-

- PCB TYPE

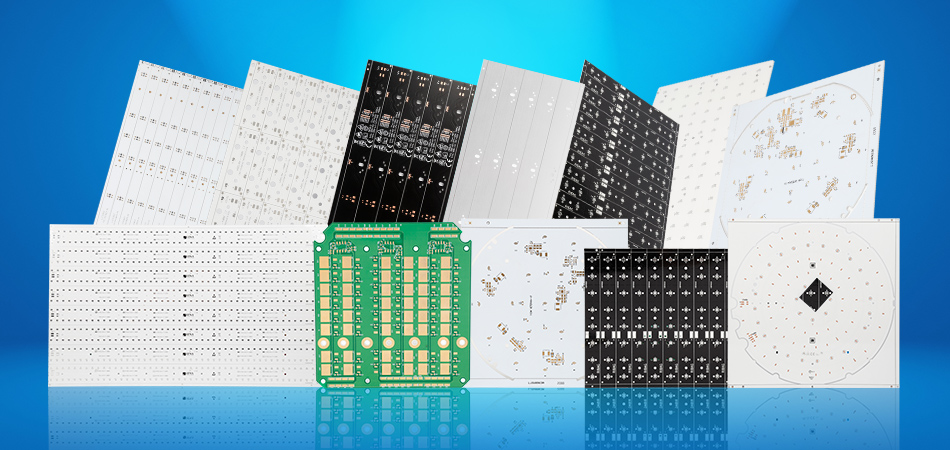

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 17. 2025, 08:41:05

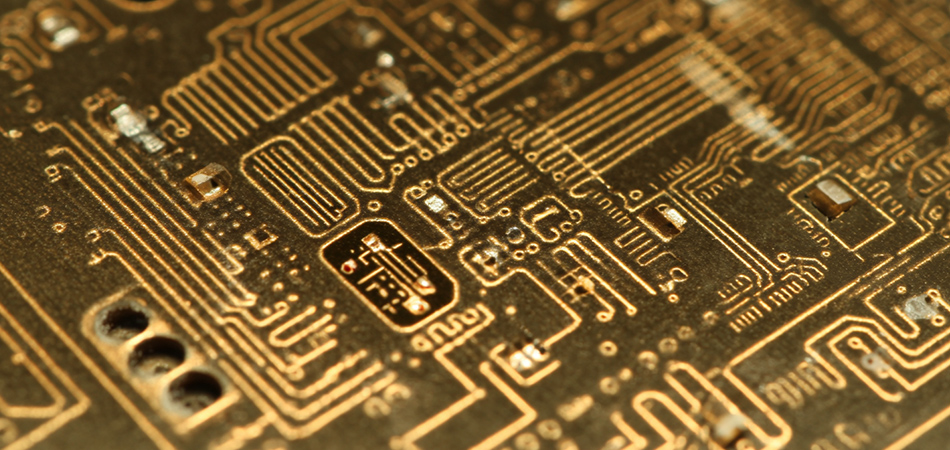

In the dynamic realm of modern electronics, the quest for materials and technologies that can enhance performance, reliability, and miniaturization is unceasing. Aluminum Backed Copper Laminate (ABCL), a specialized type of substrate material, has emerged as a game - changer. It combines the beneficial properties of aluminum and copper to address two of the most pressing challenges in electronics: thermal management and electrical conductivity. As electronic devices become more powerful and densely packed, the ability to efficiently dissipate heat and ensure stable electrical operation has become crucial. This article delves deep into the world of ABCL, exploring its fundamental characteristics, design and manufacturing aspects, diverse applications, market trends, and future prospects.

Understanding Aluminum Backed Copper Laminate

Definition and Structure

An aluminum backed copper laminate is a composite material consisting of three main layers. At the core is an aluminum layer, which serves as a robust mechanical support and an excellent heat conductor. Aluminum is chosen for its high thermal conductivity, lightweight nature, and cost - effectiveness compared to some other metals. On one or both sides of the aluminum core, a layer of copper is bonded. The copper layer is responsible for carrying electrical current, thanks to its superior electrical conductivity. Between the aluminum and copper layers, a thermally conductive dielectric layer is sandwiched. This dielectric layer provides electrical insulation between the metal layers while facilitating the transfer of heat from the copper traces (where components are mounted) to the aluminum core.

The overall structure of ABCL is designed to optimize both thermal and electrical performance. The aluminum core can quickly absorb heat generated by high - power components such as power transistors, integrated circuits, and LEDs. Once absorbed, the heat is spread across the large surface area of the aluminum and then dissipated into the surrounding environment. Meanwhile, the copper layer enables the efficient flow of electrical signals, ensuring reliable operation of the electronic circuits.

Key Material Properties

Exceptional Thermal Conductivity

One of the primary advantages of ABCL lies in its thermal conductivity. Aluminum, with its relatively high thermal conductivity, acts as an efficient heat sink. In an electronic device, when components generate heat during operation, the heat is transferred through the thermally conductive dielectric layer to the aluminum core. The aluminum core then distributes this heat over its surface, increasing the surface area available for heat dissipation. This process helps to maintain lower operating temperatures for the components, preventing thermal stress and degradation. By keeping components within their optimal temperature range, ABCL enhances the reliability and lifespan of electronic devices, which is particularly crucial in high - power applications where excessive heat can lead to performance issues and component failure.

Superior Electrical Conductivity

The copper layer in ABCL offers excellent electrical conductivity. Copper is well - known for its low electrical resistance, which allows electrical current to flow with minimal power loss. In electronic circuits, the copper layer forms the traces and pads that connect various components. The low resistance of copper ensures that signals can be transmitted quickly and accurately, minimizing signal attenuation and interference. This property is essential for applications that require high - speed data transfer, such as in telecommunications equipment, high - performance computing systems, and advanced consumer electronics.

Mechanical Strength and Lightweight

The aluminum core provides significant mechanical strength to the laminate. Aluminum is a strong and lightweight metal, making ABCL suitable for applications where the substrate needs to withstand mechanical stress, vibrations, or impacts. In industries like automotive and aerospace, where PCBs are often subjected to harsh operating conditions, the mechanical robustness of ABCL ensures that the board can maintain its integrity and functionality. At the same time, the lightweight nature of aluminum helps to reduce the overall weight of the electronic device, which is beneficial for applications where weight is a critical factor, such as in portable electronics and aircraft.

Electromagnetic Interference (EMI) Shielding

The metal layers in ABCL, particularly the aluminum core, can act as a natural shield against electromagnetic interference. When electronic components operate, they can generate electromagnetic fields that may interfere with other components on the PCB or with external devices. The aluminum core in ABCL helps to contain and redirect these electromagnetic fields, reducing EMI both within the PCB and from the PCB to the surrounding environment. This property is crucial in applications where maintaining signal integrity and complying with electromagnetic compatibility (EMC) standards is essential, such as in medical electronics, where sensitive equipment needs to operate without interference.

Design Considerations for Aluminum Backed Copper Laminate

Thermal Design

Heat Transfer Path Optimization

Designing an effective thermal pathway is essential for maximizing the performance of ABCL. Heat - generating components should be placed in close proximity to the thermally conductive dielectric layer or connected to it via thermal vias. Thermal vias are small holes filled with a highly conductive material, usually copper, that create a direct connection between the component and the aluminum core. By carefully calculating the number, size, and location of thermal vias, designers can optimize heat transfer from the components to the aluminum core. Additionally, the use of heat sinks in conjunction with ABCL can further enhance heat dissipation. Heat sinks increase the surface area available for heat transfer to the environment, either through natural convection or forced - air cooling, depending on the application requirements.

Component Placement Strategy

The layout of components on a PCB using ABCL plays a vital role in thermal management. Components that generate a significant amount of heat should be spaced out to allow for proper air circulation, which aids in natural heat dissipation. In applications where forced - air cooling is used, the component layout should be designed to optimize the flow of cooling air over the heat - generating components and towards the aluminum core. Components that are sensitive to temperature should be placed away from heat sources to prevent thermal stress. Moreover, the overall component placement should consider the symmetry of heat distribution across the aluminum core to avoid creating hotspots.

Electrical Design

Trace Routing and Impedance Control

In the electrical design of PCBs with ABCL, trace routing requires careful planning to ensure signal integrity. For high - speed signals, impedance - controlled traces are crucial. The impedance of a trace is influenced by factors such as its width, length, the distance between adjacent traces, and the dielectric constant of the insulating layer. Designers must use specialized software tools to simulate the electrical behavior of the PCB layout and calculate the appropriate impedance values for the traces. Since the aluminum core can influence the electromagnetic field around the traces, additional considerations are needed to minimize signal reflections, crosstalk, and interference.

Power and Ground Plane Design

Power and ground planes are integral parts of the electrical design when using ABCL. The aluminum core can sometimes be utilized as a ground plane, taking advantage of its low resistance and large surface area. Well - designed power and ground planes help to distribute electrical power evenly across the PCB and provide a stable return path for electrical current. To ensure optimal performance, power and ground planes should be continuous, with minimal splits or gaps. Proper grounding techniques, such as star - grounding or 多点接地,should be employed to reduce electromagnetic interference (EMI) and improve the overall electrical performance of the PCB. The design should also consider the current - carrying capacity requirements of the components to prevent voltage drops and ensure reliable power delivery.

Manufacturing Processes of Aluminum Backed Copper Laminate

Material Selection and Preparation

The manufacturing process of ABCL begins with the careful selection of materials. High - quality aluminum sheets are chosen based on their purity, thermal conductivity, and mechanical properties. The aluminum sheets are thoroughly inspected for any defects, such as scratches, dents, or impurities, which could affect the performance of the final product. Similarly, the copper foils used for the conductive layer are selected for their electrical conductivity and thickness uniformity. The thermally conductive dielectric material should have excellent electrical insulation properties, high thermal conductivity, and good adhesion to both the aluminum and copper layers.

Once the materials are selected, they undergo a preparation process. The surfaces of the aluminum and copper materials are cleaned to remove any contaminants, oxides, or grease. This cleaning process is essential to ensure a strong bond between the layers during lamination. In some cases, a pretreatment process may be applied to the surfaces to enhance adhesion. For example, the aluminum surface may be anodized or treated with a special primer to improve its bonding characteristics with the dielectric layer.

Lamination

Lamination is a critical step in the manufacturing of ABCL. In this process, the aluminum core, the thermally conductive dielectric layer, and the copper foil are bonded together to form a single, cohesive structure. The layers are carefully stacked in the correct order, and then heat and pressure are applied. The heat causes the dielectric material to soften and flow, filling any gaps between the layers and creating a strong bond. The pressure helps to ensure that the layers are in close contact and that the bond is uniform.

Precise control of the lamination parameters, such as temperature, pressure, and time, is essential. The temperature must be high enough to cure the dielectric material but not so high as to cause damage to the aluminum or copper layers. The pressure should be sufficient to ensure good adhesion but not excessive, as this could cause deformation of the layers. The lamination time is also carefully determined based on the thickness of the materials and the curing characteristics of the dielectric. Any defects in the lamination, such as voids, delaminations, or uneven bonding, can significantly impact the thermal and electrical performance of the ABCL.

Drilling and Plating

After lamination, drilling is performed to create holes for vias, component mounting, and electrical connections. High - precision drilling machines are used to ensure accurate hole placement and clean hole walls. The holes are then plated with copper to create electrical connections between the different layers of the PCB and to provide a solderable surface for component attachment. Electroplating is a common method used for copper plating. In this process, an electrical current is passed through the PCB in a copper - containing electrolyte solution. The copper ions in the solution are deposited onto the surface of the holes and the traces, forming a continuous conductive layer.

The plating process requires careful control of parameters such as the current density, plating time, and temperature. The current density affects the rate of copper deposition, while the plating time determines the thickness of the copper layer. The temperature of the electrolyte solution also plays a role in the quality of the copper deposit. A uniform and thick copper deposit is necessary to ensure reliable electrical connections and good solderability.

Circuit Patterning

Circuit patterning is the process of creating the electrical circuits on the surface of the copper layer. Photolithography is a widely used technique for circuit patterning. In this process, a photosensitive resist material is applied to the copper surface. A patterned mask, which contains the desired circuit pattern, is then placed over the resist - coated copper and exposed to ultraviolet (UV) light. The exposed areas of the resist are chemically altered and can be removed during the development process, leaving behind the unexposed resist in the shape of the circuit pattern. The remaining copper is then etched away using an etching solution, leaving only the copper traces that form the electrical circuits.

The circuit patterning process requires high - resolution masks and precise control of the exposure and etching parameters. The exposure time and intensity of the UV light must be carefully adjusted to ensure that the resist is properly exposed. The etching solution and process conditions are also optimized to achieve clean and accurate etching of the copper layer. Any errors in the circuit patterning process can lead to short circuits, open circuits, or incorrect circuit geometries, which can affect the functionality of the PCB.

Applications of Aluminum Backed Copper Laminate

LED Lighting

One of the most prominent applications of ABCL is in LED lighting. LEDs generate a significant amount of heat during operation, and efficient heat dissipation is crucial for maintaining their luminous efficiency and lifespan. ABCL, with its excellent thermal conductivity, is ideal for LED lighting applications. The aluminum core quickly absorbs the heat from the LEDs and spreads it out, preventing overheating. This allows for the design of more compact and powerful LED lighting fixtures, such as streetlights, downlights, and high - bay lights. Additionally, the mechanical strength of ABCL makes it suitable for outdoor lighting applications where it may be exposed to harsh weather conditions.

Power Electronics

In power electronics, ABCL is extensively used in applications such as power supplies, inverters, and motor drives. These applications involve high - power components that generate a substantial amount of heat. The aluminum core in the laminate helps to manage this heat effectively, ensuring the stable operation of the power electronics devices. The low resistance of the copper layer also contributes to efficient power transfer, reducing power losses during conversion and distribution. In electric vehicle (EV) charging systems, for example, ABCL plays a vital role in handling the high - voltage and high - current requirements while maintaining optimal thermal performance.

Automotive Electronics

The automotive industry has also embraced ABCL for a variety of applications. In engine control units (ECUs), these laminates are used to handle the high - speed data processing and power requirements in the harsh under - hood environment. The aluminum core helps to dissipate the heat generated by the components, ensuring reliable operation even at high temperatures. ABCL is also used in automotive lighting systems, infotainment systems, and advanced driver - assistance systems (ADAS). Their mechanical strength makes them capable of withstanding the vibrations and shocks experienced during vehicle operation, while their thermal management capabilities ensure the longevity of the electronic components.

Industrial Electronics

In industrial applications, ABCL is used in equipment such as industrial automation systems, programmable logic controllers (PLCs), and power distribution panels. Industrial environments are often characterized by high temperatures, dust, and vibrations. ABCL can withstand these harsh conditions while providing efficient thermal management for heat - generating components. In industrial automation, where precise control and reliable operation are essential, ABCL - based PCBs ensure that the electronic control systems operate smoothly, reducing the risk of downtime due to component failure caused by overheating.

Market Dynamics of Aluminum Backed Copper Laminate

Market Growth

The global market for ABCL has been experiencing significant growth in recent years. This growth is primarily driven by the increasing demand for high - performance electronics in various industries. The expansion of the LED lighting market, the growth of the electric vehicle industry, and the adoption of advanced industrial automation technologies are all contributing to the rising demand for ABCL. As these industries continue to evolve and require more efficient and reliable electronic solutions, the market for ABCL is expected to expand further in the coming years.

Competitive Landscape

The market for ABCL is highly competitive, with a large number of manufacturers operating globally. Key players in the market include both established PCB material manufacturers and emerging companies that specialize in advanced composite materials. Competition is based on factors such as product quality, performance, cost - effectiveness, and technological innovation. Manufacturers are constantly investing in research and development to improve the manufacturing processes of ABCL, reduce costs, and enhance product performance. They are also focusing on providing customized solutions to meet the specific requirements of different customers and industries.

Challenges and Future Trends

Challenges

Despite the numerous advantages of ABCL, the industry faces several challenges. One of the main challenges is the cost. The use of high - quality aluminum and copper materials, along with the specialized manufacturing processes involved in producing ABCL, can result in higher production costs compared to traditional PCB materials. Additionally, the design complexity of PCBs using ABCL requires more advanced design tools and skilled engineers to optimize their performance. Ensuring consistent quality and reliability during mass production is also a challenge, as any defects in the lamination or other manufacturing processes can significantly impact the performance of the final product.

Future Trends

The future of ABCL looks promising, with several trends expected to shape the industry. Advancements in materials science are likely to lead to the development of new thermally conductive dielectric materials with even better performance, reducing the overall cost of ABCL. The integration of emerging technologies such as 5G, the Internet of Things (IoT), and artificial intelligence (AI) will drive the demand for more compact, high - performance PCBs using ABCL that can handle increased data processing and power requirements. The adoption of advanced manufacturing technologies, such as additive manufacturing and automation, is also expected to revolutionize the production of ABCL, enabling more complex designs and shorter production cycles.

Conclusion

Aluminum Backed Copper Laminate has emerged as a revolutionary material in the electronics industry, offering a unique combination of high thermal conductivity, superior electrical performance, mechanical strength, and EMI shielding. Its applications span across a wide range of industries, from LED lighting and power electronics to automotive and industrial electronics. While the industry faces challenges such as cost and design complexity, ongoing advancements in materials science, manufacturing technologies, and design tools hold great promise for the future of ABCL. By addressing these challenges and capitalizing on emerging trends, the ABCL market is set to continue its growth trajectory, driving innovation and enabling the development of more efficient, reliable, and high - performance electronic solutions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB