-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 28. 2025, 12:31:43

In the world of electronics, the demand for faster and more efficient communication technologies is ever-growing. One of the key players in this domain is the Microwave High Frequency PCB. These specialized circuit boards are essential for applications that require high-speed data transmission and superior signal integrity. In this article, we’ll delve into what microwave high frequency PCBs are, their benefits, and how they are used in various industries.

A Microwave High Frequency PCB, often referred to as a frequency PCB or RF circuit board, is a type of printed circuit board designed to operate at microwave frequencies. These frequencies typically range from 300 MHz to 300 GHz. Unlike standard PCBs, which are used in a wide range of electronic devices, high frequency PCBs are specifically engineered to handle high-speed signals with minimal loss.

Material Selection: High frequency PCBs are made from specialized materials such as PTFE (Teflon), ceramic-filled polymers, or Rogers materials. These materials offer low dielectric constants and low loss tangents, which are essential for maintaining signal integrity at high frequencies.

Layer Structure: These PCBs often have multiple layers to support complex circuits. The multilayer structure helps in reducing electromagnetic interference and provides a stable platform for high-speed signal transmission.

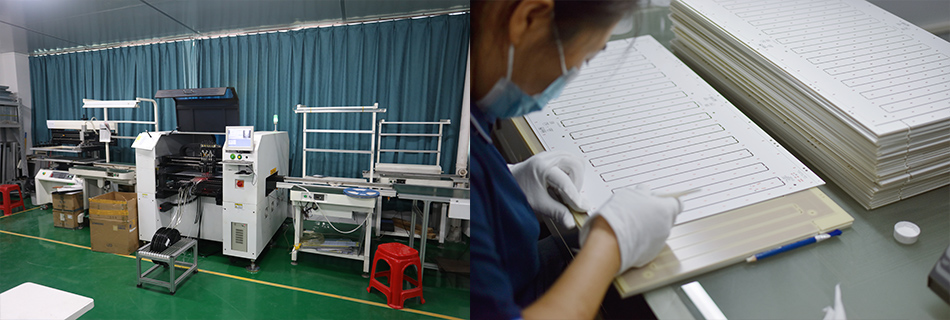

Precision Manufacturing: The manufacturing process for high frequency PCBs requires high precision to ensure accurate signal paths and impedance control. This often involves advanced techniques such as laser drilling and controlled depth drilling.

One of the primary advantages of using microwave high frequency PCBs is their ability to maintain excellent signal integrity. The specialized materials and precise manufacturing processes minimize signal loss and distortion, which is crucial for high-speed communication systems.

These PCBs support a wider bandwidth, allowing for faster data transmission rates. This is particularly important in applications such as telecommunications, where large amounts of data need to be transferred quickly and efficiently.

High frequency PCBs are designed to handle higher power levels, which means they can effectively manage the heat generated during operation. This is achieved through the use of materials with high thermal conductivity and the incorporation of thermal management features such as heat sinks and thermal vias.

In the telecommunications industry, high frequency PCBs are used in devices such as mobile phones, base stations, and satellite communication systems. They enable high-speed data transmission and support the growing demand for faster and more reliable communication networks.

With the rise of autonomous vehicles, the demand for advanced radar systems has increased. Microwave high frequency PCBs are used in automotive radar systems to provide accurate distance measurement and obstacle detection, enhancing vehicle safety and performance.

In the aerospace and defense sectors, high frequency PCBs are utilized in applications such as radar, communication systems, and electronic warfare. Their ability to handle high-speed signals and operate in harsh environments makes them ideal for these critical applications.

When designing a high frequency PCB, selecting the right material is crucial. The material should have a low dielectric constant and low loss tangent to ensure minimal signal loss. Common materials used include Rogers, DuPont, and Taconic.

The layout of a high frequency PCB is critical to its performance. Designers must pay attention to trace widths, spacing, and impedance matching to ensure optimal signal transmission. Advanced simulation tools are often used to model and predict the PCB's performance before manufacturing.

Once the PCB is manufactured, rigorous testing is conducted to ensure it meets the required specifications. This includes electrical testing, impedance testing, and thermal testing. Quality assurance is essential to ensure the reliability and performance of the PCB in real-world applications.

Manufacturing high frequency PCBs involves precise processes that require advanced machinery and skilled technicians. The complexity of the circuits and the need for tight tolerances make the manufacturing process challenging.

The materials and processes used in the production of microwave high frequency PCBs are typically more expensive than those used for standard PCBs. This can increase the overall cost of the project, making budget management an important consideration.

Microwave high frequency PCBs play a pivotal role in the advancement of modern communication technologies. Their ability to handle high-speed signals with minimal loss makes them indispensable in industries such as telecommunications, automotive, aerospace, and defense. As technology continues to evolve, the demand for high frequency PCBs will only grow, driving innovation and improvements in their design and manufacturing processes.

For businesses looking to stay competitive in these fast-paced industries, investing in high-quality microwave high frequency PCBs is a crucial step. By understanding their benefits and applications, companies can make informed decisions and leverage these advanced circuit boards to enhance their products and services.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB