-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 03. 2025, 10:24:19

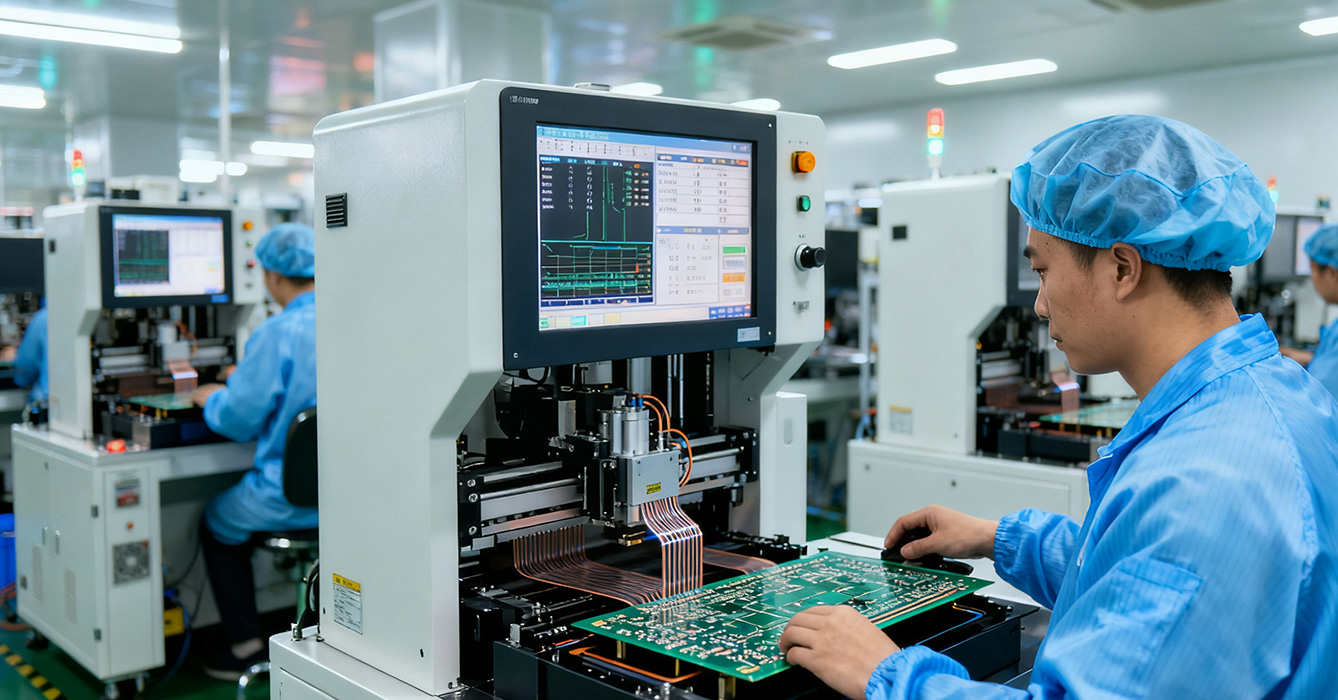

As electronic devices evolve toward ultra-miniaturization, high integration, and high-frequency operation, the demand for flexible printed circuits (FPCs) with blind and buried vias has surged dramatically. A professional Blind and Buried Vias FPC Manufacturer specializes in the design and production of FPCs integrated with blind vias (connecting surface to inner layers) and buried vias (connecting only inner layers), which are pivotal for optimizing circuit density, reducing signal loss, and enhancing design flexibility. Unlike standard FPC manufacturers focusing on through-hole vias, these specialized manufacturers possess unique expertise in blind and buried via fabrication, high-density routing, and signal integrity optimization—critical for powering next-generation devices in 5G communications, automotive electronics, and precision medical equipment. Partnering with a reputable Blind and Buried Vias FPC Manufacturer is essential for enterprises aiming to translate innovative high-density designs into practical, high-performance electronic products.

The competitive edge of a Blind and Buried Vias FPC Manufacturer lies in its specialized mastery of blind/buried via technologies and their integration into flexible circuits:

- Precision Blind & Buried Via Fabrication: Top manufacturers excel in advanced via-forming processes tailored for blind and buried structures, including laser drilling with sub-micron precision, plasma desmearing to ensure clean via walls, and high-uniformity plating (e.g., electroless nickel immersion gold, ENIG). These processes eliminate common defects such as via voids, poor interlayer adhesion, and signal leakage, ensuring stable electrical connectivity between layers. Strict process control over via positioning and interlayer alignment guarantees the accuracy required for high-density circuit layouts.

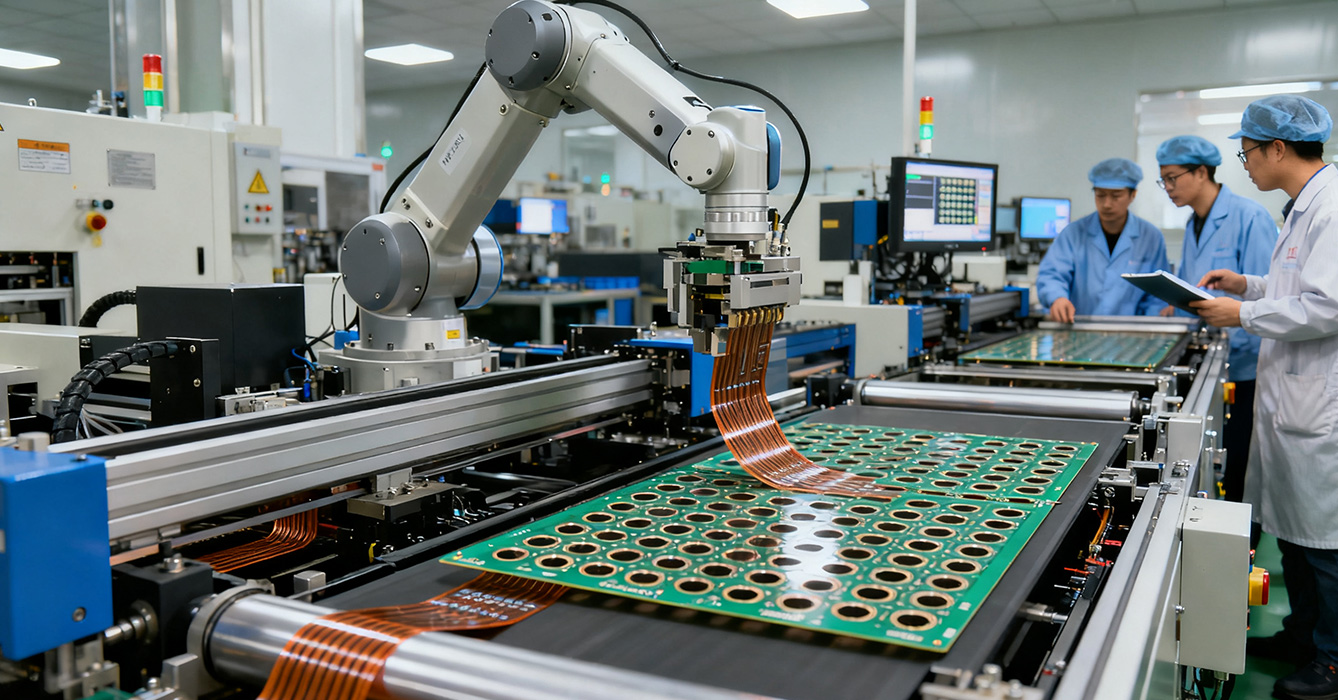

- High-Density Layout Optimization: Blind and buried vias enable dense interlayer routing without occupying surface space, a key advantage for compact devices. Manufacturers leverage professional EDA (Electronic Design Automation) tools to optimize FPC stackups and via layouts, maximizing component density while minimizing signal crosstalk. This capability allows more functional modules (e.g., sensors, communication chips, power management units) to be integrated onto a single FPC, supporting the miniaturization of electronic devices.

- High-Frequency Signal Integrity Guarantee: For high-frequency applications (e.g., 5G millimeter-wave modules, automotive radar), signal loss and electromagnetic interference (EMI) are major concerns. Blind and Buried Vias FPC Manufacturers optimize via designs and select low-loss materials (e.g., high-Tg polyimides with low dielectric constant) to shorten signal paths, reduce parasitic capacitance/inductance, and suppress EMI. This ensures stable signal transmission and reliable performance of high-frequency devices.

- Customized Solution Design: Different applications have unique requirements for blind and buried via FPCs. Manufacturers offer tailored solutions, including custom stackup designs (2-layer to 8-layer and above), selective via reinforcement for high-mechanical-stress scenarios, and compatibility with rigid-flex structures. Their engineering teams collaborate closely with customers to understand design constraints and application needs, delivering FPCs that perfectly match specific product requirements.

Specialized manufacturers of blind and buried vias FPCs provide irreplaceable value for advanced electronic product development:

1. Enabling Device Miniaturization & Lightweight: By eliminating surface-occupying through-holes, blind and buried vias significantly reduce the FPC footprint and thickness. This enables the development of ultra-compact devices such as miniaturized medical sensors, portable 5G modules, and slim wearable gadgets—critical for industries where space is at a premium.

2. Supporting High-Frequency & High-Speed Applications: The optimized signal paths of blind and buried vias minimize signal attenuation, making them ideal for high-frequency RF applications and high-speed data transmission systems. Manufacturers’ expertise in signal integrity ensures that FPCs can meet the performance requirements of 5G, automotive ADAS, and other cutting-edge technologies.

3. Enhancing Design Flexibility: Blind and buried vias allow more flexible circuit layout designs, enabling engineers to integrate complex functions without being limited by through-hole constraints. This flexibility is particularly valuable for curved or irregularly shaped devices, such as foldable smartphone hinges and automotive curved display modules.

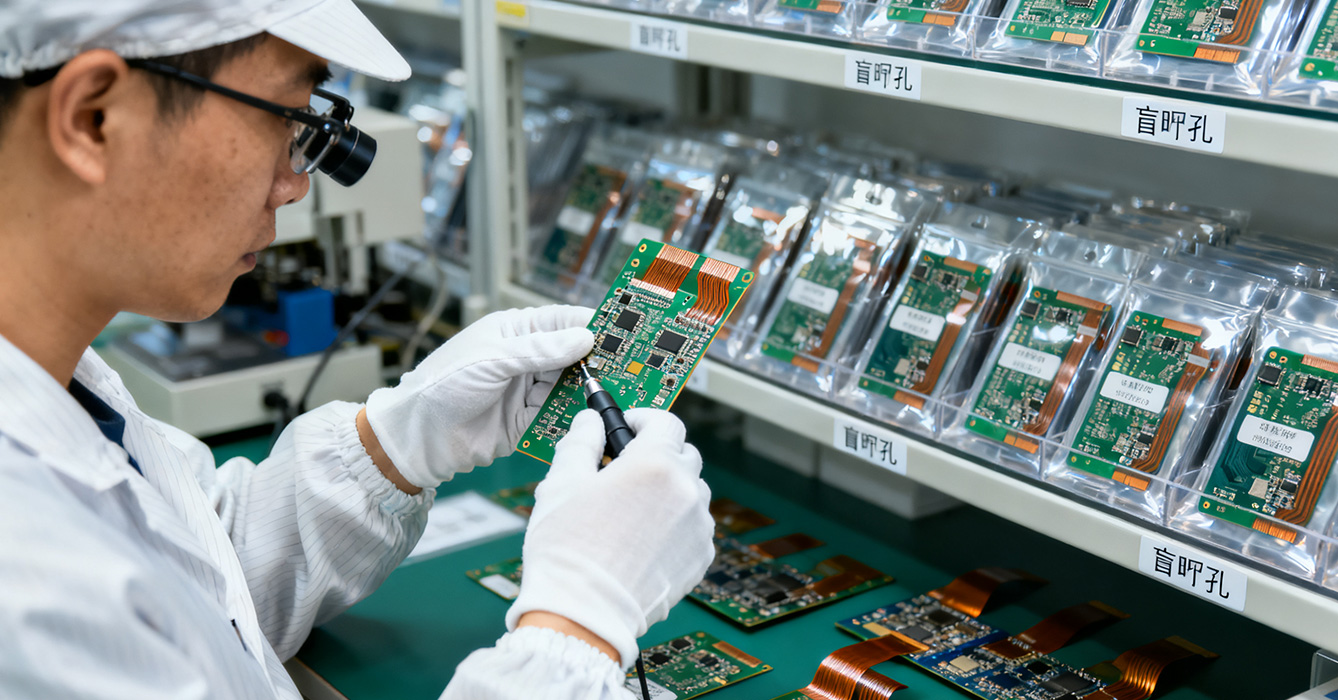

4. Improving Production Efficiency & Yield: Professional manufacturers leverage mature blind and buried via fabrication processes and advanced quality control tools (e.g., X-ray inspection, automated optical inspection) to ensure high production yield. Their experience in design-for-manufacturability also helps customers avoid common pitfalls, reducing design iterations and accelerating time-to-market.

Blind and Buried Vias FPC Manufacturers cater to high-end industries that demand high-density, high-performance flexible circuits:

- 5G & Consumer Electronics: Supplies FPCs for 5G smartphones, millimeter-wave modules, foldable devices, and VR/AR headsets. Blind and buried vias enable the integration of multiple high-frequency modules and sensors into compact spaces, supporting advanced features such as 5G full-band connectivity and high-resolution displays.

- Automotive Electronics: Delivers FPCs for ADAS (Advanced Driver Assistance Systems), in-vehicle infotainment systems, and EV battery management systems (BMS). The high-density integration and signal integrity of blind and buried vias ensure reliable operation of automotive electronic systems under high-frequency and vibration conditions.

- Precision Medical Devices: Provides miniaturized FPCs for implantable sensors, portable diagnostic equipment, and surgical robots. Blind and buried vias allow for dense component integration in small form factors, while ensuring biocompatibility and reliable signal transmission for life-critical medical applications.

- Aerospace & Industrial IoT: Manufactures high-performance FPCs for aerospace avionics, satellite communication systems, and industrial IoT edge devices. The lightweight and high-density characteristics of blind and buried vias FPCs meet the strict requirements of aerospace and industrial environments for component size, weight, and reliability.

In conclusion, a Blind and Buried Vias FPC Manufacturer is a key enabler of advanced flexible electronics, specializing in technologies that drive high-density integration, high-frequency performance, and device miniaturization. By mastering precision blind and buried via fabrication, optimizing signal integrity, and offering customized solutions, these manufacturers support innovation across critical industries. As the demand for ultra-compact, high-performance electronic devices continues to grow, partnering with a reputable Blind and Buried Vias FPC Manufacturer will remain a strategic choice for enterprises seeking to gain a competitive edge in high-end markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB