-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 10. 2025, 15:19:25

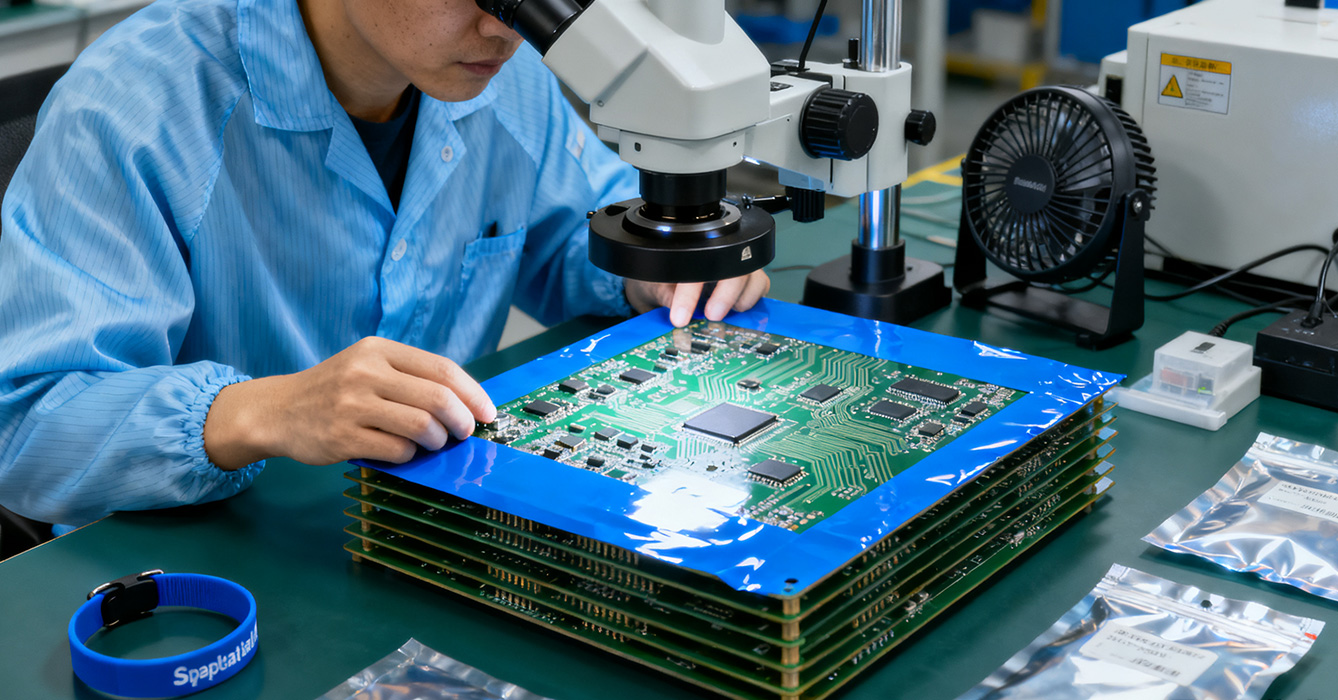

A China-Based PCB Assembly Supplier stands as a cornerstone of the global electronics manufacturing ecosystem, leveraging unique advantages in supply chain integration, scalable production, and technical agility to serve clients worldwide. Unlike regional suppliers, Chinese PCB assembly partners benefit from proximity to the world’s largest electronics component manufacturing hub—enabling faster sourcing, cost-effective production, and seamless collaboration with upstream material providers. Beyond cost competitiveness, top China-based suppliers have evolved to prioritize precision, compliance, and customer-centric flexibility, catering to diverse sectors from consumer electronics to industrial IoT and new energy. As global demand for customized, high-quality PCBs grows, these suppliers have become strategic partners for businesses seeking to balance speed-to-market, reliability, and scalability. This article explores the core strengths of China-based PCB assembly suppliers, their global service capabilities, industry-specific solutions, and how they adapt to evolving international standards.

Chinese suppliers distinguish themselves through three interconnected competitive advantages:

China’s position as a hub for electronic components (resistors, ICs, PCBs) lets suppliers build closed-loop supply networks. They partner directly with domestic and international component manufacturers, reducing lead times for sourcing by 30–40% compared to regional suppliers. This integration also enables dual-sourcing strategies—critical for mitigating shortages of high-demand components (e.g., automotive-grade chips) by tapping into diverse vendor networks across the Pearl River Delta and Yangtze River Delta.

Top suppliers balance high-volume scalability with precision manufacturing. They operate advanced SMT lines (equipped with pick-and-place machines, AI-powered AOI systems, and X-ray inspection) to handle both mass production (millions of units for consumer electronics) and low-volume, high-mix orders (prototypes for startups or custom industrial PCBs). This flexibility is supported by modular production cells that can reconfigure in hours, adapting to sudden demand shifts or design iterations.

China-based suppliers invest heavily in R&D to keep pace with emerging technologies. They quickly adopt innovations like HDI PCB assembly, flexible PCB integration, and lead-free soldering processes—ensuring clients can leverage cutting-edge manufacturing for next-gen products. In-house engineering teams also provide DFM (Design for Manufacturability) support, optimizing designs for production efficiency while maintaining technical specifications.

To serve global markets, China-based PCB assembly suppliers have built robust end-to-end support systems:

Reputable suppliers adhere to global quality and regulatory frameworks, including IPC-A-610 (electronics assembly acceptability), ISO 9001 (quality management), ISO 13485 (medical devices), and RoHS/REACH (environmental compliance). They maintain detailed traceability records (material batches, test results) to meet the strict requirements of industries like aerospace, medical, and automotive.

Suppliers partner with leading logistics providers (DHL, FedEx, UPS) to offer flexible shipping options—including air freight for urgent orders and sea freight for cost-sensitive bulk shipments. Many also establish regional warehouses (e.g., in Europe, North America) to enable just-in-time (JIT) delivery, reducing lead times and customs complexities for international clients.

To bridge cultural and linguistic gaps, suppliers provide 24/7 multilingual support (English, German, Spanish, etc.) and use cloud-based collaboration tools (e.g., Slack, Microsoft Teams) for real-time communication. Clients can track production progress via digital dashboards, share design updates, and resolve issues with engineering teams without time zone barriers.

China-based PCB assembly suppliers tailor their services to the unique needs of key sectors:

Suppliers support fast-paced consumer tech markets (smartphones, wearables, IoT devices) with rapid prototyping and mass production capabilities. They handle high-volume SMT assembly with tight tolerances, ensuring consistent quality for products with short lifecycles.

For EVs, solar inverters, and energy storage systems, suppliers specialize in high-power PCB assembly—focusing on thermal management, vibration resistance, and compliance with automotive standards (e.g., IATF 16949). They assemble BMS (Battery Management System) PCBs and power control units that withstand extreme operating conditions.

Industrial clients benefit from ruggedized PCB assembly, including conformal coating, dustproof enclosures, and sensor integration. Suppliers ensure assemblies meet the durability requirements of factory automation equipment, agricultural sensors, and smart grid devices.

The industry is evolving to meet global demands for sustainability and digitalization:

- Green Manufacturing: Suppliers are adopting eco-friendly practices—using renewable energy in factories, recycling solder scrap, and reducing waste through lean production.

- Digital Transformation: AI-driven production planning, digital twin simulation, and blockchain-based traceability are being integrated to enhance transparency and efficiency.

- Regionalization: Expanding local production hubs (e.g., in Southeast Asia, Mexico) to shorten supply chains and address geopolitical considerations.

A China-Based PCB Assembly Supplier offers more than manufacturing services—it delivers a strategic partnership built on supply chain resilience, technical agility, and global support. By combining proximity to component hubs, scalable production, and compliance with international standards, these suppliers enable businesses worldwide to accelerate time-to-market, reduce costs, and innovate with confidence. As the global electronics landscape evolves, China-based PCB assembly suppliers will remain at the forefront—adapting to new technologies, sustainability goals, and client needs to drive the next wave of manufacturing excellence.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB