-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 03. 2025, 10:25:21

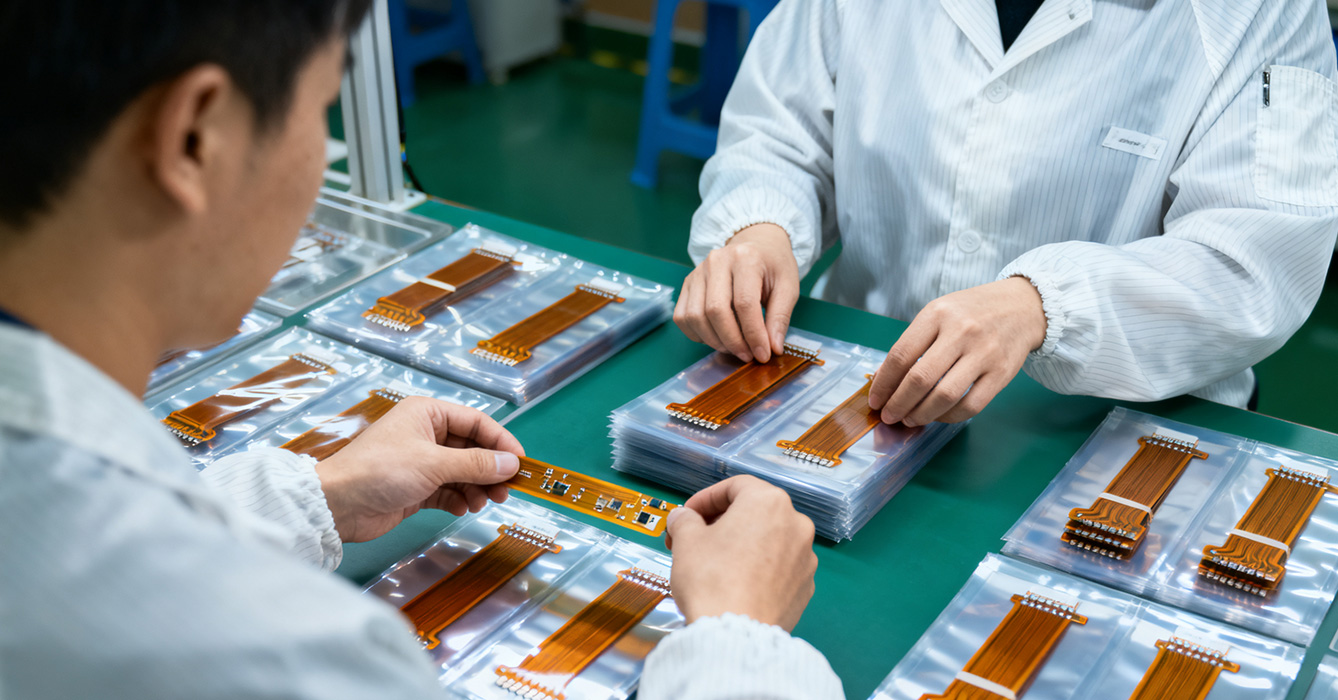

In the fast-paced global electronics market, where product lifecycles are shortening and customer demands are increasingly diverse, a professional FPC manufacturer stands out as a strategic partner rather than a mere component supplier. Specializing in flexible printed circuits (FPCs)—the foundational components enabling flexible, compact, and multi-functional electronic designs—top FPC manufacturers differentiate themselves through agile supply chain management and deep customization capabilities. Unlike generic component manufacturers, they can quickly adapt to market changes, tailor FPC solutions to specific application needs, and ensure compliance with global industry regulations. For enterprises ranging from startups to Fortune 500 companies, partnering with such an FPC manufacturer is critical to accelerating product development, reducing market risks, and maintaining competitive advantage.

The competitive edge of a leading FPC manufacturer lies in its ability to integrate agility, customization, and reliability across the entire value chain:

- Agile Supply Chain & Rapid Response: Top FPC manufacturers build resilient, flexible supply chains with diversified certified material sources and streamlined production workflows. This allows them to quickly adjust to fluctuations in order volume—whether for small-batch prototype orders or large-scale mass production—and shorten lead times significantly. Advanced demand forecasting tools and real-time production monitoring systems further enhance their responsiveness, ensuring on-time delivery even amid global supply chain disruptions.

- Deeply Customized FPC Solutions: Every electronic product has unique design constraints and performance requirements. A professional FPC manufacturer offers end-to-end customization, from material selection (e.g., high-flex polyimides, flame-retardant substrates) and circuit layout optimization to structural design (e.g., rigid-flex combinations, selective stiffeners). Their engineering teams collaborate with customers in the early design phase, providing design-for-manufacturability (DFM) insights to optimize performance while reducing production costs.

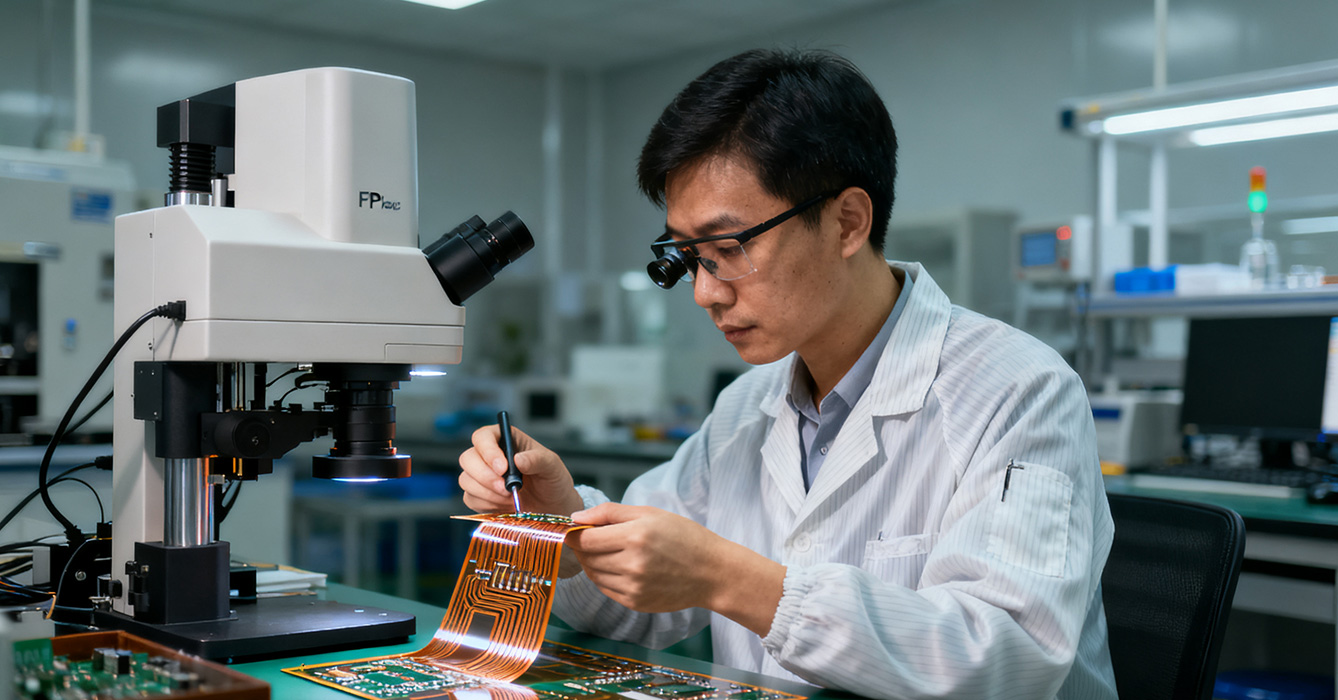

- Global Compliance & Quality Assurance: To support customers’ global market expansion, FPC manufacturers adhere to strict international standards and regional regulations, such as RoHS, REACH, IPC-6012/2221, and industry-specific certifications (IATF 16949 for automotive, ISO 13485 for medical). Rigorous quality control processes—including automated optical inspection (AOI), X-ray testing, and reliability validation (flex cycling, thermal shock tests)—ensure consistent product quality across all production batches.

- Cross-Industry Application Expertise: Leading FPC manufacturers accumulate in-depth knowledge across diverse industries, enabling them to understand the unique environmental and performance demands of different sectors. Whether it’s high-temperature resistance for automotive electronics, biocompatibility for medical devices, or ultra-miniaturization for wearables, they can tailor FPC solutions to meet the specific needs of each application scenario.

Collaborating with a reputable FPC manufacturer delivers tangible benefits for electronic product development and market success:

1. Accelerated Time-to-Market: Agile supply chains and rapid prototyping capabilities reduce the time from design validation to mass production. This allows customers to launch new products faster, capturing market opportunities ahead of competitors.

2. Reduced Development & Production Risks: DFM support and rigorous quality control minimize design iterations and defect rates, lowering the risk of production delays and cost overruns. Diversified supply chains also mitigate the impact of material shortages or geopolitical disruptions.

3. Optimized Total Cost of Ownership: Customized solutions and DFM insights help avoid over-engineering, reducing material waste and production costs. High-quality FPCs also enhance the reliability of end products, lowering warranty costs and improving brand reputation.

4. Scalability for Business Growth: As customer businesses expand, FPC manufacturers can seamlessly scale production capacity to meet increasing demand. This scalability ensures a stable supply of FPCs even during periods of rapid growth, supporting long-term business development.

FPC manufacturers support a wide range of industries, delivering customized solutions for diverse electronic products:

- Smart Wearables & Consumer Electronics: Supplies ultra-thin, high-flex FPCs for smartwatches, fitness trackers, wireless earbuds, and foldable smartphones. These FPCs enable compact designs, seamless integration of sensors and batteries, and reliable performance during daily use.

- Automotive Electronics: Delivers rugged FPCs for in-vehicle infotainment systems, ADAS (Advanced Driver Assistance Systems), EV (Electric Vehicle) powertrain components, and lighting systems. These FPCs withstand extreme temperatures, vibration, and electromagnetic interference (EMI) in automotive environments.

- Medical & Healthcare Devices: Provides biocompatible, miniaturized FPCs for portable diagnostic equipment, wearable health monitors, and surgical instruments. Strict quality control and compliance with medical standards ensure patient safety and device reliability.

- Industrial IoT & Automation: Supports industrial sensors, robotic control systems, and smart factory equipment with durable FPCs. These FPCs resist dust, humidity, and temperature fluctuations, ensuring stable operation in harsh industrial environments.

In conclusion, a professional FPC manufacturer is a vital enabler of innovation in the global electronics industry, leveraging agile supply chains, deep customization capabilities, and global compliance expertise to support customers’ success. As electronic products continue to evolve toward flexibility, miniaturization, and intelligence, the role of such manufacturers becomes increasingly critical. For enterprises seeking to thrive in a competitive market, partnering with a reputable FPC manufacturer is a strategic investment that accelerates product development, reduces risks, and drives long-term growth.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB