-

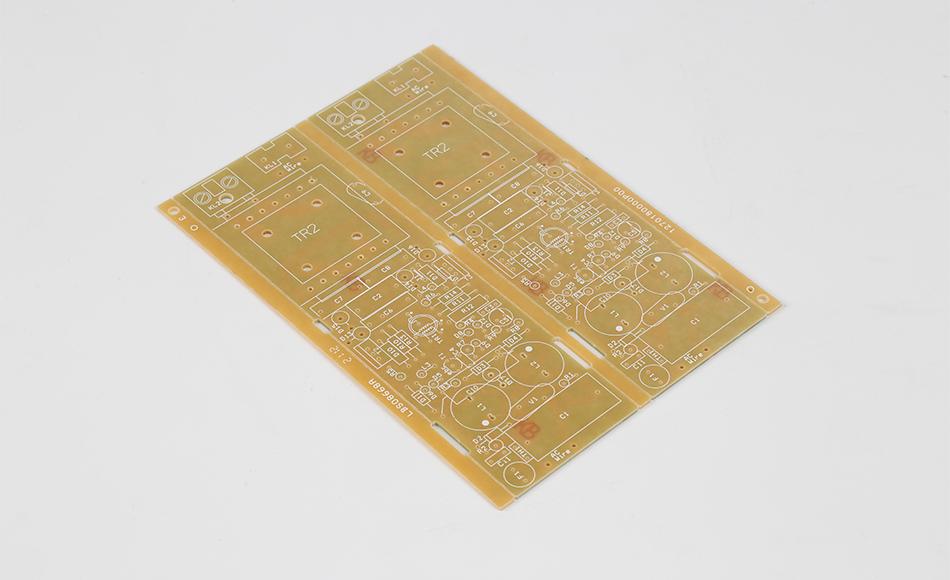

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 02. 2025, 13:32:32

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. They provide the physical platform for mounting and interconnecting electronic components. Among various PCB materials, CEM3 has emerged as a popular choice, especially for applications requiring high Comparative Tracking Index (CTI) values. This article delves into the world of high CTI value CEM3, exploring its significance, benefits, and applications.

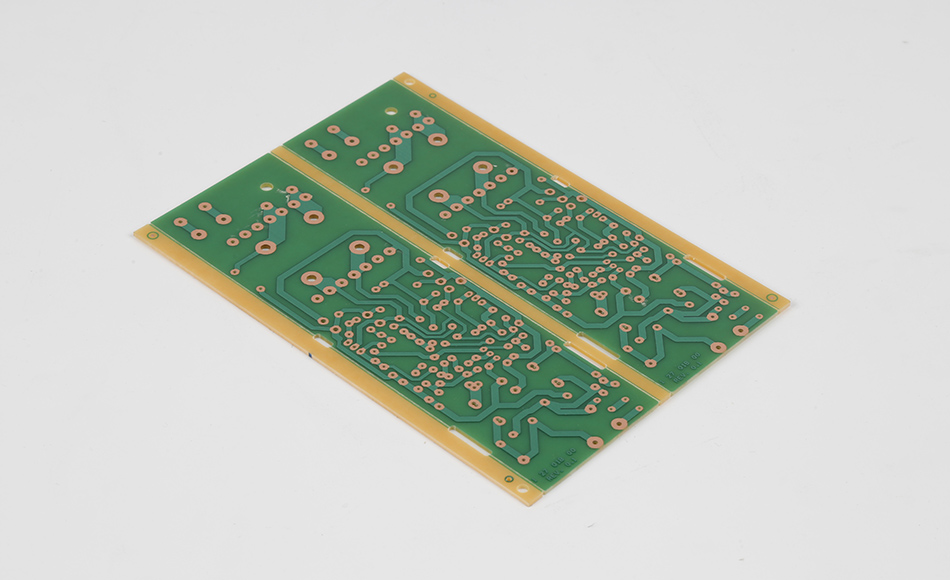

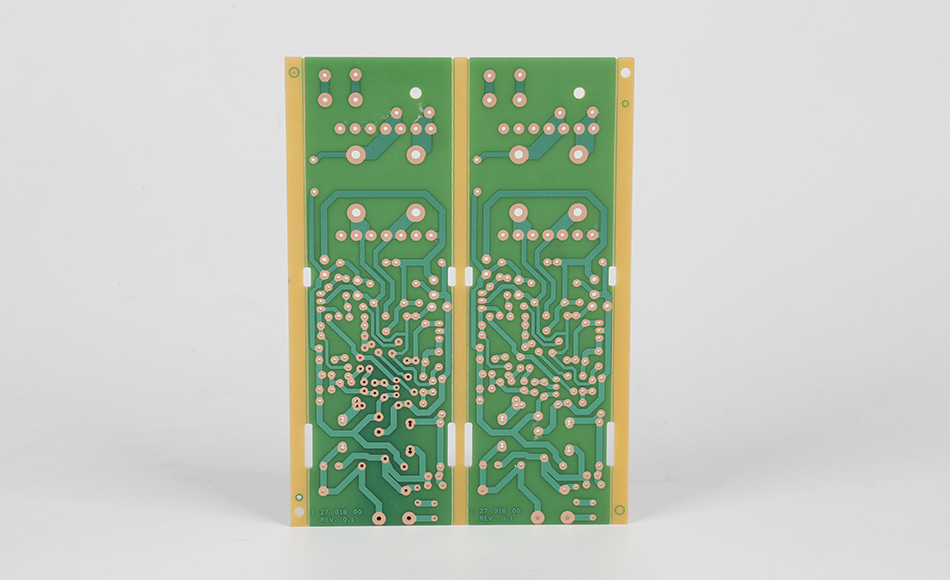

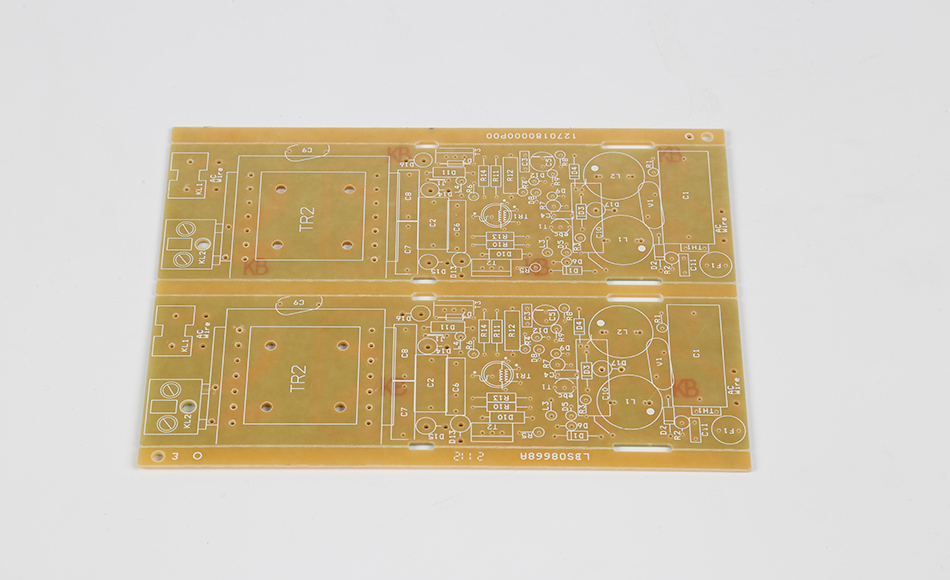

CEM3 is a type of composite PCB material that combines features of both FR4 and CEM1 materials. It is composed of woven glass fabric and non-woven glass core, which are impregnated with epoxy resin. This composition provides an excellent balance of thermal and mechanical properties, making CEM3 an ideal choice for various electronic applications.

The Comparative Tracking Index (CTI) is a measure of a material's resistance to electrical tracking, which is the formation of conductive paths across the surface of an insulating material. A higher CTI value indicates better resistance to electrical tracking, enhancing the safety and reliability of electronic devices.

A high CTI value in CEM3 materials ensures enhanced safety and reliability of electronic devices. It reduces the risk of short circuits and electrical failures, which can be catastrophic in critical applications like medical devices or aerospace systems.

Electronic devices are often exposed to harsh environments, including high humidity and temperature variations. High CTI value CEM3 materials offer superior performance in such conditions, ensuring consistent device operation and longevity.

CEM3 materials with high CTI values provide a cost-effective solution for manufacturers. They offer a balanced compromise between performance and cost, making them suitable for a wide range of applications without breaking the bank.

CEM3 PCBs with high CTI values are widely used in consumer electronics, including smartphones, tablets, and home appliances. They ensure reliable performance and safety, even in compact and densely packed electronic devices.

The automotive industry demands high reliability and safety standards. High CTI value CEM3 materials are used in automotive electronics to meet these stringent requirements, enhancing the performance and durability of components like engine control units and infotainment systems.

In industrial settings, electronic devices are often exposed to harsh conditions such as dust, moisture, and temperature extremes. High CTI value CEM3 PCBs are employed in industrial control systems, power supplies, and automation equipment to ensure reliable operation and longevity.

CEM3 materials provide excellent thermal management, which is crucial for maintaining the performance and reliability of electronic components. This is particularly important in high-power applications where heat dissipation is a major concern.

The combination of woven and non-woven glass fabric in CEM3 enhances the mechanical strength of the PCB. This ensures that the board can withstand physical stress and vibration, which are common in many electronic applications.

CEM3 materials are versatile and can be adapted to various manufacturing processes and design requirements. This flexibility makes them an attractive choice for manufacturers looking to optimize their production processes and reduce costs.

Before selecting a high CTI value CEM3 material, it is essential to assess the specific requirements of your application. Consider factors such as operating environment, electrical load, and mechanical stress to determine the most suitable material for your needs.

When choosing a supplier for high CTI value CEM3 materials, consider their reputation, product quality, and customer support. A reliable supplier will provide high-quality materials that meet industry standards, ensuring the success of your projects.

While high CTI value CEM3 materials offer numerous benefits, it is important to balance performance and cost. Evaluate the potential return on investment and long-term benefits to make an informed decision that aligns with your budget and performance goals.

Ongoing research and development in material science are likely to yield new CEM3 formulations with even higher CTI values and improved properties. These advancements will further enhance the performance and reliability of electronic devices.

As environmental concerns continue to grow, there is an increasing demand for sustainable and eco-friendly materials. Future CEM3 developments may focus on reducing environmental impact while maintaining high performance standards.

High CTI value CEM3 materials are a critical component in the design and manufacturing of reliable, safe, and cost-effective electronic devices. Their superior electrical insulation properties, mechanical strength, and adaptability make them an ideal choice for a wide range of applications. By understanding the benefits and considerations of high CTI value CEM3, manufacturers can make informed decisions that enhance the performance and reliability of their products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB