-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 15. 2025, 16:25:34

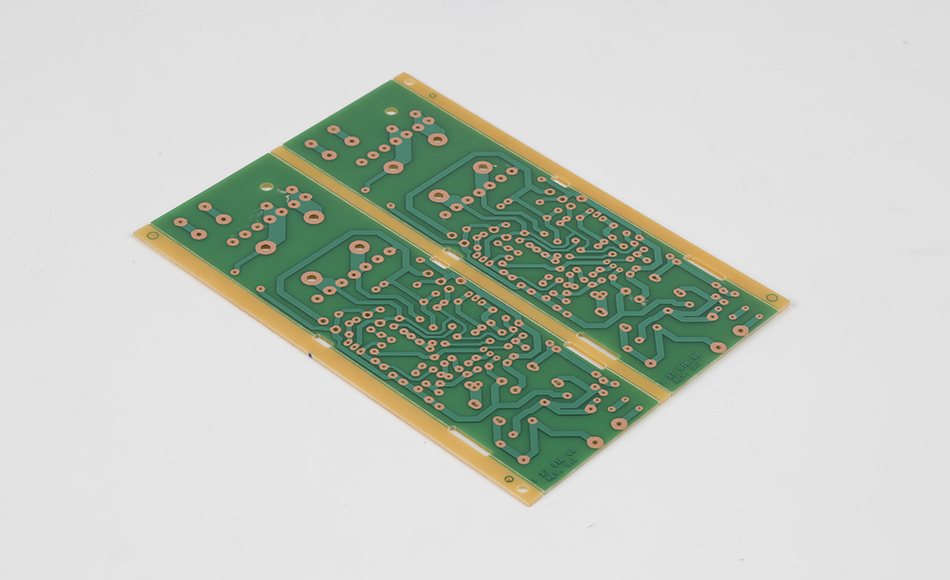

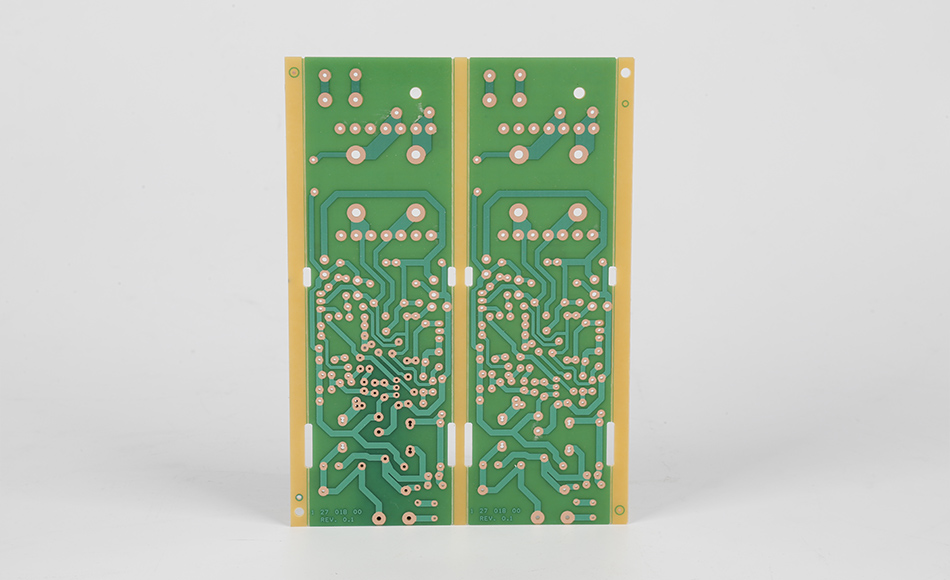

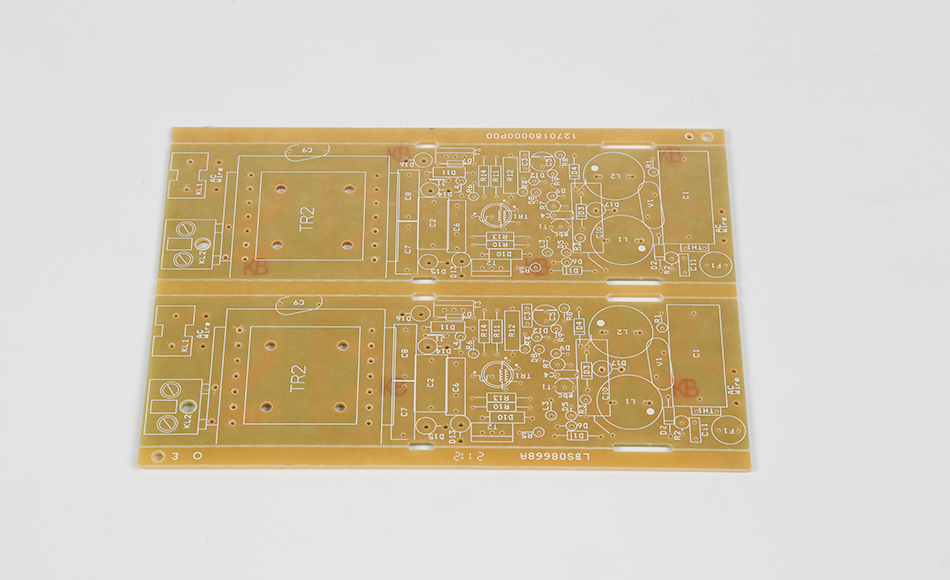

In the realm of printed circuit board (PCB) materials, the CEM3 PCB Material with a glass transition temperature (Tg) of 130°C holds a significant position. Tg is a critical parameter that determines the temperature at which a material transitions from a rigid, glassy state to a more rubbery, flexible state. For PCB materials, a well - defined Tg is essential as it impacts the material's performance under various operating conditions. CEM3, a composite epoxy material, has gained popularity due to its balanced properties, and a Tg of 130°C further refines its application scope. This article delves into the detailed characteristics, applications, and considerations related to CEM3 PCB Material with Tg130.

CEM3 (Composite Epoxy Material - 3) is composed of a combination of epoxy resin and glass fibers. It features a core made of non - woven glass fiber mat, which is sandwiched between outer layers of woven glass fabric. The non - woven glass fiber mat in the core provides excellent resin absorption capabilities, ensuring uniform distribution of the epoxy resin. This core structure also contributes to the material's isotropic mechanical properties to some extent. The outer woven glass fabric layers enhance the material's mechanical strength, especially in the plane of the board, and provide a smooth surface for copper cladding. The epoxy resin acts as a binder, holding the glass fibers together and providing electrical insulation properties.

2.2 Manufacturing Process

The manufacturing of CEM3 PCB material involves several steps. First, the glass fibers (both non - woven mat and woven fabric) are impregnated with epoxy resin. This process, known as prepreg production, results in partially cured sheets of material. These prepreg sheets are then stacked together, along with copper foils on one or both sides, and subjected to heat and pressure in a lamination process. The heat causes the epoxy resin to fully cure, bonding the layers together to form a solid, rigid PCB substrate. The curing process is carefully controlled to ensure the proper cross - linking of the epoxy resin, which is crucial for achieving the desired material properties, including the Tg of 130°C.

Operating Temperature Range

A Tg of 130°C indicates that the CEM3 material can maintain its rigid, glassy - like properties up to this temperature. In practical applications, this means that PCBs made from CEM3 with Tg130 can operate reliably in environments where the temperature does not exceed 130°C for extended periods. For example, in consumer electronics such as home appliances (refrigerators, microwave ovens), the internal temperature of the PCB - containing components usually remains well below 130°C during normal operation. This makes CEM3 with Tg130 an ideal choice for such applications as it can withstand the heat generated by the components without significant changes in its physical and electrical properties.

Thermal Cycling Resistance

Thermal cycling, which involves repeated heating and cooling of the PCB, is a common stress factor in many applications. CEM3 with Tg130 has a certain level of thermal cycling resistance. When the temperature fluctuates around the Tg, the material may experience some dimensional changes due to the transition between the glassy and rubbery states. However, proper design and manufacturing techniques can minimize the impact of these changes. For instance, in automotive interior electronics, where the temperature can vary from cold starts (low temperatures) to relatively warm temperatures during operation, CEM3 with Tg130 can endure a reasonable number of thermal cycles without significant degradation of its performance, such as delamination or cracking of the substrate.

Rigidity and Flexural Strength

Above the Tg, the material becomes more flexible. For CEM3 with Tg130, as long as the operating temperature is below this threshold, it maintains a relatively high level of rigidity. This rigidity is crucial for supporting electronic components on the PCB. Components such as integrated circuits, capacitors, and resistors need a stable and rigid substrate to ensure proper alignment and electrical connection. The flexural strength of CEM3 with Tg130 at normal operating temperatures is sufficient for most standard - duty applications. In office equipment like printers and scanners, the PCB substrate needs to be rigid enough to withstand the mechanical stresses associated with the movement of parts (such as paper feed mechanisms) and the vibrations generated during operation. CEM3 with Tg130 can meet these requirements effectively.

Dimensional Stability

Dimensional stability is closely related to the Tg. Below the Tg, CEM3 with Tg130 exhibits good dimensional stability. This means that the size and shape of the PCB remain relatively constant, which is essential for maintaining the accuracy of the circuit traces and component placement. In applications where precision is key, such as in some medical devices or high - end audio equipment, the dimensional stability of the PCB material is critical. Even under normal temperature variations within the operating range, CEM3 with Tg130 can ensure that the PCB does not warp or expand/contract significantly, thereby preventing issues like open or short circuits due to misalignment of traces.

Dielectric Properties

The dielectric properties of a PCB material, such as dielectric constant (Dk) and dissipation factor (Df), can be affected by temperature. For CEM3 with Tg130, below the Tg, its dielectric properties remain relatively stable. The dielectric constant determines how well the material can store electrical energy, and a stable Dk is important for maintaining consistent signal propagation speeds in the PCB. In low - to - medium - frequency applications, which are the typical domains of CEM3, a stable Dk ensures that the electrical signals are transmitted accurately without significant distortion. For example, in basic communication devices like landline telephones or simple wireless modules operating at lower frequencies, the stable dielectric properties of CEM3 with Tg130 contribute to reliable signal transmission.

Insulation Resistance

Insulation resistance is another crucial electrical property. CEM3 with Tg130 provides good insulation between different conductive traces on the PCB. As long as the temperature remains below the Tg, the epoxy resin in the material maintains its insulating properties effectively. This prevents electrical leakage between traces, which could otherwise lead to malfunctions in the electronic circuit. In industrial control systems, where multiple electrical signals are routed on a single PCB, the high insulation resistance of CEM3 with Tg130 at normal operating temperatures ensures the proper isolation of signals and the reliable operation of the system.

Home Appliances

As mentioned earlier, home appliances such as refrigerators, washing machines, and microwave ovens are prime candidates for using CEM3 PCB Material with Tg130. In a refrigerator, the control PCB that manages functions like temperature regulation, compressor operation, and display lighting is exposed to relatively moderate temperatures. CEM3 with Tg130 can handle these temperatures while providing the necessary electrical insulation and mechanical support for the components on the board. Similarly, in a washing machine, the PCB that controls the motor speed, water inlet and outlet valves, and timer functions can be made from CEM3 with Tg130. The material's ability to withstand the vibrations and heat generated during the washing cycle ensures the long - term reliability of the appliance.

Audio Equipment

In audio equipment, such as speakers, amplifiers, and radios, CEM3 with Tg130 is also a suitable choice. In a speaker system, the crossover PCB, which separates the audio signals into different frequency ranges for the woofer, mid - range, and tweeter, needs to have stable electrical properties. CEM3 with Tg130 can provide the required insulation and signal - handling capabilities at the relatively low temperatures typically found in audio equipment. In an amplifier, the PCB that houses the power - handling components and signal - processing circuitry can benefit from the material's mechanical strength and thermal stability. Even during extended periods of operation when the amplifier may generate some heat, CEM3 with Tg130 can maintain its performance.

Printers and Scanners

Printers and scanners are staple office equipment that rely on PCBs for their operation. The main control PCB in a printer, which manages functions like paper feeding, ink or toner deposition, and communication with the computer, is subject to mechanical stresses from the moving parts and some heat generation from the electrical components. CEM3 with Tg130 can withstand these stresses due to its good mechanical and thermal properties. In a scanner, the PCB that controls the scanning head movement, image sensor operation, and data transfer can be made from CEM3 with Tg130. The material's dimensional stability ensures that the scanning head remains accurately aligned, resulting in high - quality scanned images.

Copiers

Copiers also use CEM3 PCB Material with Tg130 for their internal circuits. The control PCB in a copier, which coordinates functions such as drum rotation, toner transfer, and paper transport, needs to be reliable. CEM3 with Tg130 can provide the necessary electrical and mechanical performance. The heat generated during the copier's operation, especially during long - term use or high - volume copying, is well within the temperature tolerance of CEM3 with Tg130. This ensures that the copier can operate continuously without issues related to the PCB material degradation.

Basic Sensors

In industrial settings, basic sensors such as temperature sensors, humidity sensors, and pressure sensors often use PCBs. CEM3 with Tg130 is suitable for the PCBs in these sensors. For example, a temperature sensor PCB may be exposed to a wide range of temperatures depending on the industrial environment. CEM3 with Tg130 can handle the temperature variations within its operating range while maintaining the electrical integrity of the sensor circuit. The material's mechanical strength also helps protect the sensor components from mechanical shocks that may occur in industrial environments.

Control Panels

Industrial control panels that monitor and control various processes in factories or plants can use CEM3 PCB Material with Tg130. These control panels typically house multiple components such as relays, switches, and microcontrollers. CEM3 with Tg130 provides the necessary electrical insulation between these components and can withstand the relatively harsh industrial environment, including vibrations, dust, and moderate temperature fluctuations. The material's flame - retardant properties (as CEM3 generally meets UL94 V - 0 standards) also add an extra layer of safety in industrial settings where there may be a risk of fire.

Thermal Performance

FR4 is a widely used PCB material. It generally has a higher Tg than CEM3, often in the range of 135 - 140°C or even higher for some high - performance variants. However, CEM3 with Tg130 still offers sufficient thermal performance for many applications where the temperature does not exceed 130°C. FR4 may be more suitable for applications that require higher temperature resistance, such as in some automotive under - hood electronics or high - power industrial equipment. But for applications like consumer electronics and office equipment, CEM3 with Tg130 can provide a cost - effective alternative without sacrificing much in terms of thermal performance.

Mechanical Performance

In terms of mechanical performance, FR4 typically has higher flexural strength and better dimensional stability compared to CEM3. However, CEM3 with Tg130 still has adequate mechanical properties for standard - duty applications. FR4 may be preferred in applications where extreme mechanical stress is expected, such as in some aerospace or military electronics. But for the majority of consumer, office, and light - industrial applications, CEM3 with Tg130 can meet the mechanical requirements at a lower cost.

Cost

One of the significant advantages of CEM3 with Tg130 over FR4 is cost. CEM3 is generally more cost - effective to produce due to its simpler manufacturing process and the use of a non - woven glass fiber mat in its core. This cost advantage makes CEM3 with Tg130 an attractive option for manufacturers who are looking to balance performance and cost, especially in high - volume production of consumer and office electronics.

Thermal and Mechanical Performance

CEM1 is another composite epoxy material, but it uses a paper - based core instead of a non - woven glass fiber mat like CEM3. CEM1 has a lower Tg compared to CEM3 with Tg130, usually around 100 - 110°C. This means that CEM3 with Tg130 can handle higher temperatures and has better thermal stability. In terms of mechanical performance, CEM3 with Tg130 also has higher flexural strength and better dimensional stability due to the glass fiber reinforcement in its core. CEM1 may be more suitable for very low - cost applications where the operating temperature is low and mechanical requirements are minimal, but for most applications that require a balance of performance and cost, CEM3 with Tg130 is a better choice.

Moisture Resistance

CEM3 with Tg130 also has better moisture resistance compared to CEM1. The paper - based core in CEM1 is more prone to absorbing moisture, which can lead to swelling, warping, and degradation of electrical properties. In applications where the PCB may be exposed to humid environments, such as in some industrial or outdoor electronics (to a limited extent), CEM3 with Tg130 is a more reliable option.

When designing a PCB using CEM3 with Tg130, it is important to select components that are compatible with the material's thermal and mechanical properties. Components that generate excessive heat should be carefully considered. If the heat generated by a component is close to or exceeds the Tg of the material, it may cause issues such as warping or degradation of the PCB. For example, high - power transistors or integrated circuits that dissipate a large amount of heat may require additional heat - sinking measures or may not be suitable for use on a CEM3 PCB with Tg130 without proper thermal management.

The electrical conductivity and insulation properties of CEM3 with Tg130 should be considered during trace routing and spacing design. The material's dielectric properties can affect signal propagation, so trace widths and spacings should be designed to minimize signal interference and ensure proper signal integrity. In high - density PCB designs, where traces are closely spaced, the insulation properties of CEM3 with Tg130 need to be sufficient to prevent electrical leakage between traces. Additionally, the material's surface smoothness, which is influenced by the manufacturing process, can also impact the quality of trace etching and the adhesion of components.

Although CEM3 with Tg130 can handle temperatures up to 130°C, proper thermal management is still crucial for ensuring the long - term reliability of the PCB. Heat - generating components should be placed in areas where the heat can be dissipated effectively. This may involve using heat - sinks, fans, or other cooling mechanisms. In some cases, thermal vias can be incorporated into the PCB design to transfer heat from the top layer to the bottom layer or to internal layers with better heat - dissipation capabilities. Thermal management not only helps in maintaining the temperature below the Tg but also in preventing hotspots on the PCB that could cause premature component failure.

CEM3 PCB Material with Tg130 offers a balanced set of properties that make it suitable for a wide range of applications, especially in consumer electronics, office equipment, and light - industrial electronics. Its composition, manufacturing process, and the significance of the 130°C Tg in determining its thermal, mechanical, and electrical performance have been explored. By understanding its applications, comparing it with other PCB materials, and considering proper design aspects, manufacturers can effectively utilize CEM3 with Tg130 to produce reliable and cost - effective PCBs. As the demand for electronics continues to grow, materials like CEM3 with Tg130 will play an important role in meeting the requirements of various industries while maintaining a balance between performance and cost.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB