-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 03. 2025, 10:51:36

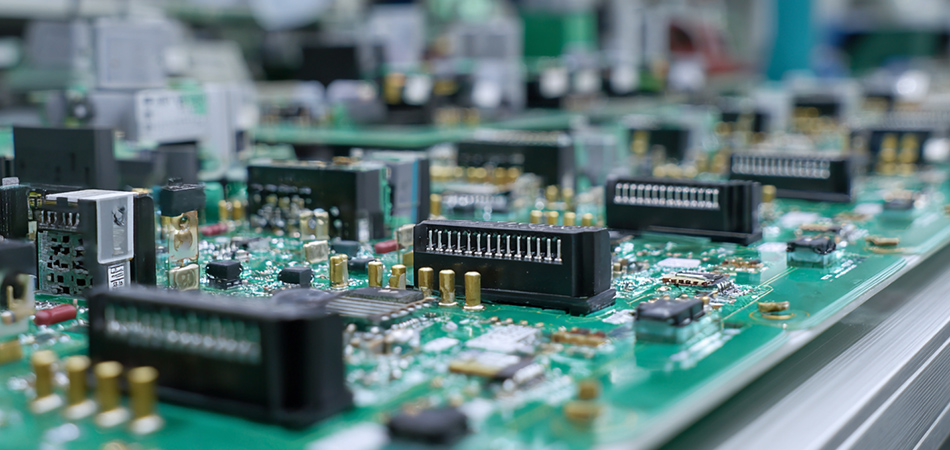

In the global electronics manufacturing landscape, Chinese original equipment manufacturer (OEM) aluminum printed circuit board (Al PCB) factories have established themselves as indispensable partners for businesses seeking customized, high-reliability circuit board solutions. With the electronics industry's relentless pursuit of smaller form factors, higher power densities, and improved thermal management, these factories have emerged as leaders in delivering tailored Al PCB solutions that meet the unique demands of diverse sectors—from automotive and aerospace to consumer electronics and renewable energy.

Chinese OEM Al PCB factories distinguish themselves through a unique combination of technical expertise, manufacturing scale, and supply chain efficiency. They serve as critical cogs in the global electronics value chain, enabling product innovation by translating client concepts into manufacturable designs and delivering high-quality PCBs at competitive prices. This article delves deep into the operational frameworks, technological capabilities, service models, and future trends of Chinese OEM Al PCB factories, shedding light on their role in shaping the future of global electronics manufacturing.

China’s OEM Aluminum PCB Manufacturing Ecosystem: Key Advantages

Integrated Supply Chain Mastery

Chinese OEM Al PCB factories benefit from a highly integrated supply chain that gives them a significant competitive edge in terms of cost, lead time, and quality control.

China's position as the world's largest producer of aluminum and copper provides a solid foundation for its OEM Al PCB industry. The country accounts for approximately 60% of global aluminum production, with numerous smelters producing high-purity aluminum suitable for PCB cores. This proximity to raw material sources allows OEM factories to reduce logistics costs and lead times by sourcing aluminum cores and copper foils domestically, maintain strict quality control over raw materials through long-term partnerships with local suppliers, and access a wide range of aluminum alloys—from general-purpose 1000-series to corrosion-resistant 3000-series and high-strength 5000-series—for material customization.

Dielectric materials, another critical component of Al PCBs, are also sourced locally. Chinese manufacturers produce a variety of dielectric films and laminates, including cost-effective FR-4 derivatives, high-temperature polyimides, and low-loss PTFE materials for RF applications. This localization ensures that OEM factories can quickly adapt to changing material demands and maintain consistent quality.

Chinese OEM Al PCB factories are embedded in a robust ecosystem of component manufacturers, including semiconductor companies, connector suppliers, and passive component producers. This integration enables concurrent engineering to optimize PCB designs for specific components, faster prototyping due to local component access, and cost optimization through bulk purchasing power.

Scalable Manufacturing Infrastructure

Chinese OEM Al PCB factories have invested heavily in scalable manufacturing infrastructure, allowing them to cater to a wide range of order sizes and complexities.

From small-batch prototyping to high-volume mass production, these factories have flexible manufacturing lines. Many offer rapid prototyping services with turnaround times as low as 24-48 hours using advanced equipment like laser drilling machines and automated plating lines. For large orders, high-speed manufacturing lines capable of producing millions of PCBs annually are optimized for efficiency, with automated material handling, high-volume plating systems, and streamlined quality control processes.

The majority of Chinese OEM Al PCB factories are concentrated in industrial hubs such as the Pearl River Delta, the Yangtze River Delta, and the Bohai Economic Rim. These clusters foster knowledge sharing, develop shared manufacturing standards, and host a wide range of supporting industries—from equipment manufacturers to testing labs—that can quickly respond to factory needs.

Technical Expertise and Engineering Support

Chinese OEM Al PCB factories distinguish themselves through their technical expertise and comprehensive engineering support, which goes beyond mere manufacturing.

Most large OEM factories employ dedicated research and development teams proficient in thermal simulation to model heat dissipation, signal integrity analysis to ensure high-frequency performance, and design for manufacturability (DFM) to provide feedback on production feasibility.

OEM factories often offer comprehensive design assistance, including concept development to translate product ideas into feasible designs, 3D modeling and simulation using CAD tools, and design optimization to improve manufacturability, reduce costs, or enhance performance.

OEM Aluminum PCB Manufacturing Processes: From Design to Delivery

Customized Design Collaboration

The OEM process begins with a detailed analysis of the client's requirements, including thermal management needs to understand heat generation and thresholds, mechanical requirements to assess environmental conditions like vibration and temperature fluctuations, electrical specifications for signal frequencies and impedance control, and application-specific needs such as industry-grade reliability or weight constraints.

Using the gathered requirements, OEM factories develop detailed design proposals that include schematic design, layer stackup design to determine core thickness and dielectric materials, component placement plans to minimize thermal hotspots, and thermal/electrical simulations using software like ANSYS or CST to validate performance.

Material Selection for OEM Applications

Chinese OEM factories offer a range of aluminum core grades: 1000-series aluminum (e.g., 1050, 1060) for general thermal management, 3000-series aluminum (e.g., 3003) for corrosion resistance, and 5000-series aluminum (e.g., 5052) for mechanical robustness.

For dielectric layers, they help clients choose from FR-4 derivatives for cost-effective general use, polyimide films for high-temperature applications, PTFE materials for RF/microwave needs, and ceramic-filled epoxies to enhance thermal conductivity in high-power designs.

Manufacturing Execution: Precision and Efficiency

Laser drilling is used for microvias (as small as 50μm) in high-density PCBs, while mechanical drilling handles through-holes in standard PCBs with multi-spindle machines for high-volume production.

Electroplating involves a two-step process of electroless and electrolytic plating to deposit uniform copper layers (25-50μm), and thermal via filling with ceramic-loaded epoxies enhances heat transfer.

High-pressure lamination creates multi-layer PCBs, and surface finishing options include HASL for cost-effectiveness, OSP for fine-pitch components, and ENIG for high-reliability applications.

Quality Assurance in Chinese OEM Al PCB Factories

Comprehensive Testing Regimes

Electrical testing includes flying probe testing for open/short circuits, bed-of-nails testing for high-volume production, and impedance testing for high-frequency signals.

Thermal performance validation uses infrared thermography for temperature mapping, thermal cycling tests (-40°C to +125°C) for reliability assessment, and thermal resistance measurement with tools like the Transient Thermal Tester (T3Ster).

Certification and Compliance

Chinese OEM Al PCB factories prioritize international certifications: IPC-6012 for PCB quality, ISO 9001 for quality management, ISO 14001 for environmental sustainability, and RoHS/REACH compliance for hazardous substance restrictions.

Advanced Inspection Technologies

Automated Optical Inspection (AOI) uses high-resolution cameras for visual defect detection, X-ray imaging verifies internal via integrity in multi-layer PCBs, and 3D scanning ensures precise dimensional accuracy.

OEM Service Models: Tailored to Client Needs

End-to-End OEM Solutions

OEM factories provide design-for-manufacture (DFM) support through design reviews to identify production issues, modification suggestions to improve manufacturability, and cost analysis for design optimization. They also assist with component sourcing, including identification, BOM management, and procurement of hard-to-find components.

Flexible Order Fulfillment

Rapid prototyping offers fast turnaround (24-72 hours) and small-batch production for testing. Just-In-Time (JIT) manufacturing synchronizes production with client assembly lines, and scalable production ensures a seamless transition from prototype to mass production with design freeze management and process validation.

Value-Added Services

Many factories offer full PCB assembly (PCBA) services, including SMT placement, through-hole assembly, reflow/wave soldering, and functional testing. System integration services may include heat sink design, cooling system development, and custom enclosure manufacturing.

Case Studies: Chinese OEM Al PCB Factory Applications

Automotive OEM Thermal Management Solutions

For EV inverters, an OEM factory designed an Al PCB with a 2mm 1060 aluminum core and thermal vias, effectively dissipating heat from IGBT modules and meeting automotive reliability standards. For ADAS sensor modules, a custom Al PCB with a 1.6mm 5052 core and low-loss PTFE dielectric ensured signal integrity and withstood vibration/temperature cycling.

Consumer Electronics OEM Projects

A global lighting brand received a cost-effective Al PCB with a 1.0mm 1050 core for high-power LED fixtures, while a battery-powered tool manufacturer obtained a lightweight Al PCB with a 0.8mm core for efficient heat management in DC-DC converters.

Industrial and Renewable Energy Applications

A renewable energy company got a multi-layer Al PCB with a 2.0mm core for solar inverters, and an industrial control systems provider received a ruggedized Al PCB with a 1.6mm 3003 core for harsh environments.

Technological Innovations in Chinese OEM Al PCB Factories

Advanced Manufacturing Technologies

AI-driven production planning optimizes scheduling, quality prediction, and material utilization. Smart factory integration uses IoT sensors, robotics, and big data analytics for process optimization.

Innovative Design Solutions

3D thermal via architectures and hybrid material integration with composite heat spreaders or metal-ceramic composites enhance thermal management.

Sustainable Manufacturing Initiatives

Green production processes include water-based cleaning and renewable energy use, while recycling programs achieve high metal recycling rates and waste reduction via lean manufacturing.

Conclusion: China’s OEM Al PCB Factories as Global Innovation Partners

Chinese OEM aluminum PCB factories have evolved into strategic innovation partners, delivering customized solutions that balance performance, reliability, and cost. Their integrated supply chains, technical expertise, and scalable manufacturing enable global OEMs to accelerate product development and access cutting-edge technology. As electronics advance, these factories will continue shaping the future of global manufacturing through innovation in materials, processes, and sustainable practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB