-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 25. 2025, 14:32:40

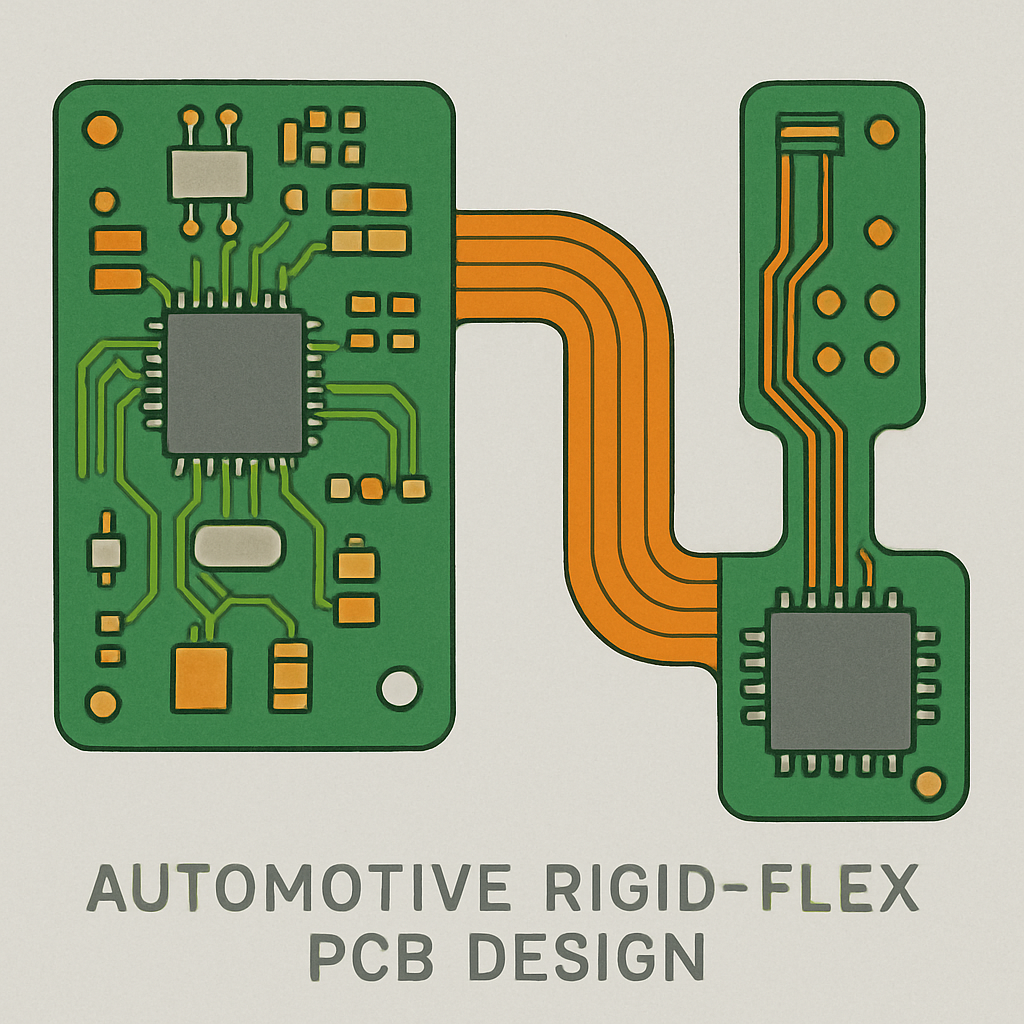

In the fast-paced world of automotive electronics, the demand for compact, reliable, and high-performance components is ever-increasing. One of the key innovations meeting this demand is the use of rigid-flex PCBs (Printed Circuit Boards). These versatile circuit boards combine the best features of rigid and flexible PCBs, providing a robust solution for the complex requirements of modern automotive systems.

Rigid-flex PCBs are a hybrid of rigid and flexible circuit boards. They consist of multiple layers of flexible circuit substrates attached to one or more rigid boards. This design allows for the creation of a single interconnected circuit that can be bent or folded as needed, without compromising its integrity or performance. This characteristic makes them ideal for applications requiring complex layouts and high-density interconnections, like in automotive electronics.

One of the primary benefits of using rigid-flex PCBs in automotive applications is their enhanced durability. The flexible layers allow the circuit to withstand vibrations and mechanical stresses common in automotive environments. This resilience ensures that the electronic components maintain their performance over time, reducing the likelihood of failure.

Automotive electronics demand compact designs that can fit into tight spaces. Rigid-flex PCBs offer significant space and weight savings by eliminating the need for connectors and cables, which are typically used to connect separate rigid boards. By integrating multiple functions into a single board, manufacturers can create more compact and lightweight electronic systems, contributing to overall vehicle efficiency.

With fewer connectors and solder joints, rigid-flex PCBs reduce the potential points of failure. This increased reliability is crucial in automotive applications, where system failures can have serious consequences. The seamless design of rigid-flex PCBs ensures consistent performance, even in harsh environments.

Designing rigid-flex PCBs for automotive applications requires careful consideration of several factors to ensure optimal performance and reliability.

Selecting the appropriate materials is critical in rigid-flex PCB design. The materials must withstand the high temperatures and harsh conditions typical of automotive environments. Polyimide is a common choice for the flexible layers due to its excellent thermal and mechanical properties.

The layer configuration of a rigid-flex PCB plays a vital role in its performance. Designers must balance the number of rigid and flexible layers to meet the specific requirements of the application. This balance impacts the board's flexibility, durability, and ability to handle electrical loads.

Automotive electronics often operate in high-temperature environments. Effective thermal management is essential to prevent overheating and ensure consistent performance. Designers must incorporate features like thermal vias and heat sinks to dissipate heat efficiently.

Rigid-flex PCBs are used in a variety of automotive applications, thanks to their versatility and reliability.

Advanced Driver-Assistance Systems (ADAS) rely heavily on electronics to enhance vehicle safety and performance. Rigid-flex PCBs are used in these systems to manage complex circuitry in a compact space, supporting functions like collision avoidance, lane departure warning, and adaptive cruise control.

Modern vehicles are equipped with sophisticated infotainment systems that require high-performance electronics. Rigid-flex PCBs provide the necessary interconnections for touchscreens, navigation systems, and multimedia interfaces, ensuring seamless operation and integration.

Engine Control Units (ECUs) manage vital engine functions, and any failure can lead to significant issues. Rigid-flex PCBs offer the reliability and performance needed to manage these critical systems, ensuring optimal engine performance and efficiency.

The success of automotive rigid-flex PCBs relies heavily on advanced PCB manufacturing processes. Manufacturers must adhere to stringent quality standards and use state-of-the-art equipment to produce reliable and high-performance boards.

Automotive applications demand precision manufacturing to ensure that each PCB meets the required specifications. This precision is achieved through advanced fabrication techniques, such as laser drilling and automated optical inspection, which help maintain tight tolerances and high-quality standards.

Quality control is a crucial aspect of PCB manufacturing. Manufacturers conduct rigorous testing at various stages of production to identify any defects or inconsistencies. This testing ensures that the final product meets the industry's reliability and performance standards.

Automotive electronics often require customized solutions to meet specific design and performance criteria. PCB manufacturers offer customization options, allowing designers to specify unique configurations, materials, and layouts to achieve the desired results.

As automotive technology continues to evolve, so too will the design and application of rigid-flex PCBs. Future trends include:

The integration of Internet of Things (IoT) technology in vehicles is driving demand for more sophisticated electronics. Rigid-flex PCBs will play a crucial role in connecting various IoT devices and sensors within the vehicle, enhancing connectivity and functionality.

The rise of electric and autonomous vehicles is creating new opportunities for rigid-flex PCBs. These vehicles require advanced electronics to manage battery systems, control algorithms, and autonomous driving features, all of which can benefit from the compact and reliable design of rigid-flex PCBs.

Sustainability is becoming increasingly important in the automotive industry. Rigid-flex PCBs contribute to sustainability by reducing material usage and weight, leading to more efficient and eco-friendly vehicles.

In conclusion, automotive rigid-flex PCB design is a critical component of modern vehicle electronics. With their durability, space-saving design, and reliability, rigid-flex PCBs are well-suited to meet the demands of the automotive industry. As technology advances, these innovative circuit boards will continue to play a vital role in the development of safer, smarter, and more efficient vehicles.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB