-

- PCB TYPE

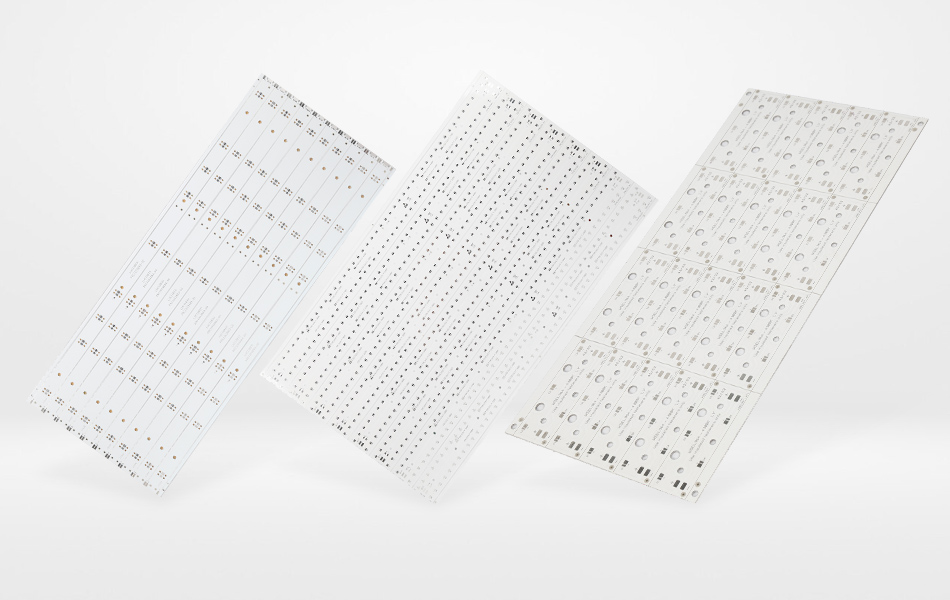

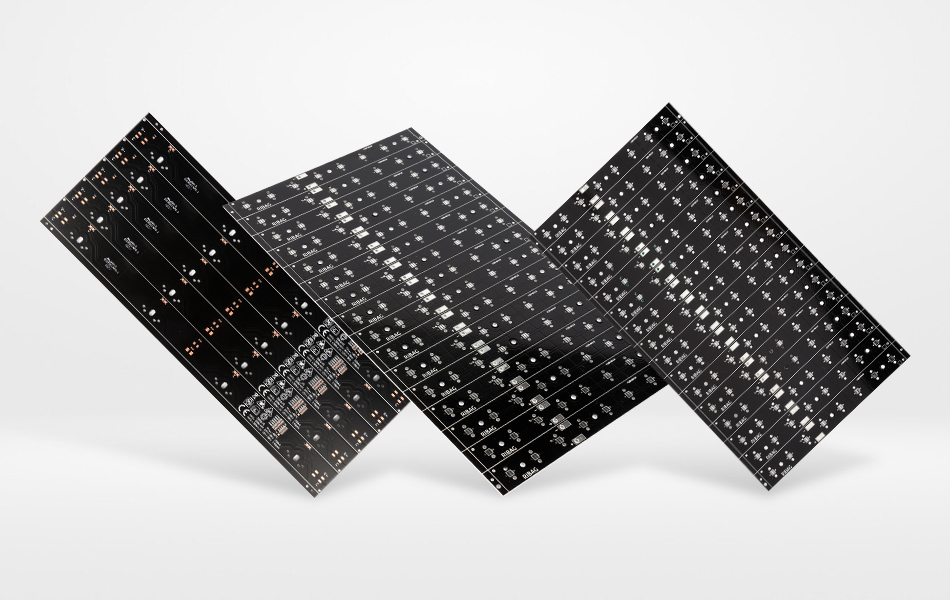

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 11. 2025, 09:05:08

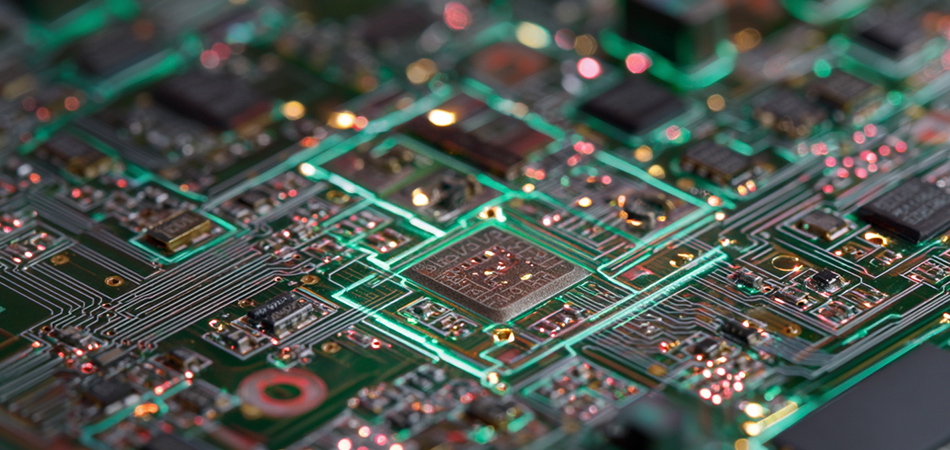

In the fast - paced evolution of modern electronics, the demand for efficient thermal management has become increasingly critical. As electronic devices grow smaller, more powerful, and more energy - dense, the need for materials that can effectively dissipate heat while maintaining mechanical and electrical reliability has never been greater. High conductivity aluminum base materials have emerged as a pivotal solution, offering a unique combination of superior thermal performance, mechanical robustness, and design flexibility. This article explores the technical nuances, applications, and future trends of high conductivity aluminum bases, highlighting their indispensable role in advancing electronic systems across industries.

The Science of High Conductivity Aluminum Base Materials

Fundamentals of Aluminum's Thermal Performance

Aluminum's prominence in thermal management stems from its inherent physical properties. As a metal, aluminum exhibits high thermal conductivity, allowing it to transfer heat rapidly from heat - generating components to the surrounding environment. This characteristic is particularly valuable in electronic applications where excessive heat can degrade component performance, reduce lifespan, or even cause catastrophic failure.

The thermal conductivity of aluminum is further optimized through alloying. Alloys such as those in the 6xxx series (e.g., 6061, 6063) are widely used in high conductivity aluminum bases. These alloys balance excellent thermal conductivity with mechanical strength and formability. For example, the addition of magnesium and silicon in 6xxx series alloys enhances their ability to conduct heat while providing the durability required for demanding environments.

Advantages Over Competing Materials

Thermal-Electrical-Mechanical Balance: Compared to copper, which has higher thermal conductivity but is heavier and more expensive, aluminum offers a superior strength - to - weight ratio and cost - effectiveness. In contrast to traditional PCB materials like FR4, which have poor thermal conductivity, aluminum bases provide a thermal pathway that is orders of magnitude more efficient, making them ideal for high - power applications.

Design Flexibility: Aluminum's malleability allows for the creation of complex shapes and thin profiles, enabling integration into compact electronic devices. It can be easily machined, drilled, or stamped, accommodating both simple and intricate designs without compromising thermal performance.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion in a variety of environments. This property is crucial for applications exposed to moisture, chemicals, or high humidity, ensuring long - term reliability without the need for additional protective coatings in many cases.

Design Principles for High Conductivity Aluminum Bases

Thermal Management Strategies

Component Placement and Heat Flow Optimization

The primary goal in designing with high conductivity aluminum bases is to create a seamless thermal pathway from components to the environment. Heat - generating components such as power transistors, integrated circuits, or LEDs should be positioned directly over the aluminum base to maximize surface contact. This direct contact minimizes thermal resistance, allowing heat to flow efficiently from the component junction to the base and subsequently to heat sinks or the ambient air.

Thermal vias or through - holes can be incorporated to connect upper copper layers (in PCBs) or component mounting surfaces to the aluminum base. These vias act as thermal bridges, enhancing heat dissipation in multi - layer configurations. In some designs, the aluminum base itself may serve as a passive heat sink, eliminating the need for additional bulky cooling components and saving valuable space.

Integration with Active and Passive Cooling

For high - power applications, combining the aluminum base with active cooling solutions (such as fans or liquid cooling systems) or passive solutions (heat sinks, heat pipes, or vapor chambers) can further enhance thermal performance. The aluminum base acts as a heat spreader, distributing heat evenly across the surface of the heat sink or cooling system, improving their efficiency. In passive cooling scenarios, the base's large surface area and high thermal conductivity enable effective natural convection, making it suitable for applications where active cooling is impractical or undesirable.

Mechanical Design Considerations

Structural Reinforcement: While aluminum is mechanically strong, high conductivity aluminum bases can be reinforced with additional layers or mechanical features (such as ribs or stiffeners) in applications subject to high vibrations or mechanical stress. This ensures that the base maintains its shape and thermal contact with components over time.

Mounting and Integration: The design must facilitate secure mounting of the aluminum base within the electronic enclosure. This may involve incorporating mounting holes, clips, or adhesive interfaces that maintain thermal conductivity while providing mechanical stability. In PCB applications, the aluminum base can be laminated with dielectric layers to create a unified structure that supports both thermal and electrical functions.

Electrical Design for Compatibility

In applications where the aluminum base is part of a printed circuit board (PCB), electrical insulation between the base and copper traces is critical. Dielectric layers with high thermal conductivity and electrical isolation properties (such as ceramic - filled epoxies or polyimides) are used to separate the aluminum base from the conductive copper layers. These dielectric materials must strike a balance between efficient heat transfer to the base and reliable electrical insulation to prevent short circuits.

For high - frequency applications, the aluminum base can also serve as a grounding plane, reducing electromagnetic interference (EMI) and improving signal integrity. Its large surface area provides a low - impedance return path for signals, minimizing noise and ensuring stable operation of high - speed circuits.

Manufacturing Processes for High Conductivity Aluminum Bases

Substrate Preparation

The manufacturing journey begins with selecting the appropriate aluminum alloy and processing it into the desired form. Raw aluminum sheets or plates are cut to size using precision methods such as CNC machining or laser cutting. Surface treatments follow to enhance the base's compatibility with subsequent layers or components:

Cleaning and Degreasing: Removing contaminants such as oils or oxides to ensure proper adhesion of dielectric layers or thermal interface materials.

Surface Roughening: Techniques like micro - etching or sandblasting create a textured surface, improving the bond strength between the aluminum base and adjacent materials (e.g., dielectric layers in PCBs or thermal pastes in component mounting).

Dielectric Layer Lamination (for PCB Applications)

When used in PCBs, high conductivity aluminum bases are typically laminated with dielectric layers on one or both sides:

Dielectric Material Selection: Materials like ceramic - filled epoxies are chosen for their moderate thermal conductivity and excellent electrical insulation. Polyimides may be used in high - temperature applications for their thermal stability and low dielectric loss.

Lamination Process: High - pressure and temperature processes bond the dielectric layers to the aluminum base, creating a uniform and void - free interface. This step is critical for maintaining thermal conductivity between the copper traces (on the dielectric surface) and the aluminum base.

Copper Layer Fabrication (for PCB Integration)

In PCB applications, copper layers are added to the dielectric - coated aluminum base:

Copper Foil Lamination: Electrolytic copper foil is laminated onto the dielectric layers, providing the conductive pathways for electrical signals and power.

Circuit Pattern Formation: Photolithography or laser direct imaging (LDI) is used to transfer circuit patterns onto the copper foil. Chemical etching then removes unwanted copper, leaving behind precisely shaped traces and pads.

Surface Finishing and Coating

Depending on the application, the aluminum base or PCB may undergo surface finishing:

Thermal Interface Materials: In component mounting, thermal pastes or pads are applied to the aluminum surface to enhance heat transfer between the component and the base.

Protective Coatings: In outdoor or corrosive environments, anodizing or powder coating may be applied to the aluminum base to further enhance its corrosion resistance without significantly impacting thermal performance.

Industrial Applications of High Conductivity Aluminum Bases

Power Electronics and Energy Systems

Power Converters and Inverters: High conductivity aluminum bases are essential in power electronics where components like IGBTs and MOSFETs generate substantial heat. The base efficiently dissipates this heat, preventing thermal runaway and ensuring stable power conversion in applications such as renewable energy inverters, electric vehicle (EV) battery chargers, and industrial motor drives.

Battery Management Systems (BMS): In EVs and energy storage systems, BMS modules use aluminum bases to manage heat from battery cells and monitoring circuits. This helps maintain optimal battery operating temperatures, improving safety and extending battery life.

LED Lighting Solutions

High - Power LED Fixtures: LEDs in commercial, industrial, and outdoor lighting generate heat that can degrade light output and color quality. High conductivity aluminum bases act as integrated heat sinks, allowing compact LED fixtures to operate efficiently without bulky external cooling. This is particularly important in applications like streetlights, stadium lighting, and architectural LED installations where reliability and energy efficiency are paramount.

Automotive Lighting: In vehicle headlights and taillights, aluminum bases enable the integration of high - power LEDs in tight spaces. Their thermal and mechanical properties ensure consistent performance in the vibration - and temperature - prone environment of automotive applications.

Automotive Electronics

Engine Control Units (ECUs): ECUs are exposed to extreme under - hood temperatures and vibrations. High conductivity aluminum bases provide reliable thermal management for microprocessors and sensors, ensuring consistent operation of critical engine control functions.

Advanced Driver - Assistance Systems (ADAS): ADAS modules, which include cameras, radar, and lidar systems, rely on aluminum bases to dissipate heat from high - performance processors. This ensures stable operation of these safety - critical systems in all weather conditions.

Aerospace and Defense

Avionics Systems: In aircraft and spacecraft, weight and reliability are critical. High conductivity aluminum bases offer a lightweight thermal solution for avionics components, helping to reduce overall vehicle weight while ensuring components operate within temperature limits during flight.

Military Electronics: Ruggedized military devices, such as portable radios and missile guidance systems, use aluminum bases to withstand harsh environments (including extreme temperatures, shocks, and vibrations) while efficiently managing heat from high - power components.

Consumer Electronics

Portable Devices: Laptops, tablets, and gaming consoles use aluminum bases to manage heat from multi - core processors and high - performance GPUs. The thin and lightweight nature of these bases allows for sleek device designs without compromising thermal performance.

Wearable Technology: Smartwatches and fitness trackers rely on high conductivity aluminum bases to dissipate heat from compact components, ensuring comfortable wear and extended battery life in devices where space is extremely limited.

Emerging Trends and Future Innovations

Miniaturization and High - Density Integration

As electronics continue to miniaturize, high conductivity aluminum bases are being engineered for even thinner profiles and higher component densities. Advanced manufacturing techniques, such as laser - drilled microvias and nanoscale surface treatments, enable better heat transfer in compact designs. This trend is particularly evident in IoT sensors, 5G small cells, and wearable devices, where every millimeter of space and every degree of temperature control matter.

Composite Materials and Hybrid Solutions

Hybrid Aluminum - Ceramic Bases: Combining aluminum with ceramic fillers or carbon - based materials creates composites with enhanced thermal conductivity and mechanical properties. These hybrids can handle higher power densities and extreme temperatures, opening up new applications in high - performance computing and aerospace.

Phase - Change Material (PCM) Integration: PCMs that absorb and store heat can be integrated with aluminum bases to create passive thermal regulation systems. This is especially useful in intermittent - use devices or environments with fluctuating temperature demands.

Sustainable Manufacturing and Green Electronics

Recycled Aluminum Sources: With increasing environmental awareness, manufacturers are using recycled aluminum in high conductivity bases, reducing the carbon footprint without compromising performance.

Energy - Efficient Processes: Innovations in lamination and machining processes are reducing energy consumption during production, aligning with global sustainability goals.

Smart Thermal Management Systems

The integration of sensors and feedback mechanisms with high conductivity aluminum bases is leading to smart thermal management solutions. These systems can dynamically adjust cooling strategies based on real - time temperature data, optimizing energy use and component lifespan in applications such as data centers and electric vehicles.

Conclusion

High conductivity aluminum bases have revolutionized thermal management in electronics, offering a versatile and reliable solution for a wide range of applications. Their unique combination of thermal efficiency, mechanical strength, and design flexibility makes them indispensable in industries from power electronics to aerospace. As technology advances towards higher power densities, smaller form factors, and greater sustainability, these bases will continue to evolve, incorporating new materials and manufacturing techniques to meet the ever - growing demands of the electronic frontier. For engineers and designers, understanding the capabilities and potential of high conductivity aluminum bases is key to unlocking the next generation of efficient, reliable, and innovative electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB