-

- PCB TYPE

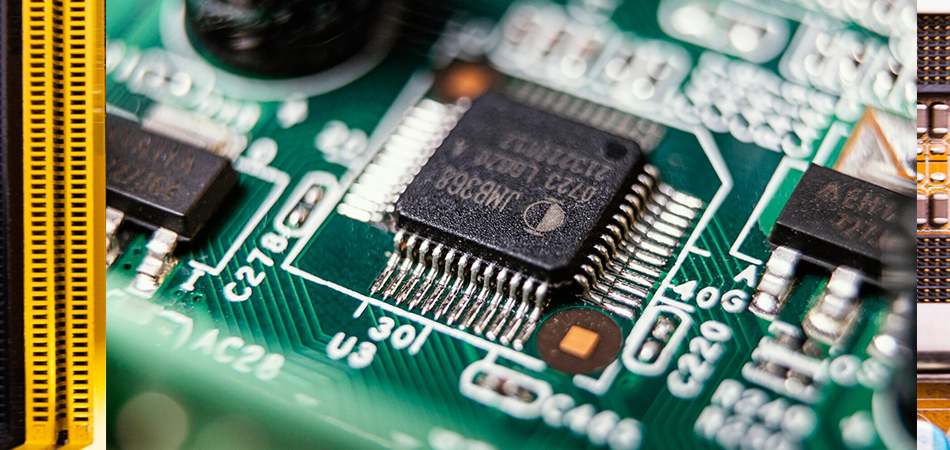

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 25. 2025, 09:48:51

In the ever - evolving landscape of lighting technology, Aluminum PCB LED model lights have emerged as a game - changer. These lights combine the efficiency of Light - Emitting Diodes (LEDs) with the thermal management capabilities of Aluminum Printed Circuit Boards (PCBs), resulting in a lighting solution that is not only energy - efficient but also highly reliable and versatile.

LEDs have revolutionized the lighting industry due to their long lifespan, low power consumption, and high luminous efficacy. However, to fully realize their potential, effective heat management is crucial. This is where Aluminum PCBs come into play. Aluminum has excellent thermal conductivity, which allows it to dissipate heat generated by LEDs quickly, ensuring their optimal performance and longevity. Aluminum PCB LED model lights are designed to meet the diverse lighting needs of various applications, from architectural and automotive lighting to consumer electronics and industrial settings.

Structure and Components of Aluminum PCB LED Model Lights

Aluminum PCB Substrate

The heart of an Aluminum PCB LED model light is the aluminum substrate. Aluminum is chosen for its high thermal conductivity, which is several times better than that of traditional FR - 4 (fiberglass - reinforced epoxy) PCBs. This high thermal conductivity enables the aluminum substrate to act as an efficient heat sink, drawing heat away from the LEDs.

The aluminum substrate typically consists of a base layer of aluminum alloy. Different aluminum alloys are used depending on the specific requirements of the application. For example, alloys with higher thermal conductivity, such as 6061 or 7075 aluminum, are preferred in high - power lighting applications where significant heat dissipation is required. The surface of the aluminum substrate may be treated to improve its adhesion to the dielectric layer and to enhance its corrosion resistance.

Dielectric Layer

Lying between the aluminum substrate and the copper traces is the dielectric layer. The dielectric layer serves two main purposes: electrical insulation and thermal conduction. It prevents electrical short - circuits between the copper traces and the aluminum substrate while allowing heat to flow from the LEDs through the copper traces and into the aluminum substrate.

Common materials used for the dielectric layer in Aluminum PCB LED model lights include thermally conductive polymers and composites. These materials are formulated to have high dielectric strength to withstand the electrical voltages present in the lighting circuit. Additionally, they are filled with thermally conductive fillers, such as aluminum oxide or boron nitride, to improve their thermal conductivity. The thickness of the dielectric layer is carefully controlled to balance electrical insulation and thermal performance.

Copper Traces

The copper traces on the Aluminum PCB are responsible for carrying the electrical current to the LEDs. Copper is an ideal material for this purpose due to its high electrical conductivity. High - purity copper is used to minimize resistance in the traces, which helps to reduce power losses and ensures that the LEDs receive a stable and efficient power supply.

The layout of the copper traces is designed to meet the specific electrical requirements of the LEDs. In a typical Aluminum PCB LED model light, the traces are routed to connect the power source to the LEDs in a way that evenly distributes the current. The width and thickness of the copper traces are determined based on the amount of current they need to carry. Thicker traces can handle higher currents, but they also increase the cost and weight of the PCB. Therefore, a balance must be struck between current - carrying capacity and cost - effectiveness.

LEDs

The LEDs themselves are the light - emitting components of the Aluminum PCB LED model light. There are various types of LEDs available, each with its own characteristics in terms of color, brightness, and efficiency. In recent years, SMD (Surface - Mount Device) LEDs have become increasingly popular in Aluminum PCB LED model lights due to their small size and high luminous density.

SMD LEDs are directly mounted onto the surface of the Aluminum PCB, which simplifies the assembly process and allows for a more compact lighting design. The choice of LED depends on the intended application of the model light. For example, in architectural lighting, LEDs with high Color Rendering Index (CRI) are preferred to accurately reproduce colors. In automotive lighting, LEDs with specific beam patterns and high brightness levels are used to meet safety and visibility requirements.

Advantages of Aluminum PCB LED Model Lights

Superior Heat Dissipation

One of the most significant advantages of Aluminum PCB LED model lights is their exceptional heat - dissipation capabilities. As mentioned earlier, the high thermal conductivity of the aluminum substrate allows heat to be quickly transferred away from the LEDs. This is crucial because excessive heat can cause LEDs to degrade in performance over time, leading to a decrease in brightness and color shift.

By maintaining the LEDs at a lower operating temperature, Aluminum PCB LED model lights can extend the lifespan of the LEDs significantly. In some cases, the lifespan of LEDs in an Aluminum PCB - based lighting system can be up to three times longer than in a traditional FR - 4 PCB - based system. This not only reduces the frequency of replacement but also lowers the overall cost of ownership for the end - user.

Compact and Lightweight Design

The combination of SMD LEDs and Aluminum PCBs enables a highly compact and lightweight design for model lights. SMD LEDs are much smaller than traditional through - hole LEDs, allowing for a higher density of LEDs to be placed on the PCB. The thin and lightweight nature of the aluminum substrate further contributes to the overall compactness of the lighting module.

This compact design is highly beneficial in applications where space is limited, such as in portable lighting devices, under - cabinet lighting, and automotive interior lighting. The reduced weight also makes Aluminum PCB LED model lights more suitable for applications where weight is a critical factor, such as in aerospace lighting.

Energy Efficiency

Aluminum PCB LED model lights are highly energy - efficient. LEDs themselves are known for their low power consumption compared to traditional lighting sources, such as incandescent bulbs and fluorescent tubes. The efficient heat management provided by the aluminum PCB ensures that the LEDs operate at their optimal efficiency.

When LEDs are not overheated, they can convert a higher percentage of electrical energy into light energy. This results in lower energy consumption for the same level of brightness. In addition, the long lifespan of LEDs in Aluminum PCB - based lighting systems means that there is less need for frequent replacements, which also contributes to overall energy savings.

High Reliability

The robust construction of Aluminum PCB LED model lights makes them highly reliable. The aluminum substrate provides a stable and rigid base for the LEDs and other components, protecting them from mechanical stress, vibration, and shock. The multi - layer structure of the PCB, with its carefully designed dielectric and copper trace layers, ensures the integrity of the electrical circuits.

Furthermore, the superior heat - dissipation capabilities of the aluminum PCB prevent thermal stress on the LEDs, reducing the likelihood of component failure. This high level of reliability makes Aluminum PCB LED model lights suitable for applications where continuous and reliable lighting is essential, such as in industrial environments, outdoor lighting, and emergency lighting systems.

Design Considerations for Aluminum PCB LED Model Lights

Thermal Design

LED Placement

Proper placement of LEDs on the Aluminum PCB is crucial for effective heat dissipation. LEDs should be positioned in a way that maximizes their contact with the aluminum substrate. This can be achieved by placing them directly over thermal vias or in areas of the PCB with high thermal conductivity.

Thermal vias are small holes drilled through the PCB that are filled with a conductive material, usually copper. They provide an additional path for heat to flow from the LEDs to the aluminum substrate. By placing LEDs near thermal vias, heat can be quickly transferred away from the LEDs, reducing their operating temperature. In addition, the layout of LEDs should be designed to ensure even heat distribution across the PCB. Avoiding clustering of high - power LEDs in a single area helps to prevent the formation of hotspots, which can lead to uneven light output and reduced LED lifespan.

Thermal Via Design

The design of thermal vias is an important aspect of the thermal design of Aluminum PCB LED model lights. The size, number, and distribution of thermal vias need to be carefully optimized to ensure efficient heat transfer. Larger thermal vias can transfer more heat, but they also take up more space on the PCB, which may affect the layout of other components.

The number of thermal vias should be sufficient to handle the heat generated by the LEDs. The distribution of thermal vias should be based on the heat - generation patterns of the LEDs. In areas where more heat is generated, such as near high - power LEDs, more thermal vias should be placed. Advanced manufacturing techniques, such as blind and buried vias, can be used to improve the thermal performance of the PCB. Blind vias connect the outer layers of the PCB to an internal layer, while buried vias connect two internal layers. These types of vias can provide more efficient heat transfer paths without taking up additional surface space on the PCB.

Heat - Sink Integration

In some high - power applications, integrating a heat sink with the Aluminum PCB can further enhance heat dissipation. A heat sink is a component with a large surface area that is designed to transfer heat from the PCB to the surrounding environment. When integrating a heat sink, it is important to ensure good thermal contact between the heat sink and the aluminum substrate.

Thermal interface materials, such as thermal paste or pads, are used to fill the gaps between the heat sink and the aluminum substrate, improving heat transfer efficiency. The design of the heat sink, including its size, shape, and fin configuration, should be tailored to the specific heat - dissipation requirements of the lighting system. A well - designed heat - sink integration can significantly improve the performance and lifespan of the LEDs, while also considering factors such as cost, size, and aesthetics.

Electrical Design

Trace Routing

The routing of copper traces on the Aluminum PCB is critical for ensuring reliable electrical performance. The traces should be routed to minimize resistance, inductance, and capacitance, especially in high - current applications. Short and wide traces are preferred to reduce resistance and power losses. Sharp corners and bends in the traces should be avoided as they can increase inductance and cause signal integrity issues.

In addition, proper separation of power and signal traces is essential to prevent electromagnetic interference (EMI). Power traces carry the high - current power supply to the LEDs, while signal traces carry control signals. By separating these traces, the risk of EMI is reduced, ensuring stable operation of the lighting system. Shielding techniques, such as using ground planes or shielding layers, can also be employed for sensitive signal traces to further enhance signal integrity.

Power and Ground Plane Design

A well - designed power and ground plane is crucial for stable power distribution and reduced EMI in Aluminum PCB LED model lights. The power plane provides a low - impedance path for the power supply to the LEDs, ensuring a stable and consistent voltage. The ground plane serves as a reference for the electrical circuits and helps to reduce EMI by providing a return path for the current.

To minimize voltage drops and improve power distribution, the power and ground planes should be as large as possible. Decoupling capacitors should be strategically placed near the LEDs and other components to filter out high - frequency noise and stabilize the power supply. Proper grounding techniques, such as star grounding or single - point grounding, can also be implemented to reduce EMI and improve the overall electrical performance of the PCB.

Design for Manufacturability

Designing Aluminum PCB LED model lights with manufacturability in mind is essential for cost - effective production. Using standard SMD LED packages and component footprints simplifies the procurement process and reduces the risk of errors during assembly. Avoiding complex shapes and geometries in the PCB design makes the manufacturing process more straightforward, reducing production time and costs.

The design should also be compatible with the selected manufacturing processes, such as surface - mount technology (SMT) assembly, soldering, and testing. Clear design guidelines and specifications should be provided to the manufacturing team to ensure consistent and high - quality production. Consideration of factors such as solderability, component placement accuracy, and testability during the design phase can significantly improve the overall manufacturing efficiency.

Manufacturing Process of Aluminum PCB LED Model Lights

Material Preparation

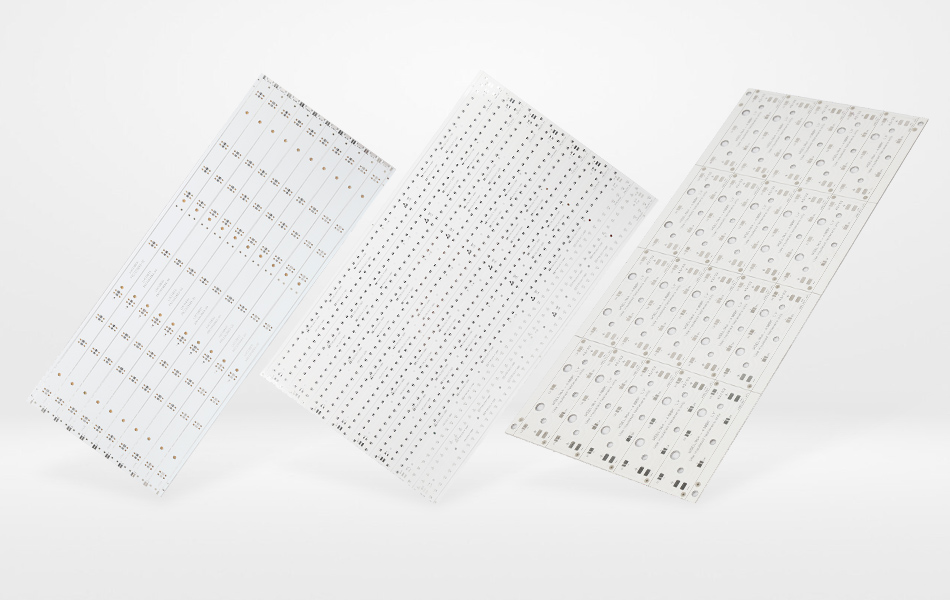

The manufacturing process of Aluminum PCB LED model lights begins with the careful selection and preparation of materials. High - quality aluminum sheets with the appropriate alloy composition are chosen based on the thermal and mechanical requirements of the PCB. These sheets are cut to the desired size and shape for the substrate.

The dielectric material, usually in the form of a pre - impregnated film or a liquid resin, is prepared. Pre - impregnated films are made by impregnating a base material, such as fiberglass, with a thermosetting resin and are cured to a semi - cured state for easy handling and lamination. Liquid resins are mixed with fillers and additives to achieve the desired electrical and thermal properties. High - purity copper foils are selected for the traces and undergo surface treatment to improve adhesion to the dielectric layer.

Lamination

Lamination is the process of bonding the aluminum substrate, dielectric layer, and copper foils together to form a single, cohesive structure. This is typically accomplished using heat and pressure in a laminator. The heat activates the thermosetting resin in the dielectric layer, causing it to flow and bond with the aluminum substrate and copper foils. The pressure ensures that the layers are in close contact, eliminating air gaps and voids.

Precise control of the lamination temperature, pressure, and time is crucial to achieve a high - quality bond. Different lamination techniques, such as vacuum lamination or press lamination, may be used depending on the specific requirements of the PCB. After lamination, the PCB is cooled and trimmed to the final dimensions.

Drilling and Plating

Following lamination, holes are drilled for vias, component mounting, and electrical connections. High - precision drilling machines are used to ensure accurate hole placement and clean hole walls. The drilled holes are then electroplated with copper to create electrical connections between the layers of the PCB.

Electroplating involves immersing the PCB in an electrolyte solution containing copper ions and applying an electric current. The copper ions are deposited on the surface of the holes and the copper traces, forming a continuous layer of copper. The thickness of the copper plating is carefully controlled to ensure proper electrical conductivity and mechanical strength.

Circuit Patterning

Circuit patterning is the process of creating the electrical circuits on the copper layers of the PCB. Photolithography is commonly used for this purpose. A photosensitive resist is applied to the copper surface, which is then exposed to ultraviolet (UV) light through a patterned mask. The areas of the resist exposed to UV light undergo a chemical change, making them soluble in a developer solution.

After development, the exposed copper areas are etched away using an etching solution, leaving behind the desired copper traces. This process requires high precision to ensure accurate trace widths, clearances, and the absence of shorts or open circuits. Advanced photolithography techniques and equipment are used to achieve the required level of precision in circuit patterning.

Surface - Mount Assembly

The surface - mount assembly process involves placing the SMD LEDs and other components onto the PCB. Automated pick - and - place machines are used to precisely position the components on the designated pads on the PCB. The components are then soldered to the PCB using reflow soldering or wave soldering techniques.

Reflow soldering is commonly used for SMD LED assembly. In this process, the PCB with the placed components is passed through a reflow oven, where the solder paste melts and bonds the components to the PCB. Proper control of the temperature profile in the reflow oven is essential to ensure good solder joints and reliable electrical connections.

Testing and Quality Control

After assembly, the Aluminum PCB LED model lights undergo a series of tests to ensure their functionality and quality. Electrical tests, such as continuity testing, voltage and current testing, and insulation resistance testing, are performed to verify the integrity of the electrical circuits. Optical tests are conducted to measure the light output, color temperature, and color rendering index of the LEDs.

Visual inspection is also carried out to check for any physical defects, such as solder bridges, missing components, or damaged traces. Automated optical inspection (AOI) and X - ray inspection can be used for more detailed and accurate quality control. Any defective model lights are identified and either repaired or discarded to ensure that only high - quality products are delivered to customers.

Applications of Aluminum PCB LED Model Lights

Architectural Lighting

Aluminum PCB LED model lights are widely used in architectural lighting to create stunning visual effects and enhance the aesthetics of buildings. They can be used for general illumination, accent lighting, and decorative lighting. In building facades, these model lights can be used to highlight architectural features, such as columns, arches, and cornices. The ability to control the color, intensity, and direction of the light allows for the creation of dynamic lighting displays that can change with the time of day or the occasion.

In interior spaces, Aluminum PCB LED model lights are used to provide ambient lighting, create focal points, and set the mood. For example, in a hotel lobby, they can be used to illuminate the reception area, while in a restaurant, they can be used to create a warm and inviting atmosphere. The compact and lightweight design of these model lights makes them suitable for installation in tight spaces, such as recessed lighting fixtures and cove lighting.

Automotive Lighting

Automotive lighting is another area where Aluminum PCB LED model lights are making significant inroads. In headlights, these model lights offer several advantages over traditional lighting sources. LEDs are more energy - efficient, which helps to reduce the overall power consumption of the vehicle. They also have a faster response time, which is crucial for safety, as it allows for quicker activation of the headlights when needed.

Aluminum PCB LED model lights are also used in automotive interior lighting, such as dashboard lighting, reading lights, and ambient lighting. The ability to customize the color and intensity of the light allows for a more personalized driving experience. In addition, the high reliability of these model lights makes them suitable for use in the harsh environment of an automotive application, where they may be exposed to vibration, temperature changes, and moisture.

Consumer Electronics

In the world of consumer electronics, Aluminum PCB LED model lights are used in a variety of products, such as smartphones, tablets, laptops, and televisions. In smartphones, they are used for the backlighting of the display, which provides a bright and clear image. The energy - efficiency of LEDs helps to extend the battery life of the device, while the compact design of Aluminum PCB - based LED modules allows for a thinner and lighter form factor. This is especially important in the highly competitive smartphone market, where consumers

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB