-

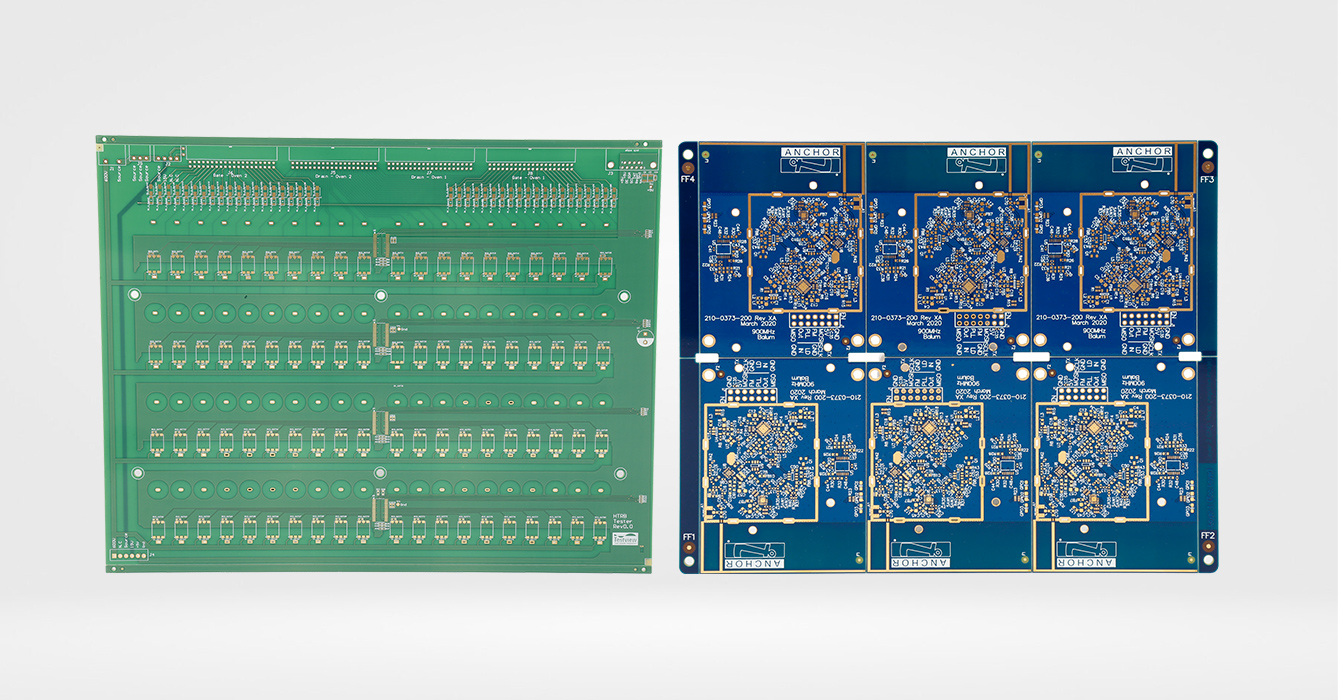

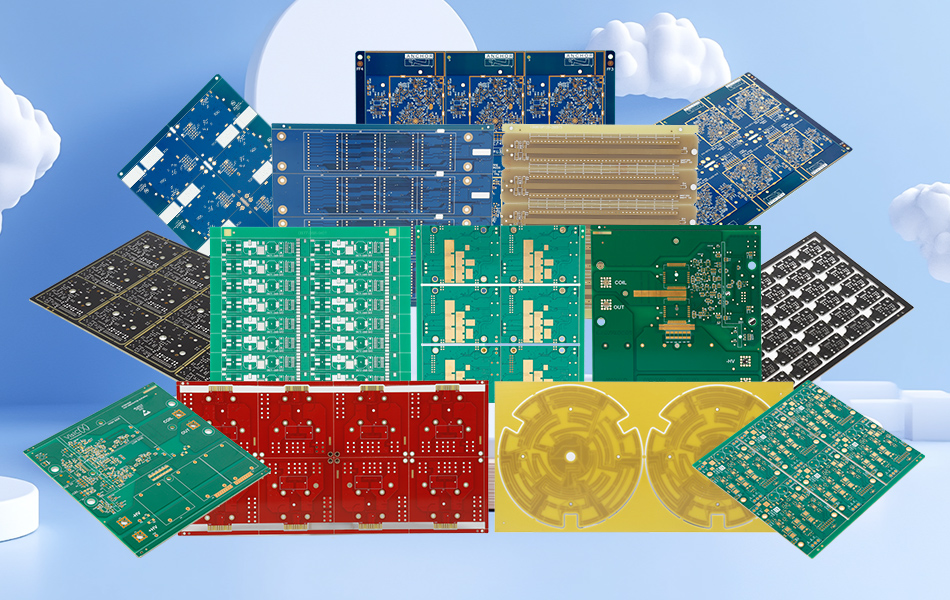

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 01. 2025, 16:20:32

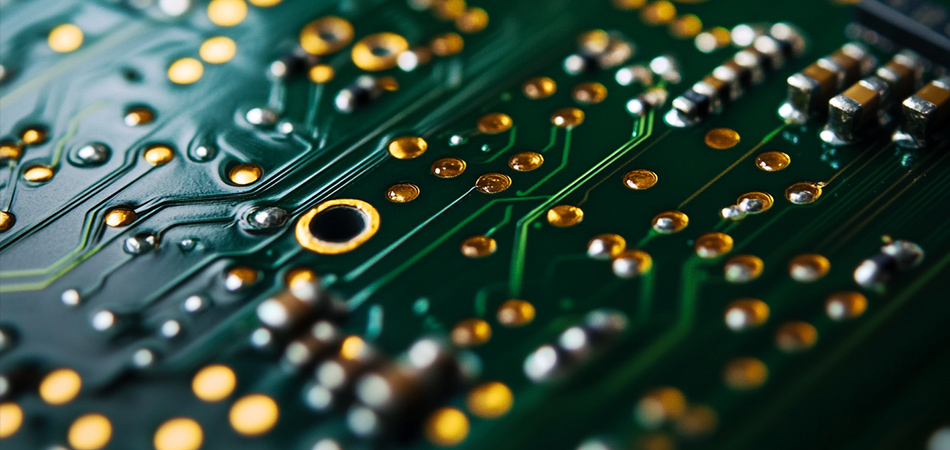

As the most widely used substrate in electronics manufacturing, FR4 PCB (Flame Retardant 4 Printed Circuit Board) serves as the backbone of electronic connectivity, enabling the functionality of devices ranging from consumer gadgets to industrial machinery. Rooted in a composite structure of glass fiber reinforcement and epoxy resin, FR4 has evolved from a basic insulating material to a versatile platform supporting advanced designs, environmental compliance, and high-performance requirements. This article explores FR4 PCB’s material science, design strategies, manufacturing advancements, application diversity, sustainability initiatives, and future trends, ensuring industryprofessionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

FR4 PCB’s enduring relevance stems from its meticulously engineered composite structure, which balances mechanical strength, electrical insulation, and processability:

Glass Fiber Reinforcement: Woven E-glass fiber cloth forms the structural framework, providing dimensional stability and resistance to thermal expansion. This fibrous network ensures the PCB retains its shape under temperature fluctuations, critical for preventing solder joint fatigue and signal integrity issues in dynamic operating environments.

Epoxy Resin Matrix: A flame-retardant epoxy resin binds the glass fibers, delivering electrical insulation, chemical resistance, and adherence to UL94 V-0 fire safety standards. Modern formulations include modifications for enhanced thermal stability, dielectric performance, or environmental compatibility (e.g., halogen-free resins to meet global regulatory standards).

Copper Cladding: High-purity copper foil is laminated to the resin-glass composite, creating conductive pathways for electrical signals. The copper layer’s adhesion quality and uniformity are tailored to application needs, balancing conductivity with durability during assembly, operation, and thermal cycling.

This synergistic structure—fibers for rigidity, resin for insulation, copper for conduction—establishes FR4 as a adaptable substrate for diverse electronic systems.

Effective FR4 PCB design goes beyond basic connectivity, integrating material properties with functional requirements to maximize performance and reliability:

Heat Dissipation Integration: Designers leverage FR4’s inherent thermal stability by incorporating copper pours, thermal vias, and strategic layer stacking to distribute heat from high-power components. Advanced FR4 variants with modified resin systems enhance thermal conductivity, supporting applications with moderate heat loads without requiring specialized substrates.

Thermal Expansion Mitigation: By aligning trace routing with the glass fiber weave direction, designers minimize dimensional changes caused by temperature variations, reducing stress on solder joints and preventing long-term reliability issues in precision devices.

HDI Compatibility: FR4 PCB supports high-density interconnect (HDI) designs through fine-pitch traces, microvias, and sequential lamination, enabling miniaturization in devices like smartphones, IoT sensors, and medical wearables. Its mechanical rigidity ensures consistent performance in designs with tight component spacing.

Signal Integrity Optimization: For high-frequency applications (e.g., 5G modules, industrial sensors), FR4 formulations with low dielectric loss are used to minimize signal attenuation. Controlled impedance routing and ground plane design further enhance signal integrity in these scenarios.

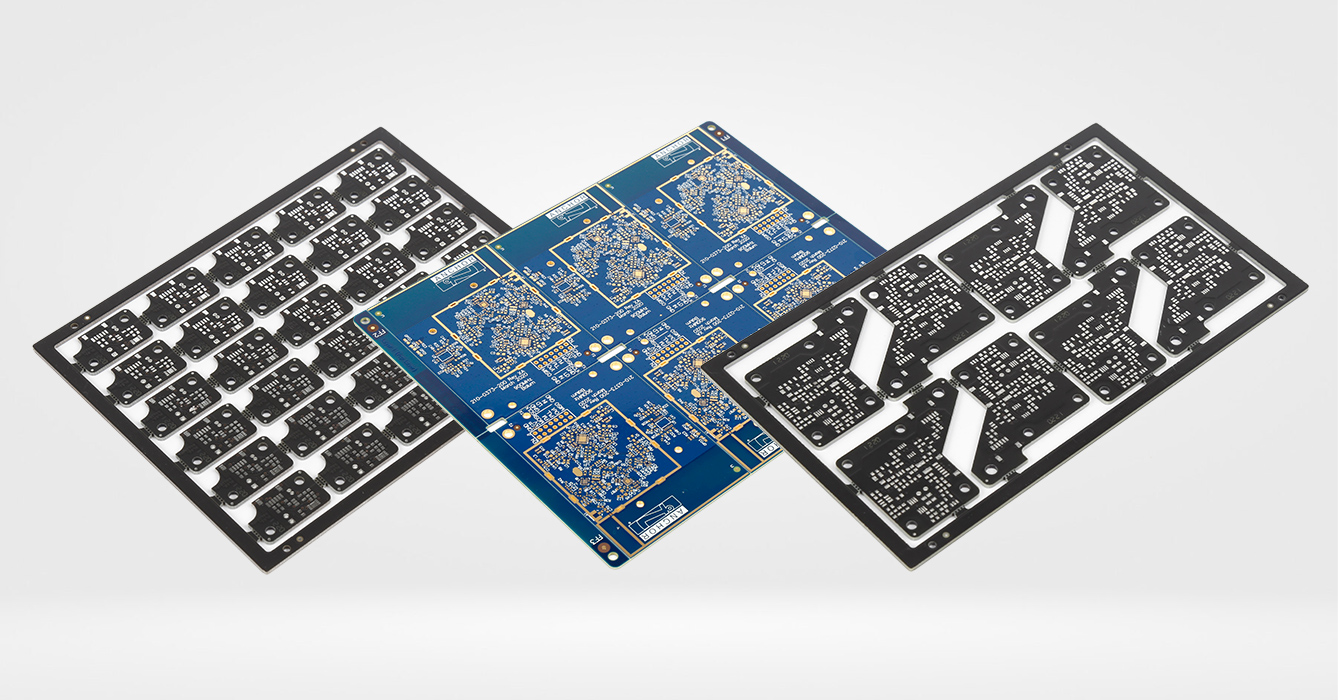

Modern manufacturing techniques have elevated FR4 PCB production from manual processes to precision-engineered workflows, ensuring consistency and scalability:

Prepreg Precision: Glass fiber cloth impregnated with epoxy resin (prepreg) is layered with copper foil and cured under controlled heat and pressure, eliminating voids and ensuring uniform adhesion between layers. Automated lamination systems maintain tight process controls, critical for multi-layer boards with complex interconnects.

Laser Ablation: Laser technology replaces traditional mechanical drilling for microvias and fine features, reducing material damage and enabling smaller, more precise openings in thin FR4 substrates—essential for high-density designs.

AI-Driven Inspection: Machine learning algorithms analyze automated optical inspection (AOI) data to detect defects like resin smearing, copper delamination, or fiber exposure, improving quality control efficiency and reducing waste.

Digital Twin Simulation: Virtual replicas of production processes model how FR4 behaves during lamination, etching, and curing, allowing manufacturers to optimize parameters before physical production, reducing prototyping cycles and costs.

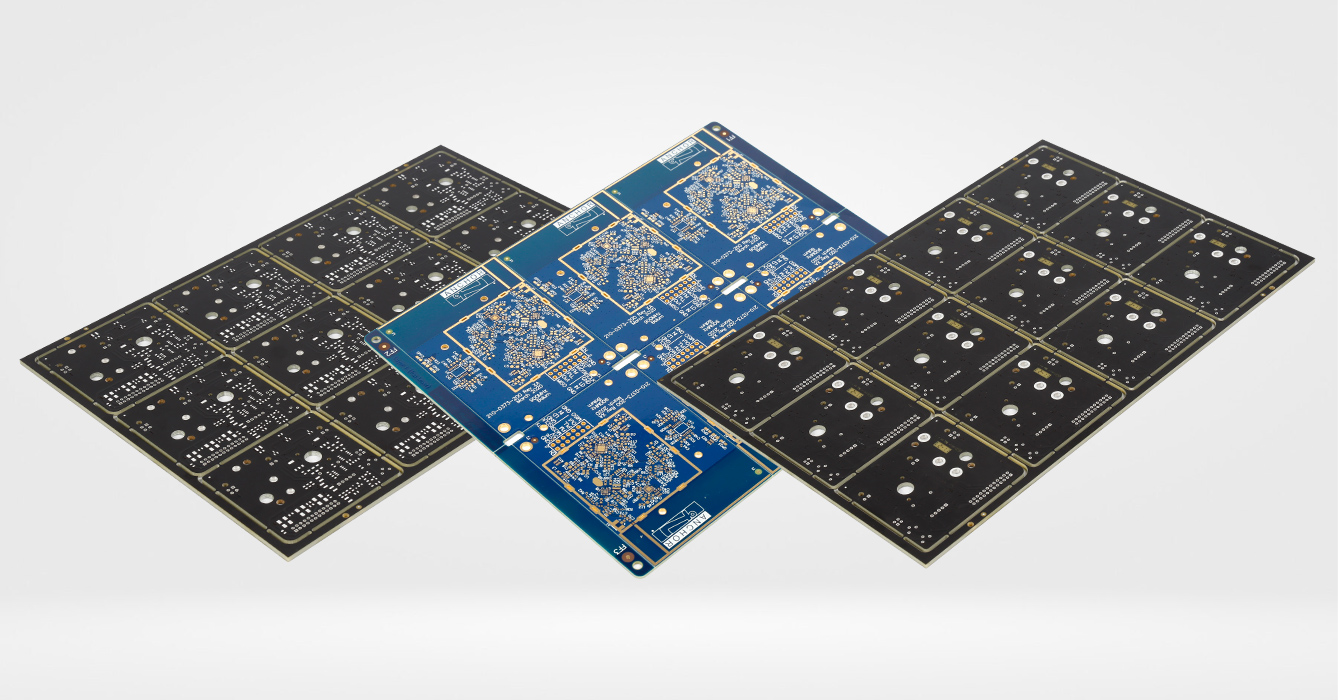

FR4 PCB’s versatility enables its adoption across diverse sectors, adapting to unique performance demands:

Smart Devices: From smartphones to home appliances, FR4 PCB provides the substrate for power management circuits, wireless modules, and sensor interfaces. Its balance of cost, reliability, and processability supports high-volume production of compact devices.

Wearable Technology: Lightweight, thin FR4 variants enable flexible form factors in fitness trackers and smartwatches, with enhanced resin formulations resisting moisture and skin oils for long-term durability.

Industrial Automation: FR4 PCB powers motor drives, programmable logic controllers (PLCs), and factory sensors, withstanding vibration, temperature fluctuations, and chemical exposure in manufacturing environments.

Renewable Energy: In solar inverters and wind turbine controllers, FR4 PCB’s insulation strength and thermal stability support power conversion and monitoring, contributing to efficient energy distribution.

Electric Vehicles (EVs): FR4 PCB forms the backbone of EV battery management systems, infotainment, and charging interfaces, with automotive-grade variants optimized for temperature resistance and vibration tolerance.

Aerospace Electronics: Lightweight FR4 substrates with enhanced mechanical strength support avionics systems, where reliability and weight reduction are critical for fuel efficiency and operational safety.

As environmental regulations tighten and circular economy goals gain traction, FR4 PCB production is evolving to reduce environmental impact:

Halogen-Free Formulations: Modern FR4 variants replace halogenated flame retardants with phosphorus-based or inorganic alternatives, meeting RoHS, REACH, and IEC 61249 standards while maintaining flame resistance and performance.

Bio-Based Resins: Emerging epoxy resins derived from plant-based feedstocks reduce reliance on petroleum, lowering carbon footprints without compromising mechanical or electrical properties.

Material Recovery: Mechanical recycling processes separate copper foil and glass fibers from spent FR4 PCBs, reclaiming valuable materials for reuse in new composites or metal production.

Design for Disassembly: PCB designs incorporating modular FR4 components simplify end-of-life recycling, reducing waste and supporting sustainable electronics lifecycles.

FR4 PCB continues to evolve, driven by advancements in electronics design and material science:

Nano-Reinforced Resins: Addition of ceramic nanoparticles or graphene to epoxy matrices improves thermal conductivity and mechanical strength, extending FR4’s applicability to higher-power electronics and industrial heating systems.

Nano-Copper Cladding: Ultra-thin, high-purity copper foils with nanoscale surface treatments enhance adhesion to the resin matrix, supporting finer trace geometries and improved current carrying capacity in compact designs.

Semi-Flexible FR4: Modified resin formulations create FR4 substrates with limited flexibility, enabling curved or conformable designs in automotive interiors, wearable devices, and compact enclosures.

Hybrid Substrates: FR4 is increasingly integrated with metal cores, ceramic layers, or flexible polymers to create hybrid PCBs, combining FR4’s cost-effectiveness with specialized properties like enhanced thermal dissipation or flexibility.

FR4 PCB remains an indispensable foundation of modern electronics, evolving from a basic insulating material to a dynamic platform that adapts to emerging technologies, sustainability demands, and performance requirements. Its composite structure—glass fiber, epoxy resin, and copper—balances mechanical strength, electrical insulation, and processability, supporting applications across consumer, industrial, automotive, and energy sectors. As manufacturing techniques advance with automation and AI, and material innovations enhance sustainability and performance, FR4 PCB continues to prove its resilience and relevance in an ever-changing electronics landscape. For engineers and manufacturers, FR4 PCB represents not just a substrate, but a versatile solution that bridges design ambition with practical functionality.

Keywords: FR4 PCB, printed circuit board substrate, electronics manufacturing, FR4 material properties, high-density interconnect PCB, sustainable PCB materials, automotive grade FR4.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB