-

- PCB TYPE

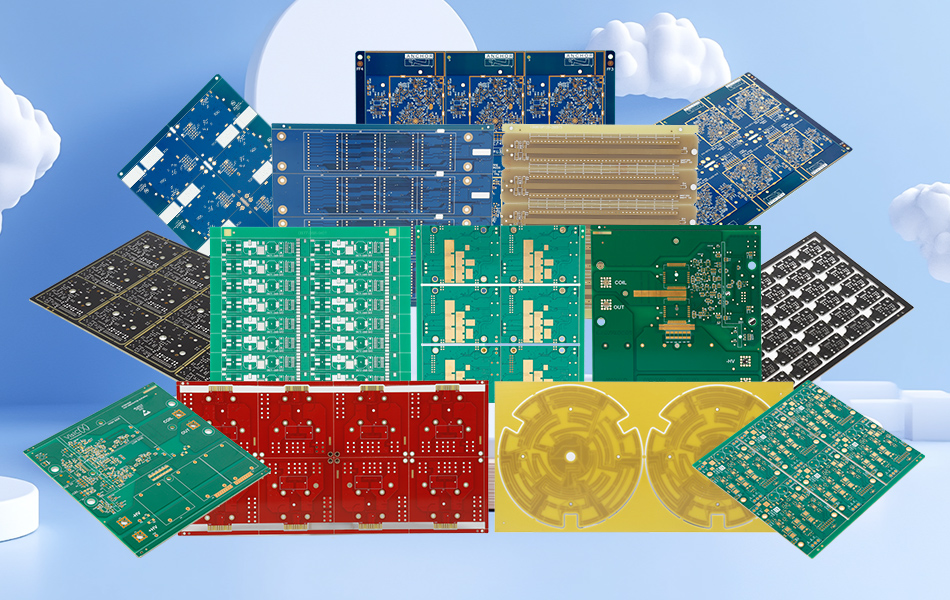

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 01. 2025, 15:52:24

In the intricate landscape of printed circuit board (PCB) design, countersink holes in FR4 PCB serve as a foundational element for secure, space-efficient component mounting, bridging mechanical stability and functional design in electronic systems. These tapered holes—engineered to recess fastener heads below the PCB surface—address critical challenges in assembly, ensuring hardware compatibility, reducing interference, and preserving structural integrity in FR4 substrates. This article explores the design fundamentals, manufacturing dynamics, quality benchmarks, application breadth, and evolving innovations of countersink holes in FR4 PCBs, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Countersink holes in FR4 PCBs are defined by their geometric precision and functional purpose, with design parameters tailored to balance mechanical and spatial requirements:

Tapered Geometry: The signature conical profile—typically with angles ranging from standard industry benchmarks—ensures fastener heads (screws, bolts, or rivets) seat flush with or below the PCB surface, eliminating protrusions that could interfere with enclosures, connectors, or adjacent components.

Dimensional Adaptability: Sizes vary to accommodate diverse fastener types, from micro-fasteners in compact devices to larger hardware in industrial PCBs. The hole diameter and depth are calibrated to match fastener specifications while preserving sufficient FR4 substrate thickness around conductive traces and vias.

Placement Strategy: Strategic positioning minimizes overlap with critical features like copper pads, solder masks, or internal layers, preventing electrical shorts or mechanical weak points. Designers leverage CAD tools to optimize placement for both assembly access and structural balance.

FR4’s composite structure—woven glass fiber reinforced epoxy resin—dictates unique considerations for countersink hole performance:

Stress Distribution: The glass fiber network influences how fastening forces spread through the substrate. Countersink holes distribute pressure across their tapered surface, reducing localized stress that could cause delamination or cracking, especially in multi-layer FR4 PCBs.

Wear Resistance: The epoxy resin matrix provides a stable interface for fastener seating, while glass fibers enhance resistance to wear from repeated assembly/disassembly—critical for field-serviceable electronics like industrial controllers or medical equipment.

Producing high-quality countersink holes in FR4 PCBs requires specialized techniques that account for the material’s composite nature and the precision demands of electronic assembly:

Specialized Cutting Tools: Carbide or coated drills with conical tips are engineered to create clean, consistent tapers in FR4. These tools feature sharp cutting edges to minimize fiber tearing and resin smearing, preserving hole integrity.

CNC Machining Systems: Computer numerical control (CNC) platforms with high-precision spindles ensure positional accuracy, critical for aligning countersink holes with enclosure mounting points and component footprints. Programmable depth control prevents over-machining, which could compromise substrate thickness.

Hybrid Machining Approaches: For complex designs, combinations of mechanical drilling and laser profiling may be used—lasers refine taper uniformity in thin FR4 layers, while mechanical tools handle deeper cuts in thicker substrates.

Cutting Parameters: Feed rates and spindle speeds are calibrated to match FR4 thickness and fiber density, balancing efficiency with surface quality. Lower speeds reduce heat-induced resin softening, while controlled feeds prevent fiber pull-out at the hole edges.

Coolant and Lubrication: Mist or flood cooling systems dissipate heat and flush debris, maintaining tool sharpness and preventing conductive particle buildup—essential for avoiding electrical anomalies in finished PCBs.

Post-Machining Finishing: Deburring processes (e.g., abrasive polishing or ultrasonic cleaning) remove residual material from hole edges, ensuring smooth fastener seating and eliminating potential short-circuit risks from loose glass fibers.

Ensuring countersink holes meet performance requirements demands rigorous inspection and compliance with industry standards:

Optical Inspection: High-resolution imaging systems verify taper uniformity, diameter consistency, and positional accuracy, ensuring alignment with design specifications. 3D scanning may assess surface finish to confirm proper fastener seating.

Structural Integrity Testing: Cross-sectional analysis checks for subsurface defects—such as delamination or voids around the hole perimeter—confirming the FR4 substrate retains strength under fastening stress.

Fastener Retention Testing: Pull-out and torque tests validate the hole’s ability to secure fasteners under operational conditions, including vibration and thermal cycling typical in automotive, aerospace, or industrial environments.

Environmental Resistance: Accelerated aging tests (humidity, temperature cycling) evaluate long-term stability, ensuring countersink holes resist degradation that could loosen fasteners over time.

IPC Standards: Manufacturing aligns with IPC-A-600 guidelines, which define acceptable criteria for hole quality, including burr limits, surface smoothness, and freedom from conductive contaminants.

Application-Specific Requirements: For regulated industries (e.g., medical, aerospace), additional testing ensures compliance with standards for material compatibility, cleanliness, and mechanical reliability.

Countersink holes in FR4 PCBs find critical use across industries where precision assembly and space efficiency are paramount:

Compact Devices: Smartphones, tablets, and wearables utilize countersink holes to mount internal components (batteries, cameras, connectors) without protruding hardware, maximizing space for touchscreens and wireless modules.

Home Appliances: Control boards in refrigerators, ovens, and smart home devices rely on these holes for vibration-resistant mounting, ensuring reliability in temperature-fluctuating environments.

Industrial Automation: PLCs, motor drives, and sensor enclosures use countersink holes to secure PCBs in rugged housings, withstanding factory floor vibrations and chemical exposure.

Power Electronics: Inverters, transformers, and energy management systems leverage countersink holes for secure mounting of heat sinks and power components, balancing thermal management with structural stability.

Medical Devices: Portable monitors, diagnostic equipment, and surgical tools use countersink holes for sterile, reliable assembly, ensuring components remain securely fastened during repeated sterilization cycles.

Aerospace Systems: Avionics PCBs employ these holes for lightweight, vibration-tolerant mounting in aircraft cabins and engine compartments, where hardware reliability is mission-critical.

Advancements in manufacturing and design are enhancing the performance and versatility of countersink holes in FR4 PCBs:

AI-Driven Quality Control: Machine learning algorithms analyze inspection data to predict and prevent defects, optimizing tool paths and cutting parameters for consistent hole quality across production runs.

Digital Twin Simulation: Virtual modeling tools simulate countersink hole performance under various loads and environmental conditions, enabling design refinement before physical prototyping.

Nano-Coated Tools: Diamond or ceramic coatings on cutting tools extend lifespan and improve surface finish, reducing tool changeover time and enhancing precision in high-volume production.

Enhanced FR4 Formulations: New epoxy resins with improved machinability reduce fiber tearing during countersink drilling, simplifying post-processing and improving hole integrity.

Parametric Design Software: CAD platforms now include libraries of pre-validated countersink hole configurations, streamlining design workflows and ensuring compatibility with standard fasteners and assembly processes.

Countersink holes in FR4 PCB represent a critical synergy of design precision and manufacturing expertise, enabling secure, efficient assembly in electronic systems spanning consumer devices to industrial machinery. By balancing geometric accuracy with FR4’s material characteristics, these holes solve key challenges in mounting, interference reduction, and structural stability. As electronics continue to miniaturize and demand higher reliability, innovations in machining, materials, and design tools will further enhance the performance of countersink holes in FR4 PCBs, solidifying their role as a foundational element in modern PCB engineering.

Keywords: Countersink Holes in FR4 PCB, PCB assembly, FR4 machining, precision mounting, PCB design, IPC standards, electronic manufacturing, industrial PCB applications.

Related Articles

FR4 PCB Manufacturer | High Tg & Reliable PCB Material FR4 Solutions

LED Lighting FR4 PCB: Technical Foundations for Illumination Systems

FR4 PCB Manufacturer for Prototype and Mass Production

Tg170 FR4 PCB Datasheet PDF: A Detailed Exploration of High-Tg Laminate Specifications

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

HDI Blind/Buried Vias FR4 PCB: High-Density Interconnect Solutions for Advanced Electronics

FR4 PCB Material Specification Sheet: A Comprehensive Technical Guide

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB