-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 03. 2025, 11:50:31

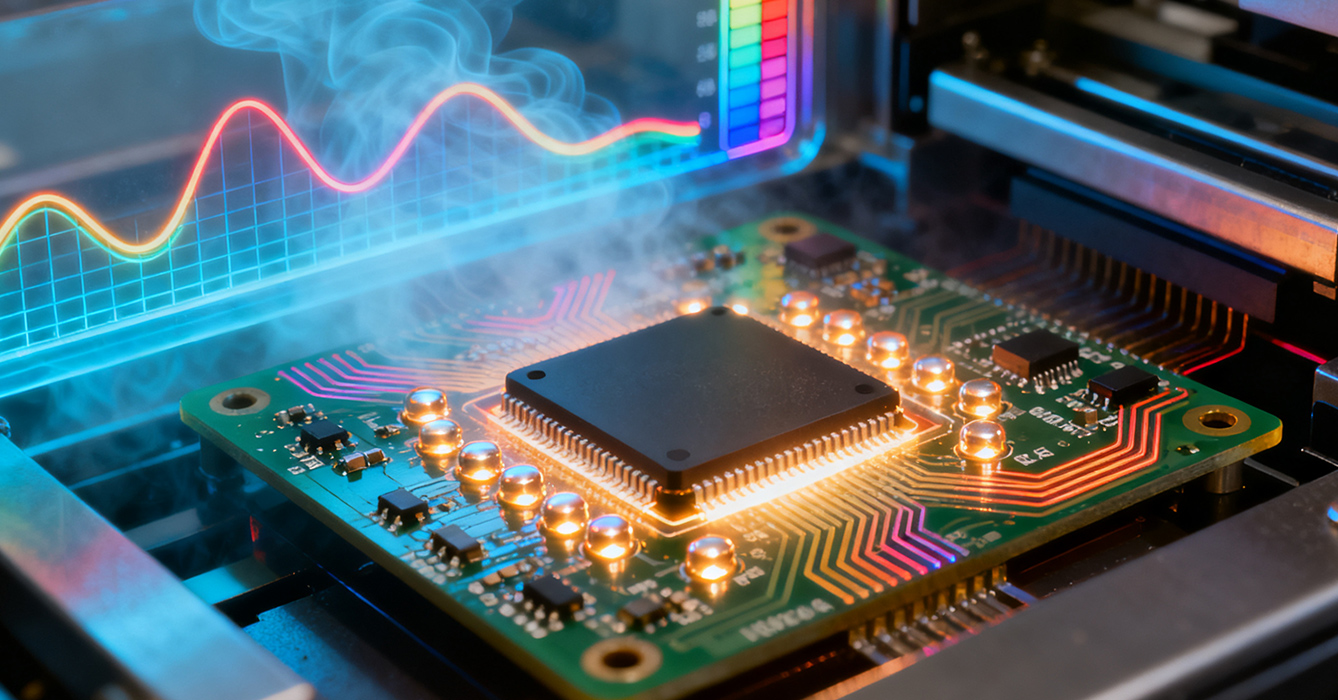

Advanced BGA (Ball Grid Array) Assembly Technology stands as a critical enabler of modern electronics, addressing the growing demand for high-density, high-performance semiconductor packaging in devices spanning consumer tech, automotive systems, and industrial equipment. Unlike traditional through-hole or surface-mount technologies, advanced BGA assembly leverages compact interconnect designs and precision manufacturing to support the miniaturization of components while enhancing electrical performance and thermal efficiency. As electronics grow more complex—driven by 5G, AI, and IoT—this technology has evolved to overcome challenges like signal integrity, thermal management, and assembly reliability, becoming indispensable for cutting-edge product development.

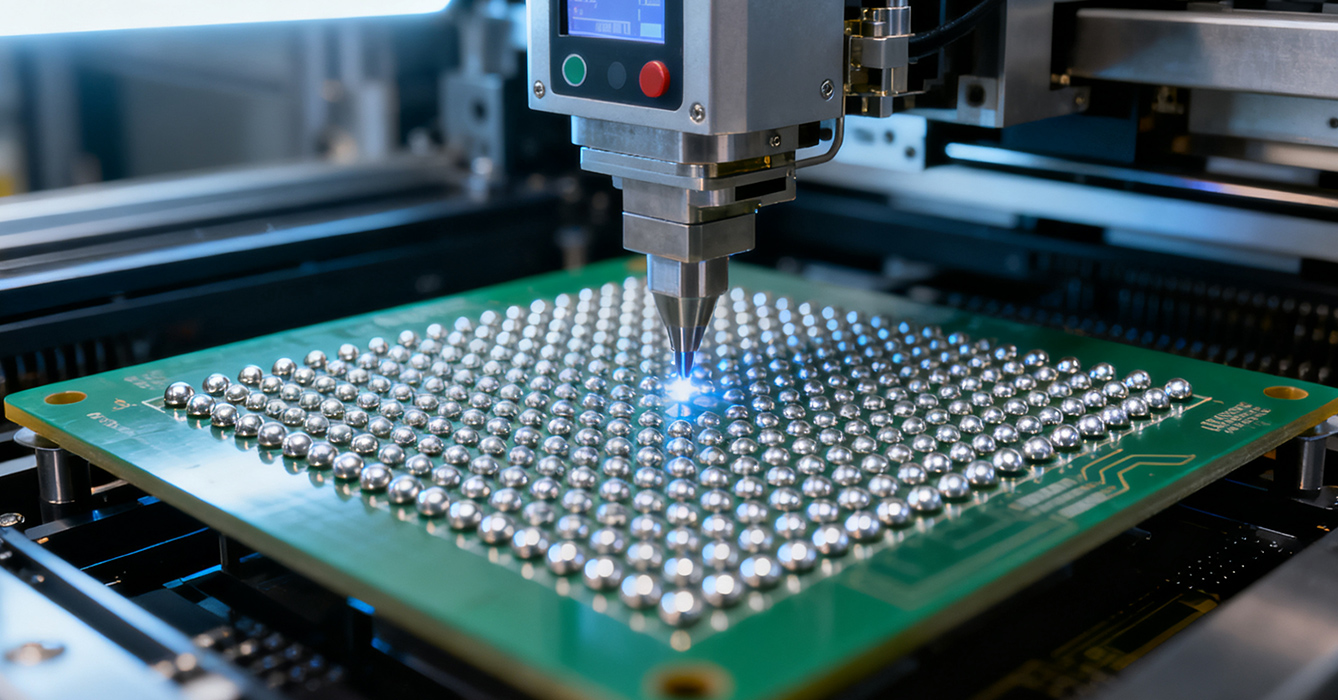

Modern BGA assembly pushes the boundaries of interconnect density with microball technology, where solder balls as small as a few micrometers enable tighter pitch between contacts. This innovation allows semiconductor designers to pack more I/O (input/output) connections onto a single chip, supporting higher data transfer rates without compromising form factor. Advanced processes like fine-pitch BGA (FPBGA) and ultra-fine-pitch BGA (UFPBGA) rely on precision placement systems to ensure consistent solder ball alignment, reducing the risk of bridging or open circuits.

Material science advancements have transformed BGA reliability, particularly in harsh operating environments. Lead-free solder alloys (compliant with RoHS standards) now incorporate additives to improve wetting, reduce voiding, and enhance thermal cycling resistance. Additionally, fluxless soldering and laser-assisted bonding techniques minimize contamination and ensure uniform solder joints, critical for applications like automotive electronics that endure extreme temperature fluctuations. These materials and processes extend the lifespan of BGA assemblies in mission-critical systems.

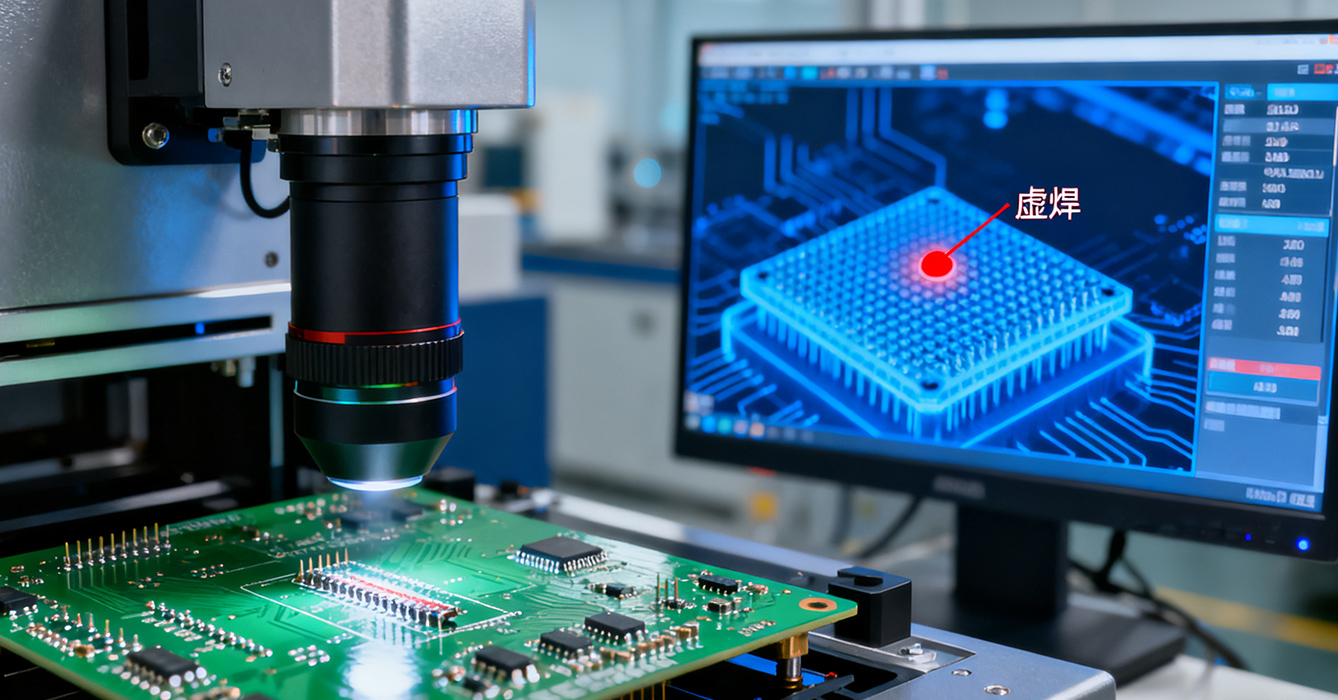

Advanced BGA assembly integrates artificial intelligence (AI) and machine learning (ML) into quality control workflows. Automated optical inspection (AOI) systems equipped with AI algorithms detect microscopic defects—such as solder ball deformation or misalignment—that human inspectors might miss. Real-time process monitoring tools analyze data from assembly lines to optimize parameters like reflow oven temperature profiles or placement accuracy, reducing waste and improving yield. This digital transformation ensures consistent quality at scale, even for high-volume production.

Smartphones, laptops, and wearables rely on advanced BGA assembly to house high-performance processors, memory chips, and RF modules. The technology’s ability to support dense interconnects enables thinner, lighter devices with faster processing speeds and longer battery life—key consumer demands.

Electric vehicles (EVs) and advanced driver-assistance systems (ADAS) require BGA assemblies that withstand vibration, temperature extremes, and electromagnetic interference (EMI). Advanced BGA technology addresses these needs with ruggedized packaging and thermal management solutions, ensuring reliable performance in powertrain controllers, sensor modules, and infotainment systems.

Industrial controllers, medical imaging equipment, and IoT sensors depend on BGA assemblies for high reliability and signal integrity. The technology’s precision interconnects support the low-latency data transfer required for real-time industrial automation, while its thermal efficiency prevents overheating in compact medical devices like portable diagnostic tools.

The evolution of advanced BGA assembly will be shaped by emerging technologies like 6G, edge computing, and quantum computing. Future developments may include even smaller solder interconnects, self-healing solder materials, and fully automated “lights-out” assembly lines. Additionally, sustainability will drive the adoption of recyclable materials and energy-efficient processes, aligning BGA manufacturing with global environmental goals.

Advanced BGA Assembly Technology is a cornerstone of modern electronics innovation, bridging the gap between semiconductor design and real-world application. Its focus on precision, reliability, and adaptability makes it essential for industries pushing the limits of performance and miniaturization. As technology continues to advance, BGA assembly will evolve to meet new challenges, solidifying its role as a critical enabler of the next generation of electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB