-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 14. 2026, 10:12:05

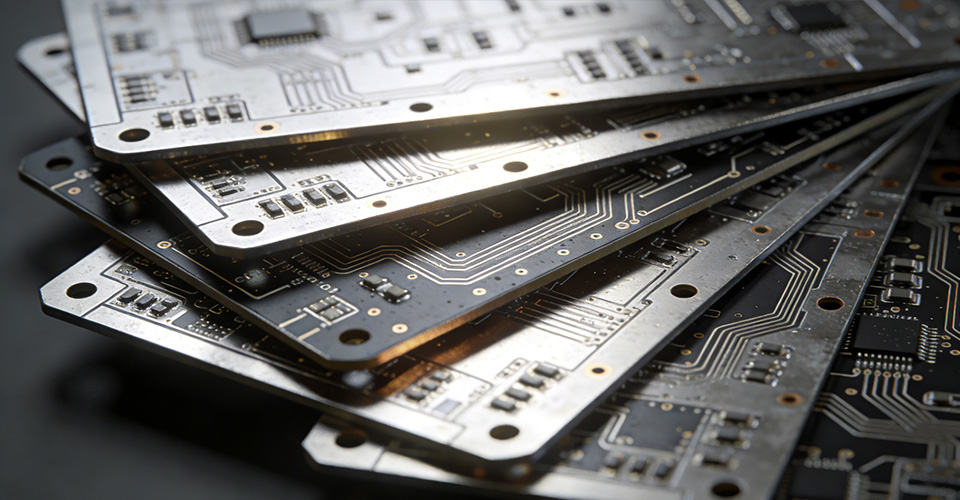

As electronic devices evolve, the demand for high-performance components grows, especially in industries requiring high-power and high-thermal solution PCB designs. Among these components, the aluminum pcb stands out as a versatile and effective choice, particularly for applications like LED lighting, automotive electronics, and power systems. This article explores the key benefits of aluminum PCB, how its structure and stackup affect performance, and why it’s increasingly being favored in power-intensive designs.

In high-power applications such as LED lighting and power converters, managing heat is crucial. Aluminum PCBs offer high thermal solution PCB capabilities due to their exceptional heat dissipation properties. The aluminum pcb structure includes an aluminum base that acts as a heat sink, efficiently transferring heat away from sensitive components. This reduces the need for additional cooling systems like heatsinks, thereby making your designs more compact and cost-effective.

When the demand for thermal management is high, particularly in LED modules, the thermal conductivity of aluminum allows the components to maintain optimal operating temperatures, ensuring extended lifespan and reliable performance.

The aluminum pcb stackup typically involves a metal base, a dielectric layer, and copper traces. The metal base provides structural integrity, ensuring the PCB remains robust and durable in harsh environments. This makes aluminum PCBs ideal for use in industrial and automotive applications, where high mechanical strength is essential.

In addition to heat dissipation, aluminum PCBs offer mechanical strength that keeps components stable and reduces the chances of failure caused by vibrations or thermal expansion. This is crucial for industries where equipment reliability is a priority.

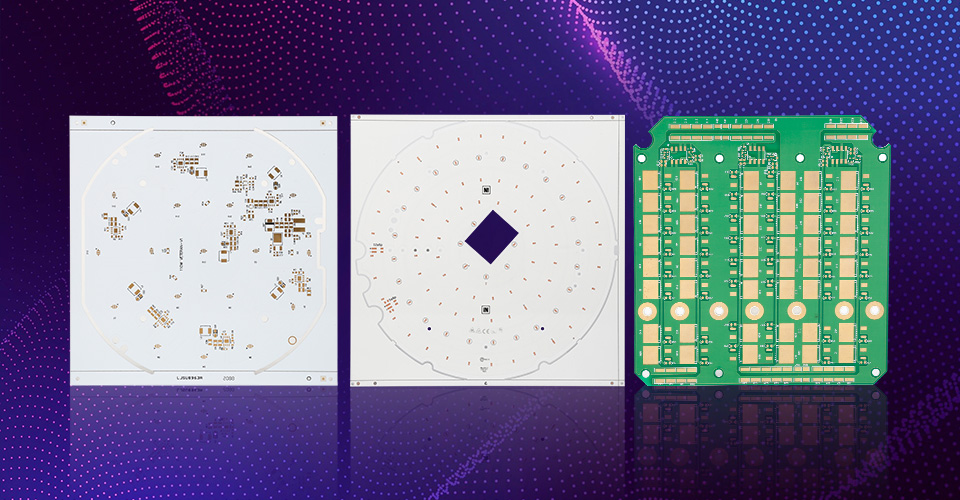

The aluminum pcb structure generally consists of three layers:

Copper layer: Carries the electrical signals and powers the components.

Dielectric layer: A thermally conductive but electrically insulating material that separates the copper layer from the metal base.

Aluminum base: Provides the heat dissipation necessary for high-power applications.

This layered structure helps manage heat efficiently while ensuring electrical isolation. The aluminum pcb stackup is designed to maximize the conductivity of the aluminum while maintaining the electrical isolation between the copper and the metal base.

Aluminium-based CCL (Copper Clad Laminate) is the material used in the creation of aluminum PCBs. It is made by bonding copper foil to the dielectric layer, which in turn is bonded to the aluminum base. This CCL ensures high electrical performance and durability, even in extreme temperatures. The use of boyu aluminum ccl—a high-quality aluminium-based CCL—further enhances the mechanical properties of aluminum PCBs, making them a trusted choice in high-demand applications.

The integration of aluminium-based CCL into the stackup ensures that the aluminum PCB can handle high voltages and power densities while maintaining reliable operation.

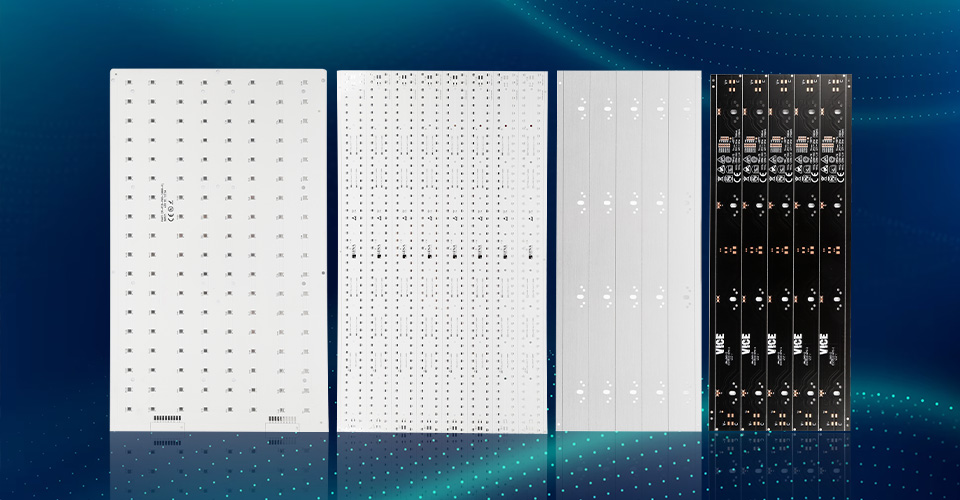

LED lights generate a significant amount of heat, and managing this heat is critical to the performance and longevity of the LEDs. Aluminum pcb designs are ideal for LED lighting applications because the aluminum base helps dissipate heat more effectively than standard FR4 PCBs. By maintaining lower temperatures, LED lighting aluminum pcb designs prevent overheating and ensure that LEDs emit the desired brightness without premature failure.

The aluminum pcb structure in LED applications helps improve lumen maintenance and light quality, making them an essential choice for high-performance lighting solutions such as outdoor street lighting, automotive headlights, and architectural lighting.

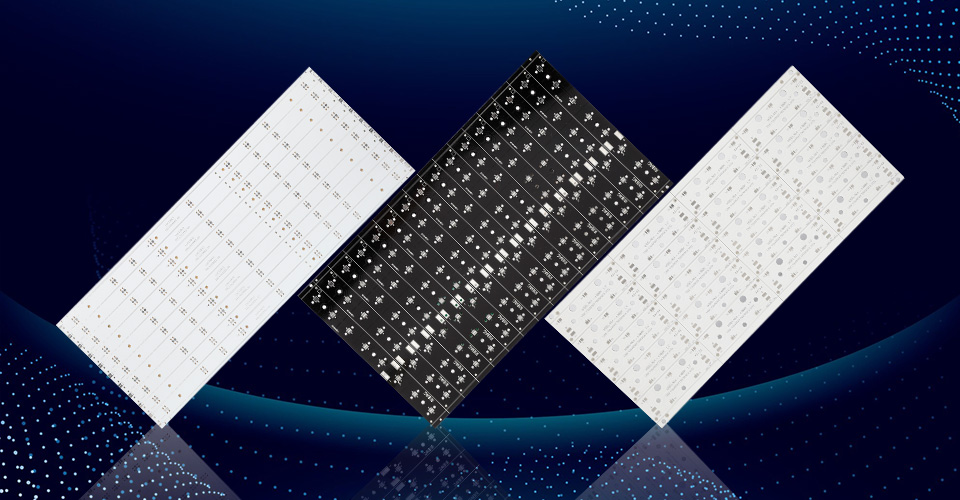

For power converters, motor drivers, and charging stations, aluminum pcb ensures superior performance by efficiently handling the power density and minimizing thermal resistance. Power systems often generate substantial heat, and aluminum-based CCL ensures that power traces are insulated, which prevents damage to the circuitry.

These systems also benefit from high thermal solution PCBs, ensuring that the critical components, such as voltage regulators and power transistors, operate within safe temperature limits, prolonging the life of the components and improving the overall system reliability.

Compared to other thermal management solutions, aluminum PCBs are cost-effective for high-volume manufacturing. They help reduce the need for additional cooling components like heatsinks, making them a preferred choice for power electronics and LED circuits board applications. Additionally, the simplicity of the aluminum base structure reduces the overall production complexity, lowering manufacturing costs.

Choosing the right aluminum pcb depends on several factors, including the application’s thermal and electrical requirements. If your design involves high currents or high power levels, selecting a double-sided aluminum pcb (where copper is applied to both sides of the board) may be the best option for better routing flexibility and heat management.

For applications with stricter thermal performance criteria, opting for an aluminum pcb stackup with a high thermal conductivity dielectric layer will help further improve heat dissipation. Make sure to choose a supplier that offers high-quality aluminium-based CCL, such as boyu aluminum ccl, to ensure optimal performance.

Aluminum PCBs are the go-to solution for LED lighting and high-power applications due to their excellent thermal performance, mechanical strength, and cost-effectiveness. With the aluminum pcb structure providing efficient heat dissipation and the aluminum pcb stackup maximizing electrical insulation and heat management, these PCBs are ideally suited for a wide range of applications in industries such as power electronics, automotive, and industrial systems.

By choosing a high-quality aluminium-based CCL like boyu aluminum ccl, you can further enhance the performance and durability of your aluminum PCB. Whether you're designing LED circuits board, power converters, or motor controllers, aluminum PCBs will help you meet the rigorous demands of high-performance designs.

Q1: What is the structure of an aluminum PCB?

An aluminum pcb structure consists of three layers: a copper layer for the electrical traces, a dielectric layer for insulation and thermal conductivity, and an aluminum base to dissipate heat. This design helps in managing high power and thermal challenges.

Q2: What is aluminium-based CCL and why is it used in aluminum PCBs?

Aluminium-based CCL is a copper-clad laminate used in aluminum PCBs. It ensures good electrical performance, mechanical stability, and high thermal conductivity, making it ideal for high-power applications and high thermal solution PCB designs.

Q3: When should I use a double-sided aluminum pcb?

A double-sided aluminum pcb is useful when you need more routing space or enhanced heat dissipation. It's especially beneficial for LED circuits board designs that require a compact form factor and higher power handling.

Q4: How does aluminum PCB improve thermal performance in LED applications?

The aluminum pcb structure offers excellent heat dissipation by using an aluminum base to transfer heat away from the components. This keeps the LED junction temperature low, ensuring consistent brightness and a longer lifetime.

Q5: What are the advantages of boyu aluminum ccl?

Boyu aluminum ccl is a high-quality copper-clad laminate designed to enhance the thermal performance and electrical reliability of aluminum PCBs. It ensures better heat dissipation and provides a solid mechanical foundation for power and LED applications.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB