-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 14. 2025, 10:34:06

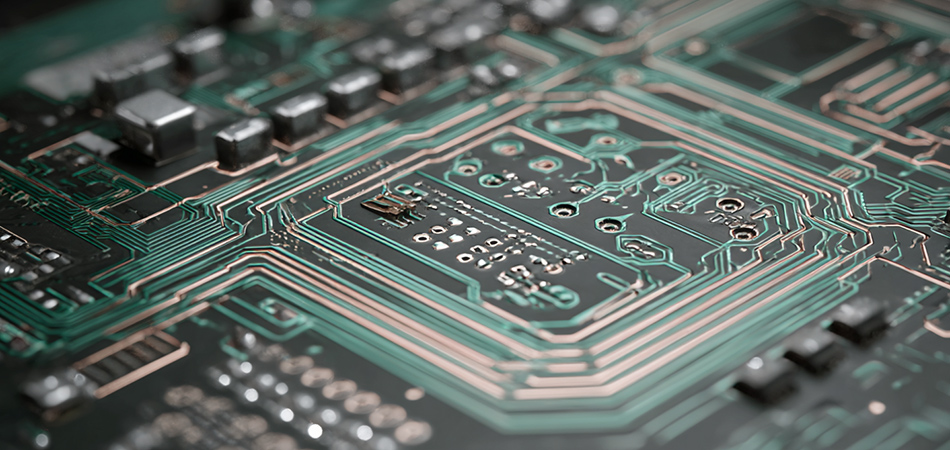

In the realm of high-performance electronics, one-size-fits-all solutions often fall short of meeting the unique demands of specialized applications. Custom aluminum PCB stackup design emerges as a critical engineering approach, enabling engineers to tailor layer configurations, material selections, and thermal pathways to address specific challenges—whether it’s extreme temperature resilience, high-frequency signal integrity, or compact form factors. This article explores the principles, methodologies, and benefits of custom aluminum PCB stackup design, highlighting its role in solving complex engineering problems across industries.

The Rationale for Custom Aluminum PCB Stackups

Limitations of Standard Stackups

Off-the-shelf aluminum PCB stackups, while cost-effective for general applications, lack the flexibility to address niche requirements:

Thermal Mismatch: Standard designs may fail in applications with extreme thermal cycling (e.g., aerospace electronics exposed to -55°C to +125°C), leading to delamination or solder joint fatigue.

Signal Integrity Gaps: High-frequency systems (e.g., 5G mmWave transceivers) require precise impedance control and EMI shielding, which generic stackups often cannot provide.

Space Constraints: Compact devices like wearable medical sensors demand ultra-thin profiles with optimized layer counts, a challenge for preconfigured stackups.

Custom stackups overcome these limitations by aligning every layer—from aluminum core to copper traces—with the application’s unique electrical, thermal, and mechanical needs.

Key Drivers for Customization

Application-Specific Thermal Loads: Industrial inverters handling high currents generate more heat than consumer LED bulbs, requiring thicker aluminum cores and high-conductivity dielectrics.

Regulatory Compliance: Medical devices must meet strict EMI/EMC standards (e.g., IEC 60601), necessitating custom grounding layers and shielding configurations.

Form Factor Innovation: Automotive infotainment systems, for example, require curved PCBs with flexible layers, a feat achievable only through custom stackup design.

Cost Optimization: Custom designs avoid over-engineering by eliminating unnecessary layers, reducing material waste while meeting performance targets.

Core Principles of Custom Stackup Design

Layer Configuration: Beyond Fixed Layer Counts

Custom stackups leverage variable layer counts and arrangements to match functionality:

2-Layer Customization: Simplified designs for low-power applications (e.g., LED strips) may use a single dielectric layer with optimized copper thickness to balance cost and thermal performance.

4- to 8-Layer Complexity: High-end systems like radar modules use additional inner layers for dedicated power distribution, differential pair routing, and EMI shielding. These layers can be asymmetrically arranged (e.g., more copper on heat-generating sides) to address uneven thermal loads.

Hybrid Structures: Combining rigid aluminum cores with flexible dielectric segments (e.g., polyimide) enables bendable sections in devices like robotic arm sensors, where both rigidity and conformability are required.

Material Tailoring: Matching Properties to Needs

Custom stackups select materials based on application-specific stressors:

Aluminum Core Alloys: 1xxx series alloys (high purity) are chosen for maximum thermal conductivity in heat-sensitive applications like laser diodes, while 7xxx series alloys (high strength) suit vibration-prone environments like automotive engine bays.

Dielectric Variability: Silicone-based dielectrics are preferred for their flexibility in wearable devices, while ceramic-filled epoxies excel in high-temperature industrial settings where rigidity is critical.

Copper Grading: Oxygen-free copper minimizes signal loss in high-frequency (GHz-range) circuits, while annealed copper enhances ductility for PCBs subject to mechanical flexing.

Thermal Pathway Engineering

Custom stackups prioritize thermal management strategies tailored to heat sources:

Direct Bonding: In high-power applications (e.g., EV chargers), copper layers are directly bonded to the aluminum core (eliminating intermediate adhesives) to reduce thermal resistance.

Strategic Vias: Blind vias connect surface components to inner heat spreaders, while buried vias link inner power layers to the aluminum core—optimizing heat flow without compromising signal layers.

Asymmetric Cooling: For PCBs with uneven heat distribution (e.g., a power amplifier on one side and sensors on the other), thicker aluminum sections on the hot side enhance heat absorption.

The Custom Stackup Design Process

Requirements Analysis: Defining Performance Metrics

The design process begins with quantifying key parameters:

Electrical Requirements: Voltage levels, current densities, and signal frequencies dictate copper thickness, dielectric constant (Dk), and impedance targets. For example, 6G transceivers require dielectrics with stable Dk (<±0.1) across 100–300 GHz.

Thermal Constraints: Maximum operating temperature, heat flux, and cooling methods (e.g., natural convection vs. liquid cooling) determine aluminum core thickness and dielectric thermal conductivity.

Mechanical Limits: Vibration tolerance (e.g., MIL-STD-883 for aerospace), flexure cycles (e.g., 10,000+ bends for wearable tech), and dimensional stability under thermal cycling guide material selection and layer bonding techniques.

Regulatory Standards: Compliance with standards like RoHS (environmental), UL 94 (flammability), or IPC-2221 (design) imposes constraints on materials and manufacturing processes.

Simulation and Modeling

Advanced tools validate custom stackups before prototyping:

Thermal Simulation: Finite element analysis (FEA) tools like ANSYS predict temperature distribution, identifying hotspots that require additional vias or thicker aluminum.

Signal Integrity Analysis: Tools like Keysight ADS simulate impedance profiles and crosstalk, ensuring high-frequency traces (e.g., PCIe 5.0) meet signal integrity targets.

Mechanical Stress Testing: FEA models assess layer adhesion under thermal cycling, preventing delamination in applications like automotive under-hood electronics.

Prototyping and Validation

Custom stackups undergo rigorous testing to refine designs:

Thermal Cycling Tests: Exposing prototypes to extreme temperature ranges (e.g., -40°C to +150°C) for hundreds of cycles validates layer bond integrity.

Signal Performance Verification: Vector network analyzers (VNAs) measure insertion loss and return loss, ensuring high-frequency compliance.

Mechanical Stress Testing: Bend tests for flexible stackups or vibration tests (per IEC 60068) validate durability in target environments.

Material Selection Strategies for Custom Stackups

Aluminum Core Customization

The aluminum core is tailored to balance thermal and mechanical needs:

Alloy Selection: 3xxx series alloys (e.g., 3003) offer enhanced corrosion resistance for marine applications, while 5xxx series (e.g., 5052) provide superior strength for structural PCBs in drones.

Surface Treatments: Anodization creates a hard, insulating layer for high-voltage applications (e.g., power distribution boards), while chromate conversion coatings improve dielectric adhesion in humid environments.

Thickness Tuning: Thin cores (≤0.3mm) reduce weight in portable devices, while thick cores (≥2mm) enhance heat capacity in industrial power supplies.

Dielectric Layer Optimization

Dielectrics are chosen based on electrical and thermal demands:

Low-Loss Dielectrics: PTFE-based materials (e.g., Rogers RO4000 series) minimize signal attenuation in microwave applications like satellite communication.

High-Thermal Conductivity Dielectrics: Ceramic-filled materials (e.g., alumina-reinforced epoxies) boost heat transfer in high-power LED drivers.

Flexible Dielectrics: Polyimide films enable foldable stackups for devices like foldable smartphones, with glass-reinforced variants adding rigidity where needed.

Copper Layer Customization

Copper layers are optimized for conductivity, thickness, and formability:

Electrolytic vs. Rolled Copper: Rolled copper, with its smoother surface, reduces signal loss in high-frequency applications, while electrolytic copper offers cost advantages for power layers.

Thickness Variability: Thin copper (≤1oz) for fine-pitch signals (e.g., 0.2mm pitch BGA) and thick copper (≥4oz) for high-current paths (e.g., EV battery management systems).

Surface Finishes: ENIG (Electroless Nickel Immersion Gold) for solderability in medical devices, or hard gold plating for connectors in industrial sensors requiring repeated mating cycles.

Industry-Specific Custom Stackup Applications

Aerospace and Defense

Radar Systems: Custom 6-layer stackups with PTFE dielectrics and thin copper signal layers minimize insertion loss in 77GHz automotive radar, while aluminum cores with integral heat sinks manage power amplifier heat.

Avionics: Asymmetric stackups with thicker aluminum on power supply layers withstand extreme temperature swings, ensuring reliability in cabin pressure sensors.

Medical Devices

Implantable Electronics: Biocompatible stackups (e.g., titanium-coated aluminum cores) with polyimide dielectrics meet ISO 10993 standards, while reduced layer counts minimize size in pacemakers.

Diagnostic Equipment: Shielded 4-layer stackups with dedicated ground planes prevent EMI in MRI machine control boards, ensuring image accuracy.

Industrial Automation

Motor Drives: Custom stackups with thick copper power layers (4oz) and ceramic dielectrics handle 3-phase inverter currents, while thermal vias direct heat to aluminum heat sinks.

Sensor Nodes: Ultra-thin (0.5mm total thickness) 2-layer stackups with flexible dielectrics fit into tight spaces in conveyor belt sensors, with aluminum cores providing EMI shielding.

Consumer Electronics

Wearables: Flexible 3-layer stackups (aluminum core + polyimide + copper) conform to wrist curvature in smartwatches, with reduced copper thickness to minimize weight.

Gaming Consoles: 8-layer stackups with dedicated power planes for GPUs and EMI-shielded signal layers ensure stable performance in high-speed data buses (e.g., HDMI 2.1).

Advantages of Custom Aluminum PCB Stackups

Performance Optimization

Custom stackups eliminate over-engineering, focusing resources on critical performance metrics:

Targeted Thermal Management: Adding thermal vias only where needed reduces cost while maintaining heat dissipation in high-power zones.

Enhanced Signal Integrity: Tailored dielectric thickness and copper surface finishes ensure high-frequency signals meet eye diagram requirements.

Cost Efficiency

By eliminating unnecessary layers or premium materials, custom designs reduce total ownership costs:

Material Savings: Using thinner copper on low-current layers cuts material expenses without performance trade-offs.

Reduced Rework: Prototyping with simulation data minimizes design iterations, lowering development costs.

Competitive Differentiation

Custom stackups enable unique product features:

Form Factor Innovation: Flexible aluminum cores in foldable devices create market-first designs.

Reliability Claims: Meeting stringent standards (e.g., MIL-STD-883) through custom stackups differentiates products in aerospace or medical markets.

Future Trends in Custom Aluminum Stackup Design

AI-Driven Optimization

Machine learning algorithms will analyze application requirements (e.g., thermal load, frequency) to recommend optimal layer configurations, reducing design cycles by automating material and layer count selections.

Advanced Material Integration

Graphene-Enhanced Dielectrics: Adding graphene to dielectrics boosts thermal conductivity by 30–50%, enabling thinner aluminum cores in high-power applications.

Phase-Change Material (PCM) Layers: Integrating PCMs into stackups provides passive thermal regulation, absorbing heat during peak loads in devices like EV chargers.

Sustainable Customization

Recycled Aluminum Cores: Custom designs will increasingly use recycled aluminum (with comparable thermal conductivity to virgin alloys) to meet sustainability goals.

Bio-Based Dielectrics: Plant-derived polymers in dielectric layers reduce environmental impact, aligning with consumer electronics’ green initiatives.

Multi-Functional Layers

Future stackups will integrate sensing capabilities directly into layers:

Embedded Sensors: Copper traces with piezoresistive properties enable strain monitoring in industrial PCBs, eliminating the need for external sensors.

Energy Harvesting Layers: Photovoltaic or thermoelectric layers in stackups power low-energy sensors in remote infrastructure, reducing battery reliance.

Conclusion

Custom aluminum PCB stackup design represents a paradigm shift from generic solutions to engineered precision, enabling electronics to meet the most demanding application requirements. By tailoring layer configurations, materials, and thermal pathways, engineers can solve complex challenges—from extreme temperatures to high-frequency signal integrity—while optimizing cost and form factor. As industries like aerospace, medical, and consumer electronics push the boundaries of innovation, custom aluminum stackups will remain a cornerstone of engineering excellence, enabling products that perform reliably where standard solutions fail. For forward-thinking engineers, mastering custom stackup design is not just a skill but a strategic advantage in creating next-generation electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB