-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 05. 2025, 10:07:36

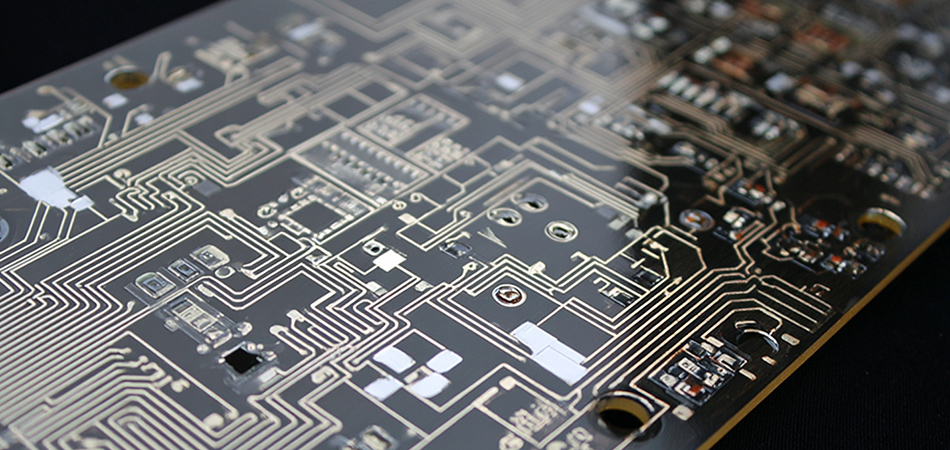

In the dynamic realm of modern electronics, where the pursuit of enhanced performance and miniaturization is relentless, the challenge of heat management has become increasingly critical. As electronic devices pack more functionality into smaller spaces, the heat generated by components can severely impact performance, reliability, and lifespan. High thermal aluminum substrate printed circuit boards (PCBs) have emerged as a revolutionary solution, offering unparalleled thermal dissipation capabilities and enabling the development of advanced electronic systems across diverse industries.

Material Science: The Foundation of High Thermal Aluminum Substrate PCBs

Aluminum Substrate Alloys

The aluminum substrate lies at the heart of these specialized PCBs, and the choice of alloy is pivotal. Pure - grade aluminum alloys, such as those in the 1xxx series, are renowned for their exceptional thermal conductivity. This makes them ideal for applications where rapid heat transfer is the primary concern, like in basic LED lighting modules or entry - level consumer electronics cooling systems. Their malleability allows for easy fabrication, enabling the creation of intricate PCB designs.

On the contrary, alloyed aluminum, especially the 6xxx series containing magnesium and silicon, strikes a balance between thermal conductivity and mechanical robustness. These alloys are favored in automotive and industrial settings, where PCBs must endure vibrations, shocks, and extreme temperature fluctuations. The addition of alloying elements not only enhances mechanical strength but also boosts corrosion resistance, making them suitable for harsh outdoor and chemically - exposed environments.

Dielectric Layers

The dielectric layer in high thermal aluminum substrate PCBs serves dual functions: electrical insulation and heat transfer facilitation. Polyimide - based dielectrics are a top choice for high - temperature and high - frequency applications. Their excellent thermal stability ensures reliable operation in power - hungry environments, such as server power supplies and high - performance computing units. With low dielectric loss, they minimize signal degradation in high - speed circuits, making them indispensable for 5G communication devices and radar systems.

Ceramic - filled epoxies, on the other hand, offer a cost - effective solution with enhanced thermal conductivity. By incorporating ceramic fillers into the epoxy matrix, these dielectrics enable efficient heat transfer from components to the aluminum substrate. They are widely used in consumer electronics, LED lighting, and industrial control systems, providing a good compromise between electrical insulation and thermal performance.

Copper Layers

High - purity copper is the standard for conductive layers due to its low electrical resistance, ensuring efficient power delivery and minimizing heat generated by ohmic losses. The thickness of the copper layer is tailored to the circuit's current - carrying needs. In high - power applications, thicker layers reduce resistance, preventing overheating and ensuring stable component operation. Surface treatments like electroless nickel immersion gold (ENIG), electroless nickel electroless palladium immersion gold (ENEPIG), or organic solderability preservatives (OSP) protect the copper from oxidation, improve solderability, and enhance overall PCB reliability.

Designing for Optimal Performance

Thermal Management

Thermal management is the cornerstone of high thermal aluminum substrate PCB design. Thermal vias, which connect the surface copper layers to the aluminum substrate, play a crucial role. Careful consideration of their size, number, and distribution is essential for efficient heat transfer. A higher density of smaller vias often offers better heat - dissipation performance. Integrating thermal vias with heat sinks or heat spreaders further enhances thermal performance by increasing the surface area for heat exchange with the surroundings, safeguarding components from overheating.

Electrical Design

In high - speed and high - frequency applications, maintaining signal integrity is paramount. Proper trace routing, impedance control, and shielding are vital to minimize signal interference. For power - intensive circuits, efficient power distribution is key, involving reducing voltage drops, minimizing electromagnetic interference (EMI), and ensuring proper isolation between power domains. Multi - layer PCB designs are commonly employed to separate power and signal layers, reducing crosstalk and improving overall system performance.

Mechanical and Environmental Design

The mechanical design of these PCBs must account for harsh operating conditions. Selecting the right aluminum alloy and its thickness ensures adequate mechanical strength. In vibration - prone or shock - exposed environments, additional reinforcement like stiffeners or rigid substrates may be necessary. The PCB's size and shape are optimized for enclosure fit, ventilation, and ease of assembly and disassembly.

For outdoor or harsh - environment applications, environmental protection is crucial. Conformal coatings shield the PCB from moisture, dust, and chemicals. Different coatings, such as silicone - based for high - temperature resistance or polyurethane - based for chemical resistance, are chosen based on application requirements. Tightly sealed enclosures with proper ventilation prevent contaminants from entering while facilitating heat dissipation.

Manufacturing Processes: Precision and Quality

Drilling

Two primary methods are used for drilling holes in high thermal aluminum substrate PCBs: mechanical and laser drilling. Mechanical drilling, a cost - effective option, is suitable for larger holes like those for through - hole components or standard vias. However, it may cause drill bit wear, burr formation, and size inaccuracies, which are addressed through post - processing.

Laser drilling offers high precision, ideal for creating small, complex holes such as microvias in high - density interconnect (HDI) PCBs. It produces clean holes with minimal burrs but is more expensive. The choice between the two methods depends on the specific requirements of the PCB design.

Plating

The plating process, consisting of electroless and electrolytic plating, deposits copper to ensure electrical conductivity. Electroless plating first coats non - conductive surfaces, providing a base for electrolytic plating, which builds up the copper layer to the desired thickness. Advanced techniques like pulse plating can improve copper layer quality, reducing voids and enhancing uniformity and mechanical properties.

Lamination

High - pressure lamination bonds the aluminum substrate, dielectric layer, and copper layers together using adhesive films or prepregs. Subjecting the stack to high pressure and temperature cures the adhesives, ensuring strong bonding. Proper lamination is crucial for structural integrity, electrical performance, and thermal conductivity, as any voids or delaminations can compromise the PCB's functionality.

Surface Finishing

Surface finishing protects copper traces from oxidation and prepares them for soldering. Hot air solder leveling (HASL) is a traditional, cost - effective option. Organic solderability preservatives (OSP) offer a thin, eco - friendly coating suitable for fine - pitch components. Electroless nickel immersion gold (ENIG) provides excellent corrosion resistance and a smooth surface, ideal for high - reliability applications.

Quality Assurance: Ensuring Reliability

Incoming Material Inspection

Before manufacturing, all materials, including the aluminum substrate, copper foil, dielectric materials, and components, are rigorously inspected. The aluminum substrate is checked for flatness, purity, alloy composition, and mechanical properties. Copper foil is examined for thickness uniformity and surface quality. Dielectric materials are tested for electrical insulation, thermal conductivity, and dielectric constant. Only materials meeting strict standards are used.

In - Process Quality Control

During manufacturing, quality control is maintained at every stage. Drilled holes are inspected for accuracy, roundness, and burrs. Plating thickness and uniformity are continuously monitored. Lamination is checked for proper bonding using X - ray inspection. Surface finishing is evaluated for coating thickness, adhesion, and defect - free application. Automated optical inspection (AOI) systems detect early defects, enabling timely corrective actions.

Final Testing

Completed PCBs undergo comprehensive final testing. Electrical tests check for short circuits, open circuits, and impedance matching. Thermal tests, such as thermal cycling and infrared thermography, assess thermal management capabilities under real - world conditions. Mechanical tests evaluate strength and durability, ensuring the PCB meets performance and reliability requirements.

Applications: Transforming Industries

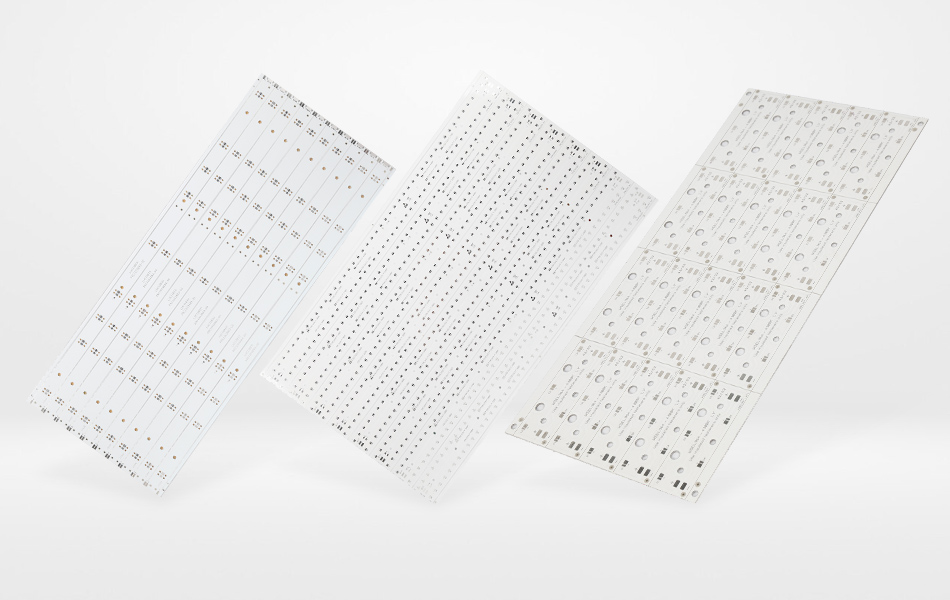

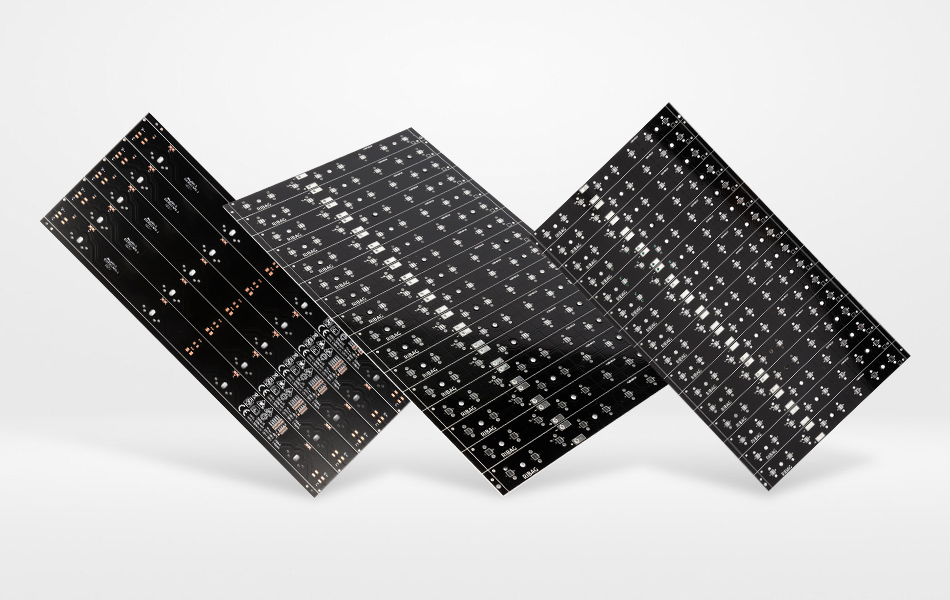

LED Lighting

LED lighting is one of the largest application areas for high thermal aluminum substrate PCBs. LEDs generate significant heat, and efficient heat dissipation is essential for consistent light output and long lifespan. These PCBs enable rapid heat transfer from LEDs, making them suitable for various lighting applications, from residential and commercial fixtures to automotive headlights, streetlights, and architectural lighting projects. Their customizability in size, shape, and thermal performance caters to diverse lighting needs.

Automotive Electronics

In the automotive industry, high thermal aluminum substrate PCBs are increasingly adopted. Modern vehicles feature numerous electronic systems like power inverters, battery management units, engine control modules, and advanced driver - assistance systems (ADAS). These systems generate substantial heat and operate in harsh environments with temperature variations, vibrations, and moisture. The high thermal conductivity, mechanical strength, and environmental resistance of these PCBs ensure reliable operation, enhancing vehicle safety, performance, and efficiency.

Industrial Electronics

Industrial electronics, including motor drives, control systems, power supplies, and automation equipment, rely on high thermal aluminum substrate PCBs. Industrial environments are characterized by dust, moisture, chemicals, and extreme temperatures. These PCBs can withstand such harsh conditions while effectively managing heat, ensuring continuous operation of industrial equipment, reducing downtime, and lowering maintenance costs. Their ability to handle high power densities makes them ideal for power - intensive industrial applications.

Consumer Electronics

With the demand for high - performance consumer electronics like smartphones, tablets, laptops, and gaming consoles on the rise, these PCBs are becoming essential. These devices generate significant heat during resource - intensive tasks. High thermal aluminum substrate PCBs help dissipate heat, allowing devices to operate at optimal temperatures, improving performance and user experience, and extending device lifespan. They also enable the development of thinner and lighter consumer electronics by facilitating efficient thermal management.

Aerospace and Defense

In aerospace and defense, high thermal aluminum substrate PCBs are used in critical applications such as avionics systems, radar, communication equipment, and military - grade electronics. These applications require PCBs that can withstand extreme conditions like high altitudes, rapid temperature changes, vibrations, and radiation. The excellent thermal management, mechanical strength, and reliability of these PCBs are crucial for mission success and personnel safety, and they must adhere to strict quality and safety standards.

Market Analysis: Trends and Opportunities

Market Size and Growth

The global market for high thermal aluminum substrate PCBs has been expanding steadily and is poised for continued growth. The increasing demand for high - performance electronics across industries, along with the need for efficient heat management solutions, drives market growth. As electronics become more power - intensive and compact, the requirement for these PCBs will only increase. Emerging technologies like 5G, the Internet of Things (IoT), artificial intelligence, and autonomous vehicles present new growth opportunities, as they demand advanced thermal management solutions.

Regional Analysis

The market is geographically diverse. Asia - Pacific dominates, led by China, which benefits from a robust manufacturing base, large domestic market, and rapid growth in consumer electronics and automotive sectors. North America and Europe are important markets, especially for high - end applications in aerospace, defense, and automotive electronics, where quality and innovation are prioritized. The Middle East, Africa, and Latin America are emerging markets, with growing investment in infrastructure, smart city projects, and the expansion of the automotive and consumer electronics industries expected to drive demand.

Competitive Landscape

The market is highly competitive, with numerous players vying for share. Key competitors focus on product quality, technological innovation, cost - effectiveness, and customer service. Some target niche markets like aerospace and defense, emphasizing high - reliability products. Others aim at mass - market applications in consumer electronics and LED lighting, leveraging cost - efficient production capabilities. New entrants bring fresh technologies and business models, intensifying competition and driving industry innovation.

In conclusion, high thermal aluminum substrate PCBs have become an indispensable part of modern electronics, enabling the development of more powerful, reliable, and efficient devices. With continuous advancements in material science, design, and manufacturing, and the emergence of new applications and markets, their importance is set to grow. As the electronics industry continues to evolve, these PCBs will play a pivotal role in shaping the future of technology across various sectors.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB