-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 17. 2025, 08:28:45

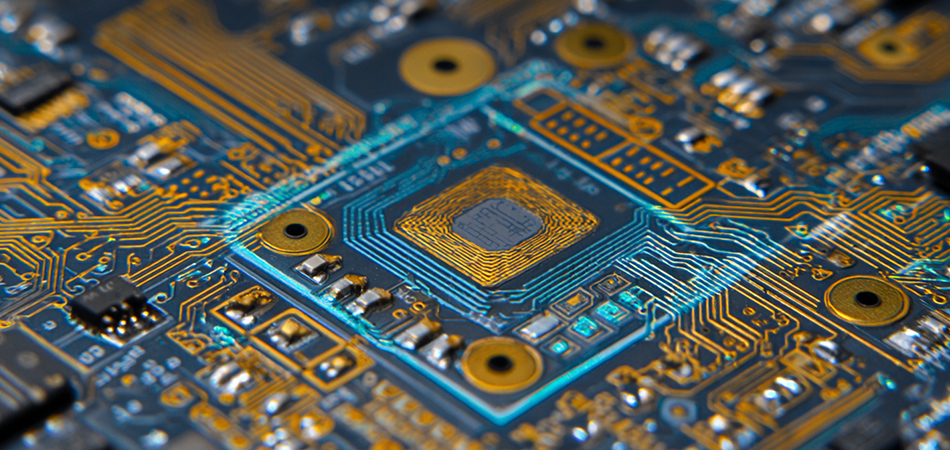

In the fast - paced world of electronics, the demand for higher - performance, more reliable, and miniaturized devices is ever - increasing. Printed Circuit Boards (PCBs) lie at the heart of these electronic systems, and the materials used in their construction play a pivotal role in determining their performance. Among these materials, High Tg Copper Clad Laminates (CCLs) have emerged as a game - changing solution, enabling the development of advanced electronics that can withstand extreme conditions and support high - speed data transfer. This article delves into the intricacies of High Tg Copper Clad Laminates, exploring their properties, applications, manufacturing processes, market dynamics, and future prospects.

Understanding High Tg Copper Clad Laminates

Definition and Glass Transition Temperature (Tg)

A High Tg Copper Clad Laminate is a type of laminate material that consists of a copper layer bonded to a substrate material, typically a resin - impregnated fiberglass or other insulating materials. The "Tg" in High Tg CCL refers to the glass transition temperature, which is a critical property of the substrate material. The glass transition temperature is the temperature at which a material transitions from a rigid, glassy state to a more flexible, rubbery state. In the context of PCBs, a high Tg value is highly desirable as it indicates that the laminate can maintain its mechanical and electrical properties at elevated temperatures.

For example, in traditional PCBs, the Tg of the laminate might be in the range of 130 - 150°C. However, for High Tg CCLs, the Tg can be as high as 170°C or even higher, depending on the specific formulation and application requirements. This higher Tg allows the PCB to withstand the higher temperatures associated with modern manufacturing processes, such as lead - free soldering, which typically requires peak temperatures in the range of 240 - 260°C.

Structure and Composition

The structure of a High Tg Copper Clad Laminate is composed of three main components: the copper layer, the substrate material, and the adhesive layer (if present).

The copper layer, which is usually made of high - purity electrolytic copper foil, serves as the conductor for electrical signals. Copper is chosen for its excellent electrical conductivity, which allows for efficient transmission of electrical current with minimal power loss. The thickness of the copper layer can vary depending on the application, but it is typically in the range of a few microns to several tens of microns.

The substrate material is the core of the High Tg CCL and is responsible for providing mechanical support, electrical insulation, and thermal management. High Tg substrate materials are often made from advanced resins, such as epoxy resins modified with special additives or high - performance polymers like polyimide. These materials are combined with reinforcing materials, such as fiberglass cloth, to enhance their mechanical strength and dimensional stability. The choice of resin and reinforcing material is carefully selected to achieve the desired balance of properties, including high Tg, low coefficient of thermal expansion (CTE), good electrical insulation, and excellent adhesion to the copper layer.

In some cases, an adhesive layer is used to bond the copper layer to the substrate material. This adhesive layer must have good adhesion properties to both the copper and the substrate and should also be able to withstand the high temperatures and mechanical stresses encountered during PCB manufacturing and use.

Key Properties of High Tg Copper Clad Laminates

Thermal Stability

One of the most significant advantages of High Tg Copper Clad Laminates is their enhanced thermal stability. As mentioned earlier, the high Tg value allows the laminate to maintain its structural integrity and electrical performance at elevated temperatures. This is crucial in applications where the PCB is exposed to high heat, such as in power electronics, automotive engines, and industrial machinery.

In power electronics, for example, components like power transistors and diodes generate a substantial amount of heat during operation. The High Tg CCL can effectively dissipate this heat, preventing thermal runaway and ensuring the reliable operation of the power electronics system. Additionally, in automotive applications, the PCB may be exposed to high temperatures under the hood, especially in hybrid and electric vehicles where the battery management system and other power - intensive components generate heat. The thermal stability of High Tg CCLs enables these automotive PCBs to function properly in such harsh thermal environments.

Mechanical Strength

High Tg Copper Clad Laminates also offer excellent mechanical strength. The combination of a high - quality substrate material and a well - bonded copper layer results in a laminate that can withstand mechanical stress, vibrations, and impacts. This mechanical robustness is essential in applications where the PCB may be subject to physical abuse, such as in portable electronics, aerospace systems, and military equipment.

In portable electronics, such as smartphones and tablets, the PCB must be able to withstand the rigors of daily use, including being dropped, bumped, and bent. High Tg CCLs provide the necessary mechanical strength to ensure that the PCB remains intact and functional, even in the face of such physical challenges. In aerospace and military applications, where the PCB may be exposed to extreme vibrations and shocks during flight or combat, the mechanical strength of High Tg CCLs is a critical factor in ensuring the reliability of the electronic systems.

Electrical Performance

In terms of electrical performance, High Tg Copper Clad Laminates exhibit good electrical insulation properties, low dielectric constant (Dk), and low dissipation factor (Df). The electrical insulation property of the substrate material prevents electrical short - circuits between different copper traces on the PCB, ensuring the proper functioning of the electrical circuits.

The low dielectric constant and dissipation factor are particularly important in high - frequency applications. In high - frequency circuits, such as those used in 5G communication systems, wireless local area networks (WLANs), and radar systems, a low Dk and Df help to minimize signal loss and distortion. This allows for the efficient transmission of high - frequency signals over long distances, enabling faster data transfer rates and better communication performance.

Design Considerations for High Tg Copper Clad Laminates

Thermal Design

When designing a PCB using High Tg Copper Clad Laminates, thermal design is of utmost importance. The high - temperature resistance of the laminate allows for more aggressive thermal management strategies. One common approach is to use thermal vias, which are small holes filled with copper that connect the top and bottom layers of the PCB. These thermal vias provide a direct path for heat to flow from the heat - generating components on the surface of the PCB to the copper layers, where it can be dissipated more effectively.

The layout of heat - generating components on the PCB also needs to be carefully considered. Components that generate a large amount of heat, such as power transistors and integrated circuits, should be placed in areas where they can be easily cooled, such as near the edges of the PCB or in areas with good ventilation. Additionally, the use of heat sinks or fans may be necessary to further enhance heat dissipation in high - power applications.

Electrical Design

In electrical design, the choice of High Tg CCL can impact the performance of the PCB in several ways. The low dielectric constant and dissipation factor of the laminate are beneficial for high - frequency signal transmission, as mentioned earlier. However, designers also need to consider the impedance of the copper traces on the PCB. The impedance of a trace is determined by its width, length, the distance between adjacent traces, and the dielectric constant of the substrate material.

In high - speed digital applications, it is often necessary to control the impedance of the traces to ensure proper signal integrity. This may involve using specialized software tools to simulate the electrical behavior of the PCB layout and adjusting the trace dimensions and spacing accordingly. Additionally, the design of the power and ground planes on the PCB is crucial for ensuring stable power distribution and minimizing electromagnetic interference (EMI). The copper layer in the High Tg CCL can be used effectively as a power or ground plane, but careful attention must be paid to the layout and connection of these planes to ensure optimal performance.

Manufacturing Processes of High Tg Copper Clad Laminates

Material Preparation

The manufacturing process of High Tg Copper Clad Laminates begins with the preparation of the raw materials. The copper foil is typically cleaned and treated to remove any impurities or oxide layers that could affect its adhesion to the substrate material. The substrate material, which may be in the form of a prepreg (resin - impregnated fiberglass) or a polymer film, is also carefully inspected and prepared.

For prepregs, the resin content and curing characteristics are carefully controlled to ensure consistent quality. In the case of high - performance polymers like polyimide, the polymer may need to be processed through a series of steps, such as polymerization, imidization, and film formation, to achieve the desired properties.

Lamination

Lamination is the process of bonding the copper layer to the substrate material. This is typically done using heat and pressure. In a typical lamination process, the copper foil and the substrate material (either a prepreg or a polymer film) are stacked together in a specific order and placed in a laminating press. The press applies heat and pressure to the stack, causing the resin in the prepreg (if used) to flow and cure, or the polymer film to bond with the copper foil.

The lamination parameters, such as temperature, pressure, and time, are carefully controlled to ensure a strong and uniform bond between the copper and the substrate. Any defects in the lamination, such as voids, delaminations, or uneven bonding, can significantly affect the performance of the High Tg CCL and the resulting PCB.

Drilling and Plating

After lamination, drilling is performed to create holes for component mounting, vias, and electrical connections. High - precision drilling machines are used to ensure accurate hole placement and clean hole walls. The holes are then plated with copper to create electrical connections between the different layers of the PCB and to provide a solderable surface for component attachment.

Electroplating is a common method used for copper plating. In this process, an electrical current is passed through the PCB in a copper - containing electrolyte solution. The copper ions in the solution are deposited onto the surface of the holes and the copper traces, forming a continuous conductive layer. The plating process requires careful control of parameters such as the current density, plating time, and temperature to ensure a uniform and thick copper deposit.

Circuit Patterning

Circuit patterning is the process of creating the electrical circuits on the surface of the copper layer. Photolithography is a widely used technique for circuit patterning. In this process, a photosensitive resist material is applied to the copper surface. A patterned mask, which contains the desired circuit pattern, is then placed over the resist - coated copper and exposed to ultraviolet (UV) light.

The exposed areas of the resist are chemically altered and can be removed during the development process, leaving behind the unexposed resist in the shape of the circuit pattern. The remaining copper is then etched away using an etching solution, leaving only the copper traces that form the electrical circuits. The circuit patterning process requires high - resolution masks and precise control of the exposure and etching parameters to ensure accurate and fine - line circuit patterns.

Applications of High Tg Copper Clad Laminates

Automotive Electronics

The automotive industry is one of the major consumers of High Tg Copper Clad Laminates. In modern vehicles, there is a significant increase in the use of electronic systems, including advanced driver - assistance systems (ADAS), infotainment systems, and electric vehicle (EV) powertrain components.

ADAS systems, such as radar - based collision avoidance systems and camera - based lane - keeping assist systems, require high - performance PCBs that can withstand the harsh environmental conditions under the hood, including high temperatures, vibrations, and electromagnetic interference. High Tg CCLs provide the necessary thermal stability and mechanical strength for these applications.

In EVs, the battery management system, which is responsible for monitoring and controlling the charging and discharging of the battery, is a critical component. The PCBs used in battery management systems need to be highly reliable and able to handle high currents and temperatures. High Tg Copper Clad Laminates are well - suited for these demanding applications, ensuring the safe and efficient operation of the EV.

Aerospace and Defense

Aerospace and defense applications also rely heavily on High Tg Copper Clad Laminates. In aircraft and spacecraft, the electronic systems are exposed to extreme temperatures, high altitudes, and intense vibrations. PCBs made with High Tg CCLs can withstand these harsh conditions and maintain their performance, ensuring the reliable operation of critical systems such as avionics, navigation, and communication systems.

In defense applications, such as military radar systems, missile guidance systems, and electronic warfare equipment, the use of High Tg CCLs enables the development of high - performance, compact, and reliable electronic systems. These systems need to be able to operate in challenging environments and support high - speed data processing and communication, and High Tg CCLs provide the necessary properties to meet these requirements.

Telecommunications

With the rapid development of 5G technology, the telecommunications industry has a growing need for High Tg Copper Clad Laminates. 5G networks operate at higher frequencies and require faster data transfer rates compared to previous generations of mobile networks. High Tg CCLs, with their low dielectric constant and dissipation factor, are essential for manufacturing PCBs that can support the high - frequency signals and high - speed data transmission in 5G base stations, smartphones, and other 5G - enabled devices.

In addition to 5G, High Tg CCLs are also used in other telecommunications applications, such as fiber - optic communication systems and satellite communication systems. These applications require PCBs that can handle high - speed data transfer and operate in a variety of environmental conditions, and High Tg CCLs provide the necessary performance and reliability.

Industrial Electronics

Industrial electronics, such as industrial automation systems, power distribution panels, and motor control centers, also benefit from the use of High Tg Copper Clad Laminates. In industrial environments, PCBs are often exposed to high temperatures, humidity, dust, and mechanical stress. High Tg CCLs can withstand these harsh conditions and ensure the long - term reliability of the industrial electronic systems.

For example, in industrial automation systems, where precise control and reliable operation are crucial, High Tg CCL - based PCBs can support the high - speed data processing and communication required for the control of industrial robots, conveyor belts, and other automated equipment. In power distribution panels and motor control centers, the thermal stability of High Tg CCLs helps to prevent overheating and ensure the safe and efficient operation of the electrical systems.

Market Dynamics of High Tg Copper Clad LaminMarket Growth

The global market for High Tg Copper Clad Laminates has been experiencing steady growth in recent years. This growth is driven by several factors, including the increasing demand for advanced electronics in various industries, the adoption of high - temperature manufacturing processes such as lead - free soldering, and the development of new applications for High Tg CCLs.

The automotive industry's shift towards electric and autonomous vehicles, the expansion of 5G networks, and the growth of the aerospace and defense sectors are all contributing to the rising demand for High Tg Copper Clad Laminates. As these industries continue to develop and require more reliable and high - performance PCBs, the market for High Tg CCLs is expected to expand further in the coming years.

Competitive Landscape

The market for High Tg Copper Clad Laminates is highly competitive, with numerous manufacturers operating globally. Key players in the market include established companies such as Rogers Corporation, Isola Group (now part of TTM Technologies), and Panasonic Corporation. These companies have a long - standing reputation for producing high - quality CCLs and have a strong presence in the global market.

In addition to the major players, there are also many regional and emerging manufacturers that are competing in the market. These manufacturers often focus on providing cost - effective solutions and catering to specific niche markets. Competition in the market is based on factors such as product quality, performance, price, and customer service. Manufacturers are constantly investing in research and development to improve the performance of their High Tg CCLs, develop new materials and manufacturing processes, and meet the evolving needs of their customers.

Challenges and Future Trends

Challenges

Despite the many advantages of High Tg Copper Clad Laminates, there are several challenges that the industry faces. One of the main challenges is the cost. High Tg CCLs often use advanced materials and manufacturing processes, which can result in higher production costs compared to traditional CCLs. This cost factor can limit the adoption of High Tg CCLs in some price - sensitive applications.

Another challenge is the environmental impact of the manufacturing process. The production of High Tg CCLs may involve the use of chemicals and materials that can have a negative impact on the environment. As environmental regulations become more stringent, manufacturers need to find ways to reduce the environmental footprint of their manufacturing processes, such as by using more sustainable materials and implementing more efficient waste management practices.

Future Trends

Looking to the future, there are several trends that are likely to shape the development of High Tg Copper Clad Laminates. One trend is the continued development of new materials with even higher Tg values, better electrical and mechanical properties, and improved environmental performance. For example, researchers are exploring the use of nanocomposites, advanced polymers, and new types of reinforcing materials to create next - generation High Tg CCLs.

Another trend is the integration of High Tg CCLs with other emerging technologies, such as 3D printing, flexible electronics, and the Internet of Things (IoT). 3D printing technology has the potential to revolutionize the manufacturing of PCBs, allowing for more complex and customized designs. High Tg CCLs can be used in combination with 3D printing to create high - performance, three - dimensional electronic structures.

In the area of flexible electronics, High Tg CCLs can be used to create flexible PCBs that can bend and stretch without losing their electrical and mechanical properties. This is particularly useful in applications such as wearable electronics and flexible displays.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB