-

- PCB TYPE

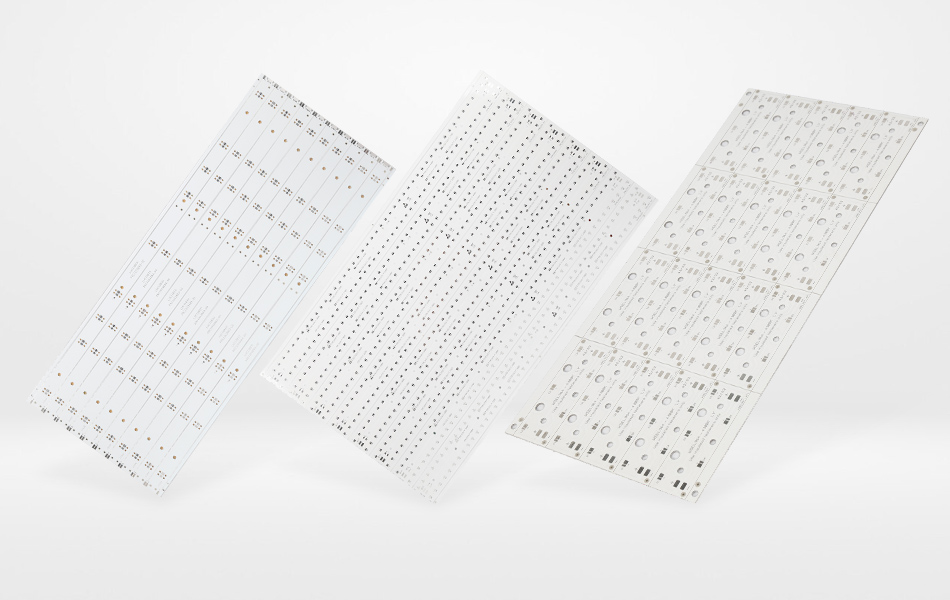

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 03. 2025, 11:05:30

In the global electronics manufacturing landscape, Chinese original equipment manufacturer (OEM) aluminum printed circuit board (Al PCB) factories have established themselves as indispensable partners for businesses seeking customized, high-reliability circuit board solutions. With the electronics industry's relentless pursuit of smaller form factors, higher power densities, and improved thermal management, these factories have emerged as leaders in delivering tailored Al PCB solutions that meet the unique demands of diverse sectors—from automotive and aerospace to consumer electronics and renewable energy.

Chinese OEM Al PCB factories distinguish themselves through a unique combination of technical expertise, manufacturing scale, and supply chain efficiency. They serve as critical cogs in the global electronics value chain, enabling product innovation by translating client concepts into manufacturable designs and delivering high-quality PCBs at competitive prices. This article delves deep into the operational frameworks, technological capabilities, service models, and future trends of Chinese OEM Al PCB factories, shedding light on their role in shaping the future of global electronics manufacturing.

China’s OEM Aluminum PCB Manufacturing Ecosystem: Key Advantages

Integrated Supply Chain Mastery

Chinese OEM Al PCB factories benefit from a highly integrated supply chain that gives them a significant competitive edge in terms of cost, lead time, and quality control.

China's position as the world's largest producer of aluminum and copper provides a solid foundation for its OEM Al PCB industry. The country accounts for approximately 60% of global aluminum production, with numerous smelters producing high-purity aluminum suitable for PCB cores. This proximity to raw material sources allows OEM factories to reduce logistics costs and lead times by sourcing aluminum cores and copper foils domestically, maintain strict quality control over raw materials through long-term partnerships with local suppliers, and access a wide range of aluminum alloys—from general-purpose 1000-series to corrosion-resistant 3000-series and high-strength 5000-series—for material customization.

Dielectric materials, another critical component of Al PCBs, are also sourced locally. Chinese manufacturers produce a variety of dielectric films and laminates, including cost-effective FR-4 derivatives, high-temperature polyimides, and low-loss PTFE materials for RF applications. This localization ensures that OEM factories can quickly adapt to changing material demands and maintain consistent quality.

Chinese OEM Al PCB factories are embedded in a robust ecosystem of component manufacturers, including semiconductor companies, connector suppliers, and passive component producers. This integration enables concurrent engineering to optimize PCB designs for specific components, faster prototyping due to local component access, and cost optimization through bulk purchasing power.

Scalable Manufacturing Infrastructure

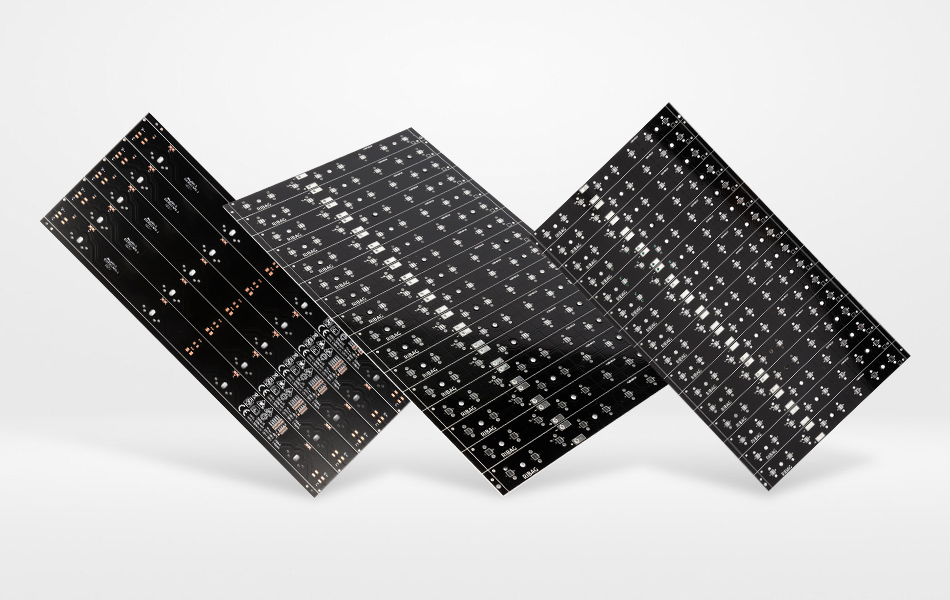

Chinese OEM Al PCB factories have invested heavily in scalable manufacturing infrastructure, allowing them to cater to a wide range of order sizes and complexities.

From small-batch prototyping to high-volume mass production, these factories have flexible manufacturing lines. Many offer rapid prototyping services with turnaround times as low as 24-48 hours using advanced equipment like laser drilling machines and automated plating lines. For large orders, high-speed manufacturing lines capable of producing millions of PCBs annually are optimized for efficiency, with automated material handling, high-volume plating systems, and streamlined quality control processes.

The majority of Chinese OEM Al PCB factories are concentrated in industrial hubs such as the Pearl River Delta, the Yangtze River Delta, and the Bohai Economic Rim. These clusters foster knowledge sharing, develop shared manufacturing standards, and host a wide range of supporting industries—from equipment manufacturers to testing labs—that can quickly respond to factory needs.

Technical Expertise and Engineering Support

Chinese OEM Al PCB factories distinguish themselves through their technical expertise and comprehensive engineering support, which goes beyond mere manufacturing.

Most large OEM factories employ dedicated research and development teams proficient in thermal simulation to model heat dissipation, signal integrity analysis to ensure high-frequency performance, and design for manufacturability (DFM) to provide feedback on production feasibility.

OEM factories often offer comprehensive design assistance, including concept development to translate product ideas into feasible designs, 3D modeling and simulation using CAD tools, and design optimization to improve manufacturability, reduce costs, or enhance performance.

OEM Aluminum PCB Manufacturing Processes: From Design to Delivery

Customized Design Collaboration

The OEM process begins with a detailed analysis of the client's requirements, including thermal management needs to understand heat generation and thresholds, mechanical requirements to assess environmental conditions like vibration and temperature fluctuations, electrical specifications for signal frequencies and impedance control, and application-specific needs such as industry-grade reliability or weight constraints.

Using the gathered requirements, OEM factories develop detailed design proposals that include schematic design, layer stackup design to determine core thickness and dielectric materials, component placement plans to minimize thermal hotspots, and thermal/electrical simulations using software like ANSYS or CST to validate performance.

Material Selection for OEM Applications

Chinese OEM factories offer a range of aluminum core grades: 1000-series aluminum (e.g., 1050, 1060) for general thermal management, 3000-series aluminum (e.g., 3003) for corrosion resistance, and 5000-series aluminum (e.g., 5052) for mechanical robustness.

For dielectric layers, they help clients choose from FR-4 derivatives for cost-effective general use, polyimide films for high-temperature applications, PTFE materials for RF/microwave needs, and ceramic-filled epoxies to enhance thermal conductivity in high-power designs.

Manufacturing Execution: Precision and Efficiency

Laser drilling is used for microvias (as small as 50μm) in high-density PCBs, while mechanical drilling handles through-holes in standard PCBs with multi-spindle machines for high-volume production.

Electroplating involves a two-step process of electroless and electrolytic plating to deposit uniform copper layers (25-50μm), and thermal via filling with ceramic-loaded epoxies enhances heat transfer.

High-pressure lamination creates multi-layer PCBs, and surface finishing options include HASL for cost-effectiveness, OSP for fine-pitch components, and ENIG for high-reliability applications.

Quality Assurance in Chinese OEM Al PCB Factories

Comprehensive Testing Regimes

Electrical testing includes flying probe testing for open/short circuits, bed-of-nails testing for high-volume production, and impedance testing for high-frequency signals.

Thermal performance validation uses infrared thermography for temperature mapping, thermal cycling tests (-40°C to +125°C) for reliability assessment, and thermal resistance measurement with tools like the Transient Thermal Tester (T3Ster).

Certification and Compliance

Chinese OEM Al PCB factories prioritize international certifications: IPC-6012 for PCB quality, ISO 9001 for quality management, ISO 14001 for environmental sustainability, and RoHS/REACH compliance for hazardous substance restrictions.

Advanced Inspection Technologies

Automated Optical Inspection (AOI) uses high-resolution cameras for visual defect detection, X-ray imaging verifies internal via integrity in multi-layer PCBs, and 3D scanning ensures precise dimensional accuracy.

OEM Service Models: Tailored to Client Needs

End-to-End OEM Solutions

OEM factories provide design-for-manufacture (DFM) support through design reviews to identify production issues, modification suggestions to improve manufacturability, and cost analysis for design optimization. They also assist with component sourcing, including identification, BOM management, and procurement of hard-to-find components.

Flexible Order Fulfillment

Rapid prototyping offers fast turnaround (24-72 hours) and small-batch production for testing. Just-In-Time (JIT) manufacturing synchronizes production with client assembly lines, and scalable production ensures a seamless transition from prototype to mass production with design freeze management and process validation.

Value-Added Services

Many factories offer full PCB assembly (PCBA) services, including SMT placement, through-hole assembly, reflow/wave soldering, and functional testing. System integration services may include heat sink design, cooling system development, and custom enclosure manufacturing.

Case Studies: Chinese OEM Al PCB Factory Applications

Automotive OEM Thermal Management Solutions

For EV inverters, an OEM factory designed an Al PCB with a 2mm 1060 aluminum core and thermal vias, effectively dissipating heat from IGBT modules and meeting automotive reliability standards. For ADAS sensor modules, a custom Al PCB with a 1.6mm 5052 core and low-loss PTFE dielectric ensured signal integrity and withstood vibration/temperature cycling.

Consumer Electronics OEM Projects

A global lighting brand received a cost-effective Al PCB with a 1.0mm 1050 core for high-power LED fixtures, while a battery-powered tool manufacturer obtained a lightweight Al PCB with a 0.8mm core for efficient heat management in DC-DC converters.

Industrial and Renewable Energy Applications

A renewable energy company got a multi-layer Al PCB with a 2.0mm core for solar inverters, and an industrial control systems provider received a ruggedized Al PCB with a 1.6mm 3003 core for harsh environments.

Technological Innovations in Chinese OEM Al PCB Factories

Advanced Manufacturing Technologies

AI-driven production planning optimizes scheduling, quality prediction, and material utilization. Smart factory integration uses IoT sensors, robotics, and big data analytics for process optimization.

Innovative Design Solutions

3D thermal via architectures and hybrid material integration with composite heat spreaders or metal-ceramic composites enhance thermal management.

Sustainable Manufacturing Initiatives

Green production processes include water-based cleaning and renewable energy use, while recycling programs achieve high metal recycling rates and waste reduction via lean manufacturing.

Conclusion: China’s OEM Al PCB Factories as Global Innovation Partners

Chinese OEM aluminum PCB factories have evolved into strategic innovation partners, delivering customized solutions that balance performance, reliability, and cost. Their integrated supply chains, technical expertise, and scalable manufacturing enable global OEMs to accelerate product development and access cutting-edge technology. As electronics advance, these factories will continue shaping the future of global manufacturing through innovation in materials, processes, and sustainable practices.

China's Al PCB Industry: A Global Powerhouse

Market Dominance and Growth Trajectory

China commands over half of the global Al PCB market, a testament to its rapid industrial evolution. The country's strategic focus on high-tech manufacturing, as outlined in initiatives like "Made in China 2025," has fostered the growth of specialized production clusters. Regions such as the Pearl River Delta and the Yangtze River Delta have become epicenters for Al PCB manufacturing, housing state-of-the-art facilities and attracting top-tier talent. This concentration of resources has not only streamlined production but also accelerated technological adoption, allowing Chinese manufacturers to stay ahead of global competition.

Catalysts Driving Industry Expansion

1. Electrification Revolution

The global shift towards electric vehicles (EVs) and renewable energy has created a surge in demand for Al PCBs. Chinese manufacturers have been quick to respond, developing tailored solutions for EV powertrains, battery management systems, and charging infrastructure. These PCBs are designed to manage high power densities while ensuring reliable thermal performance, enabling more efficient and compact electronic systems in modern EVs.

5G and IoT Deployment

As 5G networks expand worldwide and the Internet of Things (IoT) ecosystem grows, the need for high-frequency, thermally efficient PCBs has skyrocketed. Chinese Al PCB producers have mastered the art of balancing electrical performance with thermal management, crafting boards capable of handling mmWave frequencies with minimal signal loss. Their solutions are integral to 5G base stations, small cells, and a plethora of IoT devices, from smart sensors to wearable electronics.

Consumer Electronics Evolution

The relentless pursuit of thinner, more powerful consumer devices has also fueled Al PCB demand. Chinese manufacturers cater to this market by producing lightweight, high-performance boards for smartphones, tablets, laptops, and home appliances. These PCBs optimize heat dissipation, ensuring devices maintain peak performance even under heavy usage.

Technical Prowess: China's Edge in Al PCB Design and Production

Material Innovation and Customization

Aluminum Core Expertise

Chinese manufacturers have developed a deep understanding of different aluminum alloys, leveraging their unique properties to meet specific application needs. For general thermal management, pure aluminum alloys offer excellent heat conductivity. In contrast, alloyed variants enhance mechanical strength, corrosion resistance, or formability, making them suitable for rugged automotive or aerospace applications.

Advanced Dielectric Materials

The choice of dielectric material significantly impacts an Al PCB's electrical and thermal performance. Chinese researchers and manufacturers have been at the forefront of developing advanced dielectrics, including low-loss PTFE for RF applications, high-temperature polyimides for harsh environments, and ceramic-filled epoxies that combine thermal conductivity with cost-effectiveness.

Engineering Excellence

Thermal Management Solutions

Efficient thermal management is crucial for Al PCBs, especially in high-power applications. Chinese engineers have pioneered innovative designs, such as through-core vias that provide direct heat transfer paths, and composite heat spreaders that combine aluminum with materials like graphite or graphene for enhanced thermal conductivity. These solutions ensure components operate within optimal temperature ranges, extending product lifespan and reliability.

High-Frequency Design Capabilities

With the rise of 5G and other high-frequency technologies, precise impedance control and signal integrity are paramount. Chinese Al PCB manufacturers employ advanced simulation tools and meticulous layer stackup designs to maintain impedance tolerance and minimize signal degradation. They also integrate effective EMI shielding mechanisms, ensuring interference-free operation in complex electronic systems.

Manufacturing Ecosystem: A Well-Oiled Machine

Integrated Supply Chain

China's robust supply chain is a key pillar of its Al PCB manufacturing dominance. Proximity to major aluminum and copper producers reduces material sourcing costs and lead times. Moreover, a dense network of component suppliers, equipment manufacturers, and testing labs enables seamless collaboration, from initial design to final production. This ecosystem fosters innovation through knowledge sharing and accelerates time-to-market for new products.

Advanced Manufacturing Technologies

Precision Fabrication Processes

Chinese factories utilize state-of-the-art equipment for precision drilling, plating, and lamination. Laser drilling creates microvias with high precision, while advanced plating techniques ensure uniform copper deposition. Automated lamination processes guarantee consistent layer bonding, essential for multi-layer PCB reliability.

Smart Manufacturing Initiatives

The adoption of Industry 4.0 technologies has revolutionized Chinese Al PCB production. AI-driven algorithms optimize production scheduling, reducing lead times and minimizing waste. IoT sensors monitor equipment performance in real-time, enabling predictive maintenance and ensuring continuous operation. Robotics and automation enhance assembly accuracy and speed, further boosting productivity.

Quality Assurance: Upholding Global Standards

Rigorous Testing Regimes

Chinese Al PCB manufacturers implement comprehensive testing protocols to ensure product quality. Electrical tests verify circuit integrity and impedance matching, while thermal tests, such as thermal cycling and infrared thermography, assess heat dissipation capabilities. These tests simulate real-world operating conditions, identifying potential issues early in the production process.

International Certification and Compliance

To meet global market requirements, Chinese manufacturers adhere to international standards and regulations. Certifications such as IPC-6012 for PCB quality, ISO 9001 for quality management, and RoHS/REACH for environmental compliance are commonplace. For automotive applications, compliance with IATF 16949 ensures the highest levels of safety and reliability.

Real-World Applications: Powering Diverse Industries

Automotive Electronics

In the automotive sector, Al PCBs play a vital role in EV components, ADAS systems, and in-vehicle infotainment. They manage heat in power inverters, enable precise radar and camera functionality in ADAS, and support high-performance computing in infotainment systems. Chinese manufacturers' ability to deliver reliable, cost-effective solutions has made them preferred partners for global automakers.

Renewable Energy

Al PCBs are integral to solar inverters, wind turbine control systems, and energy storage devices. Chinese-produced boards withstand harsh environmental conditions while optimizing power conversion efficiency. Their thermal management capabilities ensure stable operation, even in extreme temperatures.

Consumer Electronics

From smartphones to smart home devices, Al PCBs enhance consumer electronics performance. They enable faster processing, longer battery life, and better heat dissipation, contributing to improved user experiences. Chinese manufacturers' flexibility in producing customized boards supports rapid innovation in this highly competitive market.

Future Outlook: Trends Shaping the Industry

Technological Advancements

AI and Machine Learning Integration

AI and machine learning will increasingly influence Al PCB design and production. These technologies will optimize thermal simulations, predict manufacturing defects, and automate design processes, leading to faster development cycles and higher-quality products.

3D Printing and Additive Manufacturing

Additive manufacturing techniques offer new possibilities for Al PCB production. 3D-printed heat sinks and customized PCB structures can be created on-demand, reducing production costs and enabling more complex designs.

Sustainability Initiatives

As environmental concerns grow, Chinese manufacturers are adopting sustainable practices. This includes using recycled materials, implementing energy-efficient manufacturing processes, and reducing waste generation. Green certifications will become increasingly important for accessing global markets.

New Application Frontiers

Emerging technologies like autonomous vehicles, quantum computing, and space exploration will open new markets for Al PCBs. Chinese manufacturers are well-positioned to develop specialized solutions for these cutting-edge applications, leveraging their existing expertise and R&D capabilities.

Conclusion: China's Enduring Leadership in Al PCB Manufacturing

China's dominance in aluminum PCB manufacturing is a result of its strategic investments in technology, talent, and infrastructure. By combining innovation, scale, and quality, Chinese manufacturers have become indispensable partners for global electronics companies. As the demand for advanced electronic systems continues to grow, China will likely maintain its leadership position, driving further advancements in Al PCB technology and shaping the future of the electronics industry. For businesses seeking reliable, high-performance Al PCBs, China offers a wealth of expertise, resources, and innovation potential.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB