-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 11. 2025, 08:58:58

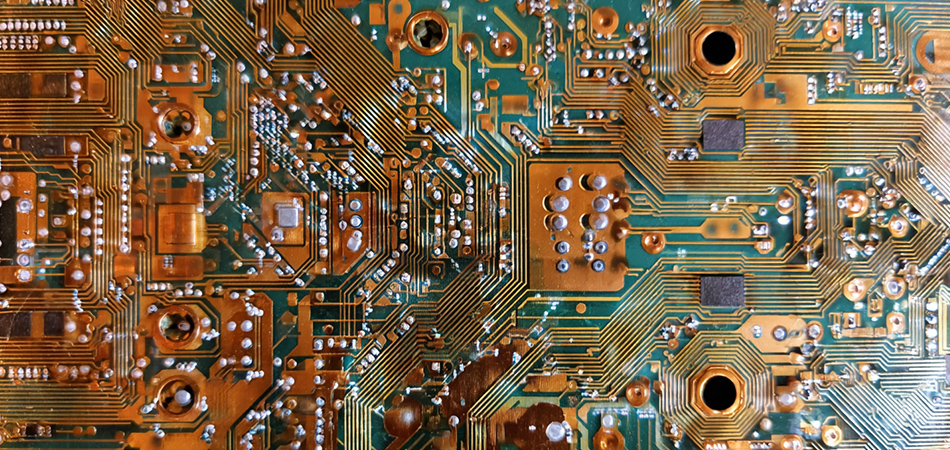

In the intricate world of electronic engineering, the quest for optimal performance, reliability, and efficiency has led to the development of specialized printed circuit boards (PCBs). Among these, the aluminum base PCB with a specific copper thickness, often denoted as 3oz, stands out as a game - changing solution for a diverse range of applications. This article delves deep into the unique characteristics, design intricacies, manufacturing processes, real - world applications, and future trends of aluminum base PCBs with 3oz copper, highlighting their pivotal role in modern electronics.

Material Science Underpinning Aluminum Base PCB 3oz Copper

Aluminum Substrate: The Thermal and Mechanical Core

The aluminum substrate forms the foundation of these PCBs, offering a multitude of advantages that are essential for high - performance electronics. Its exceptional thermal conductivity makes it an ideal heat sink, enabling rapid dissipation of the heat generated by power - hungry electronic components. In applications where overheating can lead to performance degradation, component failure, or reduced lifespan, the aluminum substrate acts as a safeguard, ensuring that components operate within their optimal temperature range.

Moreover, aluminum's favorable strength - to - weight ratio provides robust mechanical stability. This allows the PCB to withstand mechanical stresses such as vibrations, shocks, and impacts, making it suitable for use in harsh environments. Whether it's in automotive electronics that endure constant vibrations on the road, or in aerospace systems that face extreme temperature fluctuations and mechanical stresses during flight, the aluminum substrate ensures the integrity of the PCB and the components mounted on it.

Dielectric Layers: Balancing Insulation and Thermal Transfer

Sandwiched between the aluminum substrate and the copper layers, the dielectric layers play a crucial dual role. As insulators, they prevent electrical short circuits between the aluminum core and the copper conductive pathways, maintaining the electrical integrity of the PCB. This is vital for the proper functioning of the electronic circuits, ensuring that electrical signals are transmitted accurately without interference.

At the same time, these dielectric layers are engineered to have high thermal conductivity, facilitating the efficient transfer of heat from the components to the aluminum substrate. The choice of dielectric material is critical, as it directly impacts the thermal resistance of the PCB. High - quality dielectric materials, carefully selected for their thermal and electrical properties, strike the perfect balance between insulation and heat transfer, optimizing the overall performance of the PCB.

3oz Copper Layers: The Conductive Powerhouses

The 3oz copper thickness is a defining feature of these PCBs, offering distinct advantages over thinner copper layers. Copper, renowned for its excellent electrical conductivity, serves as the medium for transmitting electrical current in PCBs. With a 3oz thickness, the copper layers can handle higher currents with minimal resistance. This is particularly beneficial in applications where high - power components, such as power transistors, integrated circuits in power supplies, or high - current LED arrays, are used.

The reduced resistance in 3oz copper layers translates to lower power losses as heat, enhancing the overall efficiency of the electronic system. Additionally, the increased thickness provides a more robust foundation for soldering components, ensuring reliable mechanical and electrical connections. This is crucial for maintaining the long - term reliability of the PCB, especially in applications where continuous operation and high reliability are required.

Design Principles for Optimal Performance

Thermal Management Strategies

Effective thermal management is the cornerstone of successful designs involving aluminum base PCBs with 3oz copper. Component placement is a key consideration in thermal management. Heat - generating components should be positioned in areas that maximize heat transfer to the aluminum substrate. Thermal vias, strategically placed to connect the copper layers to the aluminum core, create additional pathways for heat to flow, reducing thermal resistance and ensuring efficient heat dissipation.

In high - power applications, external heat sinks or cooling fans may be integrated with the PCB to further enhance thermal performance. The design of the heat sink, its size, shape, and material, as well as the placement of the cooling fan, all need to be carefully optimized to work in harmony with the PCB's thermal properties. By effectively managing heat, these strategies not only protect the components from overheating but also improve the overall efficiency and lifespan of the electronic device.

Electrical Design for Reliable Power Delivery

The electrical design of these PCBs focuses on ensuring reliable power delivery and signal transmission. Power traces, with their 3oz copper thickness, are designed to handle the high currents required by power - intensive components. The layout of the power traces is optimized to minimize voltage drops and ensure uniform power distribution across the board. This is essential for maintaining the performance of the components, as voltage fluctuations can lead to instability or reduced efficiency.

For signal transmission, especially in high - frequency applications, the design of the signal traces needs to be carefully considered. The 3oz copper layers, while mainly designed for power delivery, also need to support the transmission of high - speed signals with minimal loss and interference. Grounding strategies are crucial in electrical design, as a proper grounding scheme helps to reduce electromagnetic interference (EMI) and noise, improving the overall signal integrity of the circuit.

Mechanical Design for Durability and Integration

Mechanical design considerations for aluminum base PCBs with 3oz copper include the form factor, mounting options, and structural support. The PCB should be designed to fit seamlessly into the enclosure of the electronic device, with appropriate mounting holes and features. The thickness of the 3oz copper layers, along with the aluminum substrate and dielectric layers, needs to be taken into account when determining the overall form factor to ensure compatibility with the device's design requirements.

In addition, the mechanical design should ensure that the PCB can withstand the mechanical stresses of its intended application. Reinforcements, such as additional layers or mechanical supports, may be incorporated to protect the PCB from damage during handling, installation, or operation. The design should also facilitate the integration of other components and systems, ensuring a smooth and reliable assembly process.

Manufacturing Processes for Precision and Quality

Substrate Preparation

The manufacturing process of aluminum base PCBs with 3oz copper begins with substrate preparation. The aluminum substrate is first cut to the desired size and shape using precision cutting techniques, such as CNC machining or laser cutting. After cutting, the surface of the aluminum substrate undergoes a series of treatments, including cleaning, degreasing, and surface roughening. These surface treatments are essential for improving the adhesion of the dielectric layers, ensuring a strong and reliable bond that is critical for the thermal and electrical performance of the PCB.

Dielectric Layer Lamination

Once the substrate is prepared, the dielectric layers are laminated onto the aluminum surface. High - pressure lamination processes are used to bond the dielectric materials firmly to the aluminum substrate. The lamination process requires precise control of temperature, pressure, and time to achieve a uniform and defect - free bond. The quality of the lamination directly impacts the thermal and electrical insulation properties of the PCB, as well as its overall mechanical strength.

Copper Layer Fabrication

Fabricating the 3oz copper layers involves several complex processes. First, the copper foil of the appropriate thickness is laminated onto the dielectric - coated aluminum substrate. Photolithography or laser direct imaging (LDI) techniques are then used to transfer the circuit pattern onto the copper foil with high precision. Chemical etching follows, selectively removing the unwanted copper to create the desired conductive traces and pads.

The copper layer fabrication process requires strict quality control to ensure accurate trace widths and spacing, especially for fine - pitch designs. Any deviation in the copper layer thickness or trace dimensions can affect the electrical performance of the PCB, leading to issues such as increased resistance, voltage drops, or signal integrity problems.

Surface Finishing and Component Assembly

To protect the copper traces and improve solderability, surface finishing processes are applied. Common surface finishes for these PCBs include electroless nickel immersion gold (ENIG), organic solderability preservative (OSP), or hot air solder leveling (HASL). Each surface finish has its own advantages and is selected based on the specific requirements of the application, such as the need for corrosion resistance, solderability, or cost - effectiveness.

Once the surface finishing is complete, the components are assembled onto the PCB using automated pick - and - place machines. Reflow soldering or wave soldering processes are then used to attach the components securely to the board. The assembly process requires careful control to ensure proper alignment and soldering of the components, as any assembly defects can lead to functional failures of the electronic device.

Diverse Applications of Aluminum Base PCB 3oz Copper

Power - Intensive Industrial Equipment

In industrial applications, such as power supplies, motor drives, and industrial control systems, high - power components generate a significant amount of heat and require high - current power delivery. Aluminum base PCBs with 3oz copper are ideal for these applications. The 3oz copper layers can handle the high currents with minimal resistance, reducing power losses and improving the efficiency of the power - conversion processes.

The excellent thermal management provided by the aluminum substrate ensures that the components remain cool during operation, even under continuous high - load conditions. This reliability is crucial in industrial settings, where downtime can result in significant losses. The mechanical strength of the PCB also allows it to withstand the vibrations and harsh environments typical of industrial applications.

High - Performance Computing Systems

In high - performance computing (HPC) systems, such as servers and supercomputers, the demand for power and heat dissipation is extremely high. Aluminum base PCBs with 3oz copper can meet these demands by providing efficient power delivery to the high - power processors, graphics processing units (GPUs), and other components. The 3oz copper layers reduce the resistance in the power delivery network, minimizing voltage drops and ensuring stable operation of the components.

The effective thermal management of these PCBs helps to keep the components at optimal temperatures, preventing thermal throttling and ensuring consistent high - performance operation. The ability to support high - density component integration, thanks to the reliable electrical and thermal performance of the PCB, is also essential in HPC systems where space is often at a premium.

Automotive Electronics

The automotive industry has strict requirements for the reliability and performance of electronic components. Aluminum base PCBs with 3oz copper are increasingly being used in automotive applications, such as engine control units (ECUs), advanced driver - assistance systems (ADAS), and automotive lighting. The 3oz copper layers can handle the high currents required by the power - hungry components in these systems, ensuring stable power supply.

The thermal management capabilities of the aluminum substrate are crucial in automotive environments, where components are exposed to a wide range of temperatures. The mechanical strength of the PCB allows it to withstand the vibrations and shocks experienced during vehicle operation. Additionally, the ability to support high - density component integration enables the development of smaller, more efficient automotive electronics, contributing to the overall performance and safety of the vehicle.

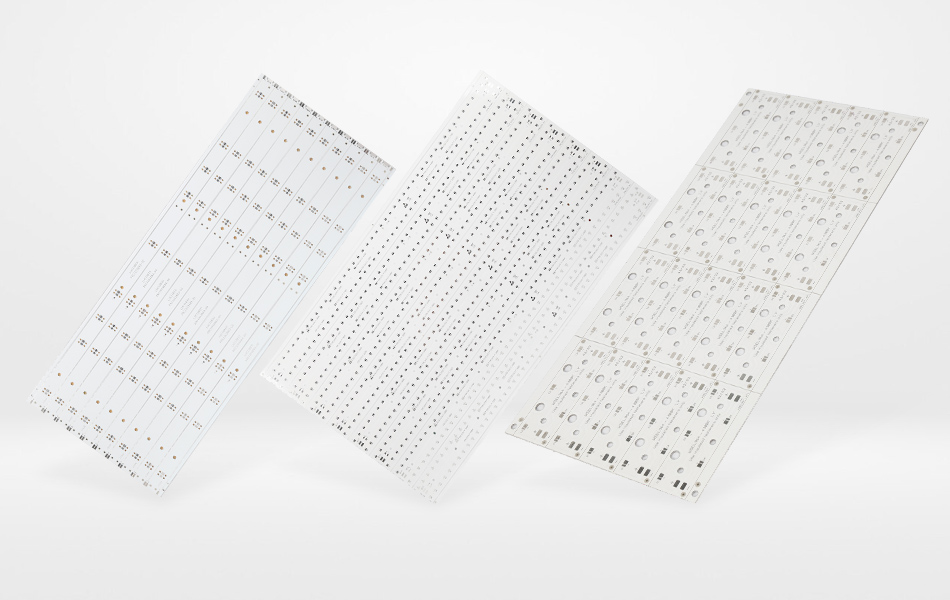

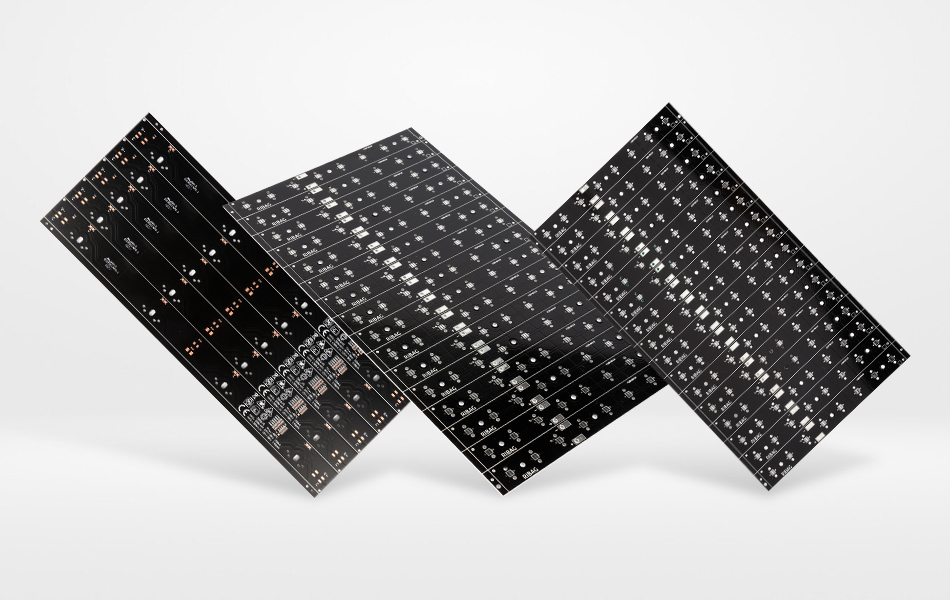

LED Lighting Systems

In LED lighting, especially in high - power applications such as streetlights, stadium lighting, and industrial lighting, aluminum base PCBs with 3oz copper offer significant advantages. LEDs generate a large amount of heat during operation, and effective thermal management is essential for their performance and lifespan. The aluminum substrate efficiently dissipates the heat from the LEDs, ensuring consistent light output and preventing color shift.

The 3oz copper layers can handle the high currents required by the LED arrays, reducing power losses and improving the energy efficiency of the lighting system. The robust mechanical design of the PCB also makes it suitable for outdoor applications, where it needs to withstand harsh weather conditions and mechanical stresses.

Emerging Trends and Future Outlook

Integration with Advanced Technologies

As technology continues to evolve, aluminum base PCBs with 3oz copper are likely to be integrated with more advanced technologies. The rise of the Internet of Things (IoT), artificial intelligence (AI), and 5G communication will require PCBs that can support high - speed data transfer, low - power operation, and intelligent control. These PCBs may be designed to incorporate sensors, wireless communication modules, and advanced control circuits, enabling the development of smart and connected electronic devices.

Miniaturization and High - Density Integration

The trend towards miniaturization in electronics is driving the development of smaller and more densely populated PCBs. Despite the relatively thick 3oz copper layers, advancements in manufacturing techniques, such as micro - via technology and fine - pitch trace routing, will enable the creation of aluminum base PCBs with 3oz copper that can support high - density component integration. This will be essential for applications such as wearable electronics, medical implants, and miniaturized sensors, where space is extremely limited but high - performance is still required.

Sustainable Manufacturing Practices

Sustainability is becoming an increasingly important consideration in the electronics industry. Manufacturers of aluminum base PCBs with 3oz copper are likely to adopt more sustainable manufacturing practices, such as using recycled materials for the aluminum substrate and copper layers, reducing energy consumption during manufacturing, and minimizing waste generation. These practices will not only benefit the environment but also help to reduce production costs and improve the overall competitiveness of the industry.

Enhanced Thermal and Electrical Performance Optimization

With the continuous increase in the power density of electronic components, there will be a growing demand for further enhancing the thermal and electrical performance of aluminum base PCBs with 3oz copper. Research and development efforts will focus on developing new materials, improving manufacturing processes, and optimizing design techniques to achieve even better heat dissipation, lower electrical resistance, and higher reliability. This will enable the development of more powerful and efficient electronic devices in the future.

Conclusion

Aluminum base PCBs with 3oz copper represent a significant advancement in electronic design, offering a unique combination of superior thermal management, high - current handling capabilities, and mechanical strength. Their applications span a wide range of industries, from power - intensive industrial equipment and high - performance computing systems to automotive electronics and LED lighting. As technology continues to evolve, these PCBs will play an even more crucial role in the development of future - proof electronic devices.

By staying at the forefront of material science, design innovation, and manufacturing excellence, engineers and designers can fully leverage the potential of aluminum base PCBs with 3oz copper to create innovative, reliable, and high - performance electronic solutions that meet the ever - growing demands of the modern world.va a

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB