-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 04. 2025, 11:43:43

In the rapidly evolving landscape of electronics, printed circuit boards (PCBs) serve as the backbone of electronic devices, providing a platform for component interconnection and electrical signal transmission. Among the different types of PCBs, aluminum PCBs have emerged as a game - changer, especially in applications where efficient thermal management is critical.

Aluminum PCBs feature a unique structure with an aluminum core, a dielectric layer, and a copper layer. The aluminum core, known for its excellent thermal conductivity, enables effective heat dissipation, making these PCBs ideal for high - power and heat - generating electronic applications. From consumer electronics to industrial machinery, automotive systems, and aerospace equipment, aluminum PCBs are increasingly being adopted to enhance the performance, reliability, and lifespan of electronic devices. This article will explore the various aspects of aluminum PCBs that contribute to their growing significance in the electronics industry.

Material Science of Aluminum PCBs

Aluminum Core

The choice of aluminum alloy for the core of an aluminum PCB is a crucial decision that significantly impacts its performance. Different aluminum alloys possess distinct properties, making them suitable for specific applications.

Pure aluminum, such as the 1000 - series alloys, offers high thermal conductivity, which is beneficial for general - purpose thermal management applications. Its soft nature also allows for easy machining and fabrication, enabling the creation of complex PCB shapes. However, pure aluminum may have relatively lower mechanical strength, which can be a limitation in some demanding environments.

Alloyed aluminum, on the other hand, provides enhanced mechanical properties. For example, 3000 - series aluminum alloys, which contain manganese, offer improved corrosion resistance. This makes them a preferred choice for applications where the PCB may be exposed to moisture or corrosive substances, such as in outdoor lighting or marine electronics. 5000 - series aluminum alloys, with the addition of magnesium, provide higher strength and formability, making them suitable for applications that require the PCB to withstand mechanical stress, such as in automotive engine compartments.

Dielectric Layers

The dielectric layer in an aluminum PCB serves two primary functions: electrical insulation between the copper traces and the aluminum core, and facilitating heat transfer from the components to the core. A variety of dielectric materials are used, each with its own advantages and suitable applications.

Polytetrafluoroethylene (PTFE) - based dielectrics are commonly employed in high - frequency applications. PTFE offers low dielectric loss, which minimizes signal degradation at high frequencies. This is crucial in applications such as radio frequency (RF) circuits, 5G communication systems, and satellite electronics, where maintaining signal integrity is of utmost importance.

Polyimide dielectrics are another popular choice, especially in high - temperature environments. They can withstand elevated temperatures without degrading, ensuring the long - term reliability of the PCB. Polyimide dielectrics also have good mechanical properties, providing resistance to cracking and delamination under thermal and mechanical stress.

Ceramic - filled epoxies are often used to strike a balance between cost - effectiveness and thermal performance. These materials can effectively transfer heat while providing adequate electrical insulation. They are suitable for a wide range of power electronics applications, where both thermal management and electrical isolation are required.

Copper Layers

The copper layers in an aluminum PCB are responsible for conducting electrical current. High - purity copper is typically used to minimize electrical resistance and ensure stable power delivery to the electronic components. The thickness of the copper layer is carefully selected based on the current - carrying requirements of the circuit.

Thicker copper layers can handle higher currents, reducing the risk of overheating due to excessive resistance. In power - intensive applications, such as power supplies and motor drives, relatively thick copper layers are used to ensure efficient power transfer. Surface treatments, such as electroless nickel immersion gold (ENIG), electroless nickel electroless palladium immersion gold (ENEPIG), or organic solderability preservatives (OSP), are often applied to the copper layers to protect them from oxidation, improve solderability, and enhance the overall reliability of the PCB.

Design Considerations for Aluminum PCBs

Thermal Management Design

Efficient thermal management is the primary advantage of aluminum PCBs, and proper design is essential to fully exploit this benefit. One of the key design elements is the layout of thermal vias. Thermal vias are holes that connect the surface copper layers to the aluminum core, providing a direct path for heat to flow from the heat - generating components to the core.

The size, quantity, and distribution of thermal vias need to be carefully optimized based on the power consumption and heat - generating characteristics of the components. Additionally, the use of heat sinks or heat spreaders in conjunction with the aluminum PCB can further enhance heat dissipation. These components increase the surface area available for heat transfer to the surrounding environment, helping to maintain the components at optimal operating temperatures.

Electrical Design

In addition to thermal management, electrical design considerations are also crucial for aluminum PCBs. Signal integrity is a major concern, especially in high - speed and high - frequency applications. Proper trace routing, impedance control, and shielding are necessary to minimize signal interference and ensure reliable signal transmission.

For power - intensive circuits, the design must also account for power distribution. This includes minimizing voltage drops, reducing electromagnetic interference (EMI), and ensuring proper isolation between different power domains. Multi - layer PCB designs are often used in complex applications to separate power and signal layers, providing better isolation and reducing the risk of crosstalk.

Mechanical Design

The mechanical design of aluminum PCBs focuses on ensuring the board's physical integrity and compatibility with the overall system. The choice of aluminum alloy and its thickness can impact the mechanical strength of the PCB. In applications where the PCB may be subjected to vibrations, shocks, or other mechanical stresses, additional reinforcement techniques may be employed.

These can include adding stiffeners, using a more rigid substrate, or implementing proper mounting and fastening methods. The size and shape of the aluminum PCB need to be carefully considered to fit within the constraints of the enclosure and other components in the system. Moreover, the design should allow for easy assembly and disassembly, facilitating manufacturing, maintenance, and repair processes.

Manufacturing Processes of Aluminum PCBs

Drilling

The drilling process in aluminum PCB manufacturing is used to create holes for vias, component mounting, and other purposes. There are two main drilling methods: mechanical drilling and laser drilling.

Mechanical drilling involves using drill bits to physically remove material from the PCB. It is a cost - effective method for creating larger holes and is commonly used for through - hole vias. However, mechanical drilling may introduce issues such as drill bit wear, burrs, and inaccuracies in hole size, which require proper post - processing to address.

Laser drilling, on the other hand, uses a laser beam to ablate the material, creating highly precise holes with small diameters. This method is ideal for creating microvias in high - density interconnect (HDI) PCBs. Laser drilling offers advantages such as high accuracy, minimal burr formation, and the ability to drill complex shapes, but it is generally more expensive than mechanical drilling.

Plating

Plating is a critical process in aluminum PCB manufacturing as it deposits a layer of copper on the drilled holes and the surface of the PCB to ensure electrical conductivity. The plating process typically consists of two stages: electroless plating and electrolytic plating.

Electroless plating is the first step, which deposits a thin, uniform layer of copper on the non - conductive surfaces of the PCB, such as the drilled holes. This provides a base layer for the subsequent electrolytic plating. Electrolytic plating then builds up the copper layer to the desired thickness, ensuring sufficient conductivity and mechanical strength. Advanced plating techniques, such as pulse plating, can be used to improve the quality of the copper layer, reducing voids and enhancing its ductility.

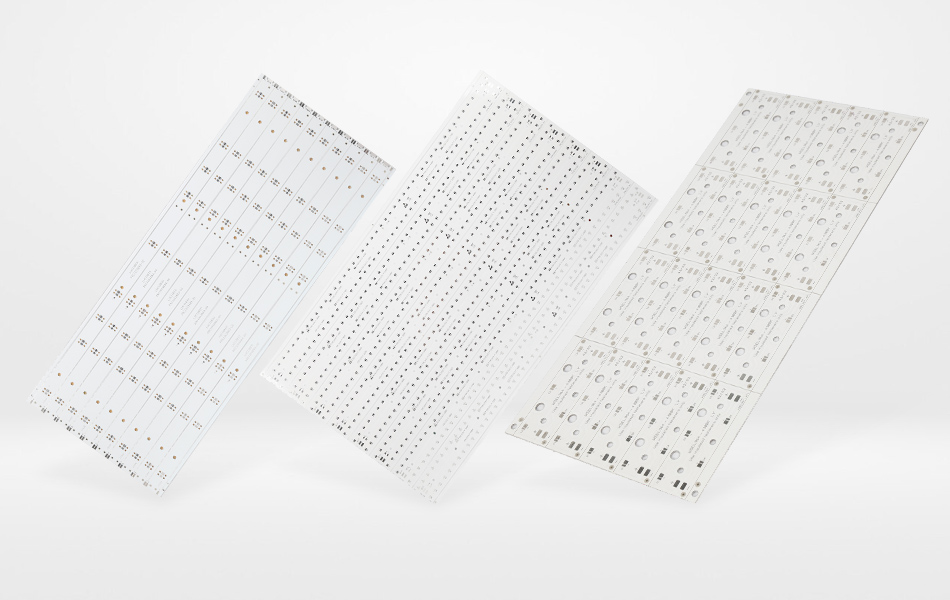

Lamination

Lamination is the process of bonding the different layers of the aluminum PCB together. This includes bonding the aluminum core, dielectric layer, and copper layers. High - pressure lamination is commonly used, where the layers are stacked and subjected to high pressure and temperature.

This ensures a strong and reliable bond between the layers, maintaining the structural integrity of the PCB and its electrical and thermal performance. Specialized adhesives or prepregs are often used in the lamination process to enhance the bonding strength and ensure uniform layer thickness.

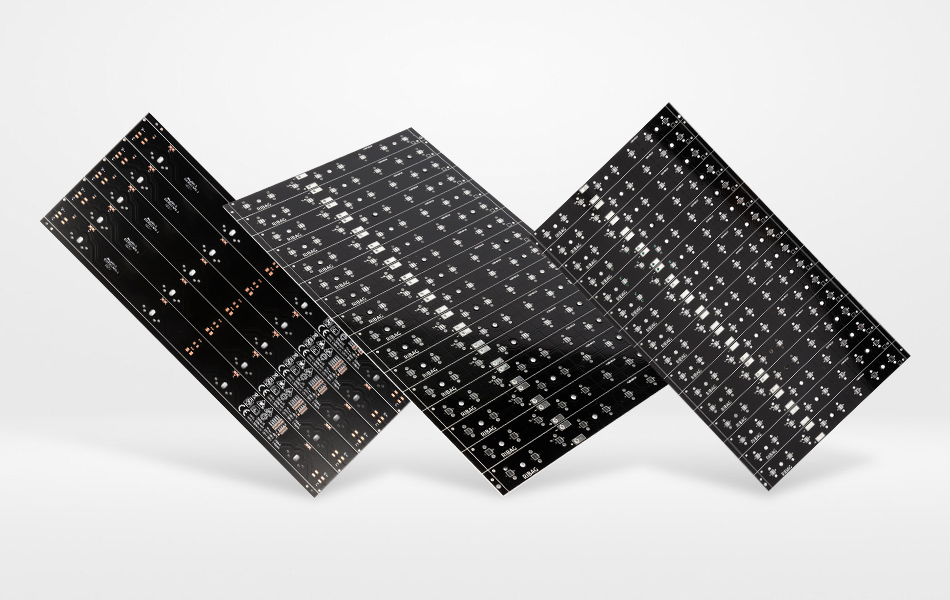

Surface Finishing

Surface finishing of aluminum PCBs is essential for protecting the copper traces from oxidation and providing a suitable surface for soldering components. There are several types of surface finishes available, each with its own characteristics.

Hot air solder leveling (HASL) is a traditional and cost - effective surface finish. It involves immersing the PCB in molten solder and then blowing off the excess solder with hot air, leaving a thin, even layer of solder on the copper traces. Organic solderability preservatives (OSP) provide a thin, transparent organic coating that protects the copper from oxidation. OSP is suitable for fine - pitch components and is becoming increasingly popular due to its environmental friendliness. Electroless nickel immersion gold (ENIG) offers excellent corrosion resistance and a smooth, flat surface, making it ideal for high - reliability applications, although it is more expensive than the other two options.

Quality Assurance in Aluminum PCB Production

Incoming Material Inspection

Before the manufacturing process begins, incoming materials such as the aluminum core, copper foil, and dielectric layers are thoroughly inspected. The aluminum core is checked for its flatness, purity, and mechanical properties. Copper foil is inspected for thickness uniformity and surface quality. Dielectric materials are tested for their electrical insulation properties, thermal conductivity, and dimensional stability.

Only materials that meet the specified quality standards are used in the production process to ensure the overall quality of the final aluminum PCB.

In - Process Quality Control

During the manufacturing process, various quality control measures are implemented at different stages. After drilling, the holes are inspected for size accuracy, roundness, and the presence of burrs. In the plating process, the thickness and uniformity of the copper layer are continuously monitored.

Lamination is also closely inspected to ensure proper bonding between the layers, with techniques such as X - ray inspection used to detect any voids or delaminations. Surface finishing is checked for coating thickness, adhesion, and the absence of defects.

Final Testing

Once the aluminum PCB is fully manufactured, it undergoes a series of final tests to verify its functionality and reliability. Electrical tests include checking for short circuits, open circuits, and impedance matching. Thermal tests, such as thermal cycling and infrared thermography, are conducted to assess the PCB's thermal management capabilities.

These tests simulate real - world operating conditions, identifying potential issues early in the production process. Additionally, mechanical tests may be performed to evaluate the board's strength and durability.

Applications of Aluminum PCBs

Consumer Electronics

In the consumer electronics sector, aluminum PCBs are widely used in devices such as smartphones, tablets, laptops, and gaming consoles. These devices are becoming increasingly powerful, generating more heat in a compact form factor. Aluminum PCBs help manage this heat, ensuring the devices operate smoothly and efficiently.

They also contribute to the development of thinner and lighter consumer electronics by enabling better thermal management without adding excessive weight or thickness. For example, in high - performance gaming laptops, aluminum PCBs are used to dissipate the heat generated by powerful processors and graphics cards, preventing overheating and maintaining optimal performance during intense gaming sessions.

Automotive Electronics

The automotive industry has witnessed a significant adoption of aluminum PCBs in recent years. In electric vehicles (EVs), aluminum PCBs play a crucial role in power inverters, battery management systems, and charging modules. These components generate a substantial amount of heat during operation, and efficient thermal management is essential for their safe and reliable performance.

Aluminum PCBs also find applications in advanced driver - assistance systems (ADAS), where they support the complex electronics involved in radar, camera, and sensor modules. In automotive environments, PCBs are exposed to harsh conditions such as temperature variations, vibrations, and moisture, and the robust design of aluminum PCBs makes them well - suited for these challenges.

LED Lighting

LED lighting is one of the largest application areas for aluminum PCBs. LEDs generate a significant amount of heat, and efficient thermal management is necessary to maintain their performance and lifespan. Aluminum PCBs provide an ideal solution by quickly dissipating the heat away from the LEDs, ensuring consistent light output and preventing premature failure.

They are used in a wide range of LED lighting applications, from residential and commercial lighting fixtures to automotive headlights, streetlights, and large - scale architectural lighting projects. The ability to customize the size, shape, and thermal performance of aluminum PCBs makes them suitable for different lighting requirements.

Industrial Electronics

In industrial electronics, aluminum PCBs are used in various applications such as motor drives, control systems, power supplies, and industrial automation equipment. These applications often involve high - power components that generate a large amount of heat.

Aluminum PCBs help in managing this heat, ensuring the reliable operation of the industrial equipment. In harsh industrial environments, where the PCBs may be exposed to dust, moisture, chemicals, and extreme temperatures, the mechanical strength and corrosion resistance of aluminum PCBs make them a preferred choice. They can withstand the rigors of industrial operations, reducing downtime and maintenance costs.

Aerospace and Defense

The aerospace and defense sectors have strict requirements for the performance and reliability of electronic components. Aluminum PCBs are used in avionics systems, radar systems, communication equipment, and military - grade electronics.

Their ability to handle high power densities, provide excellent thermal management, and withstand the extreme conditions of flight, such as high altitudes, rapid temperature changes, and vibrations, makes them indispensable in these applications. The use of aluminum PCBs in aerospace and defense also requires compliance with stringent quality and safety standards, ensuring the reliability of critical systems.

Market Analysis of Aluminum PCBs

Market Size and Growth

The global market for aluminum PCBs has been experiencing significant growth in recent years and is expected to continue this trend in the future. The increasing demand from various industries, such as consumer electronics, automotive, LED lighting, and industrial electronics, is the main driver of this growth.

As the electronics industry continues to evolve towards more power - intensive and compact designs, the need for efficient thermal management solutions like aluminum PCBs will only increase. Additionally, the growth of emerging technologies, such as 5G, the Internet of Things (IoT), and artificial intelligence, will further fuel the demand for aluminum PCBs in the coming years.

Regional Analysis

The market for aluminum PCBs is geographically diverse. Asia - Pacific is currently the largest market, with China leading the way. China's strong manufacturing base, extensive supply chain, and large domestic market have contributed to its dominance in the global aluminum PCB market. Other countries in the Asia - Pacific region, such as Japan and South Korea, also have significant shares of the market, driven by their advanced electronics industries.

In North America and Europe, the demand for aluminum PCBs is also growing, especially in the automotive, aerospace, and defense sectors. These regions have a strong focus on high - quality and high - reliability electronics, which creates opportunities for aluminum PCB manufacturers that can meet their stringent requirements.

Competitive Landscape

The aluminum PCB market is highly competitive, with numerous manufacturers vying for market share. Key players in the market compete based on factors such as product quality, technological innovation, cost - effectiveness, and customer service.

Some manufacturers focus on providing high - end, specialized aluminum PCBs for niche markets, such as aerospace and defense, where quality and reliability are of utmost importance. Others target the mass - market applications in consumer electronics and LED lighting, emphasizing cost - effective solutions and large - scale production capabilities. New entrants are also emerging, bringing in fresh technologies and business models, further intensifying the competition in the market.

Future Trends in Aluminum PCBs

Technological Advancements

Advancements in material science are expected to further enhance the performance of aluminum PCBs. The development of new aluminum alloys with improved thermal conductivity, mechanical strength, and corrosion resistance will open up new application possibilities. Additionally, research into novel dielectric materials with lower dielectric loss and higher thermal conductivity will improve the electrical and thermal performance of aluminum PCBs, especially in high - frequency and high - power applications.

In terms of manufacturing technologies, the increasing adoption of automation and artificial intelligence (AI) will improve the efficiency and precision of aluminum PCB production. AI - driven design tools will enable more optimized PCB designs, reducing development time and costs. Automated manufacturing processes, such as robotic assembly and inspection, will increase production speed and quality while reducing human error.

Integration with Emerging Technologies

The future of aluminum PCBs lies in their integration with emerging technologies. With the growth of 5G, IoT, and autonomous vehicles, there will be a need for aluminum PCBs that can support high - speed data transmission, advanced sensor integration, and intelligent control systems.

Aluminum PCBs will be designed to accommodate the complex electronics required for these technologies, enabling seamless communication and reliable operation. For example, in 5G base stations, aluminum PCBs will play a crucial role in managing the heat generated by high - power RF components and ensuring stable signal transmission.

Sustainability Initiatives

As environmental concerns grow, there will be a greater emphasis on sustainable manufacturing practices in the aluminum PCB industry. This includes the use of recycled materials, reducing energy consumption during production, and minimizing waste generation.

Manufacturers will also strive to develop more environmentally friendly surface finishing processes and dielectric materials. Green certifications and compliance with environmental regulations will become more important for companies to remain competitive in the global market and meet the growing demand from environmentally conscious customers.

Conclusion

Aluminum printed circuit boards have emerged as a key enabler in modern electronics, offering superior thermal management capabilities and contributing to the development of more powerful, reliable, and compact electronic devices. From material selection and design to manufacturing and quality assurance, every aspect of aluminum PCB production is critical in ensuring its performance and reliability.

The wide range of applications across various industries, combined with the growing market demand and emerging trends, highlights the significant potential of aluminum PCBs in the future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB