-

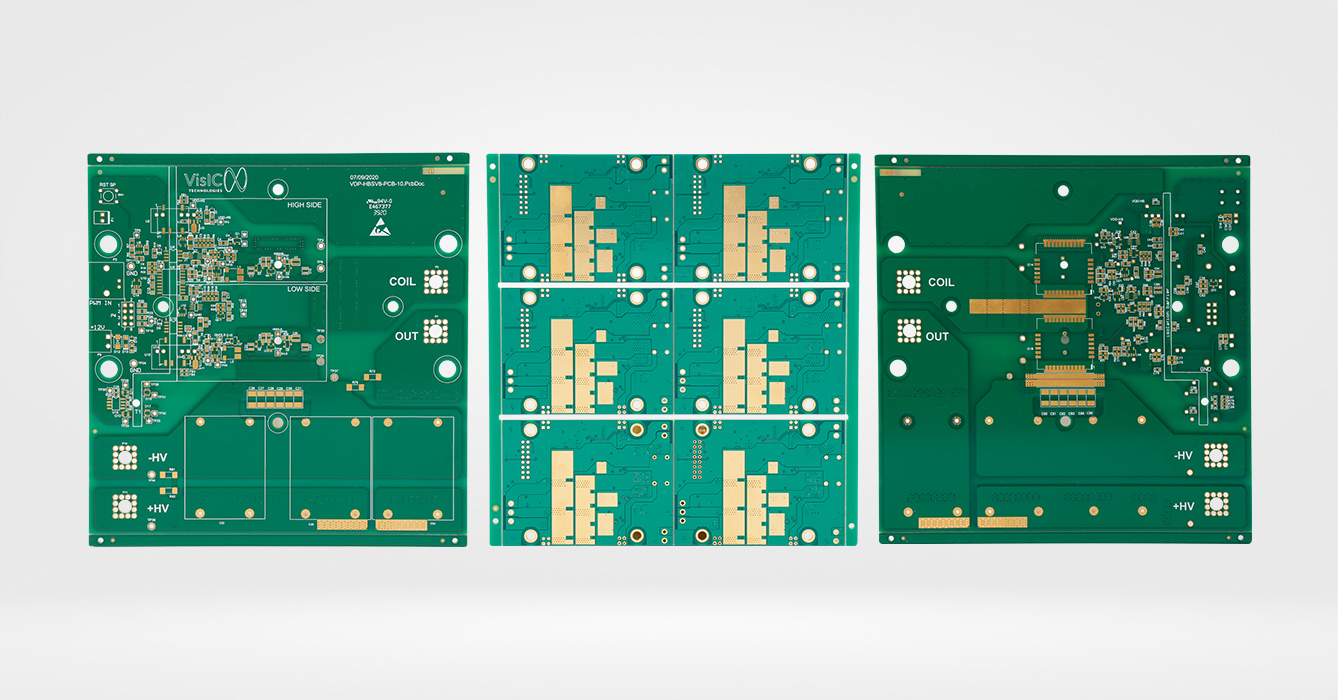

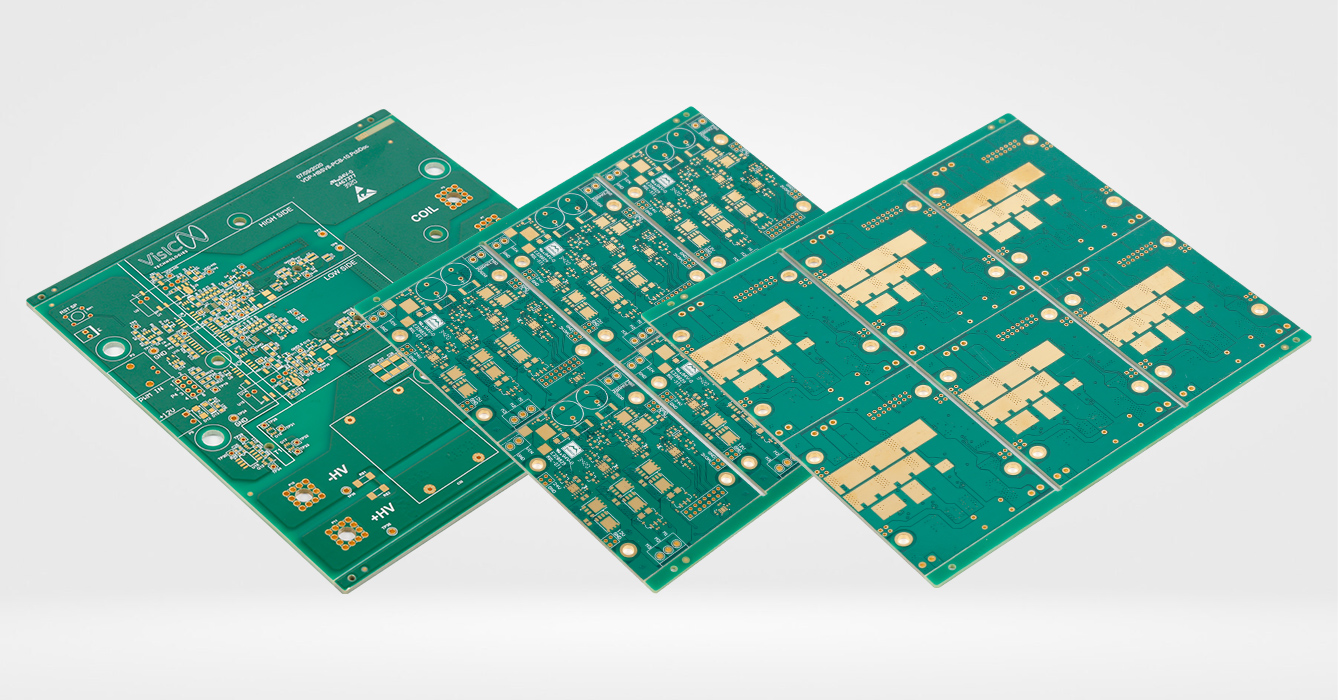

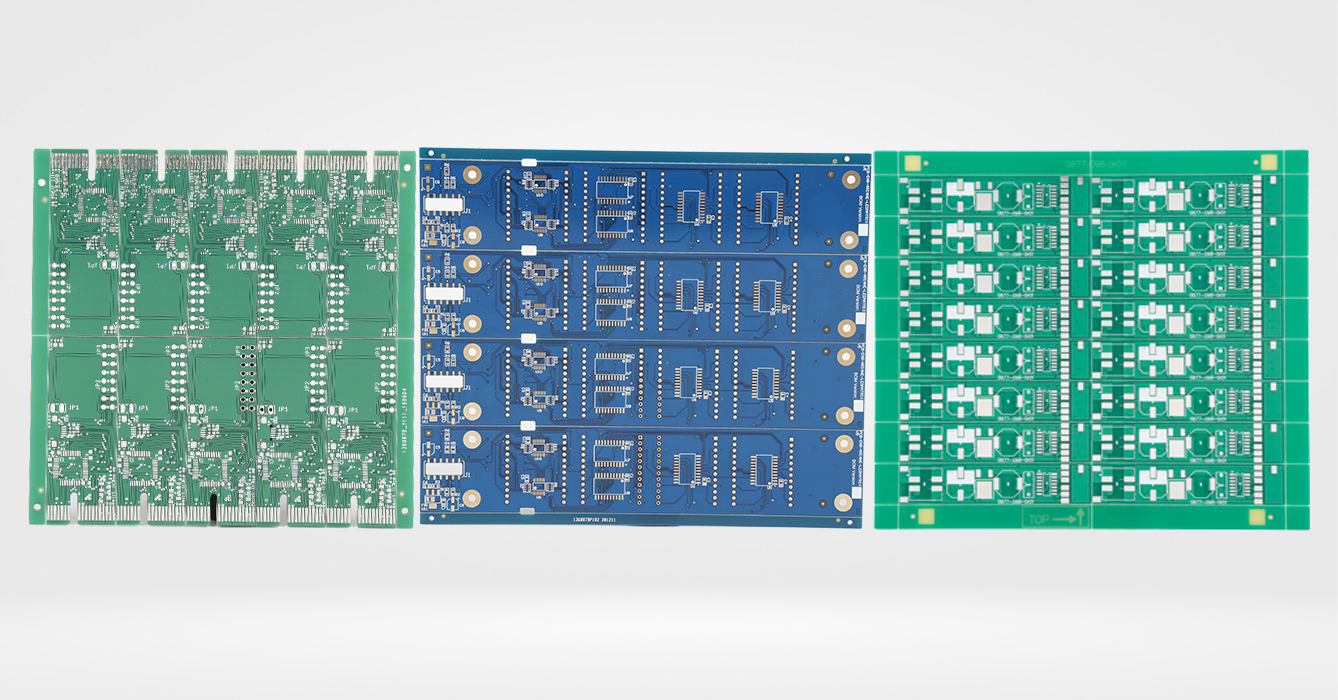

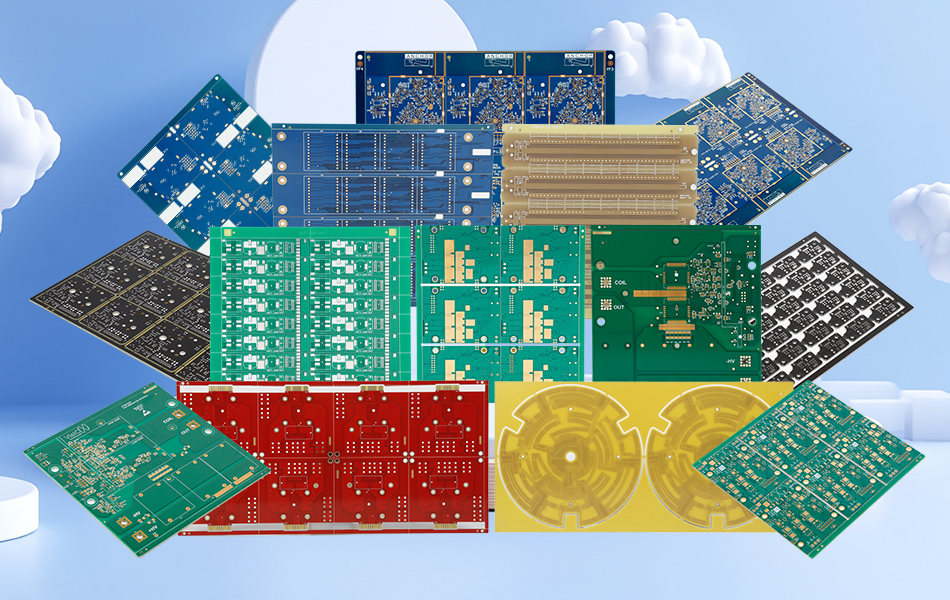

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 02. 2025, 13:42:52

In the intricate world of printed circuit board (PCB) design, counterbore holes in FR4 PCB serve as a foundational element for balancing mechanical stability and functional efficiency, enabling the seamless integration of hardware in diverse electronic assemblies. These specialized recesses—characterized by their flat-bottomed, cylindrical profile—are engineered to accommodate fastener heads, spacers, or component bases while preserving the integrity of the FR4 substrate. This article delves into the design principles, manufacturing methodologies, application landscapes, quality assurance protocols, and emerging innovations surrounding counterbore holes in FR4 PCBs, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Counterbore holes are distinct from other mounting features like countersinks due to their straight-walled, flat-bottomed structure, which provides a stable platform for hardware attachment. In FR4 PCBs, this design is tailored to leverage the material’s unique properties:

Flush Mounting: Counterbore holes allow fasteners or component housings to sit flush with or below the PCB surface, eliminating protrusions that could interfere with enclosures, adjacent components, or user interfaces—critical in devices like consumer electronics and medical monitors.

Load Distribution: The expanded diameter of the counterbore spreads mechanical stress across a larger area of the FR4 substrate, reducing the risk of cracking or delamination, especially in high-vibration environments such as industrial machinery or automotive systems.

Component Compatibility: These recesses accommodate a range of hardware, from standard screws and bolts to custom spacers, making them versatile for both off-the-shelf and custom electronic assemblies.

FR4’s composite structure—glass fiber reinforcement embedded in epoxy resin—influences counterbore design and performance:

Structural Support: The glass fiber matrix provides the rigidity needed to withstand the pressure of fastener installation, while the epoxy resin ensures a smooth, consistent surface finish that facilitates proper seating of hardware.

Dimensional Stability: FR4’s low coefficient of thermal expansion (CTE) ensures counterbore dimensions remain stable across temperature fluctuations, preventing loose fittings in applications exposed to extreme heat or cold.

Producing high-quality counterbore holes in FR4 requires precision machining techniques that account for the material’s unique blend of toughness and brittleness:

Specialized Cutting Tools: Carbide or high-speed steel (HSS) end mills with sharp, multi-flute designs are used to create clean, burr-free counterbores. These tools are engineered to minimize heat generation, preventing resin softening and glass fiber damage.

CNC Machining Centers: Computer numerical control (CNC) systems with high positional accuracy (±0.01mm) ensure consistent hole placement relative to circuit traces and component pads, avoiding electrical shorts or misalignment issues.

Depth Control Systems: Precision Z-axis actuators maintain uniform counterbore depth, ensuring compatibility with fastener lengths and preventing penetration through the PCB substrate—a critical factor in multi-layer boards.

Pilot Hole Drilling: A small-diameter pilot hole is first drilled to guide the counterbore tool, reducing deflection and ensuring positional accuracy. This step is particularly important for larger counterbores, where tool stability is paramount.

Counterbore Formation: The main recess is machined using a specialized end mill, with controlled feed rates and spindle speeds to avoid fiber tearing or resin smearing. Coolant systems (typically mist-based) dissipate heat and flush away debris, preserving hole integrity.

Post-Processing: Deburring techniques—such as abrasive brushing or ultrasonic cleaning—remove residual material from hole edges, ensuring smooth hardware insertion and preventing electrical interference from loose glass fibers.

Ensuring the reliability of counterbore holes demands rigorous testing and inspection to validate dimensional accuracy, structural integrity, and functional performance:

Optical Metrology: High-resolution cameras and laser scanners measure counterbore diameter, depth, and positional accuracy, comparing results to design specifications. 3D profilometry assesses surface roughness, ensuring a uniform finish for proper hardware seating.

Cross-Sectional Analysis: Microscopic examination of sample PCBs checks for subsurface defects, such as delamination between FR4 layers or uneven fiber distribution around the counterbore, which could compromise structural strength.

Fastener Retention Tests: Torque testing evaluates the ability of counterbores to secure fasteners under operational stress, simulating real-world conditions like vibration or thermal cycling.

Stress Resistance Testing: PCBs with counterbores are subjected to bending or compression tests to verify that the recesses do not weaken the substrate, ensuring durability in applications like portable electronics or aerospace systems.

IPC Standards: Manufacturing aligns with IPC-A-600 guidelines, which specify criteria for hole quality, including allowable burr heights, edge smoothness, and freedom from conductive contaminants.

Environmental Certifications: For applications in regulated industries (e.g., medical or automotive), counterbores are processed using RoHS-compliant coolants and cleaning agents to meet global environmental standards.

Counterbore holes in FR4 PCBs find utility across a broad spectrum of industries, where secure, space-efficient mounting is essential:

Smartphones and Tablets: Counterbores secure internal components like batteries and cameras, ensuring a slim profile and preventing hardware interference with touchscreens or wireless antennas.

Home Appliances: In devices like smart refrigerators or televisions, these recesses mount control boards, balancing stability with the need for compact design in tight enclosures.

Factory Automation: Counterbores secure PCBs in robotic arms and control panels, withstanding vibration and temperature fluctuations in manufacturing environments.

Automotive Electronics: In vehicle dashboards and infotainment systems, these holes mount circuit boards, ensuring reliability under the mechanical stress of driving.

Medical Equipment: Counterbores in FR4 PCBs secure sensors and control modules in devices like MRI machines or portable defibrillators, where precision and sterility are critical.

Aerospace Systems: In avionics and satellite components, these recesses provide lightweight, vibration-resistant mounting, meeting strict weight and durability requirements.

Advancements in manufacturing and materials are expanding the capabilities of counterbore holes in FR4 PCBs:

Nanocoated Tools: End mills with diamond-like carbon (DLC) or titanium aluminum nitride (TiAlN) coatings reduce friction and wear, extending tool life and improving surface finish in high-volume production.

Adaptive Machining: AI-driven CNC systems adjust cutting parameters in real time based on material feedback, optimizing tool paths to minimize defects in FR4 substrates with varying fiber density.

Generative Design Software: Algorithms optimize counterbore placement and dimensions to reduce weight while maintaining strength, particularly valuable in aerospace and portable electronics.

Integrated Mounting Solutions: Combining counterbores with adhesive bonding creates redundant fastening systems, enhancing reliability in safety-critical applications like medical devices.

Eco-Friendly Coolants: Plant-based lubricants and water-soluble coolants reduce the environmental impact of counterbore machining, aligning with green manufacturing initiatives.

Waste Reduction: Precision machining techniques minimize material waste, while recycled carbide tooling supports circular economy practices in PCB production.

Counterbore holes in FR4 PCB represent a critical innovation in the design and assembly of modern electronics, offering a versatile solution for secure, space-efficient hardware mounting. By leveraging FR4’s structural properties and advanced machining techniques, these recesses balance mechanical stability with functional flexibility, enabling their use in applications from consumer gadgets to aerospace systems. As electronics continue to evolve toward miniaturization and higher performance, counterbore holes will remain essential, adapting through innovations in tooling, design, and sustainability to meet emerging industry demands. Their role in bridging mechanical engineering and PCB design ensures they will remain a cornerstone of electronic manufacturing for years to come.

Keywords: Counterbore holes in FR4 PCB, FR4 machining, PCB mounting solutions, electronic assembly, precision drilling, industrial PCB design.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB