-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 16. 2025, 11:58:17

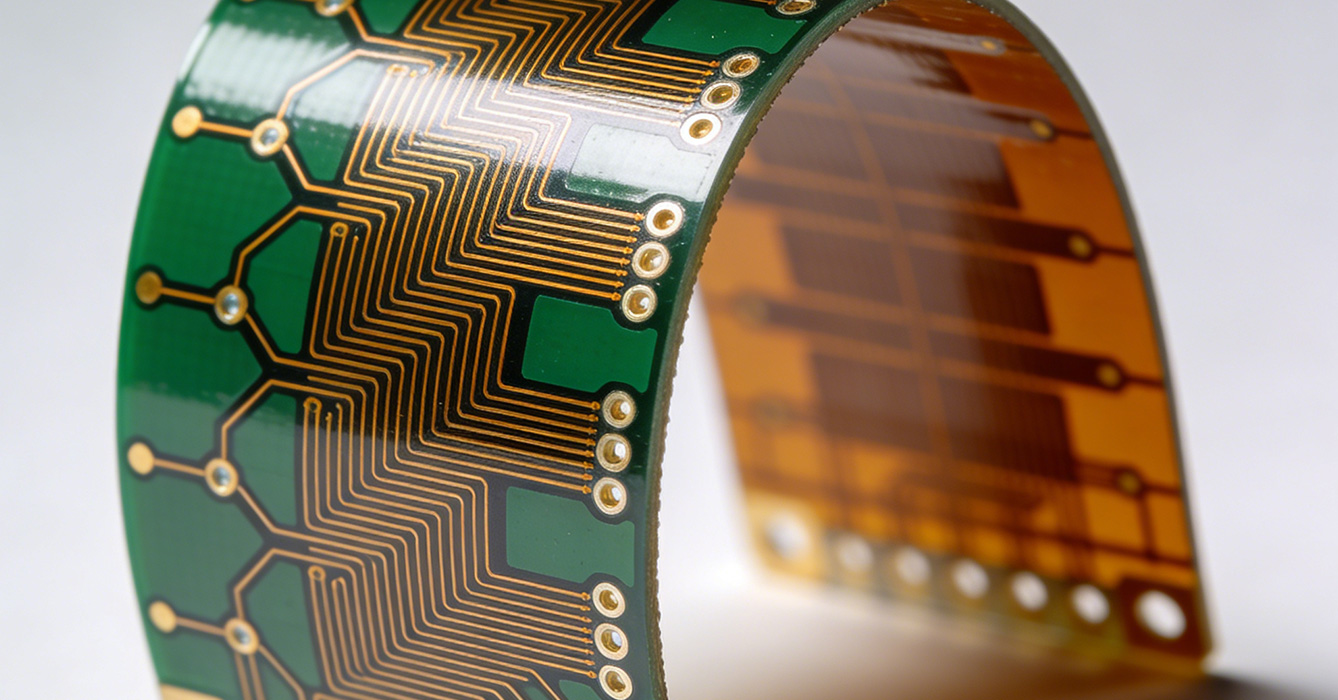

In the era of precision medicine and intelligent healthcare, medical electronic devices are evolving toward miniaturization, invasiveness, and real-time data monitoring. Medical Grade Vias Flexible PCB, a specialized circuit solution tailored for healthcare applications, has emerged as a critical component by integrating biocompatible materials, reliable via structures, and strict compliance with medical industry standards. Unlike conventional flexible PCBs, it must meet rigorous requirements for biocompatibility, sterilization resistance, and signal integrity to ensure safe and stable operation in complex medical environments—from human body implantation to high-precision diagnostic equipment. For medical device manufacturers, adopting Medical Grade Vias Flexible PCB is essential to advancing diagnostic accuracy, treatment efficacy, and patient safety.

Medical Grade Vias Flexible PCB distinguishes itself through adherence to stringent medical regulations and specialized performance attributes, addressing the unique risks of healthcare applications:

- Biocompatibility & Material Safety: The substrate and conductive materials of Medical Grade Vias Flexible PCB must undergo rigorous biocompatibility testing to ensure no harmful reactions with human tissues or bodily fluids. Common materials include medical-grade polyimide (PI), which offers excellent biocompatibility, thermal stability, and resistance to degradation. All components, including via plating materials, must comply with international standards such as ISO 10993, eliminating the risk of cytotoxicity, sensitization, or inflammation in both short-term and long-term medical applications.

- Sterilization Resistance: Medical devices equipped with flexible PCBs require repeated sterilization via methods such as gamma radiation, ethylene oxide (EO), or high-temperature autoclaving. Medical Grade Vias Flexible PCB is designed to withstand these processes without compromising structural integrity or electrical performance. The via structures are optimized to prevent moisture absorption or material degradation during sterilization, ensuring consistent functionality across the device's service life.

- Reliable Signal Integrity for Precision Monitoring: Medical devices rely on accurate signal transmission for physiological data collection (e.g., heart rate, brain waves) and treatment delivery. The via design of Medical Grade Vias Flexible PCB minimizes signal attenuation and electromagnetic interference (EMI), ensuring high-fidelity transmission of weak biological signals. This reliability is critical for implantable pacemakers, EEG monitors, and other devices where signal distortion could lead to misdiagnosis or treatment failure.

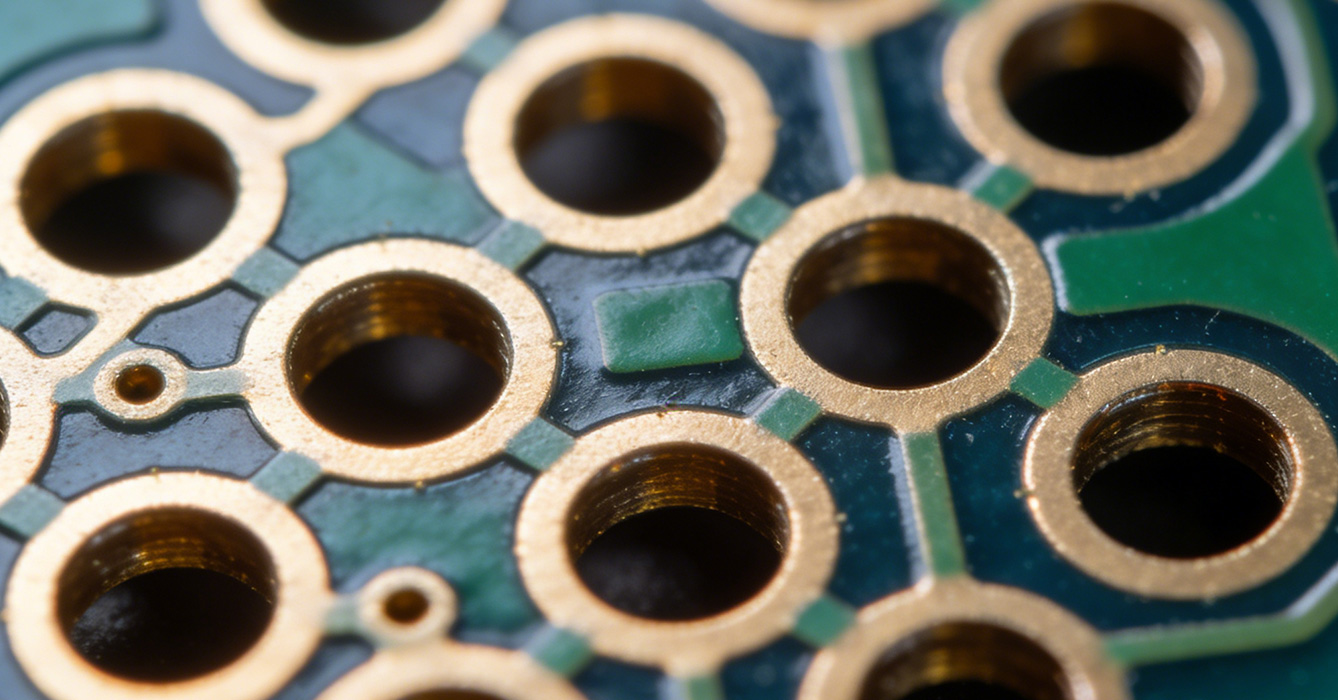

The via structure of Medical Grade Vias Flexible PCB is specifically optimized to adapt to the diverse and demanding conditions of medical devices:

- Minimized Profile & Flexibility for Implantation: For implantable devices (e.g., neurostimulators, implantable sensors), the PCB must be ultra-thin and highly flexible to conform to human anatomy without causing tissue irritation. Via structures are designed with minimal size and smooth surfaces to reduce mechanical stress on surrounding tissues. Advanced laser drilling technology ensures precise via positioning, enabling high-density circuit integration in limited implantable spaces.

- Enhanced Mechanical Stability for Dynamic Environments: Surface-mounted medical devices (e.g., wearable health monitors, surgical instruments) are subject to repeated bending and mechanical stress during use. The via connections of Medical Grade Vias Flexible PCB are reinforced to improve flex fatigue resistance, preventing solder joint failure or circuit breakage. This stability ensures long-term reliability in dynamic clinical environments.

- Sealing & Corrosion Resistance: To withstand bodily fluids or clinical disinfectants, via structures are sealed with biocompatible coatings to prevent corrosion and short circuits. This sealing technology also enhances the PCB's resistance to chemical degradation, extending the service life of medical devices used in harsh clinical settings.

Medical Grade Vias Flexible PCB is driving innovation across critical medical application areas, enabling breakthroughs in diagnosis, treatment, and patient monitoring:

- Implantable Medical Devices: In devices such as pacemakers, implantable cardioverter-defibrillators (ICDs), and neurostimulators, it provides reliable circuit interconnection in ultra-compact spaces. Its biocompatible materials and stable via connections ensure safe operation inside the human body for years, supporting life-sustaining functions.

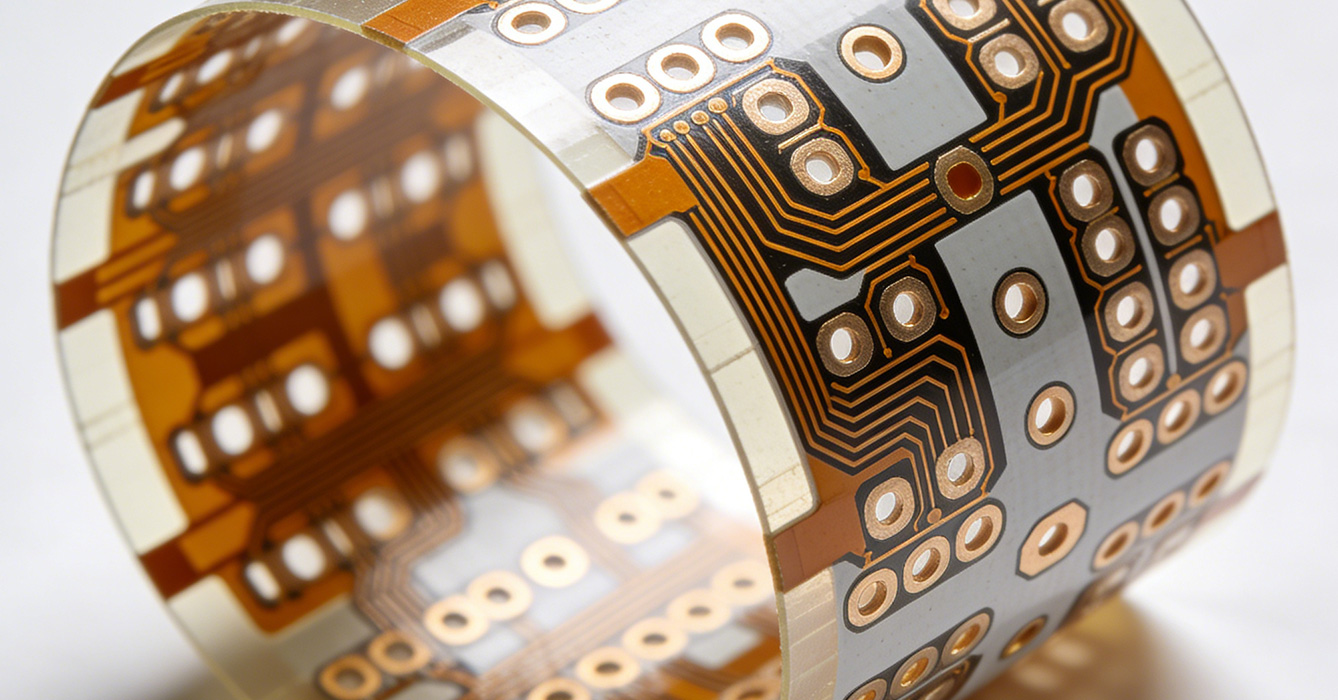

- Surface-Mounted & Wearable Monitoring Devices: For wearable health monitors, continuous glucose monitors, and EEG headsets, it enables flexible, lightweight designs that conform to the body. The reliable via structures ensure consistent transmission of physiological data, supporting real-time health monitoring and early disease detection.

- Minimally Invasive Surgical & Therapeutic Devices: In minimally invasive surgical instruments and targeted drug delivery systems (e.g., flexible electronic patches for precision drug delivery), it integrates control circuits and sensor arrays into thin, flexible form factors. This enables precise manipulation and real-time feedback during surgical procedures, reducing patient trauma and improving treatment outcomes.

The development of Medical Grade Vias Flexible PCB is focused on enhancing biocompatibility, integrating smart functionalities, and improving manufacturing scalability to meet evolving healthcare demands:

- Smart Function Integration: Future innovations will integrate sensing, actuation, and wireless communication functionalities directly into the PCB, enabling "all-in-one" medical device solutions. For example, via structures could be optimized to support both signal transmission and sensing, enhancing the versatility of implantable and wearable devices.

- Advanced Material Synergy: Integration of bioresorbable materials with via structures will enable temporary implantable devices that dissolve naturally in the body, eliminating the need for secondary surgical removal. This innovation will reduce patient risk and improve clinical efficiency.

- Compliance-Driven Quality Enhancement: Adoption of AI-powered quality control systems will ensure 100% traceability and defect detection, meeting the strict regulatory requirements of the medical industry. This will further improve product reliability and accelerate time-to-market for new medical devices.

In conclusion, Medical Grade Vias Flexible PCB is a cornerstone technology in modern healthcare, enabling the development of safe, reliable, and high-performance medical electronic devices. Its unique focus on biocompatibility, sterilization resistance, and application-specific via design addresses the critical needs of the medical industry. As healthcare continues to advance toward precision and personalization, the strategic importance of Medical Grade Vias Flexible PCB will continue to grow, driving innovations that improve patient outcomes and transform the future of medicine.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB