-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 28. 2025, 12:33:50

When it comes to designing electronic devices, the printed circuit board (PCB) is at the heart of the operation. For projects requiring high-frequency applications, selecting the right high frequency PCB manufacturer is crucial. The right manufacturer ensures that your PCB design services are up to par, offering custom PCB fabrication that meets your specific needs. In this article, we'll guide you through the key considerations for choosing the right high frequency PCB manufacturer.

High frequency PCBs are used in devices that transmit signals at high speeds, such as radio frequency (RF) communications, microwaves, and satellite communications. These PCBs must handle frequencies in the gigahertz range, demanding precision and expertise in their design and fabrication.

High frequency PCBs differ from standard PCBs in several ways:

Material Selection: They require specialized materials like PTFE and ceramics, which provide minimal signal loss at high frequencies.

Dielectric Constant: The materials used must have a stable dielectric constant to ensure signal integrity.

Thermal Management: High frequency operations generate significant heat, requiring efficient thermal management solutions.

Signal Integrity: Maintaining signal integrity at high frequencies is critical, necessitating precise fabrication and testing.

Choosing the right manufacturer for your high frequency PCB is vital for several reasons:

Expertise: Not all PCB manufacturers have experience with high frequency designs. Expertise in this niche is essential.

Quality Assurance: High frequency PCBs require rigorous quality checks to ensure performance.

Customization: Every project has unique needs. A capable manufacturer will offer custom PCB fabrication to meet these requirements.

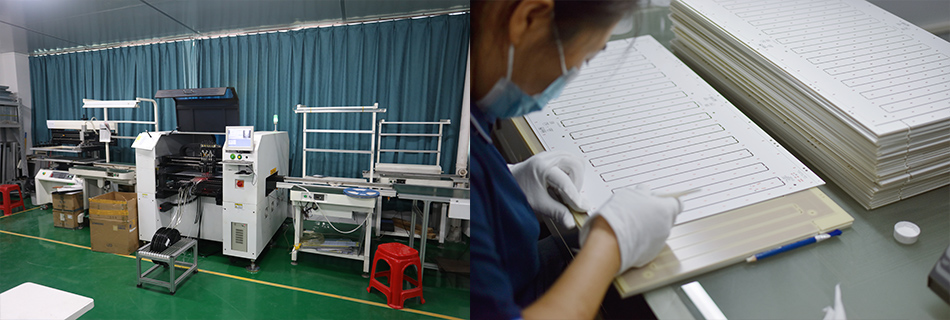

Technology and Equipment: Advanced technology and equipment are necessary to produce high frequency PCBs with accuracy.

Experience in high frequency PCB manufacturing is non-negotiable. Look for manufacturers with a track record in handling projects similar to yours. Their expertise can help in overcoming common challenges associated with high frequency applications.

Each project is unique, and your PCB should reflect your specific requirements. A good manufacturer will offer flexibility in design and fabrication, allowing for custom PCB solutions tailored to your needs.

The choice of materials can make or break your project. Ensure that the manufacturer uses high-quality materials suitable for high frequency applications. Discuss options with them to understand the benefits and limitations of each material.

Quality control processes are crucial in PCB manufacturing. Inquire about the manufacturer's quality assurance protocols. Do they test for signal integrity and thermal management? Reliable manufacturers will have stringent quality checks in place.

Modern, well-maintained equipment is a sign of a capable manufacturer. Advanced technology allows for precise fabrication, which is crucial for maintaining signal integrity at high frequencies. Ask about the technology they use and any recent upgrades to their facilities.

While cost is always a consideration, it should not be the sole determining factor. Balance cost with quality and lead time. Understand the manufacturer's production schedules and ensure they can meet your deadlines without compromising on quality.

When evaluating potential manufacturers, consider asking the following questions:

What is your experience with high frequency PCB projects?

Can you provide references or case studies of similar projects?

What materials do you recommend for my application, and why?

What quality control measures do you have in place?

How do you ensure signal integrity in your high frequency PCBs?

What is your typical lead time for custom PCB fabrication?

Choosing the right high frequency PCB manufacturer is a critical step in ensuring the success of your project. By considering factors like experience, customization capabilities, material selection, quality control, technology, and cost, you can make an informed decision. Remember, the right manufacturer will not only provide high-quality PCBs but will also be a valuable partner in bringing your electronic innovations to life.

By following these guidelines, you can ensure that your high frequency PCB meets your performance expectations and contributes to the overall success of your product.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB