-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 05. 2025, 10:21:15

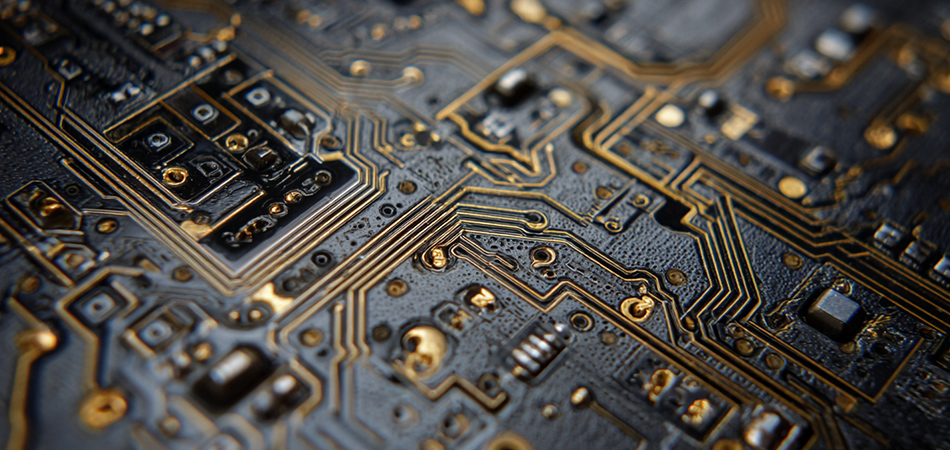

In the rapidly evolving electronics industry, where technological progress continuously drives the development of smaller, faster, and more powerful devices, printed circuit boards (PCBs) serve as the fundamental building blocks. Among the diverse PCB options, aluminum substrate PCBs have emerged as a revolutionary solution, transforming heat management and component integration. Their unique combination of properties makes them indispensable across numerous industries, from consumer electronics to aerospace and defense. This article comprehensively explores aluminum substrate PCBs, covering material composition, design, manufacturing, quality control, applications, and market trends.

Material Composition of Aluminum Substrate PCBs

Aluminum Substrate Varieties

The performance of aluminum substrate PCBs is significantly influenced by the choice of aluminum alloy for the substrate. Aluminum stands out for its relatively high thermal conductivity compared to many other common PCB substrate materials.

Pure aluminum offers excellent thermal transfer but may lack sufficient mechanical strength for certain applications. Aluminum alloys, like those in the 6xxx series containing magnesium and silicon, enhance mechanical robustness. These alloys can withstand mechanical stress, vibrations, and temperature fluctuations typical in industrial and automotive environments. Alloying elements also boost corrosion resistance, enabling reliable operation in harsh outdoor or chemically exposed conditions.

Dielectric Materials

The dielectric layer in aluminum substrate PCBs serves as an electrical insulator between the copper layers and the aluminum substrate while facilitating heat transfer.

Polyimide - based dielectrics excel in high - temperature and high - frequency applications. They maintain structural and electrical integrity at elevated temperatures, making them suitable for power - intensive electronics like data center servers and high - performance computing systems. Their low dielectric loss minimizes signal degradation in high - speed circuits, crucial for 5G communication and radar systems.

Ceramic - filled epoxies provide a cost - effective alternative with enhanced thermal conductivity. By incorporating ceramic particles into the epoxy matrix, they improve heat - transfer efficiency. These materials are widely used in consumer electronics, LED lighting, and industrial control panels, balancing electrical insulation and thermal performance.

Copper Layers

Copper, with its low electrical resistance, is the standard for conductive layers in aluminum substrate PCBs. This property enables efficient power transmission, reducing power losses and heat generation.

Copper layer thickness is determined by circuit current - carrying needs. In high - power applications, thicker layers lower resistance. Surface treatments like electroless nickel immersion gold (ENIG), electroless nickel electroless palladium immersion gold (ENEPIG), and organic solderability preservatives (OSP) protect copper from oxidation, improve solderability, and ensure long - term reliable electrical connections.

Design Methodologies for Aluminum Substrate PCBs

Thermal Management Strategies

Thermal management is a key advantage of aluminum substrate PCBs. Thermal vias are essential in their thermal design, creating direct pathways for heat to flow from heat - generating components to the aluminum substrate, which acts as a heat sink.

Designing thermal vias requires considering size, number, and distribution. A well - planned layout enhances heat - dissipation efficiency. Integrating external heat - dissipating components like heat sinks and spreaders further improves thermal performance by increasing the surface area for heat exchange, preventing thermal - induced failures.

Electrical Design Considerations

Electrical design is crucial for aluminum substrate PCB development. In high - speed and high - frequency circuits, maintaining signal integrity is vital. Proper trace routing, impedance control, and shielding minimize signal interference and ensure accurate transmission, considering factors like trace length, bend radius, and shielding methods.

For power - intensive circuits, efficient power distribution is essential. Designers focus on reducing voltage drops, minimizing electromagnetic interference (EMI), and isolating power domains. Multi - layer PCB designs separate power and signal layers, improving electrical isolation and reducing crosstalk.

Mechanical Design Elements

The mechanical design of aluminum substrate PCBs must account for mechanical stresses and vibrations during operation. The choice of aluminum alloy and its thickness determines the board's mechanical strength.

In applications with significant mechanical forces, additional reinforcement like stiffeners or a more robust substrate may be used. Mounting and fastening methods are carefully designed to ensure secure attachment while minimizing stress transmission to the PCB.

Environmental Protection Design

Aluminum substrate PCBs are often used in harsh environments. To ensure reliable operation, their design includes protection against moisture, dust, chemicals, and extreme temperatures.

Conformal coatings provide a protective barrier. Different types, such as silicone - based for high - temperature resistance and polyurethane - based for chemical resistance, are selected based on application requirements. The device enclosure, with tight seals and proper ventilation, also plays a crucial role in preventing contaminants and facilitating heat dissipation.

Manufacturing Processes of Aluminum Substrate PCBs

Drilling Operations

The drilling process in aluminum substrate PCB manufacturing creates holes for vias, component mounting, etc. There are two main techniques: mechanical and laser drilling.

Mechanical drilling, a cost - effective method for larger holes, uses rotating drill bits but may cause drill bit wear, burr formation, and size variations. Post - processing steps like deburring and hole - size calibration are often needed to address these issues.

Laser drilling offers high precision, ideal for small, complex holes like microvias in high - density interconnect (HDI) PCBs. It uses a laser beam to ablate material, resulting in clean holes with minimal burrs. However, it is more expensive and may have lower throughput for large - scale production.

Plating Processes

The plating process deposits copper to establish electrical conductivity, consisting of electroless and electrolytic plating.

Electroless plating first coats non - conductive surfaces, like drilled holes, through a chemical reaction without external current, providing a base for electrolytic plating.

Electrolytic plating then builds up the copper layer to the desired thickness using an electrical current. Advanced techniques like pulse plating can improve copper layer quality by reducing voids, enhancing uniformity, and boosting mechanical properties.

Lamination Procedures

Lamination bonds the aluminum substrate, dielectric layer, and copper layers together. High - pressure lamination is commonly used, where layers are stacked with adhesive films or prepregs and subjected to high pressure and temperature in a laminating press.

The heat and pressure cure the adhesives, ensuring strong bonding. Proper lamination is crucial for the PCB's structural integrity, electrical performance, and thermal conductivity, as voids or delaminations can compromise functionality.

Surface Finishing Techniques

Surface finishing protects copper traces from oxidation and prepares them for soldering. Common surface finishes include:

Hot air solder leveling (HASL): A traditional, cost - effective method that immerses the PCB in molten solder and blows off excess with hot air, leaving a thin solder layer.

Organic solderability preservatives (OSP): Provides a thin, transparent organic coating, suitable for fine - pitch components and environmentally friendly.

Electroless nickel immersion gold (ENIG): Offers excellent corrosion resistance and a smooth surface, ideal for high - reliability applications but more expensive.

Quality Control in Aluminum Substrate PCB Production

Incoming Material Inspection

Before manufacturing, all incoming materials, including the aluminum substrate, copper foil, dielectric materials, and components, are thoroughly inspected. The aluminum substrate is checked for flatness, purity, alloy composition, and mechanical properties. Copper foil is inspected for thickness uniformity and surface defects.

Dielectric materials are tested for electrical insulation, thermal conductivity, and dielectric constant. Components are verified for specifications and functionality. Only materials meeting strict quality standards are used in production.

In - Process Quality Monitoring

During manufacturing, quality control measures are implemented at various stages. Drilled holes are inspected for size accuracy, roundness, and burrs. Plating thickness and uniformity are continuously monitored.

Lamination is checked for proper bonding, with X - ray inspection used to detect hidden voids or delaminations. Surface finishing is examined for coating thickness, adhesion, and defects. Automated optical inspection (AOI) systems quickly detect visual defects, enabling prompt corrective actions.

Final Testing

Once manufactured, aluminum substrate PCBs undergo comprehensive final tests. Electrical tests check for short circuits, open circuits, and impedance matching to ensure effective signal and power transmission.

Thermal tests, such as thermal cycling and infrared thermography, evaluate thermal management. Thermal cycling simulates real - world temperature variations to identify thermal - related failures, while infrared thermography visualizes temperature distribution and detects hotspots. Mechanical tests may also assess the board's strength and durability.

Applications of Aluminum Substrate PCBs

LED Lighting Systems

LED lighting is a major application area for aluminum substrate PCBs. LEDs generate significant heat during operation, and effective heat management is essential for maintaining performance and extending lifespan.

These PCBs efficiently dissipate heat, making them suitable for various LED products, from residential and commercial lighting to automotive headlights, streetlights, and architectural lighting. Their customizability in size, shape, and thermal performance caters to different lighting requirements.

Automotive Electronics

The automotive industry increasingly adopts aluminum substrate PCBs for systems like engine control units, power inverters, battery management systems, and advanced driver - assistance systems (ADAS).

These systems generate heat and operate in harsh environments with temperature variations, vibrations, and exposure to moisture and dust. Aluminum substrate PCBs' high thermal conductivity, mechanical strength, and environmental resistance ensure reliable operation, enhancing vehicle safety, performance, and fuel efficiency.

Industrial Electronics

In the industrial sector, aluminum substrate PCBs are widely used in motor drives, industrial control systems, power supplies, and automation equipment. Industrial environments are characterized by dust, moisture, chemicals, and extreme temperatures, posing challenges to electronic components.

These PCBs can withstand harsh conditions while managing component heat, ensuring continuous and reliable equipment operation, reducing downtime, and lowering maintenance costs. They are also suitable for power - intensive industrial applications due to their ability to handle high power densities.

Consumer Electronics

With the growing demand for high - performance consumer electronics like smartphones, tablets, laptops, and gaming consoles, aluminum substrate PCBs are becoming more prevalent. These devices generate significant heat during resource - intensive tasks.

These PCBs help dissipate heat, allowing devices to operate at optimal temperatures, improving performance and user experience, and extending device lifespan. Their thin and lightweight nature suits modern consumer electronics' sleek designs.

Aerospace and Defense

In aerospace and defense, where reliability is paramount, aluminum substrate PCBs are used in critical applications such as avionics systems, radar systems, communication equipment, and military - grade electronics.

These applications involve operating in extreme conditions like high altitudes, rapid temperature changes, intense vibrations, and radiation exposure. Aluminum substrate PCBs' excellent thermal management, mechanical strength, and reliability are crucial for ensuring the proper functioning of critical electronic systems, essential for mission success and personnel safety.

Market Trends of Aluminum Substrate PCBs

Market Growth Drivers

The global market for aluminum substrate PCBs has been growing significantly and is expected to continue. The increasing demand for high - performance electronics across industries drives this growth, as smaller and more powerful devices require efficient heat management, which these PCBs provide.

The emergence of new technologies like 5G, the Internet of Things (IoT), artificial intelligence, and autonomous vehicles also creates opportunities. These technologies demand advanced PCBs with excellent thermal and electrical performance, further fueling the growth of the aluminum substrate PCB market.

Regional Market Dynamics

The market is geographically diverse. The Asia - Pacific region dominates, mainly due to its strong manufacturing base, large domestic market, and rapid growth in consumer electronics and automotive industries. China is a major player, holding a significant share in production and consumption.

North America and Europe are important markets, especially for high - end applications in aerospace, defense, and automotive electronics, where quality, innovation, and reliability are prioritized. The Middle East, Africa, and Latin America are emerging markets, with growing investment in infrastructure, smart city projects, and electronics industry expansion expected to drive demand for aluminum substrate PCBs.

Competitive Landscape

The market for aluminum substrate PCBs is highly competitive. Key competitors differentiate themselves through product quality, technological innovation, cost - effectiveness, and customer service.

Some companies focus on high - end niche markets like aerospace and defense, investing heavily in research and development to meet strict quality and reliability standards. Others target mass - market applications in consumer electronics and LED lighting, leveraging cost - efficient production and economies of scale.

New entrants bring innovative technologies and business models, intensifying competition and driving continuous innovation. As demand grows, companies must adapt and evolve to remain competitive in this dynamic market.

In conclusion, aluminum substrate PCBs have become an integral part of the modern electronics ecosystem. Their unique combination of properties makes them essential for a wide range of applications. As technology continues to advance, the demand for these PCBs will likely increase further. Manufacturers need to focus on continuous innovation, quality improvement, and cost - optimization to meet market demands and stay competitive in the evolving electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB