-

- PCB TYPE

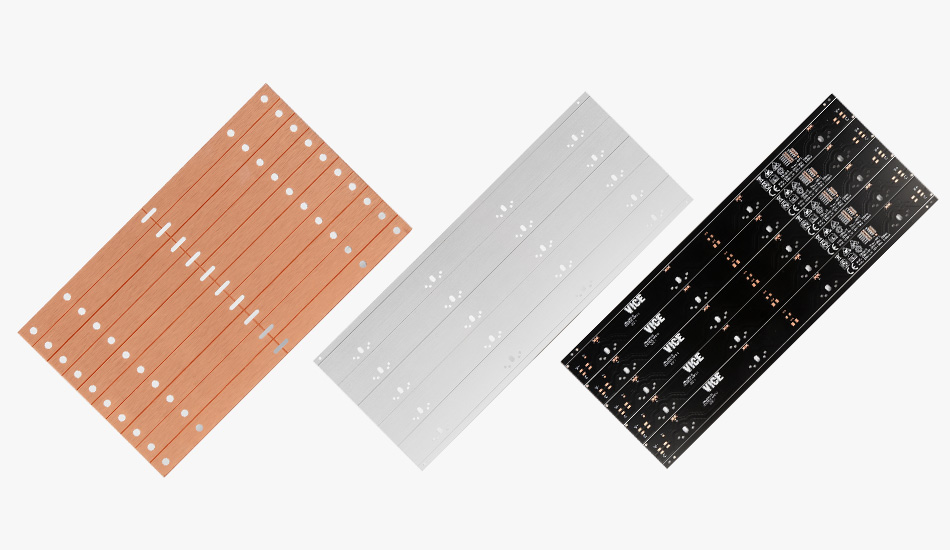

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 11. 2025, 14:58:46

In the dynamic realm of electronics, Metal Core Printed Circuit Boards (MCPCBs) have become essential components, especially in high - power applications where efficient thermal management is crucial. Among the various features of MCPCBs, countersink holes with a specific depth, such as 0.5mm, play a vital role in ensuring the mechanical, electrical, and thermal integrity of the board. This article provides an in - depth analysis of these countersink holes, covering their design, manufacturing, quality control, applications, and future prospects.

Understanding MCPCBs and the Significance of Countersink Holes

Basics of MCPCBs

MCPCBs are engineered to handle high - power loads and effectively dissipate heat. They typically consist of three main layers: a metal core, an insulating layer, and a conductive copper layer. The metal core, usually made of aluminum or copper, serves as a heat sink, efficiently transferring heat away from power - consuming components. The insulating layer, which has a balance of electrical isolation and thermal conductivity, separates the metal core from the copper layer. The copper layer forms the electrical circuitry, connecting various components on the board.

2.2 Function of Countersink Holes in MCPCBs

Countersink holes with a 0.5mm depth are designed to accommodate conical - headed fasteners, such as flat - head screws. When these fasteners are inserted, their heads sit flush with the PCB surface, offering several advantages.

Mechanical Stability: The flush - mounted fasteners distribute clamping force evenly across the PCB, reducing stress concentrations. This is particularly important in applications subject to vibrations and mechanical stress, like automotive and industrial electronics, where it helps prevent PCB warping and component damage.

Aesthetic and Space - Saving: In visible applications, such as consumer electronics and decorative lighting, countersink holes provide a smooth, clean appearance. Additionally, they save space by eliminating the protrusion of fastener heads, enabling more compact designs.

Electrical and Thermal Benefits: In some cases, countersink - mounted fasteners can enhance electrical grounding when the metal core is used as a ground plane. They also improve thermal transfer by creating a secure connection between the MCPCB and heat - dissipating structures, ensuring efficient heat dissipation.

Design Considerations for Countersink Holes in MCPCBs

3.1 Hole Dimensions

Diameter: The diameter of the countersink and the straight part of the hole must be precisely matched to the fastener. The countersink diameter should be slightly larger than the fastener head diameter to allow for a proper fit with a small clearance. The straight part diameter should be marginally larger than the fastener shank diameter for easy insertion.

Depth: The 0.5mm depth of the countersink is carefully specified to ensure that the fastener head is fully recessed into the hole, achieving a flush surface. The overall hole depth, including the straight part for the shank, needs to be sufficient for proper thread engagement with the mating component.

Taper Angle: A common taper angle for countersink holes is either 82° or 90°, depending on the fastener type. Accurate maintenance of the taper angle during manufacturing is essential for a secure and stable fastener fit.

3.2 Location on the MCPCB

The location of countersink holes must be carefully planned to avoid electrical traces and components, ensuring that installation does not cause damage. They should also be positioned for easy access during assembly and align with mounting points on enclosures or other components. Even distribution of the holes across the PCB helps maintain mechanical balance and prevent warping under clamping force.

3.3 Interaction with PCB Layers

Insulating Layer: The design of the 0.5mm depth countersink hole must prevent penetration through the insulating layer to avoid electrical short - circuits. Precise coordination between the hole depth and the insulating layer thickness is necessary, and additional measures like non - conductive coatings may be employed for enhanced isolation.

Copper Layer: Depending on the application, the copper layer around the countersink hole may need modification. For grounding purposes, it might be widened or connected to a larger ground plane. If not for electrical connection, the copper layer may be etched away to prevent accidental electrical contact with the fastener.

Manufacturing Processes for Countersink Holes in MCPCBs

4.1 Drilling and Countersinking

Drilling the Straight Hole: High - precision drilling machines, often computer - numerically controlled (CNC), are used to create the straight part of the hole. Parameters such as drilling speed, feed rate, and coolant usage are carefully controlled to ensure accurate hole dimensions and prevent damage to the PCB material.

Countersinking Operation: After drilling, the countersinking process is carried out using specialized countersink drill bits, milling cutters, or in some advanced cases, lasers. Each method has its own advantages in terms of precision, speed, and suitability for different production volumes.

4.2 Surface Treatment and Finishing

Plating: If the countersink hole is intended for electrical connection, plating, commonly with copper, nickel, or gold, can improve conductivity. The plating process requires careful control of thickness to ensure both electrical performance and proper fastener fit.

Deburring and Cleaning: After manufacturing, deburring is essential to remove burrs and rough edges from the hole. This can be done through mechanical or chemical methods. Thorough cleaning follows to remove debris, plating residues, and chemicals, ensuring a clean surface for fastener installation.

Quality Control and Inspection for Countersink Holes in MCPCBs

5.1 Dimension Inspection

Diameter and Depth Measurement: Precision tools like calipers, micrometers, optical comparators, and 3D coordinate measuring machines (CMMs) are used to measure the diameter, depth, and taper angle of the countersink holes. Measurements must adhere to strict tolerance limits to ensure proper fastener fit and overall PCB functionality.

Taper Angle Verification: Angle - measuring tools, such as goniometers or specialized fixtures, are employed to verify the taper angle. Advanced inspection systems may use digital imaging and image - processing algorithms for highly accurate angle measurement.

5.2 Surface Quality Inspection

Burr and Roughness Check: Visual inspection under magnification, along with surface roughness testing using specialized equipment, is conducted to detect burrs and ensure a smooth surface finish. Non - destructive testing methods may also be used to identify hidden surface irregularities.

Plating Quality Assessment: For plated holes, inspection includes checking for uniform plating thickness, absence of defects like blisters or pits, and good adhesion. Cross - section analysis under a microscope and X - ray fluorescence (XRF) analysis can provide detailed information on plating quality.

5.3 Electrical and Mechanical Testing

Electrical Continuity Test: When the countersink hole is part of an electrical connection, electrical continuity and impedance tests are performed to ensure proper conductivity and signal transmission.

Mechanical Strength Testing: Mechanical tests, such as torque testing and pull - out testing, are carried out to evaluate the strength of the fastener connection. These tests ensure that the MCPCB can withstand the mechanical forces applied during normal use without damage or loosening.

Applications of MCPCBs with 0.5mm Depth Countersink Holes

LED Lighting

High - Power LED Modules: In high - power LED lighting, MCPCBs with 0.5mm depth countersink holes are used to securely mount LED modules to heat - sinks. The flush - mounted fasteners ensure efficient heat transfer and can withstand the vibrations and mechanical stress in outdoor and industrial lighting environments.

Decorative LED Lighting Fixtures: For decorative lighting, countersink holes provide an aesthetically pleasing and space - saving solution. They enable a sleek design, making the fixtures suitable for various residential, commercial, and hospitality settings.

6.2 Automotive Electronics

Headlight and Taillight Assemblies: In automotive lighting, MCPCBs with these countersink holes are used to mount PCBs inside headlight and taillight housings. They can withstand the vibrations, shocks, and temperature variations experienced during vehicle operation, ensuring reliable lighting performance.

Engine Control Units (ECUs): ECUs in automobiles, which generate significant heat, use MCPCBs with countersink holes for secure mounting to heat - dissipating structures. This ensures stable operation in the harsh automotive environment.

6.3 Industrial Electronics

Power Electronics Modules: In industrial power electronics, such as inverters and motor - drive systems, MCPCBs with 0.5mm depth countersink holes are used to mount power - semiconductor components. The secure mechanical connection provided by the countersink - mounted fasteners ensures proper electrical contact and heat transfer.

Industrial Control Panels: For industrial control panels, countersink holes allow for secure mounting of MCPCBs inside enclosures. They can withstand the vibrations and harsh conditions in industrial settings, maintaining the reliability of the control system.

Challenges and Future Trends in Countersink Hole Technology for MCPCBs

7.1 Current Challenges

Miniaturization and Precision: As electronics miniaturize, creating 0.5mm depth countersink holes with high precision in smaller and more complex MCPCBs becomes increasingly challenging. Tighter manufacturing tolerances and advanced techniques are required.

Cost - Effectiveness: The manufacturing processes for high - quality countersink holes can be costly. Balancing quality with cost - effectiveness is a constant challenge, requiring optimization of processes and exploration of alternative materials and methods.

Material Compatibility: Ensuring compatibility between the materials used in MCPCBs and the manufacturing processes for countersink holes, especially during plating and surface treatment, can be difficult. Different materials may react differently to processing, affecting quality.

7.2 Future Trends

Advanced Manufacturing Technologies: The adoption of emerging technologies like laser - based machining, micro - electro - mechanical systems (MEMS) - based manufacturing, and additive manufacturing techniques is expected to improve the precision and efficiency of creating countersink holes in MCPCBs.

Integration with Smart Manufacturing: Integration with smart manufacturing systems, including the Internet of Things (IoT) and artificial intelligence (AI), will enable real - time monitoring and optimization of the manufacturing process for countersink holes, enhancing quality control and productivity.

Sustainable Manufacturing Practices: With growing environmental awareness, there will be a push for more sustainable manufacturing of MCPCBs with countersink holes. This includes using recycled materials, reducing waste, and implementing energy - efficient manufacturing processes.

Conclusion

Countersink holes with a 0.5mm depth in MCPCBs are essential features that significantly impact the performance and functionality of these specialized circuit boards. From design and manufacturing to quality control and a wide range of applications, every aspect of these countersink holes requires careful consideration. Despite the challenges they present, ongoing technological advancements and industry trends offer promising solutions for the future. As the electronics industry continues to evolve, the role of countersink holes in MCPCBs will remain crucial, driving innovation and enabling the development of more efficient, reliable, and compact electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB