-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 12. 2025, 11:01:34

Active Cooling PCB Thermal Design represents a targeted solution for managing heat in power-dense electronics where passive cooling (e.g., heat sinks, thermal vias) alone is insufficient. Unlike passive systems that rely on natural heat transfer, active cooling actively removes heat from PCBs using energy-driven mechanisms—addressing the critical challenge of compact, high-performance devices (such as AI server GPUs, EV powertrain inverters, and industrial motor controllers) where space limitations restrict passive cooling scalability. By integrating dynamic heat-removal technologies with PCB layout optimization, this design approach ensures components operate within safe temperature ranges while preserving form factor efficiency. This article explores the core active cooling technologies for PCBs, key design integration principles, industry-specific applications, and strategies to balance performance with energy efficiency.

Three primary active cooling technologies dominate modern PCB thermal design, each tailored to specific power and space requirements:

The most widely adopted active solution, forced air cooling uses fans or blowers to direct airflow across heat-generating components and PCB surfaces. Design success hinges on airflow path optimization:

Component Positioning: High-power devices (e.g., power ICs) are placed in airflow "hotspots"—typically near fan inlets or outlets—while heat-sensitive components (e.g., sensors) are routed away from turbulent or stagnant air zones.

Heat Sink Integration: Low-profile, finned heat sinks are attached to high-power components, with fan airflow aligned to maximize contact between cool air and heat sink fins. For dense PCBs, stacked or ducted fan systems ensure uniform airflow across all critical components.

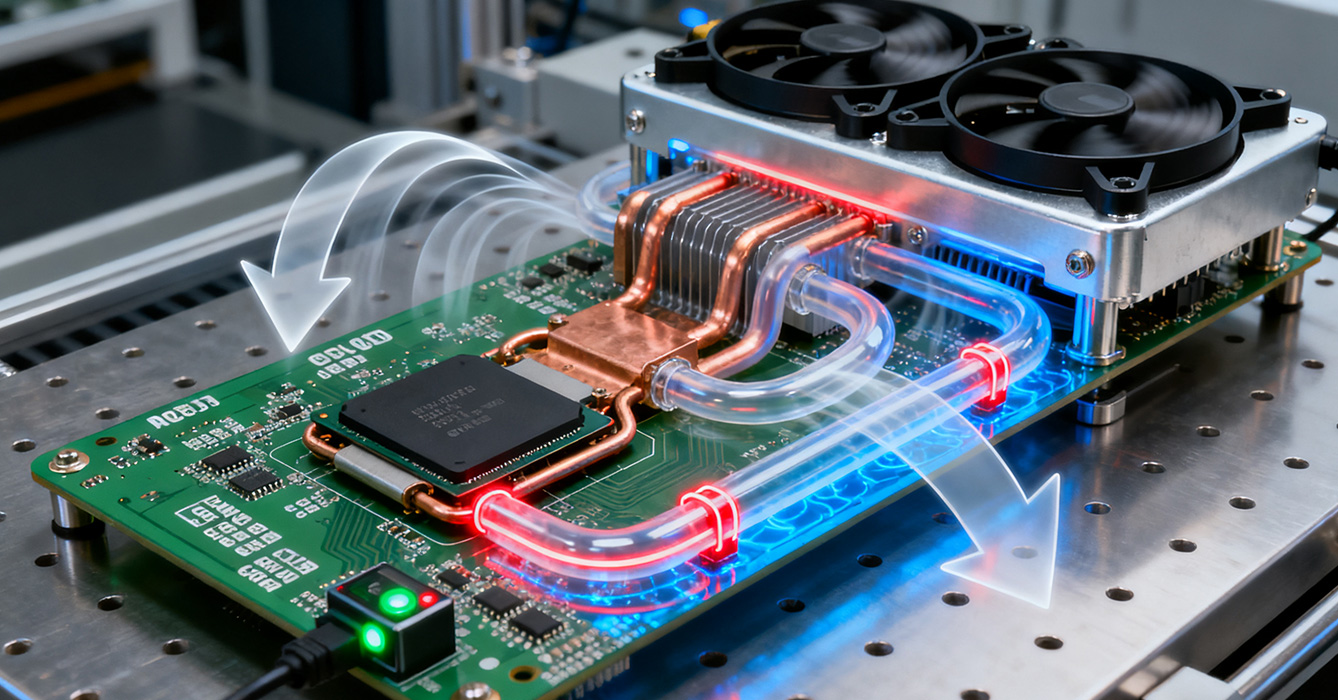

Ideal for ultra-high-power applications (e.g., 500W+ GPU clusters), liquid cooling uses closed-loop systems to circulate coolant (e.g., water-glycol mixtures) through PCB-integrated cold plates or microchannels:

Cold Plate Attachment: Custom-machined cold plates are bonded directly to heat-dense components (e.g., EV inverter IGBTs), with thermal interface materials (TIMs) eliminating air gaps. Coolant absorbs heat and transfers it to a remote radiator for dissipation.

Microchannel PCB Design: For compact systems, microchannels (thin, etched channels in PCB copper layers) circulate coolant directly within the board. This integrates cooling into the PCB structure, reducing reliance on external hardware.

A precision-focused solution, TEC uses semiconductor modules to create temperature gradients—absorbing heat from PCB components and releasing it to a heat sink or liquid loop. TEC is critical for applications requiring tight temperature control:

Thermal Management: TEC modules are paired with temperature sensors to adjust cooling intensity dynamically. For example, in medical diagnostic PCBs, TEC maintains component temperatures within ±0.5°C to ensure measurement accuracy.

Heat End Dissipation: Effective TEC design requires robust heat removal from the module’s "hot side" (typically via a heat sink or liquid cold plate) to prevent performance degradation.

Successful Active Cooling PCB Thermal Design relies on aligning cooling systems with PCB layout and functionality:

Cooling components (e.g., fans, liquid tubes) are routed to avoid interfering with high-speed signal traces or power paths. For example, liquid cooling tubes are placed parallel to PCB edges to prevent signal crosstalk, while fan wiring is integrated into low-noise ground planes.

Embedded temperature sensors and microcontrollers regulate cooling intensity based on real-time heat loads. This "on-demand" cooling reduces energy consumption: a server PCB might run fans at 50% speed during low-load operation and ramp to 100% only when GPU temperatures exceed 70°C.

For harsh environments (e.g., industrial or automotive), active cooling systems are designed to withstand vibration, dust, and temperature swings:

Forced air systems use dust-resistant fan filters and vibration-dampened mounts.

Liquid cooling loops include leak-detection sensors and corrosion-resistant materials (e.g., stainless steel tubing).

High-density GPU servers use liquid cooling to manage 300–500W per GPU. Microchannel PCBs circulate coolant directly beneath GPU sockets, eliminating thermal throttling and enabling 24/7 high-performance computing.

EV inverters and battery management systems (BMS) rely on liquid-cooled cold plates. These are integrated into the PCB’s power module layer, transferring heat from IGBTs and capacitors to the vehicle’s main cooling loop—critical for maintaining performance during fast charging and high-speed driving.

Industrial motor controllers use forced air cooling with ducted fans to dissipate heat in dusty factory environments. Heat sinks with hydrophobic coatings prevent dust buildup, ensuring consistent airflow and reducing maintenance needs.

Integrated Active-Passive Hybrid Systems: Combining active cooling (e.g., small fans) with passive solutions (e.g., heat spreaders) to balance performance and energy efficiency.

3D-Printed Cooling Components: Additive manufacturing creates custom cold plates and fan shrouds tailored to unique PCB layouts, reducing size and weight.

Sustainable Coolants: Bio-based, non-toxic coolants replace traditional chemical mixtures in liquid cooling systems, aligning with eco-friendly manufacturing goals.

Active Cooling PCB Thermal Design is essential for unlocking the full potential of high-power, compact electronics. By leveraging forced air, liquid, or thermoelectric technologies—paired with smart integration and control—it addresses heat challenges that passive cooling cannot solve. As devices grow more power-dense (e.g., next-gen AI chips, EV powertrains), this design approach will remain a cornerstone of reliable, efficient electronics. For engineers, prioritizing active cooling early in the PCB design process ensures thermal performance is built into the system, rather than added as an afterthought.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB