-

- PCB TYPE

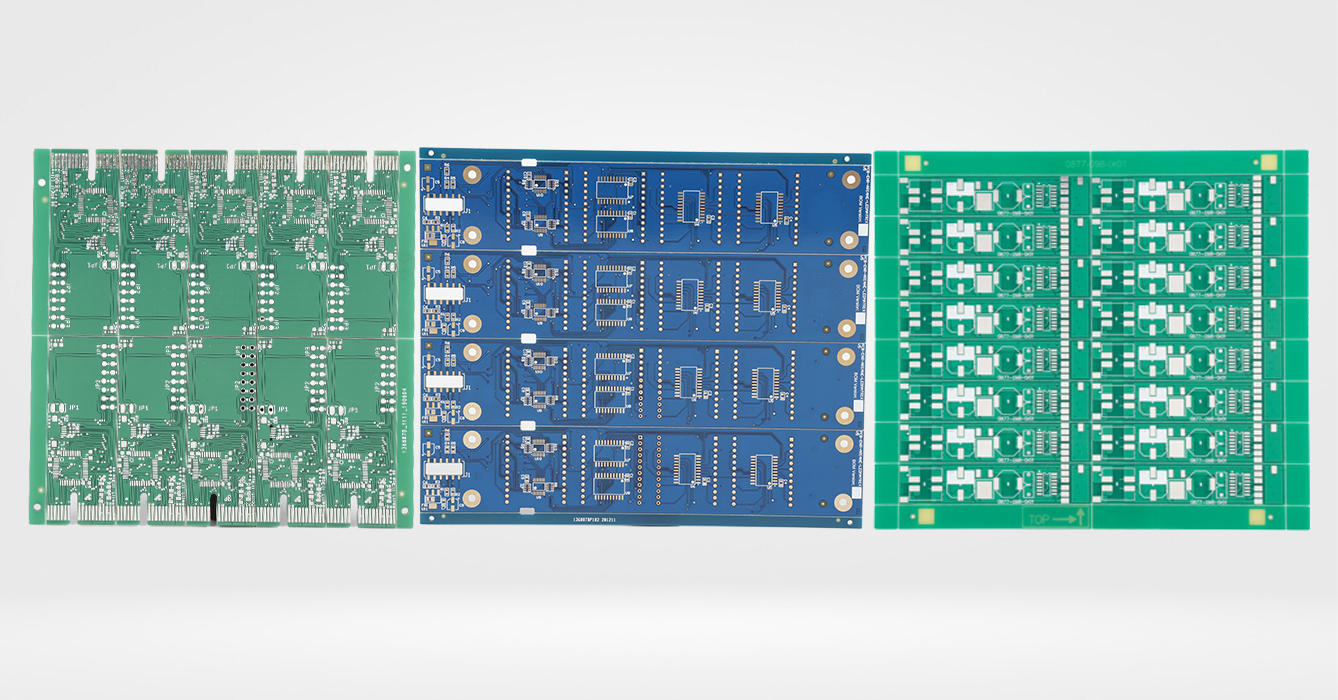

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 14. 2025, 16:51:22

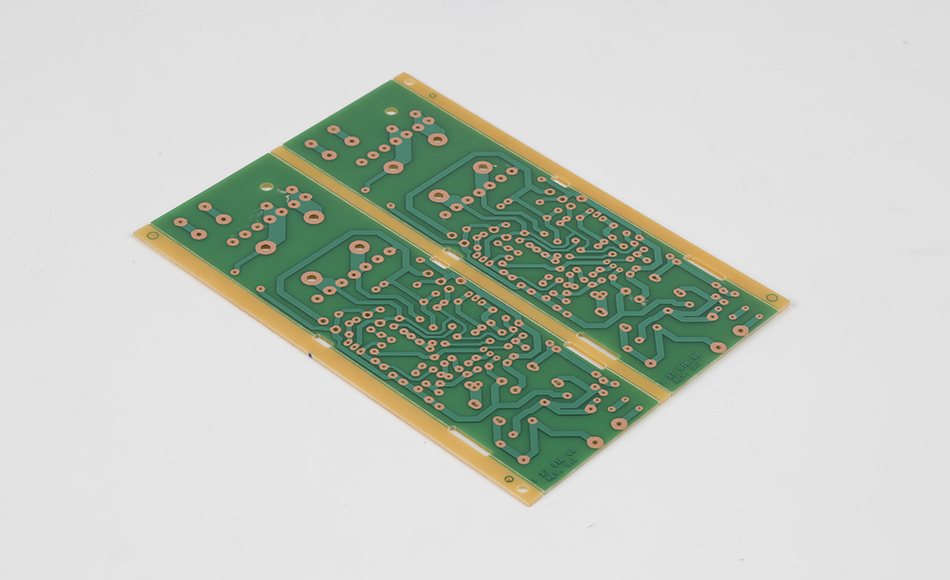

CEM3 PCB represents a pragmatic choice in the world of printed circuit boards, leveraging the unique properties of Composite Epoxy Material-3 (CEM3) to deliver reliable performance at a competitive cost. Unlike PCBs made with specialized materials—such as high-frequency PTFE or heavy-duty FR4—CEM3 PCBs are engineered for applications where a balance of functionality, durability, and affordability is key. They bridge the gap between basic paper-reinforced PCBs (which lack robustness) and premium woven glass PCBs (which often exceed necessary performance requirements). This article explores the design principles, assembly considerations, performance characteristics, and ideal use cases of CEM3 PCBs, highlighting why they remain a staple in electronics manufacturing for cost-conscious yet reliability-focused projects.

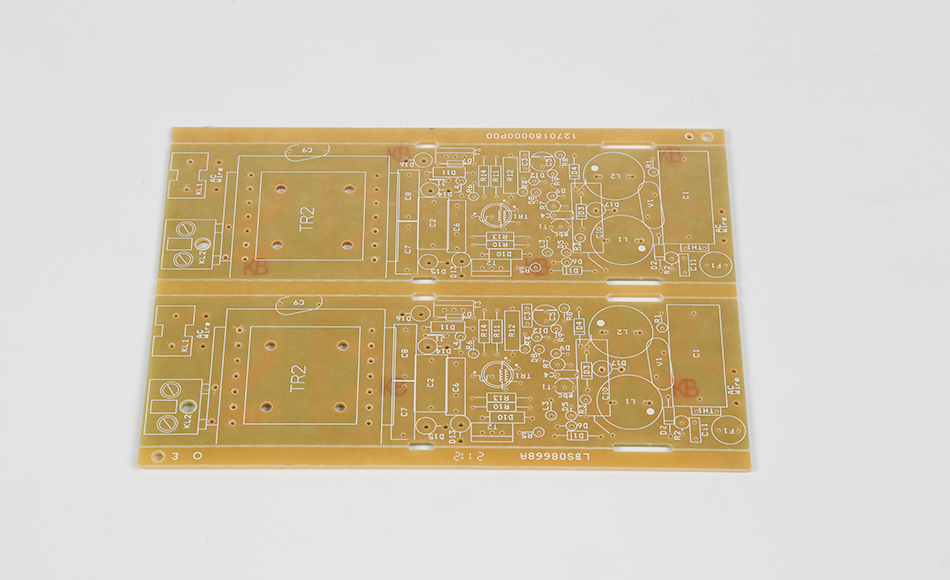

A CEM3 PCB is a printed circuit board constructed using Composite Epoxy Material-3 as its substrate. This substrate’s hybrid structure—non-woven glass fiber mat core with woven glass fabric outer layers—gives CEM3 PCBs their defining traits: sufficient mechanical strength for standard components, reliable electrical insulation for low-to-moderate frequencies, and a manufacturing-friendly design that keeps production costs in check.

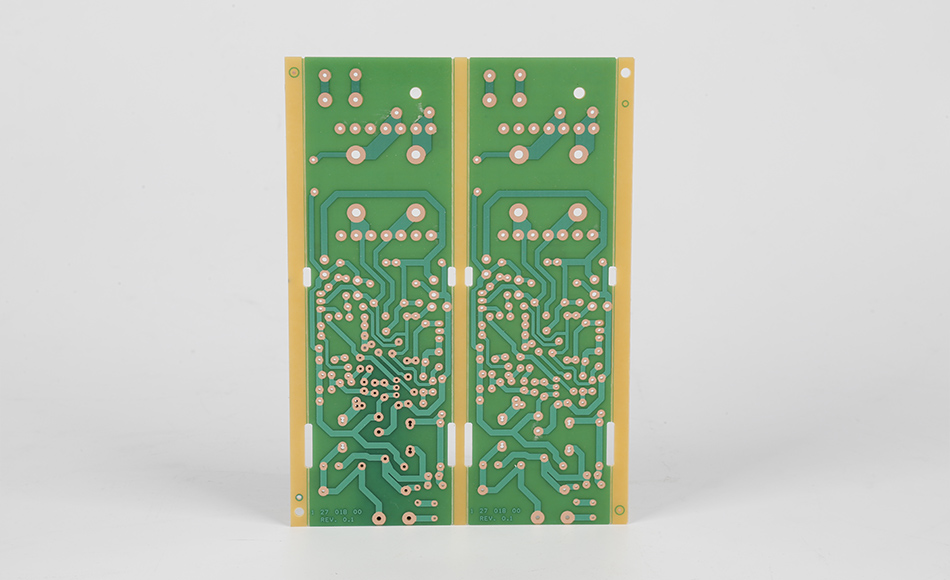

CEM3 PCBs are classified by their adherence to industry standards, such as IPC-4101, which ensures consistency in flame resistance (UL94 V-0), dielectric properties, and dimensional stability. They are available in single-layer, double-layer, and limited multi-layer configurations, though their use in complex multi-layer designs is less common than with FR4 due to slightly lower mechanical rigidity.

What sets CEM3 PCBs apart is their practicality. They avoid over-engineering, providing just enough performance to meet the needs of most consumer, office, and light industrial electronics without the premium price tag of higher-grade materials.

Designing a CEM3 PCB requires balancing functional requirements with the material’s inherent properties, ensuring optimal performance without unnecessary complexity:

CEM3 PCBs are most effective in single or double-layer designs, where their mechanical stability and insulation properties shine. While multi-layer CEM3 PCBs are possible, they are typically limited to 4 layers due to the non-woven core’s slightly lower rigidity compared to FR4. This makes them ideal for circuits with moderate component density, such as those found in home appliances or basic sensors.

For low-to-moderate frequency applications (up to several hundred MHz), CEM3 PCBs handle signal routing reliably. However, designers should avoid extremely fine traces or tight spacing, as the material’s surface smoothness—while sufficient for standard designs—is not as consistent as FR4’s. Impedance control is achievable but requires careful calculation of trace width and spacing, as CEM3’s dielectric constant is slightly more variable than FR4’s.

CEM3 PCBs support both through-hole and surface-mount components, but their mechanical strength is best suited for standard-weight components. Heavy components (e.g., large transformers) may require additional support, such as mounting hardware, to prevent stress on the substrate. Heat-generating components should be limited to those with moderate power dissipation, as CEM3’s thermal conductivity is lower than FR4’s, making it less effective at dissipating extreme heat.

Designers must account for CEM3’s operating limits: temperatures between -30°C and 105°C, and resistance to moderate moisture and chemical exposure. For applications in harsh environments—such as industrial ovens or coastal areas with high humidity—additional protective measures (e.g., conformal coating) may be needed to extend lifespan.

CEM3 PCBs benefit from compatibility with standard PCB manufacturing processes, with subtle adjustments to optimize for the material’s properties:

Lamination: CEM3’s hybrid core allows for lower lamination pressure than FR4, reducing energy costs and equipment wear. This makes CEM3 PCB fabrication accessible to smaller manufacturers with standard press equipment.

Drilling: The non-woven core drills cleanly with standard carbide tools, minimizing burring and reducing the need for post-drilling cleaning. This simplifies production and lowers scrap rates.

Etching: CEM3’s smooth copper-clad surface ensures consistent etching, though slightly slower etch times may be required compared to FR4 to achieve precise trace definition.

Soldering: CEM3 PCBs work well with standard reflow and wave soldering processes, thanks to the epoxy resin’s good heat resistance during short-term exposure to soldering temperatures. However, prolonged exposure to high heat (e.g., repeated rework) should be avoided to prevent delamination.

Handling: While sufficiently rigid, CEM3 PCBs are slightly more flexible than FR4, requiring careful handling during assembly to prevent bending or warping. Automated assembly lines with gentle gripping mechanisms are ideal for maintaining dimensional stability.

Testing: Standard electrical testing methods—such as flying probe or bed-of-nails testing—are effective for CEM3 PCBs, ensuring continuity and insulation integrity without specialized equipment.

These manufacturing advantages make CEM3 PCBs a cost-effective choice for low-to-medium volume production runs, where setup and processing costs are critical.

CEM3 PCBs deliver a set of performance traits tailored to practical applications, avoiding the extremes of high-cost materials:

In low-to-moderate frequency circuits, CEM3 PCBs maintain reliable signal integrity. Their epoxy matrix provides good dielectric strength, preventing crosstalk between traces in most consumer and office electronics. While not optimized for high-speed digital or RF applications, they perform admirably in devices like audio amplifiers, remote controls, and basic sensor modules.

CEM3 PCBs offer sufficient rigidity to withstand standard assembly and operational stresses. They resist warping during temperature changes and provide stable mounting for components in environments with mild vibration, such as office equipment or home appliances. Their flexibility, while limited, allows for minor adjustments during assembly without cracking.

Meeting UL94 V-0 standards, CEM3 PCBs self-extinguish quickly when exposed to flame, reducing fire risk in enclosed spaces. This safety feature is critical for consumer electronics, where devices are often used in homes or offices.

The most compelling performance metric of CEM3 PCBs is their cost-to-performance ratio. They typically cost 20–30% less than equivalent FR4 PCBs while meeting the requirements of 80% of standard electronic applications. This makes them a favorite for budget-conscious manufacturers without compromising on basic reliability.

CEM3 PCBs are best suited for applications that demand reliability without extreme performance, aligning with their balanced set of properties:

Home Appliances: Refrigerators, microwaves, and washing machines use CEM3 PCBs for their control panels and sensor interfaces. These applications require stable performance at moderate temperatures and low frequencies, which CEM3 delivers cost-effectively.

Audio Equipment: Speakers, amplifiers, and radios rely on CEM3 PCBs for signal routing. Their electrical insulation properties ensure clean audio signals without interference, while their affordability keeps consumer prices accessible.

Printers and Scanners: These devices operate in climate-controlled environments with low vibration, making CEM3 PCBs an ideal fit. Their ability to support both digital control circuits and motor drivers at a low cost is a key advantage.

Copiers and Fax Machines: Basic logic boards and interface circuits in these devices use CEM3 PCBs, which handle the low-frequency signals and moderate component density required for document processing.

Basic Sensors: Temperature, humidity, and motion sensors often use CEM3 PCBs for their signal conditioning circuits. These sensors operate at low power and frequency, matching CEM3’s capabilities.

Relay Controllers: Simple industrial controllers for lights, fans, or small motors rely on CEM3 PCBs to manage switching logic. Their flame resistance adds a layer of safety in factory settings.

In-Car Entertainment: Radio head units and speaker controllers use CEM3 PCBs, which perform reliably in the moderate temperatures of vehicle cabins.

Convenience Features: Power window controls, seat adjusters, and interior lighting circuits benefit from CEM3’s cost-effectiveness and stable performance.

CEM3 PCBs occupy a unique niche in the market, offering distinct advantages over other PCB types in specific scenarios:

FR4 PCBs provide higher mechanical strength, better thermal resistance, and superior high-frequency performance, but at a higher cost. CEM3 PCBs are preferable for applications where these extreme properties are unnecessary, such as basic consumer electronics, where cost savings outweigh the need for FR4’s robustness.

CEM1 PCBs use paper reinforcement, making them cheaper but prone to moisture absorption and heat damage. CEM3 PCBs, with their glass reinforcement, offer better durability in humid or slightly elevated temperature environments, justifying their modest price premium over CEM1.

Metal-core PCBs excel at heat dissipation but are heavier and more expensive. They are reserved for high-power applications (e.g., LED drivers), while CEM3 PCBs are better for low-heat, cost-sensitive designs.

Flexible PCBs (polyimide-based) offer bendability but are more expensive and less rigid. CEM3 PCBs are the better choice for rigid, flat designs where shape conformity is not required.

Ensuring reliability in CEM3 PCBs requires adherence to industry standards that govern their production and performance:

IPC-4101: This standard defines material requirements for CEM3 substrates, including resin content, glass fiber type, and mechanical properties, ensuring consistency across manufacturers.

UL94 V-0 Certification: Mandatory for most consumer and industrial electronics, this certification confirms CEM3 PCBs’ flame resistance, a critical safety feature.

IPC-A-600: Governs PCB acceptability, providing guidelines for inspecting CEM3 PCBs for defects like delamination, trace damage, or insufficient solder mask coverage.

RoHS Compliance: Modern CEM3 PCBs are free of hazardous substances, meeting global regulations to reduce environmental impact and ensure safe disposal.

Adherence to these standards gives manufacturers and end-users confidence that CEM3 PCBs will perform as expected in their intended applications.

As electronics manufacturing evolves, CEM3 PCBs continue to adapt, retaining their relevance through targeted improvements:

Producers are developing CEM3 PCBs using recycled glass fibers and bio-based epoxy resins, reducing their environmental footprint. This aligns with consumer and regulatory demands for eco-friendly electronics, particularly in Europe and North America.

New formulations of CEM3 substrates with slightly improved thermal resistance (up to 120°C) are expanding their use into light industrial applications previously dominated by FR4. These variants maintain cost advantages while offering broader operating ranges.

Advances in manufacturing automation—such as robotic assembly and AI-driven quality inspection—are making CEM3 PCB production more efficient, reducing lead times and costs. This strengthens their position as a cost-effective alternative for high-volume, low-complexity designs.

CEM3 PCB embodies practicality in electronics manufacturing, offering a balanced mix of performance, reliability, and affordability. Its design, based on Composite Epoxy Material-3, makes it ideal for a wide range of applications—from consumer gadgets to light industrial controls—where extreme performance is unnecessary. By leveraging standard manufacturing processes and avoiding over-engineering, CEM3 PCBs provide a cost-effective solution without compromising on essential properties like flame resistance, electrical insulation, and mechanical stability. As sustainability and efficiency become increasingly important, CEM3 PCBs are evolving to meet new demands, ensuring they remain a vital part of the electronics ecosystem for years to come. For engineers and manufacturers seeking value without sacrifice, CEM3 PCBs stand as a testament to the power of practical design.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB