-

- PCB TYPE

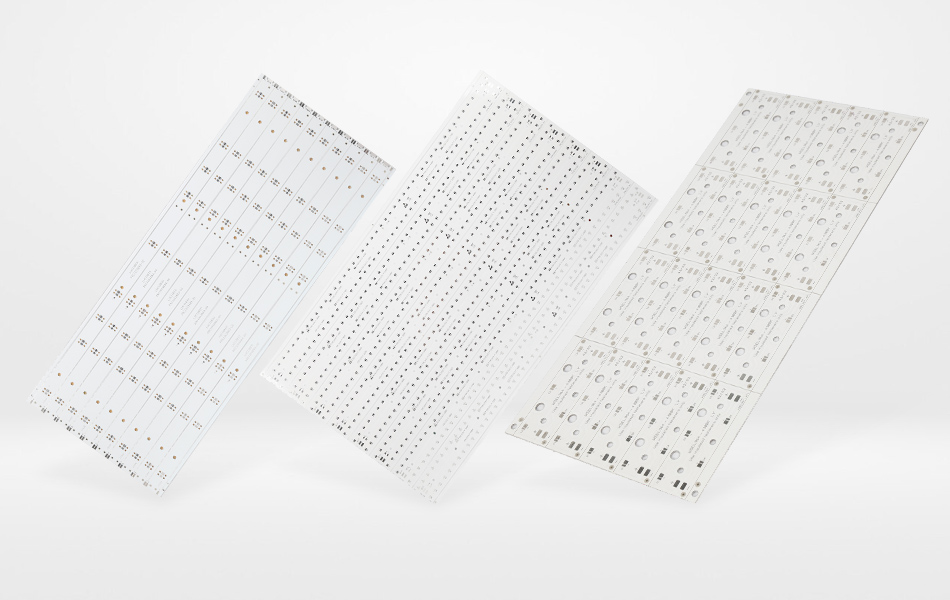

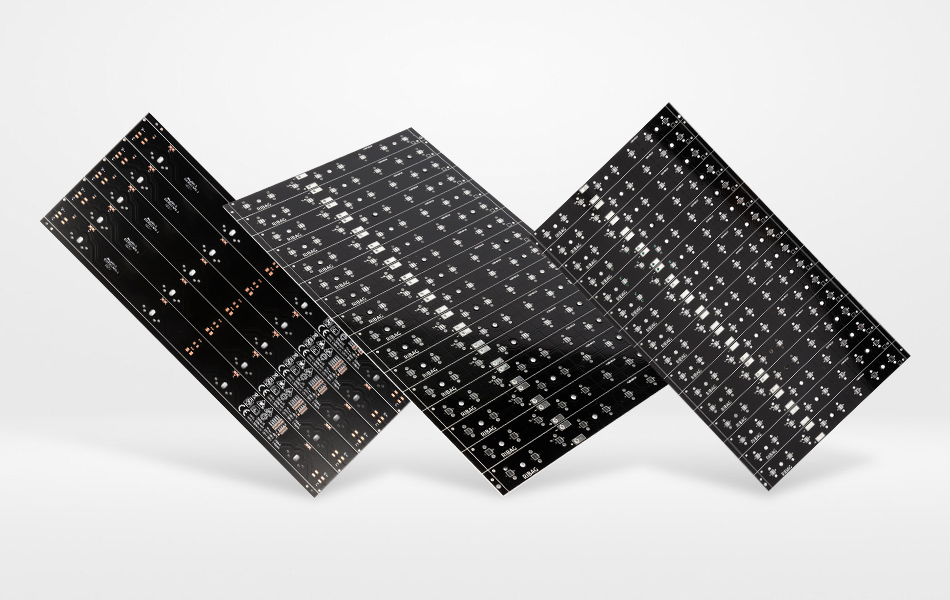

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 01. 2025, 15:28:49

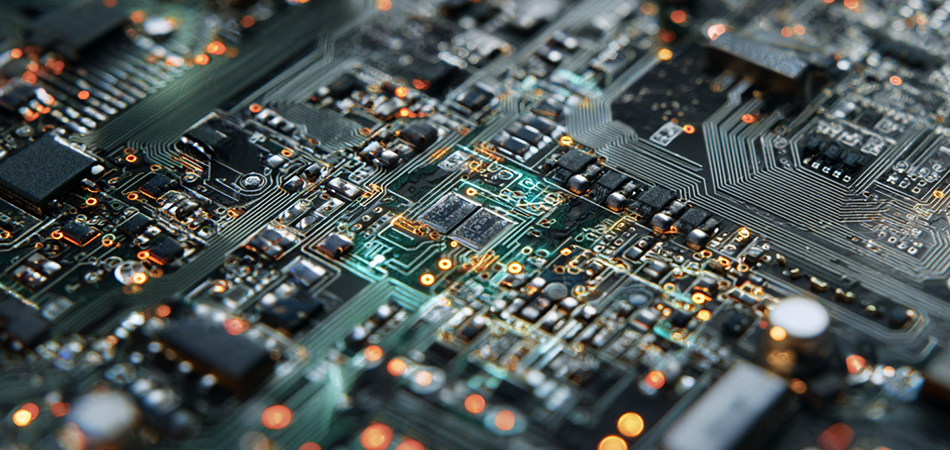

Introduction: When Heat Meets Innovation in the Electronic Realm

In the bustling universe of modern electronics, where tiny chips pulse with the power of thousands of stars, a quiet revolution is taking place. Aluminum Printed Circuit Boards (PCBs) emerge as the unsung heroes, the master builders tasked with taming the fiery beast of heat that threatens to engulf our technological marvels. Picture a world where every smartphone, every streetlight, every medical device is a delicate balance between incredible power and precise cooling—this is the domain of aluminum PCBs. Unlike their fiberglass counterparts, these boards harness the earth's own aluminum.

Technical Foundations: Layers of Mastery in Material and Design

Thermal Management: Crafting Coolness in a Hot World

Designing an aluminum PCB is like planning a city's infrastructure, with heat as the traffic that must be managed:

Thermal Path Optimization: Engineers create smooth roads for heat to travel from power-hungry components to the aluminum base. They place hot components strategically, like positioning factories on the outskirts of a city to prevent congestion, and use thermal vias as tunnels to speed heat away.

Thermal Vias: These are the vertical tunnels in the PCB, drilling through the layers to connect the hot copper traces to the cool aluminum below. Filled with special materials, they act like elevators, quickly moving heat from the upper floors of the PCB to the ground level where it can dissipate.

Heat Sink Integration: Like attaching a radiator to a car engine, aluminum PCBs often work with external heat sinks. A thin layer of thermal paste acts as the glue, ensuring heat moves seamlessly from the board to the sink, where it spreads out and cools down, much like how a radiator cools engine coolant.

Balancing Act: Electricity and Durability

Electrical Design: Just as a conductor balances different instruments in an orchestra, engineers balance the electrical elements of a PCB. They calculate the width of copper traces to handle current without overheating, lay out ground planes to act as both heat spreaders and noise reducers, and ensure high-frequency signals travel without interference, like clear voices in a noisy room.

Mechanical Robustness: An aluminum PCB must withstand the bumps and shakes of daily use. Think of it as a bridge built to handle heavy traffic and harsh weather. Engineers match the expansion rates of different materials to prevent cracking, choose the right board thickness for stability, and design it to endure temperature changes without warping, just like a well-constructed building that stands through seasons.

Manufacturing Processes: From Raw Materials to Electronic Masterpieces

Preparing the Canvas: Cleaning and Bonding

Substrate Pretreatment: The aluminum base is cleaned and activated, much like preparing a canvas for painting. It might be washed to remove dirt, etched to create a rough surface, or treated with plasma to make it more receptive to the next layers, ensuring everything sticks together firmly.

Lamination: In a large, precise machine, the copper foil, dielectric layer, and aluminum substrate are pressed together under heat and vacuum. This is like pressing a sandwich in a panini maker, ensuring all layers bond tightly without air bubbles, creating a uniform, strong base for the PCB.

Etching and Drilling: Sculpting the Circuitry

Photolithography: Using laser light, engineers transfer the circuit design onto the copper foil, like using a stencil to paint a pattern. The laser defines the traces, and then etching solutions remove the unwanted copper, leaving behind the precise circuitry, as intricate as a lace doily.

Precision Drilling: Diamond-tipped drills spin at high speeds, creating tiny holes in the aluminum for vias. Coolant sprays keep everything from overheating, and the result is holes so precise they could be mistaken for pinpricks, each one placed with the accuracy of a watchmaker.

Via Processing: The holes are plated with copper to make them conductive, like lining a tunnel with metal to ensure electricity can pass through. Sometimes, they're filled with a thermal compound to make heat transfer even better, like packing a tunnel with insulation to keep it efficient.

Finishing and Testing: Ensuring Perfection

Lead-Free Surface Finishes: The top of the PCB is coated with a protective layer, like applying a clear coat to a painting. This finish prevents corrosion, makes soldering easier, and ensures the board stays reliable for years, whether it's in a smartphone or a satellite.

Comprehensive Testing: Each PCB goes through a series of tests to mimic real-world use:

Thermal tests heat and cool the board to see how it handles temperature changes, like testing a car in both the desert and the arctic.

Electrical tests check that all circuits work perfectly, ensuring no shorts or open paths, much like an electrician inspecting a building's wiring.

Environmental tests subject the board to humidity, vibration, and other stresses, making sure it can withstand the rough and tumble of its intended use, whether that's in a vibrating factory or a humid tropical climate.

Performance Advantages: Why Aluminum PCBs Shine

Thermal Superpowers

Aluminum PCBs are like the superheroes of heat management, carrying away heat up to 200 times better than traditional PCBs. This means devices stay cooler, components last longer, and performance doesn't dip when things get tough, just like a marathon runner who doesn't tire in the heat.

Tough as Nails

These boards can take a beating. Whether it's the shake of a construction vehicle or the drop of a smartphone, aluminum PCBs stand strong. The aluminum base provides a rigid platform, keeping components secure and preventing damage, much like a hard - shell suitcase protecting fragile items.

Slim and Smart

Despite their strength, aluminum PCBs can be as thin as a credit card, allowing designers to create sleek, lightweight devices. Their ability to handle heat also means more components can be packed into a small space, supporting the trend of smaller, more powerful electronics, like a tiny apartment that fits all the amenities of a large house.

Friend to the Earth

Aluminum is highly recyclable, so when a device reaches the end of its life, the PCB can be broken down and used again. Additionally, their thermal efficiency means devices use less energy, reducing both costs and environmental impact, like a car that gets better gas mileage and produces fewer emissions.

Industry Applications: Where Aluminum PCBs Make a Difference

Lighting Up the World

High-Power LED Applications: In streetlights and industrial fixtures, aluminum PCBs ensure that bright LED lights don't dim over time due to heat. They're like the reliable caretakers of city illumination, keeping streets safe and factories well - lit for years.

Automotive Lighting: In cars, these PCBs withstand the constant vibration and temperature changes, ensuring headlights and taillights always work, like a trustworthy companion on every drive.

Powering the Future

Power Supplies: Inside the boxes that convert wall power to device power, aluminum PCBs manage the heat generated, making sure the supply stays efficient and reliable, like a steady heartbeat for electronic devices.

Renewable Energy: In solar panels and wind turbines, these PCBs handle the harsh outdoor conditions and high power levels, contributing to the fight against climate change by enabling clean energy, much like the unsung workers behind a successful mission.

Consumer Electronics: Making Life Easier

Portable Devices: The thin aluminum PCBs in smartphones and tablets allow them to be sleek and lightweight, while also keeping them cool during intense use, like a thin coat that keeps you warm without weighing you down.

Home Appliances: In smart thermostats and connected kitchen gadgets, these PCBs ensure reliable operation, managing heat to keep everything running smoothly, like the quiet but essential systems in a modern home.

Medical Marvels

Diagnostic Equipment: In machines that take X - rays or MRI scans, aluminum PCBs provide the precision needed for accurate results, like the steady hand of a surgeon during a delicate procedure.

Wearable Monitors: For devices that track heart rate or blood pressure, these PCBs are compact and durable, with thermal management that ensures sensor accuracy, like a reliable nurse keeping watch over a patient.

Reaching for the Stars

Avionics Systems: In airplanes, aluminum PCBs must withstand extreme altitudes and temperatures, guiding planes safely through the sky, like the navigators of ancient ships plotting a course through uncharted waters.

Military Electronics: For devices used in the field, these PCBs are ruggedized to handle harsh environments, from scorching deserts to freezing mountains, like soldiers prepared for any mission.

Technological Trends: What's Next for Aluminum PCBs

Materials: The Cutting Edge

Nano-Enhanced Dielectrics: Scientists are adding tiny particles, like graphene or boron nitride, to the dielectric layer, making it even better at conducting heat, like adding superhighways to an already efficient road system.

Eco-Friendly Materials: Research is underway to create dielectrics that break down naturally and aluminum substrates made from recycled materials, reducing the environmental impact, like using recycled paper instead of new for a report.

Metal Matrix Composites: Combining aluminum with ceramics to create materials that can handle specific tasks, like a tool designed for a particular job, whether it needs to be extra strong or extra good at conducting heat.

Manufacturing: New Tools and Techniques

3D Printing: Imagine printing a PCB layer by layer, creating complex shapes and integrated heat sinks, much like a chef piping intricate designs onto a cake, allowing for custom solutions and rapid prototyping.

Laser Technology: Using lasers to drill and etch with incredible precision, creating tiny vias and fine traces, like an artist using a fine brush to create detailed work.

AI and Robots: Implementing smart systems that can predict when a machine might fail or optimize production processes, like having a team of experts constantly monitoring and improving operations.

Integration with Future Technologies

5G and IoT: As we move to faster networks and more connected devices, aluminum PCBs will be designed to handle high frequencies and manage heat in compact IoT sensors, like the infrastructure that supports a bustling city's communication.

Electric Vehicles: In EVs, these PCBs will be crucial for battery management and charging systems, helping cars go farther and charge faster, like the engine that powers a new era of transportation.

AI and Edge Computing: For powerful AI chips that process data locally, aluminum PCBs will manage the intense heat generated, ensuring these systems work efficiently, like the cooling system in a supercomputer.

Challenges and Solutions: Navigating the Road Ahead

Rising Costs: Finding Efficiency

Solution: Investing in robots and automation to do repetitive tasks, optimizing processes to use less material, and sourcing locally to reduce shipping costs, much like a farmer using modern equipment to grow more crops with less waste.

Technological Complexity: Staying Ahead

Solution: Working with universities and research labs to develop new materials and processes, training workers on the latest technologies, and collaborating with other companies to share knowledge, like a group of students studying together to master a difficult subject.

Environmental Regulations: Going Green

Solution: Adopting manufacturing practices that use less water and energy, developing materials that are safe for the environment, and following strict recycling protocols, like a company that recycles all its paper and plastic waste.

Supply Chain Issues: Being Prepared

Solution: Working with multiple suppliers to avoid shortages, keeping extra inventory of critical materials, and building factories in different regions to ensure production continues even if one area is affected, like a store that keeps stock in multiple warehouses to avoid running out of popular items.

Future Outlook: Aluminum PCBs in a Connected World

As our devices become more powerful, more connected, and more compact, aluminum PCBs will be at the center of it all. They will enable the next generation of technologies, from 5G networks that let us download movies in seconds to electric cars that drive across continents on a single charge. Manufacturers who focus on innovation, sustainability, and efficiency will lead the way, creating PCBs that are not just components, but enablers of a smarter, greener future.

For engineers and designers, understanding the capabilities of aluminum PCBs is like having a key to unlock new possibilities. It allows them to dream up devices that were once impossible, safe in the knowledge that heat will no longer be a barrier.

In the end, aluminum PCBs are more than just pieces of technology. They are the silent partners in our daily lives, working behind the scenes to ensure our devices work flawlessly, our lights stay on, our cars run smoothly, and our medical equipment saves lives. As we move forward, these unassuming boards will continue to revolutionize how we interact with technology, making the impossible possible, one thermal solution at a time.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB