-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 25. 2025, 14:28:11

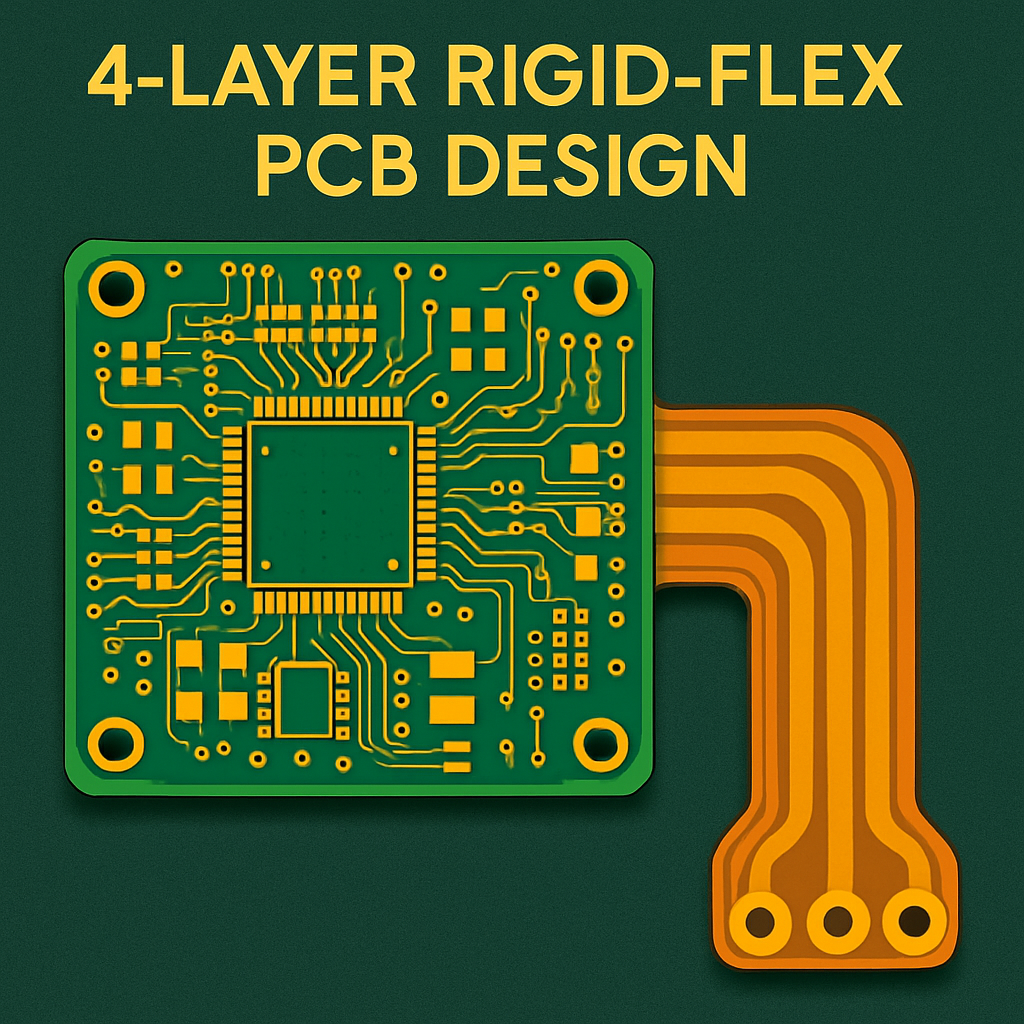

In the ever-evolving world of electronics, the demand for compact and flexible designs continues to rise. One of the innovations meeting this demand is the 4 layer rigid-flex PCB solution. This technology offers a perfect blend of flexibility and durability, making it an ideal choice for various applications. In this article, we'll delve into the intricacies of rigid-flex PCBs, explore their benefits, and understand why they are becoming a popular choice in PCB manufacturing.

A 4 layer rigid-flex PCB is a type of printed circuit board that combines rigid and flexible substrates into a single unit. This unique construction allows for more complex designs while maintaining reliability and performance. The "4 layer" aspect refers to the number of conductive layers within the PCB, which are used to route electrical signals and provide power.

Rigid-flex PCBs consist of multiple layers of flexible circuit substrates that are attached to rigid boards. The flexible parts are often used to connect the rigid sections, allowing for complex and compact configurations. This structure enables the board to bend and fold, which is essential for applications where space is limited.

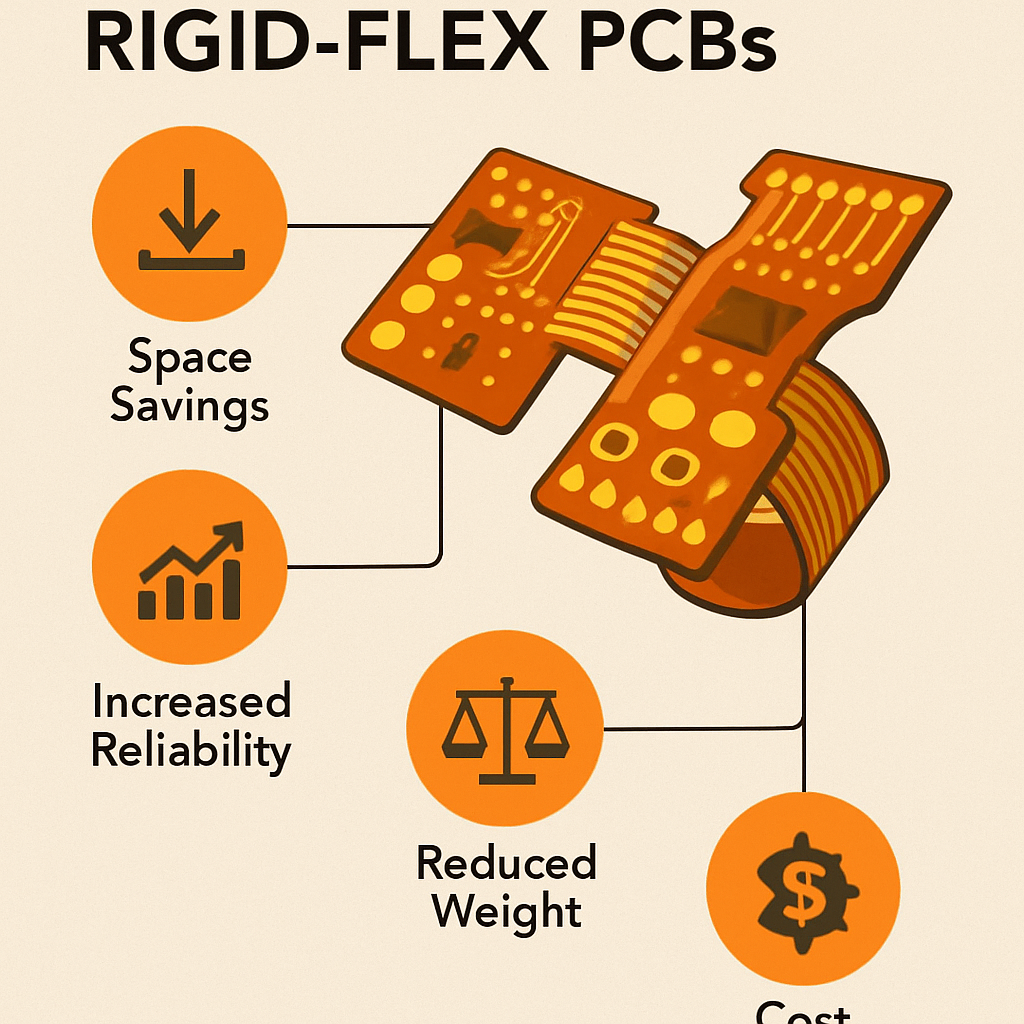

The integration of flexible and rigid sections in a single PCB brings several advantages:

One of the main benefits of rigid-flex PCBs is their ability to save space. By integrating multiple circuits into one board, designers can reduce the need for connectors and cables, leading to a more compact and streamlined design.

The connection between different parts of a device is often a weak point in electronic designs. By reducing the need for traditional connectors, rigid-flex PCBs enhance the reliability of the entire system. The connections are more secure and less prone to failure due to mechanical stress.

While the initial manufacturing cost of rigid-flex PCBs might be higher than traditional PCBs, they can be more cost-effective in the long run. The reduction in the number of components, such as connectors and wiring, can lower assembly costs and reduce maintenance needs.

Rigid-flex PCBs are known for their superior performance in demanding environments. The combination of rigid and flexible layers provides excellent thermal stability and can withstand harsh conditions, making them suitable for aerospace, military, and medical applications.

Rigid-flex PCBs are versatile and can be used in various industries:

In the consumer electronics sector, there is always a push for smaller, more efficient devices. Rigid-flex PCBs are used in smartphones, tablets, and wearable devices to achieve compact designs without compromising performance.

Medical devices require high precision and reliability. Rigid-flex PCBs are used in equipment like pacemakers and diagnostic imaging tools, where space is limited, but performance cannot be compromised.

The aerospace and defense industries demand components that can withstand extreme conditions. Rigid-flex PCBs are ideal for these applications due to their durability and resistance to vibration and temperature fluctuations.

With the rise of electric and autonomous vehicles, the automotive industry is increasingly relying on advanced electronics. Rigid-flex PCBs are used in various automotive systems, such as navigation, control systems, and infotainment modules, where space and reliability are critical.

The manufacturing process of rigid-flex PCBs is more complex than that of standard PCBs, but understanding the process can help in appreciating their benefits.

The process begins with designing the PCB layout. Engineers use CAD software to create a detailed design that outlines the placement of components and routing of electrical paths. The design must consider both the rigid and flexible sections to ensure optimal performance.

Selecting the right materials is crucial for the performance of rigid-flex PCBs. The materials must provide the necessary flexibility and durability. Common materials include polyimide for flexible layers and FR4 for rigid sections.

Once the design is finalized, the layers are stacked and bonded together. This involves laminating the flexible and rigid sections to form a cohesive unit. The bonding process requires precision to ensure the layers are properly aligned.

Holes are drilled into the PCB to create vias, which connect different layers electrically. These vias are then plated with metal to ensure conductivity. The drilling and plating processes must be precise to maintain the integrity of the connections.

Before the PCB is ready for use, it undergoes rigorous testing to ensure it meets quality standards. This includes electrical testing to verify the integrity of the circuits and mechanical testing to ensure the board can withstand the intended operating conditions.

The 4 layer rigid-flex PCB solution is a remarkable advancement in PCB manufacturing, offering a perfect blend of flexibility, durability, and performance. Its ability to save space, enhance reliability, and provide cost-effective solutions makes it an attractive choice for various industries. As technology continues to evolve, rigid-flex PCBs are likely to play an even more significant role in the future of electronic design. Whether you're in the consumer electronics, medical, aerospace, or automotive industry, considering rigid-flex PCBs can lead to innovative and efficient solutions.

Understanding the manufacturing process and applications of rigid-flex PCBs can help businesses make informed decisions and stay ahead in the competitive electronics market. Embrace the potential of rigid-flex PCBs and discover how they can transform your next project.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB