-

- PCB TYPE

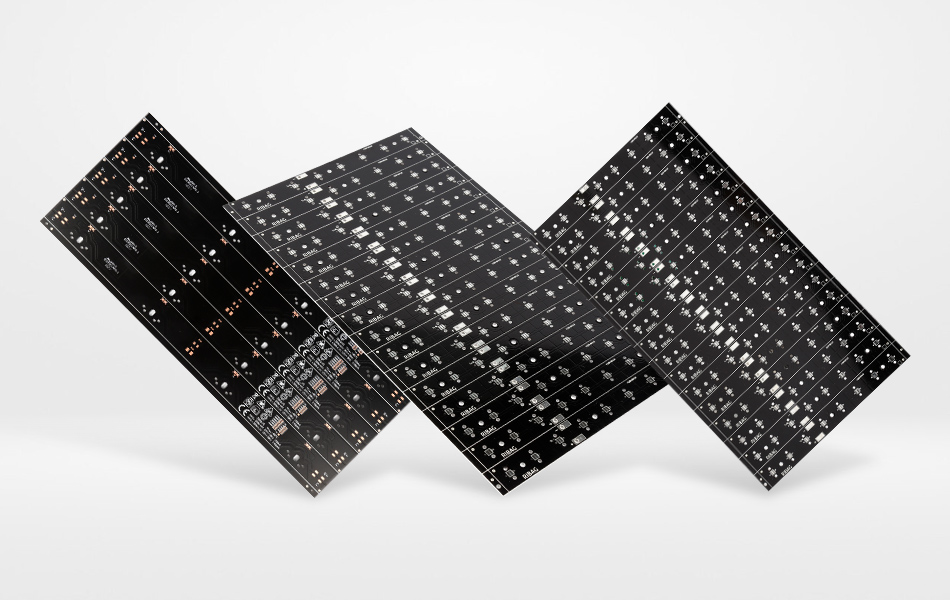

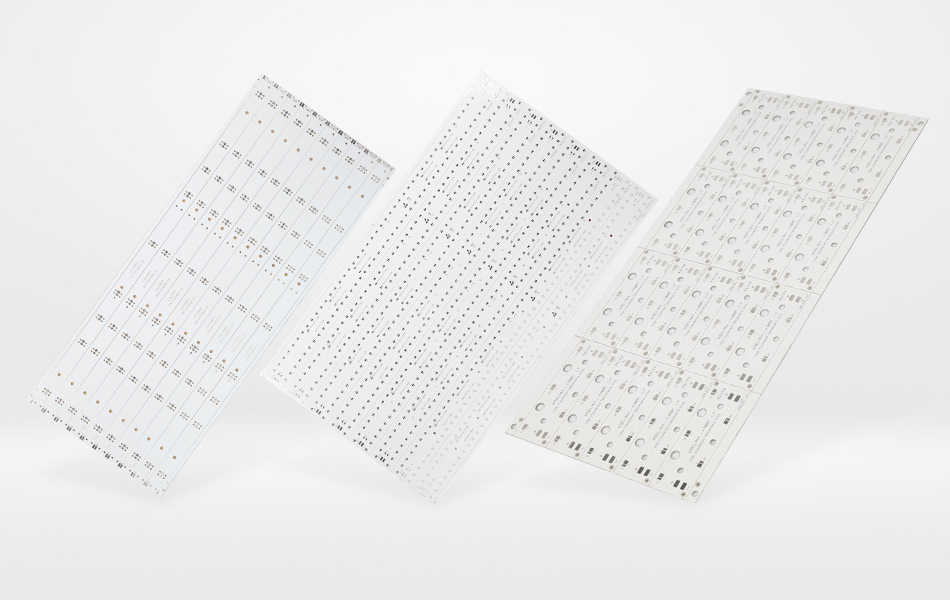

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 16. 2025, 09:35:15

Aluminum printed circuit board (PCB) structure design represents a specialized discipline that merges thermal management, electrical engineering, and material science to create high-performance electronic platforms. Unlike traditional FR4 PCBs, aluminum-based designs leverage the unique properties of aluminum—excellent thermal conductivity, mechanical rigidity, and cost efficiency—to address the demands of power-dense applications. This comprehensive guide outlines the fundamental principles, design methodologies, and best practices for developing robust aluminum PCB structures, equipping engineers with the knowledge to optimize thermal dissipation, signal integrity, and mechanical reliability in their designs.

Foundational Concepts: Aluminum PCB Structure Fundamentals

Definition and Core Purpose

An aluminum PCB structure consists of layered materials engineered to facilitate three primary functions: electrical signal/power distribution, thermal dissipation, and mechanical support. The defining feature—the aluminum substrate—serves as both a heat-dissipating element and a structural backbone, distinguishing it from conventional PCBs that rely on non-conductive cores. This dual functionality makes aluminum PCBs indispensable in applications where heat management directly impacts performance and longevity, such as LED lighting, power converters, and automotive electronics.

Key Design Drivers in Aluminum PCB Structure

Effective aluminum PCB design balances three critical considerations:

Thermal Performance: The structure must create low-resistance pathways for heat transfer from components to the aluminum substrate, minimizing hotspots that can degrade performance.

Electrical Integrity: Layer configurations must maintain signal integrity (for high-frequency designs) and current-carrying capacity (for power applications) through strategic material selection and layer arrangement.

Mechanical Stability: The structure must withstand thermal cycling, vibration, and environmental stress without delamination or dimensional changes that could compromise component connections.

These drivers influence every aspect of structure design, from material selection to layer stacking sequences.

Material Interaction Principles

Successful aluminum PCB structures depend on harmonious interaction between components:

Adhesion Compatibility: The dielectric layer must form strong bonds with both the aluminum substrate and copper conductive layers to prevent delamination during thermal expansion/contraction.

Thermal Coefficient Matching: Materials with complementary thermal expansion rates minimize stress during temperature fluctuations—a critical consideration in automotive and aerospace applications with extreme operating ranges.

Electrical Isolation: The dielectric layer must provide sufficient insulation between conductive copper and aluminum while enabling efficient heat transfer, creating a balance that defines aluminum PCB performance.

Core Components of Aluminum PCB Structure

Aluminum Substrate: Foundation and Heat Sink

The aluminum substrate forms the structural and thermal foundation of the PCB:

Alloy Selection Factors: Aluminum alloys are chosen based on thermal conductivity requirements, mechanical strength needs, and environmental resistance. Common selections include 6xxx series alloys for general-purpose applications and 5xxx series for enhanced corrosion resistance in marine or industrial environments.

Surface Preparation Techniques: Substrate surfaces undergo treatments like etching, anodization, or conversion coating to enhance dielectric adhesion and corrosion resistance. These processes create micro-roughness that improves mechanical bonding while maintaining thermal conductivity.

Thickness Considerations: Substrate thickness varies based on thermal load and mechanical requirements—thicker substrates provide greater heat capacity for high-power devices, while thinner variants reduce weight in portable electronics.

Dielectric Layer: The Critical Interface

The dielectric layer serves as both insulator and thermal conduit:

Material Classifications: Polyimide-based dielectrics offer high-temperature stability, ceramic-filled epoxies provide enhanced thermal conductivity, and silicone composites excel in flexible applications. Selection depends on operating temperature range, thermal performance needs, and flexibility requirements.

Thickness Optimization: Thinner dielectrics improve thermal transfer but require higher dielectric strength, while thicker layers enhance insulation for high-voltage applications. Designers balance these factors based on voltage levels and heat flux requirements.

Adhesion Mechanisms: Dielectrics bond to aluminum substrates through mechanical interlocking, chemical adhesion, or a combination of both. Advanced formulations include coupling agents that improve bonding at the molecular level.

Conductive Copper Layers: Signal and Power Distribution

Copper layers enable electrical functionality while contributing to thermal management:

Foil Types and Properties: Electrolytic copper offers cost advantages for general applications, while rolled copper provides superior surface smoothness for high-frequency signals. Annealed copper enhances flexibility in bendable PCBs.

Thickness Variability: Copper weight varies based on current requirements—thicker copper handles higher currents in power applications, while thinner foils enable finer trace geometries for dense digital circuits.

Patterned vs. Solid Layers: Signal layers feature etched traces for routing, while solid copper planes (power or ground) enhance thermal dissipation and reduce EMI. Hybrid configurations combine both approaches in multi-layer designs.

Design Methodologies for Aluminum PCB Structure

Application-Driven Design Approach

Effective aluminum PCB structures begin with application requirements analysis:

Power Electronics Focus: High-current designs prioritize thick copper layers, large thermal vias, and direct copper-to-aluminum thermal paths. The structure emphasizes low resistance and maximum heat dissipation for components like MOSFETs and IGBTs.

High-Frequency Applications: Structures for RF and microwave circuits focus on controlled impedance, low-loss dielectrics, and smooth copper surfaces to minimize signal attenuation. Ground plane design and EMI shielding become critical structural considerations.

Flexible Electronics Requirements: Bendable aluminum PCBs feature thin substrates, flexible dielectrics, and strain-relief trace patterns. The structure balances flexibility with thermal performance for applications like wearable devices and curved displays.

Thermal-First Design Methodology

Thermal considerations drive structural decisions in aluminum PCB design:

Heat Source Mapping: Identifying primary heat-generating components early determines substrate thickness, via placement, and copper distribution. High-power devices require dedicated thermal paths to the aluminum substrate.

Thermal Via Optimization: Strategic via placement creates vertical thermal conduction paths from copper layers to aluminum. Via size, density, and distribution patterns are engineered to match heat flux patterns.

Copper Plane Design: Solid or hatched copper planes act as heat spreaders, distributing thermal energy across the PCB surface for more uniform dissipation through the aluminum substrate.

Electrical Performance Integration

Electrical requirements influence structural configuration:

Impedance Control: Dielectric thickness, copper weight, and trace geometry are precisely controlled to achieve target impedance values, critical for high-speed digital and RF designs.

Power Distribution Network: Multi-layer structures incorporate dedicated power planes sized to minimize voltage drop, with sufficient copper cross-section to handle current demands without excessive heating.

EMI Mitigation: Ground plane placement, trace spacing, and shielding structures within the PCB layout reduce electromagnetic interference, ensuring signal integrity in sensitive applications.

Layer Configuration Strategies

Single-Layer Aluminum PCB Structures

Basic configurations for cost-sensitive, low-complexity applications:

Structure Overview: A single copper layer bonded to an aluminum substrate via dielectric, featuring etched traces for simple circuits. Ideal for LED modules, basic sensors, and low-power devices.

Design Considerations: Component placement prioritizes thermal proximity to the aluminum substrate. Trace routing balances current capacity with space constraints, often using wider traces for power paths.

Limitations and Advantages: Cost-effective and easy to manufacture but limited in complexity and thermal management capabilities compared to multi-layer designs.

Multi-Layer Aluminum PCB Structures

Advanced configurations for complex, high-performance applications:

Layer Stacking Principles: Signal, power, and ground layers are arranged to optimize thermal and electrical performance. Common configurations include signal-dielectric-ground-aluminum or signal-power-dielectric-aluminum structures.

Interlayer Connection: Plated through-holes and microvias provide electrical and thermal connections between layers. Via design includes thermal vias (larger, unplated) for heat transfer and signal vias for electrical connectivity.

Design Complexity Management: Layer count is minimized while meeting performance requirements, balancing thermal benefits with manufacturing costs. Four to six-layer structures are common in automotive and industrial electronics.

Hybrid Structure Innovations

Specialized configurations merging aluminum and traditional PCB technologies:

Aluminum-Core FR4 Hybrids: Structures combining aluminum-core sections for thermal management with FR4 sections for high-density interconnects, ideal for mixed-signal applications with both power and data components.

Flex-Rigid Aluminum PCBs: Rigid aluminum-core sections connected via flexible polyimide segments, enabling 3D assembly and dynamic applications while maintaining thermal performance.

Embedded Component Structures: Components partially or fully embedded within dielectric layers reduce thermal resistance, creating direct thermal paths to the aluminum substrate for enhanced heat dissipation.

Mechanical Design and Reliability Considerations

Structural Integrity Engineering

Mechanical robustness ensures long-term performance:

Thermal Cycling Resistance: Layer materials and bonding techniques are selected to withstand repeated temperature fluctuations without delamination or cracking. Thermal stress analysis identifies potential failure points during design.

Vibration and Shock Tolerance: Structural reinforcement around connectors and heavy components prevents solder joint fatigue in high-vibration environments like automotive and aerospace applications. Substrate thickness and mounting design are critical factors.

Environmental Protection: Coating selections (conformal coatings, potting compounds) and edge sealing techniques protect aluminum PCB structures from moisture, chemicals, and contaminants in harsh environments.

Dimensional Stability Control

Maintaining precise dimensions under operational conditions:

Warpage Prevention: Symmetrical layer designs, balanced copper distribution, and controlled curing processes minimize warpage during manufacturing and operation. Substrate thickness and material selection influence dimensional stability.

Thermal Expansion Management: Material selection and layer arrangement compensate for differential expansion between aluminum, copper, and dielectric. This is particularly critical for large-format PCBs and those with tight component placement tolerances.

Mounting Considerations: PCB mounting points are strategically placed to distribute mechanical stress evenly, avoiding localized pressure that could cause substrate deformation or component damage.

Validation and Testing for Aluminum PCB Structures

Thermal Performance Verification

Ensuring effective heat dissipation through testing:

Infrared Thermography: Visualizes temperature distribution across the PCB surface, identifying hotspots and validating thermal via effectiveness and copper spreader performance.

Thermal Resistance Measurement: Quantifies heat transfer efficiency from component junctions to ambient air, verifying thermal path effectiveness in the structure design.

Thermal Cycling Testing: Subjects PCBs to repeated temperature extremes to evaluate structural integrity and performance degradation over time, simulating long-term operational conditions.

Electrical Performance Validation

Confirming electrical functionality meets design requirements:

Signal Integrity Testing: Evaluates high-frequency performance through time-domain reflectometry (TDR) and eye diagram analysis, ensuring impedance control and minimal signal distortion.

Power Distribution Testing: Verifies current handling capability and voltage regulation across power planes, ensuring sufficient copper cross-section and minimal voltage drop under load.

EMI/EMC Testing: Measures electromagnetic emissions and susceptibility, validating shielding effectiveness and grounding strategies in the PCB structure.

Mechanical Reliability Assessment

Validating structural robustness through physical testing:

Peel Strength Testing: Measures bond strength between layers, ensuring adhesion meets industry standards and application requirements.

Bend Testing: For flexible aluminum PCBs, evaluates performance under repeated bending cycles, verifying copper trace integrity and layer adhesion.

Environmental Exposure Testing: Subjects PCBs to humidity, temperature, and chemical exposure to validate corrosion resistance and long-term reliability in target environments.

Emerging Trends in Aluminum PCB Structure Design

Advanced Material Integration

Next-generation materials are expanding structural capabilities:

Graphene-Enhanced Dielectrics: Nanomaterial integration improves thermal conductivity while maintaining electrical insulation, enabling thinner dielectrics with superior heat transfer.

Metal Matrix Composites: Aluminum substrates reinforced with ceramic particles or carbon fibers offer enhanced thermal conductivity and mechanical strength for extreme applications.

Phase-Change Materials: Integration of PCMs within PCB structures provides passive thermal regulation, absorbing excess heat during peak power events in high-density designs.

AI-Driven Design Optimization

Intelligent design tools are transforming structural engineering:

Generative Design Algorithms: AI-powered tools create optimized PCB structures based on thermal, electrical, and mechanical constraints, exploring design possibilities beyond human intuition.

Predictive Modeling: Machine learning models predict thermal performance, reliability, and manufacturing outcomes based on structural parameters, reducing prototyping needs.

Digital Twins: Virtual replicas of aluminum PCB structures enable real-time performance monitoring and predictive maintenance, optimizing design iterations and operational efficiency.

Sustainable Design Practices

Eco-friendly approaches in aluminum PCB structure design:

Recycled Aluminum Integration: Use of recycled aluminum substrates maintains performance while reducing environmental impact and material costs.

Lead-Free and Halogen-Free Materials: Compliance with environmental regulations drives adoption of sustainable dielectric and solder materials in PCB structures.

Energy-Efficient Manufacturing: Process optimization reduces energy consumption in aluminum PCB production, aligning with global sustainability initiatives.

Conclusion: Engineering Excellence in Aluminum PCB Structure Design

Aluminum PCB structure design represents a sophisticated balance of thermal management, electrical performance, and mechanical reliability. By leveraging aluminum's unique properties and advanced material combinations, engineers can create electronic platforms that meet the demanding requirements of modern applications—from high-power industrial systems to precision consumer electronics. Successful designs begin with application-specific requirements analysis, employ thermal-first engineering principles, and validate performance through comprehensive testing. As materials advance and design tools evolve, aluminum PCB structures will continue to enable innovation across industries, providing efficient thermal solutions for increasingly power-dense electronic systems. This guide serves as a foundation for engineers seeking to harness the full potential of aluminum PCB technology in their designs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB