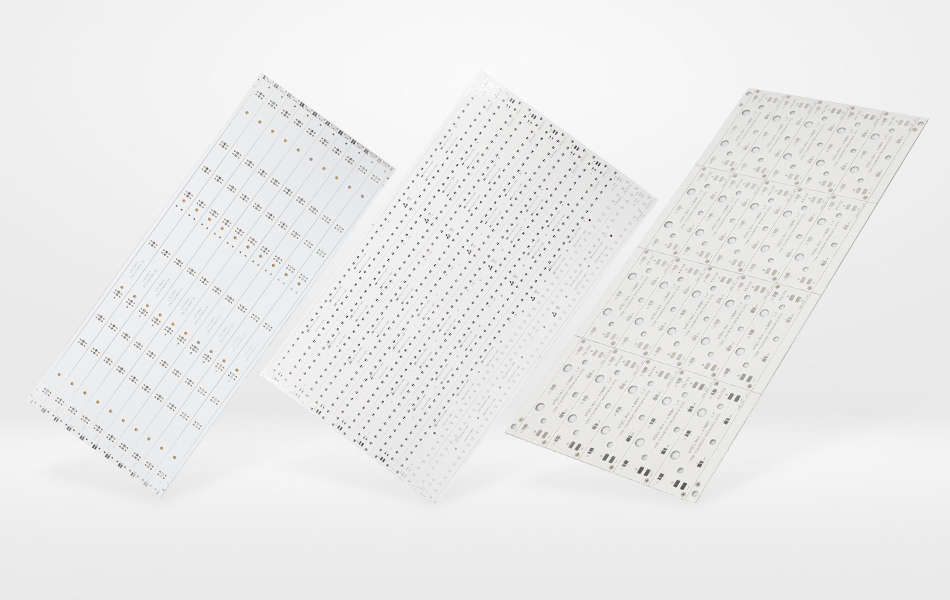

White high reflective solder mask has emerged as a critical material in modern PCB manufacturing, bridging optical performance and electrical functionality in applications where light efficiency is paramount. Unlike standard green or black solder masks, which prioritize electrical insulation and corrosion resistance, white high reflective variants are engineered to maximize light reflection, making them indispensable in LED lighting, display technologies, and optical sensors. This article explores the material composition, performance characteristics, manufacturing processes, and key applications of white high reflective solder mask, highlighting its role in enhancing energy efficiency and optical precision in electronic systems.

Material Composition and Reflective Mechanisms

Core Formulation Principles

White high reflective solder mask is formulated to balance optical performance with PCB manufacturing requirements:

Polymer Matrix: A base of epoxy or acrylate polymers provides mechanical stability and adhesion to PCB substrates (aluminum, FR-4, or ceramic). These polymers are selected for their low yellowing tendency under UV exposure, ensuring long-term reflectivity retention.

Reflective Pigments: Titanium dioxide (TiO₂) is the primary pigment, chosen for its high refractive index (≈2.7) and ability to scatter light across a broad spectrum (400–700 nm). Other additives, such as zinc oxide (ZnO) or barium sulfate (BaSO₄), may be included to optimize reflection uniformity.

Functional Additives: UV stabilizers prevent degradation from prolonged light exposure, while leveling agents ensure a smooth surface finish—critical for minimizing light absorption at the mask-air interface.

The ratio of pigments to polymer is carefully calibrated: too much pigment can compromise adhesion, while too little reduces reflectivity. This balance ensures the mask adheres strongly to copper traces and substrates while maintaining high light bounce-back.

How Reflectivity Works in Solder Mask Design

Light interaction with white high reflective solder mask involves two key mechanisms:

Specular Reflection: Smooth surface finishes reflect light in parallel beams, minimizing diffusion. This is achieved through precise curing processes that prevent surface irregularities.

Diffuse Reflection: Pigment particles scatter light in multiple directions, ensuring light emitted from components (e.g., LEDs) is redirected toward the target (e.g., a lighting fixture’s output lens) rather than being absorbed by the PCB.

Together, these mechanisms maximize the amount of light reaching the application’s intended area, reducing energy waste from light absorption in the PCB itself.

Performance Characteristics Beyond Reflectivity

Electrical and Mechanical Properties

While reflectivity is the primary focus, white high reflective solder mask must meet standard PCB performance criteria:

Electrical Insulation: High dielectric strength prevents current leakage between copper traces, critical for high-voltage applications like automotive lighting.

Thermal Resistance: The mask must withstand operating temperatures up to 150°C (and higher in industrial settings) without degrading, ensuring stability in heat-generating environments like LED arrays.

Chemical Resistance: Resistance to soldering fluxes, cleaning agents, and environmental contaminants (moisture, dust) preserves both reflectivity and electrical performance over time.

Durability and Longevity

UV Resistance: Additives like hindered amine light stabilizers (HALS) prevent yellowing, a common issue in standard white masks that reduces reflectivity over time. This is especially important in outdoor applications (e.g., streetlights, solar-powered devices).

Abrasion Resistance: A tough surface layer resists scratches during PCB assembly and handling, maintaining optical performance through the product lifecycle.

Adhesion Strength: Strong bonding to copper and substrates (aluminum, FR-4) prevents delamination, which can create shadows and reduce light output in precision applications.

Applications of White High Reflective Solder Mask

LED Lighting Systems

White high reflective solder mask is indispensable in LED technology:

General Lighting: In LED bulbs and fixtures, the mask reflects light emitted sideways or backward from LEDs toward the fixture’s output, increasing overall luminous efficacy by reducing light loss into the PCB.

Automotive Lighting: Headlights, taillights, and interior lighting use the mask to enhance light output uniformity, ensuring consistent visibility and reducing hotspots.

Horticultural Lighting: In grow lights, precise reflection of specific wavelengths (e.g., blue and red light) optimizes plant growth while minimizing energy use.

Display Technologies

Backlit Displays: LCD and OLED displays use the mask on backlight PCBs to distribute light evenly across the screen, reducing brightness variations and improving image quality.

Signage and Screens: Digital billboards and indoor displays leverage the mask to enhance color vibrancy and visibility, especially in bright ambient light conditions.

Specialized Optical Electronics

Medical Devices: Surgical lighting and diagnostic equipment require precise light control; the mask ensures light is directed to the target area (e.g., a surgical site) without glare or unevenness.

Sensor Systems: In optical sensors (e.g., proximity sensors, barcode scanners), the mask minimizes light interference from the PCB, improving detection accuracy.

Aerospace Lighting: High-reliability variants with extreme temperature resistance are used in aircraft cabin lighting and exterior navigation lights, where performance failures are critical.

Manufacturing and Processing Considerations

Application Methods

White high reflective solder mask is applied using standard PCB manufacturing techniques, with adjustments to optimize optical performance:

Screen Printing: The most common method, using fine-mesh screens to apply a uniform layer thickness (typically 10–30 μm). Thickness consistency is critical—too thin and reflectivity suffers; too thick and surface smoothness declines.

Spray Coating: Used for complex PCB geometries, ensuring even coverage on curved or irregular surfaces (e.g., automotive headlight PCBs with 3D shapes).

Photolithographic Patterning: For high-precision applications, photopolymer masks are exposed to UV light through a pattern, then developed to create precise openings for solder pads—ensuring both optical performance and solderability.

Curing Processes

UV Curing: Most white high reflective masks use UV-curable polymers, curing in seconds under UV light. This process ensures rapid production while maintaining surface smoothness.

Thermal Curing: For masks requiring higher temperature resistance, thermal curing (120–180°C) creates cross-linked polymer structures with enhanced durability, ideal for industrial applications.

Curing parameters (temperature, time, UV intensity) are tightly controlled to prevent surface yellowing or unevenness, which would reduce reflectivity.

Quality Control and Testing

Reflectivity Measurement: Spectrophotometers assess reflectivity across relevant wavelengths (400–700 nm for visible light applications) to ensure consistency across production batches.

Surface Profilometry: Checks for surface roughness, as even minor irregularities can scatter light in unintended directions.

Environmental Testing: Accelerated aging tests (UV exposure, thermal cycling, humidity chambers) validate long-term performance, ensuring reflectivity remains stable over the product’s lifespan.

Design Considerations for Integrating White High Reflective Solder Mask

PCB Layout Optimization

Component Placement: LEDs and optical components are positioned to leverage the mask’s reflectivity, with minimal shadowing from tall components.

Trace Design: Narrow copper traces reduce light blockage, while strategic trace routing ensures even light distribution.

Substrate Selection: Pairing with aluminum substrates enhances both thermal management (dissipating LED heat) and reflectivity, creating a synergistic effect in high-power systems.

Compatibility with Manufacturing Processes

Solder Paste Compatibility: The mask must withstand solder reflow temperatures without discoloration, ensuring reflectivity remains intact after component assembly.

Mask Thickness: Balancing thickness for reflectivity (thicker layers can enhance reflection) with precision in fine-pitch applications, where excess mask may interfere with soldering.

Cost vs. Performance Trade-offs

Pigment Quality: High-purity titanium dioxide improves reflectivity but increases material costs. Manufacturers often offer tiered options based on application needs (e.g., standard vs. premium UV-stable variants).

Surface Finish: Polished finishes enhance specular reflection but require more precise manufacturing, making them suitable for high-end applications like medical devices.

Emerging Innovations in White High Reflective Solder Mask

Nanomaterial Enhancements

Nano-Pigments: Titanium dioxide nanoparticles (≤100 nm) improve reflectivity uniformity by reducing light scattering at particle boundaries. This results in higher overall reflectivity across a broader wavelength range.

Graphene Oxide Additives: Small amounts of graphene oxide enhance thermal conductivity, helping dissipate heat from high-power LEDs while maintaining optical performance—a critical advancement for compact lighting systems.

Sustainable Formulations

Bio-Based Polymers: Plant-derived epoxy resins reduce environmental impact without compromising performance, aligning with green manufacturing trends in electronics.

Low-VOC Curing: Water-based or solvent-free formulations minimize volatile organic compound emissions during manufacturing, improving workplace safety and reducing environmental footprint.

Multifunctional Designs

Integrated Light Diffusion: Masks with microstructured surfaces combine reflection with controlled diffusion, eliminating the need for separate diffuser layers in lighting fixtures.

Thermo-Responsive Materials: Experimental masks that adjust reflectivity based on temperature, optimizing performance in environments with variable heat loads (e.g., outdoor lighting with changing ambient temperatures).

Conclusion: White High Reflective Solder Mask as a Critical Enabler of Efficient Optoelectronics

White high reflective solder mask has evolved from a niche material to a foundational technology in optoelectronics, where light efficiency and precision are paramount. By balancing high reflectivity with robust electrical, thermal, and mechanical performance, it enables energy-efficient LED lighting, high-visibility displays, and advanced optical sensors. As demand for sustainable, high-performance electronics grows, innovations in material science—from nano-pigments to eco-friendly formulations—will further enhance its capabilities. For engineers and manufacturers, understanding the nuances of white high reflective solder mask selection and design is key to unlocking the full potential of next-generation optical electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB