-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 15. 2026, 09:40:07

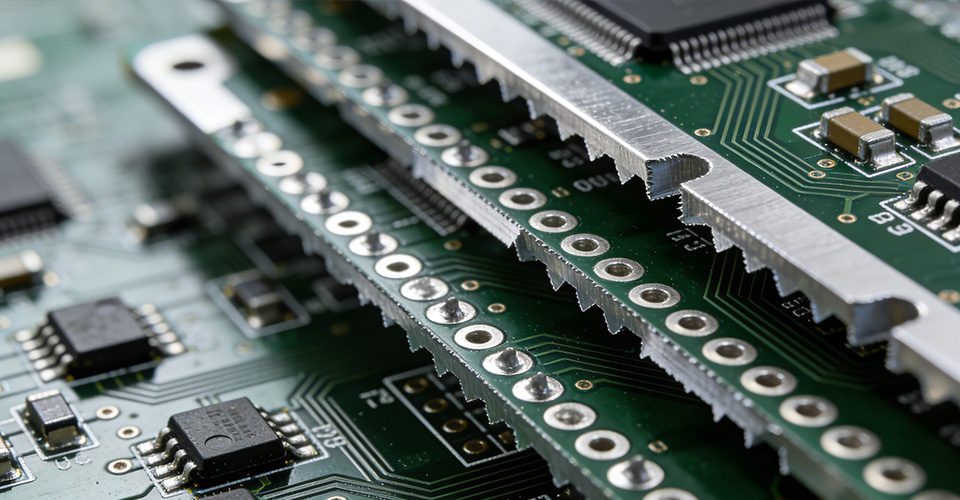

For factories producing LED lighting modules and high-power electronics, reliability usually comes down to one core challenge: heat. Excess heat accelerates LED lumen depreciation, increases driver failure rates, and reduces lifetime under thermal cycling. That’s why more engineering and procurement teams are selecting aluminum pcb solutions—especially in LED lighting, power conversion, automotive lighting, and industrial control—where thermal stability directly affects warranty cost and field returns.

This article explains what makes a dependable aluminum pcb manufacturer for LED and power programs, how to select material systems (including GDM aluminum based ccl and ventec aluminum based ccl), and why specifying high reflective soldermask can improve optical efficiency and production consistency for LED products.

An aluminum pcb uses a metal substrate to spread heat away from hotspots more efficiently than typical FR4 designs. For LED arrays and power devices, better heat spreading often means:

lower component operating temperature

improved efficiency and stability

longer product lifetime and fewer early failures

If your product is an LED module or LED panel, the PCB is essentially a thermal platform. A well-designed aluminum pcb helps reduce the thermal bottleneck between the LED package and the mechanical base.

Beyond thermal benefits, aluminum substrates provide rigidity and dimensional stability. This matters for:

panel flatness during SMT

consistent assembly yield

stable mounting and optical alignment in lighting products

For factories, stability across production lots is just as important as single-board performance.

Aluminum pcb is commonly adopted in LED lighting because LED performance and lifetime are strongly temperature-dependent. In power electronics (drivers, converters, motor controllers), thermal control improves stability and prevents derating issues.

A professional aluminum pcb is a layered system engineered for both heat transfer and electrical insulation.

Most aluminum pcb designs follow this functional aluminum pcb structure:

Copper circuit layer (conductive routing for power/signals)

Dielectric insulation layer (thermally conductive, electrically insulating)

Aluminum base layer (heat spreading + mechanical support)

Optional layers: solder mask, surface finish, markings

This layered design is what makes aluminum pcb a practical high thermal solution pcb approach for many LED and power assemblies.

Your aluminum pcb stackup directly affects:

thermal resistance (heat flow from components to base)

dielectric strength (voltage isolation capability)

thermal cycling reliability (crack/void risk over time)

manufacturability and yield

Factory tip: When a project fails in the field, the root cause is often not “aluminum vs FR4,” but a mismatch between dielectric thickness, thermal target, and electrical isolation requirement. A good manufacturer will review these tradeoffs during DFM.

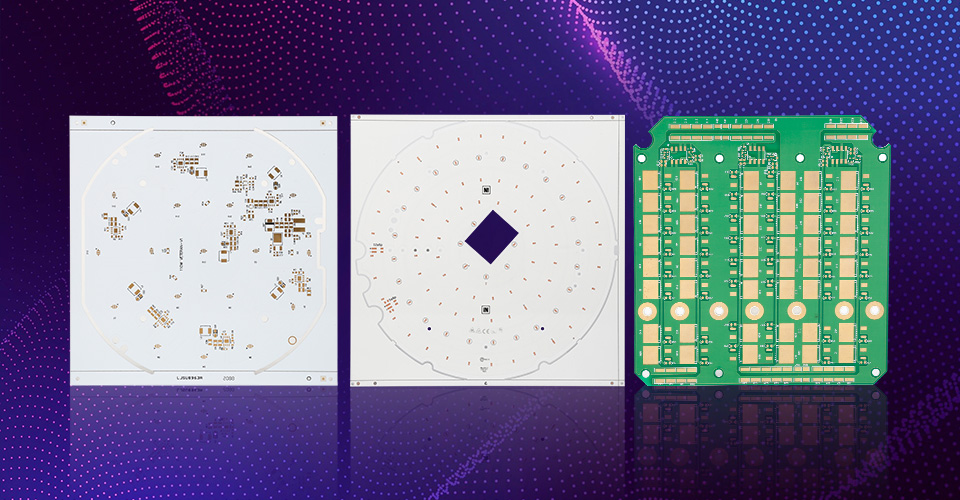

Factories often optimize thermal design, but overlook optical efficiency and cosmetic consistency. For LED modules, specifying high reflective soldermask can create measurable benefits.

High reflective soldermask is typically a glossy or optimized white solder mask formulation intended to reflect more light. In LED boards, reflectivity can:

increase usable light output by reflecting stray photons

improve brightness uniformity

support better product appearance consistency across lots

Consider high reflective soldermask if:

the LED PCB is visible in the optical cavity

you want higher luminous efficiency without changing LEDs

your product demands consistent “white” appearance for premium fixtures

Factory tip: If you use reflective white solder mask, keep solder mask thickness and process control consistent to avoid color deviation across batches.

When power density increases, “standard” aluminum pcb constructions may be insufficient. Material selection becomes a performance lever.

GDM aluminum based ccl is often described as an engineered composite system combining aluminum substrate, dielectric, and copper circuit layer—aimed at balancing thermal performance, electrical isolation, and mechanical durability. It is frequently discussed in contexts such as LED drivers, industrial power control, and power-dense modules.

Use it when your factory program needs:

stronger thermal headroom

stable insulation performance

robust reliability under vibration and long runtime

ventec aluminum based ccl is commonly referenced as part of IMS material families that offer multiple thermal conductivity options, supporting a broader range of thermal targets. In practice, specifying ventec aluminum based ccl (or an equivalent defined IMS class) can help when:

your junction temperature target is aggressive

the module is compact with limited heatsinking

you need stable long-life operation under thermal cycling

Important procurement note: In RFQs and purchase specs, writing “ventec aluminum based ccl” clearly (and repeating it consistently) reduces material ambiguity and speeds supplier alignment—especially for multi-site production programs.

When factories search “aluminum pcb manufacturer,” they typically need predictable production outcomes, not just a low unit cost. Evaluate suppliers using these criteria:

A reliable aluminum pcb manufacturer should flag early:

dielectric thickness vs isolation requirements

copper distribution and hotspot risks

pad design choices that impact voiding/solder reliability

panelization strategy for mass production yield

Your supplier should support quick iterations and then maintain consistency at volume. That includes stable raw material sourcing, process parameters, and QC checkpoints.

Factory programs benefit from suppliers that can document:

process control flow and inspection checkpoints

consistent mechanical processing (routing/deburr)

stable surface finish and solder mask control for cosmetic consistency

A good aluminum pcb manufacturer will quote quickly and ask the right questions (thermal target, finish, mask, material class). That prevents hidden cost surprises later.

To avoid delays and mismatched quotes, include:

Gerber + drill files

Target thickness and copper weight

Thermal target (power dissipation, max operating temp, environment)

Surface finish requirement (e.g., OSP/ENIG/lead-free HASL)

Solder mask requirement: specify high reflective soldermask for LED modules

Material callout if needed: GDM aluminum based ccl or ventec aluminum based ccl

Quantity plan (prototype / pilot / monthly volume) and delivery target

If assembly is required: BOM, placement file, assembly drawing, test requirements

For LED lighting, an aluminum pcb helps control temperature, supporting stable brightness and longer life. Pairing it with high reflective soldermask can further improve optical utilization in fixtures where the PCB is part of the reflective cavity.

Converters, drivers, motor controllers, and regulators benefit from aluminum pcb’s thermal stability and mechanical robustness—especially in compact enclosures.

Automotive and industrial environments amplify thermal cycling and vibration risks. Material choice (including GDM aluminum based ccl or ventec aluminum based ccl) and stackup definition become more important here.

If you’re sourcing a reliable aluminum pcb manufacturer for LED fixtures or high-power electronics, send your Gerber files and key specs (thermal target, finish, solder mask, and material requirements). A clear aluminum pcb stackup definition—plus optional upgrades like high reflective soldermask and specified materials such as GDM aluminum based ccl or ventec aluminum based ccl—can reduce redesign time, improve production yield, and strengthen long-term reliability.

Q1: What is the standard aluminum pcb structure for LED boards?

A typical aluminum pcb structure includes a copper circuit layer, a thermally conductive dielectric insulation layer, and an aluminum base for heat spreading and rigidity. This design supports thermal control for LED and power devices and is widely used as a high thermal solution pcb approach.

Q2: Why should I use high reflective soldermask on LED products?

High reflective soldermask helps reflect more light back into the optical path, improving brightness and uniformity in many LED fixtures. It can also improve cosmetic consistency when the PCB is visible in the lighting cavity.

Q3: What should I define in an aluminum pcb stackup to avoid reliability issues?

Your aluminum pcb stackup should specify dielectric thickness (for isolation and thermal), copper weight (for current and spreading), board thickness, and surface finish. For higher voltage designs, insulation requirements must be clearly stated to prevent breakdown risk.

Q4: When is GDM aluminum based ccl a better choice than a standard aluminum pcb?

Choose GDM aluminum based ccl when your product has higher power density or needs better durability under thermal cycling and harsh environments. It is often selected for modules like LED drivers and industrial power control where thermal, electrical, and mechanical balance is critical.

Q5: Why do buyers specify ventec aluminum based ccl in RFQs?

Factories specify ventec aluminum based ccl to reduce material ambiguity and align suppliers to a defined IMS class with targeted thermal performance. Clear material callouts make quoting faster and help maintain consistency across prototype, pilot, and mass production.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB