-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 02. 2025, 13:40:20

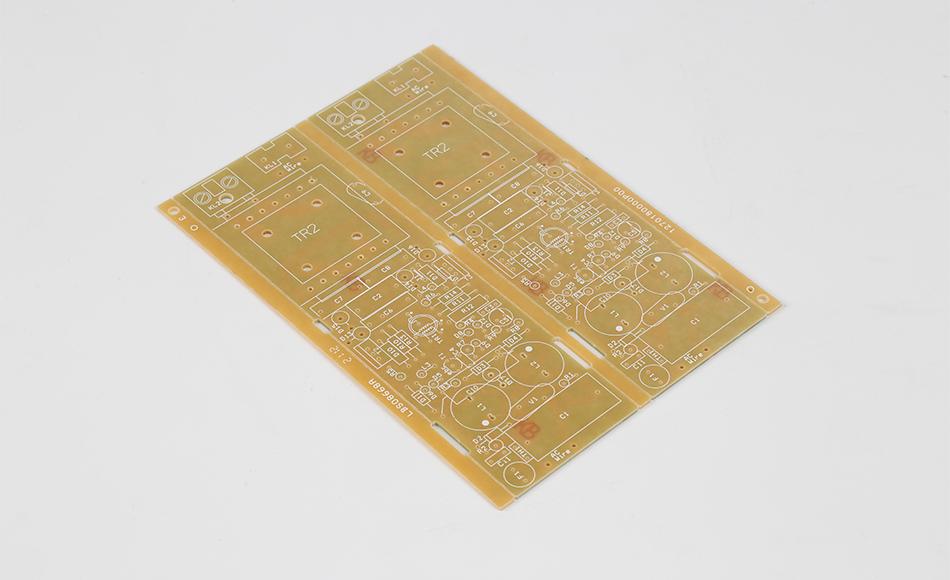

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. They come in various types, each with unique properties and applications. Among the different types, CEM3 PCBs have carved a niche for themselves. In this article, we'll explore what CEM3 PCBs are, their benefits, and how they compare to the more commonly known FR4 PCBs. We'll also delve into their applications in various industries.

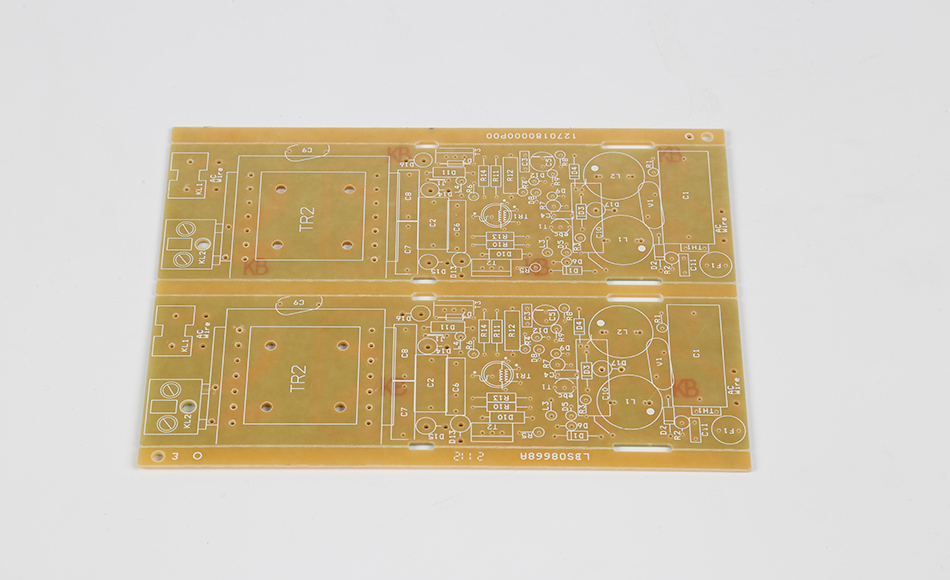

CEM3 stands for Composite Epoxy Material 3. It is a type of PCB substrate made from a combination of woven glass fabric and epoxy resin. CEM3 was developed as an alternative to FR4, providing similar performance characteristics but with some distinct advantages.

CEM3 PCBs are made by laminating layers of glass fabric and epoxy resin. This combination results in a material that is not only lightweight but also offers excellent electrical insulation and mechanical strength.

Key characteristics of CEM3 include:

Thermal Resistance: CEM3 PCBs can withstand high temperatures, making them suitable for devices that generate a lot of heat.

Electrical Insulation: These PCBs provide reliable electrical insulation, ensuring safe and efficient operation of electronic devices.

Cost-Effectiveness: CEM3 PCBs tend to be more affordable than FR4, making them an attractive option for budget-conscious projects.

Both CEM3 and FR4 PCBs use epoxy resin as a primary component, but their reinforcement materials differ. FR4 uses woven glass fiber, while CEM3 uses a combination of glass fabric and non-woven fabric. This slight difference in composition gives CEM3 a few unique properties.

Thermal Conductivity: CEM3 has a slightly lower thermal conductivity than FR4. This means that while both can handle high temperatures, FR4 might perform better in extremely high-heat applications.

Mechanical Strength: FR4 has a slight edge in mechanical strength due to its pure glass fiber composition. However, CEM3 still provides adequate strength for most applications.

Cost: CEM3 is generally less expensive than FR4, providing a cost-effective alternative without significantly compromising on performance.

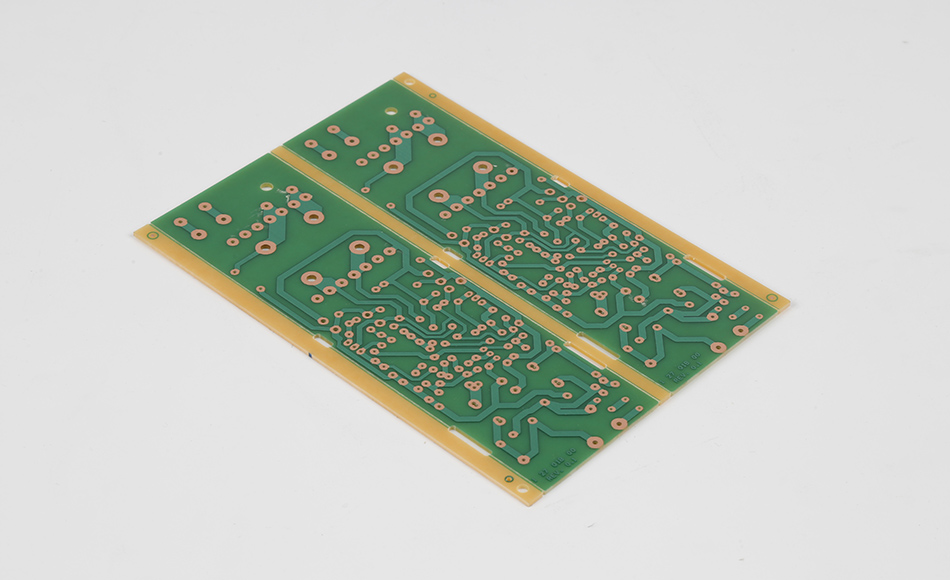

CEM3 PCBs find applications in various sectors where cost and performance need to be balanced. They are commonly used in:

Consumer Electronics: Devices like televisions, radios, and household appliances often use CEM3 PCBs due to their cost-effectiveness and adequate performance.

Automotive Industry: Many automotive electronics utilize CEM3 boards for their reliability and ability to withstand moderate thermal conditions.

Lighting Solutions: LED lighting systems benefit from CEM3 PCBs, which offer sufficient heat dissipation and electrical insulation.

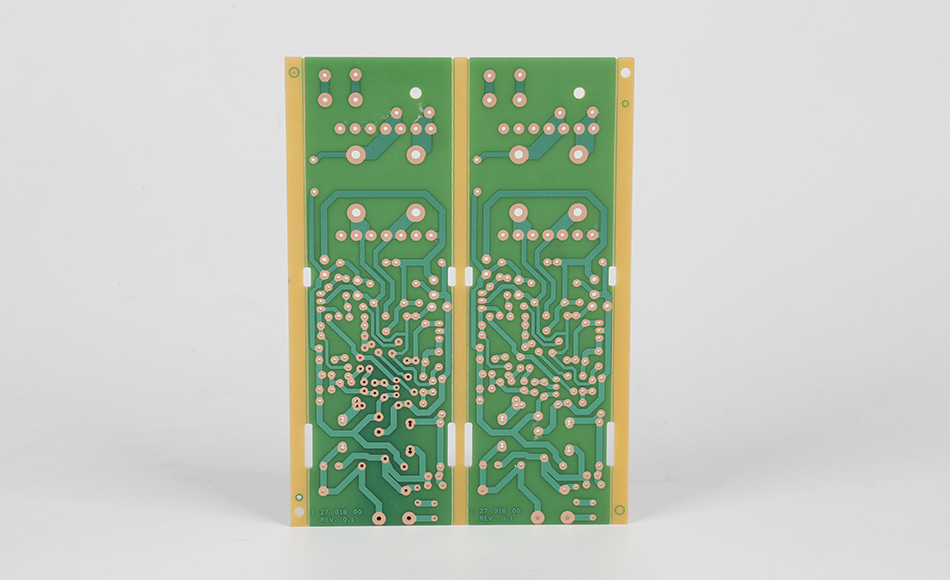

One of the primary benefits of CEM3 PCBs is their affordability. For manufacturers looking to minimize costs without sacrificing quality, CEM3 provides a viable alternative to more expensive materials like FR4.

While CEM3 may not match the high-end performance of FR4 in every aspect, it still offers reliable thermal resistance, electrical insulation, and mechanical strength for most standard applications.

CEM3 PCBs are versatile and can be used in a wide range of applications, making them a popular choice for manufacturers in various industries.

Despite their many benefits, CEM3 PCBs do have some limitations:

Lower Thermal Conductivity: In applications that require superior thermal management, FR4 might be a better choice.

Mechanical Strength: For applications requiring the highest levels of mechanical strength, FR4 may be preferable.

CEM3 PCBs offer a unique blend of affordability and performance that makes them suitable for a wide range of applications. While they may not always match the high-performance characteristics of FR4, their cost-effectiveness and adequate performance make them a popular choice for many manufacturers.

Understanding the differences between CEM3 and FR4, and knowing where to apply each, can help in making informed decisions for your electronic projects. Whether you're designing consumer electronics, automotive components, or lighting solutions, CEM3 PCBs provide a reliable option that balances cost and functionality.

By keeping these factors in mind, you can select the right type of PCB for your needs, ensuring efficiency and effectiveness in your electronic designs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB