-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 16. 2025, 11:59:20

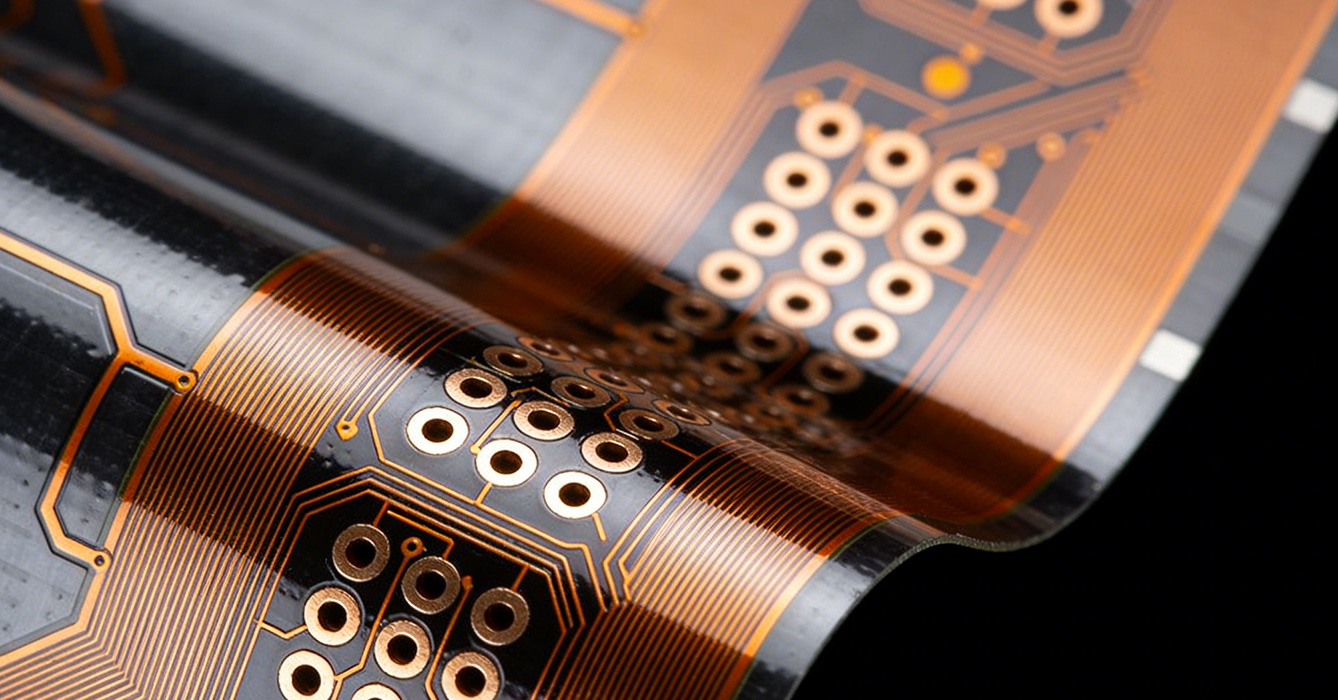

As the electronics industry evolves toward miniaturization, high-frequency operation, and multi-functional integration, the demand for flexible PCBs capable of supporting dense interconnections and reliable signal transmission has never been higher. Blind and Buried Vias Flexible PCB emerges as a pivotal solution, integrating blind vias (connecting surface and inner layers) and buried vias (linking inner layers exclusively) into flexible substrates to overcome the limitations of traditional through-hole designs. Unlike standard flexible PCBs, this advanced technology achieves superior space utilization, minimized signal loss, and enhanced mechanical flexibility—critical for powering 5G communication, autonomous driving, and wearable smart devices. For electronics manufacturers pursuing innovation in high-performance, compact products, Blind and Buried Vias Flexible PCB has become an indispensable core component.

The unique structure of Blind and Buried Vias Flexible PCB is specifically engineered to address the challenges of high-frequency signal transmission, a key requirement for next-generation electronic systems:

- Signal Path Shortening & Interference Reduction: Blind and buried vias eliminate the need for through-holes that penetrate the entire substrate, significantly shortening signal transmission paths. This minimizes signal attenuation and delay, which are major issues in high-frequency applications such as 5G millimeter-wave communication. Additionally, the non-penetrating via structure reduces electromagnetic interference (EMI) between layers, ensuring signal integrity and improving the overall performance of high-speed electronic systems.

- Low-Dielectric Material Synergy: Advanced Blind and Buried Vias Flexible PCB leverages high-performance substrates such as liquid crystal polymer (LCP) and modified polyimide (MPI), which possess excellent dielectric properties. The combination of these low-dielectric materials with optimized blind/buried via designs further enhances high-frequency transmission efficiency, making the PCBs ideal for 5G base stations, satellite communication modules, and high-speed data processing devices.

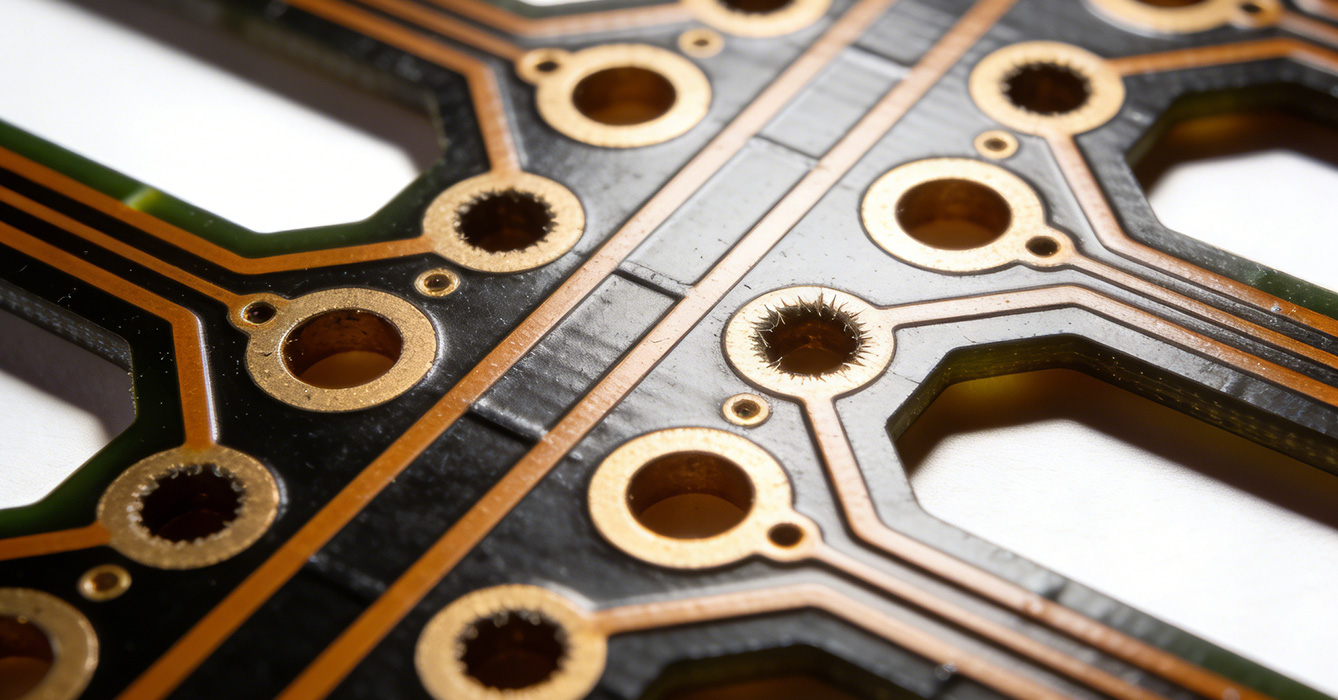

The production of Blind and Buried Vias Flexible PCB relies on the synergy of cutting-edge manufacturing technologies to ensure precision, reliability, and scalability:

- Precision Laser Drilling Technology: Replacing traditional mechanical drilling, laser drilling enables the creation of ultra-small blind and buried vias with high positional accuracy. This technology overcomes the limitations of mechanical drilling in flexible substrates, avoiding material damage and ensuring consistent via quality. Advanced laser systems also support real-time adjustment of drilling parameters, accommodating different substrate materials and via design requirements.

- Horizontal Copper Deposition & Pulse Plating: To address the challenge of reliable via plating in flexible substrates, advanced horizontal copper deposition and pulse plating processes are adopted. These processes ensure uniform and dense copper coverage on via walls, enhancing via conductivity and mechanical strength. The optimized plating parameters also reduce internal stress in the substrate, maintaining the flexibility and structural integrity of the PCB.

- Optical Alignment Compensation: Flexible substrates are prone to thermal deformation during manufacturing, which can affect via positioning accuracy. Optical target compensation algorithms are employed to real-time correct for deformation, ensuring layer-to-layer alignment errors are minimized. This precision control is critical for achieving high-density interconnections in complex blind and buried via structures.

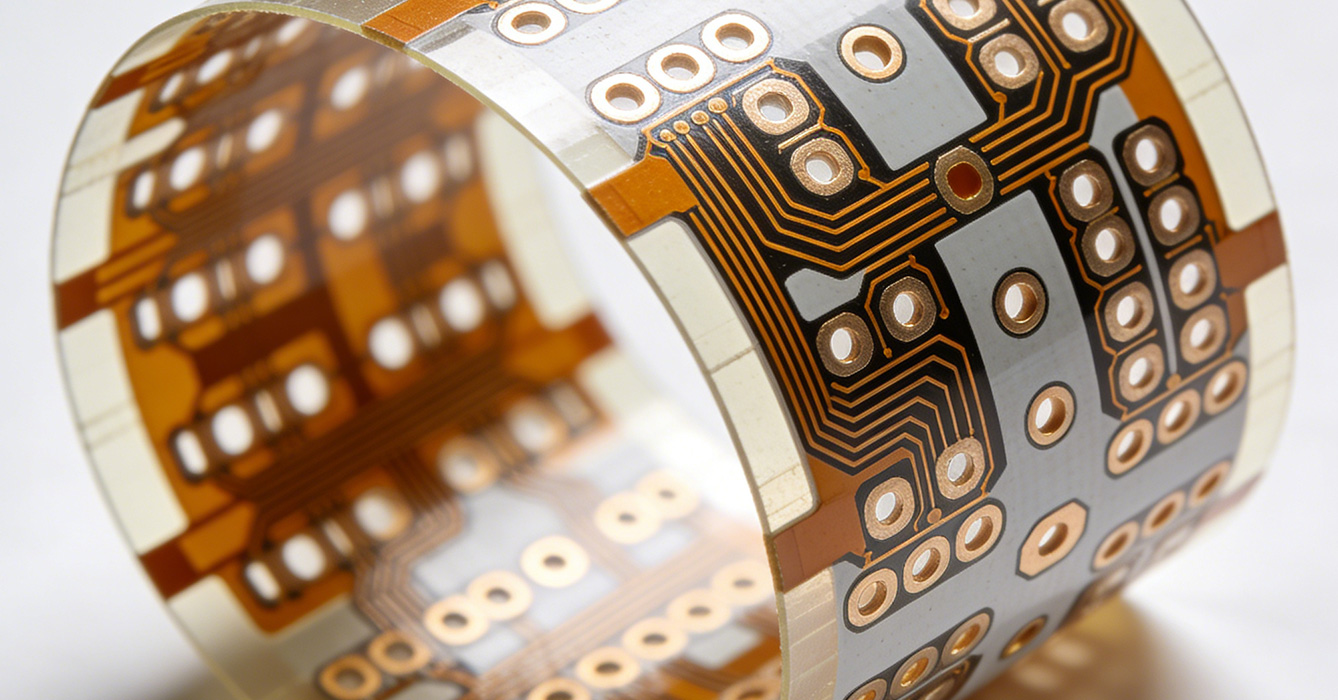

Blind and Buried Vias Flexible PCB is a key enabler of innovation in emerging smart electronic fields, addressing the demand for compact, high-performance, and flexible circuit solutions:

- 5G Communication Systems: In 5G base stations and mobile devices, the PCB provides high-density interconnections and reliable high-frequency signal transmission. Its compact design helps reduce the size of 5G modules, while its flexible nature enables integration into complex device structures, supporting the widespread deployment of 5G technology.

- Autonomous Driving Electronics: Autonomous vehicles rely on a multitude of sensors (e.g., lidar, millimeter-wave radar) and control systems that require high-speed data transmission. Blind and Buried Vias Flexible PCB offers the necessary high-frequency performance and compact form factor, enabling seamless integration into vehicle electronics while withstanding the harsh operating conditions of automotive environments.

- High-End Wearable Devices: For advanced wearables such as smart glasses and health monitors, the PCB's flexibility and high-density integration support miniaturization and ergonomic design. The blind and buried via structure ensures reliable signal transmission between multiple sensors and processing units, enabling accurate health data collection and real-time feedback.

The development of Blind and Buried Vias Flexible PCB is focused on further enhancing performance, reducing costs, and expanding application boundaries to meet evolving market demands:

- AI-Driven Quality Control: The integration of artificial intelligence (AI) into manufacturing processes will enable real-time detection and prediction of defects in blind and buried vias. This improves production yield, reduces manufacturing costs, and ensures consistent product quality, supporting large-scale deployment in high-volume electronic applications.

- Multifunctional Integration: Future innovations will integrate additional functionalities such as sensing, energy harvesting, and thermal management into Blind and Buried Vias Flexible PCB. This creates all-in-one circuit solutions that reduce component count, improve system efficiency, and enable new applications in smart electronics.

- Green Manufacturing Advancement: The industry will continue to adopt eco-friendly manufacturing processes, such as low-toxicity materials and energy-efficient production technologies. This aligns with global sustainability goals while maintaining the high-performance characteristics of the PCB, supporting the development of environmentally responsible electronic products.

In conclusion, Blind and Buried Vias Flexible PCB represents a critical advancement in flexible circuit technology, enabling the development of compact, high-frequency, and reliable electronic systems. Its unique combination of high-frequency performance optimization, advanced manufacturing process synergy, and application in emerging smart fields positions it as a key driver of innovation in the electronics industry. As 5G, autonomous driving, and wearable technology continue to evolve, the strategic importance of Blind and Buried Vias Flexible PCB will only grow, shaping the future of next-generation electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB